Abstract

Comparison of physicochemical properties and electrocatalytic behavior of different N-doped carbonaceous materials as potential catalysts for oxygen reduction reaction (ORR) was attended. Ball-milling of graphite with melamine and solvothermal treatment of graphite oxide, graphene nanoplatelets (GNP) with ammonia were used as preparation methods. Elemental analysis and N2 physisorption measurements revealed the synthesis of N-doped materials with strongly different morphological parameters. Contact angle measurements proved that all three samples had good wettability properties. According to analysis of XRD data and Raman spectra a higher nitrogen concentration corresponded to a smaller size of crystallites of the N-doped carbonaceous material. Surface total N content determined by XPS and bulk N content assessed by elemental analysis were close, indicating homogenous inclusion of N in all samples. Rotating disc electrode tests showed that these N-doped materials weremuch less active in acidic medium than in an alkaline environment. Although the presence of in-plane N species is regarded to be advantageous for the ORR activity, no particular correlation was found in these systems with any type of N species. According to Koutecky–Levich analysis, both the N-containing carbonaceous materials and the reference Pt/C catalyst displayed a typical one-step, four-electron ORR route. Both ball-milled sample with high N-content but with low SSA and solvothermally synthesized N-GNP with high SSA but low N content showed significant ORR activity. It could be concluded that beside the total N content other parameters such as SSA, pore structure, structural defects, wettability were also essential for achieving high ORR activity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

New environmentally friendly and renewable energy sources are the focus of recent research in an effort to replace traditional fossil fuels and mitigate their negative environmental effects. A diverse energy source like hydrogen can assist in addressing a number of pressing energy-related issues. Hydrogen can help to increase energy security and urban air quality. Being one of the very few choices for storing power over days, weeks, or months, hydrogen can also facilitate the integration of varying renewables in the electricity system [1]. The stored hydrogen can be easily transported and converted to electrical energy by means of fuel cells. Fuel cells are electrochemical systems that transform the chemical energy of the fuel directly into electrical energy [2]

Polymer electrolyte membrane fuel cells (PEMFCs) are a viable alternative to traditional fossil fuel-based systems [3, 4]. PEMFCs employ a quasi-solid electrolyte that is built on a polymer backbone with side-chains that have acid-based groups, in contrast to the majority of other forms of fuel cells [5]. PEMFCs stand out for their relatively low operating temperature (below 90 °C), high power density, compact design, and simplicity in handling liquid fuel [5]. In spite of the benefits such as starting from ambient conditions, there are drawbacks of the low operating temperature of PEMFC as well. Since reforming hydrogen contains traces of carbon monoxide, the platinum catalyst sites will get poisoned by CO, which will obscure the catalytic activity and reduce cell efficiency. At 80 °C, however, only a few ppm of CO may be tolerated [6].

Another widely studied fuel cell type is the alkaline fuel cell (AFC) with a concentrated alkaline electrolyte. In comparison to an acidic electrolyte, the alkaline solution promotes the oxygen reduction reaction (ORR) at the AFC cathode to happen more quickly, which results in a better efficiency for comparable cell conditions [7]. The majority of low-temperature AFCs have employed the same platinum catalysts as other low-temperature fuel cell types in practice since nonprecious metal catalysts, such as nickel-based catalysts [8], have a tendency to oxidize quickly at the cathode, which can lower efficiency. However, practical application of AFC has been constrained by a number of factors, including the ability of the electrolyte to absorb carbon dioxide and produce carbonate as well as the parts of the cell proneness to corrosion when in contact with strong alkali media [9].

The oxygen reduction reaction (ORR), a crucial process at the cathode of fuel cells, exhibits sluggish kinetics, which has a significant impact on the efficiency of energy conversion [5, 10, 11]. It has been thoroughly computationally and empirically researched how ORR works. The two-electron pathway and four-electron route are the usual mechanisms that O2 can be reduced [12, 13]. In case of four-electron transfer route, O2 is directly reduced into H2O in an acidic medium (Eq. 1) or OH molecules in an alkaline medium (Eq. 2) [14]:

However, two-electron route ORR proceeds by two steps in which O2 is reduced to either OOH or H2O2 as the intermediate species depending on whether the medium is acidic or alkaline [14]. The two-electron route often produces a lower voltage than the four-electron pathway. Because the 4-electron pathway ORR mechanism converts oxygen more effectively and avoids the corrosive side products created by the 2-electron pathway, which can harm other fuel cell components, it is more advantageous in both acidic and alkaline situations [14, 15]. Because of superior kinetics and lower overpotentials, the ORR in alkaline medium at ambient temperature is preferable to that in acidic conditions [16]. In particular, the metrics of onset potential, half-wave potential, and diffusion-limited current show how electrocatalytic activity of ORR catalysts is manifested [17]. These characteristics are established by several dynamic processes (kinetic, mixed kinetic-diffusion or diffusion). To evaluate the ORR efficiency, the mass/specific current at relatively high potential is typically used [18, 19].

The cathode electrocatalyst is among the major obstacles to the mass adoption of fuel cells [20, 21]. It is critically needed to use high-performance catalysts. However, the most active commercial Pt/C catalysts are expensive and suffer from low reserves [18, 22,23,24]. It would be desirable to use widely available and inexpensive platinum-free catalysts as electrocatalysts for ORR [25, 26]. The use of non-noble metal electrocatalysts is now possible due to the exchange current density being around an order of magnitude greater [27]. Some transition metal nitrides and carbides have ORR activity in alkaline membrane fuel cells that is comparable to commercial platinum-based carbon supported electrocatalyst [28, 29]. In addition to the extensive research being done to design nonprecious metal ORR electrocatalysts, a novel class of metal-free ORR catalysts based on heteroatom-doped carbonaceous materials, including N-, B-, P-, and S-doped carbon nanostructures, have shown a great potential for ORR catalysis, according to recent studies [30]. Nitrogen (N) doped carbon nanomaterials, such as graphene [31], carbon nanotubes (CNT) [32,33,34,35], graphene nanoplatelets (GNP) [36,37,38], graphite oxide (GO) [39], and multilayer graphene (MLG) [40, 41], have recently been discovered.

Regarding the N-doped graphene foreign atoms and other topological defects behave as scattering centers and lead to a decrease in conductivity when compared to pristine graphene [42]. On the other hand, while graphene is intrinsically a semimetal, absorption of oxygen or water from air can induce p-type semiconducting behavior [42]. At the same time, different chemical forms of the N dopant result in different electronic effects in N-doped graphene [43]. Due to the delocalized excess valence electrons, graphitic N can result in n-type semiconducting graphene with high mobility of charge carriers. In contrast, pyridinic N and pyrrolic N atoms generate weak n-type or p-type semiconducting behavior [43] However cationic N doped graphene preserving the planar structure behaves as a p-type semiconductor with high carrier concentration and electrical conductivity [43].

While oxidized nitrogen is often thought to be electrocatalytically inactive, three types of nitrogen structures—pyridinic N, pyrrolic N, and graphitic N—are considered to be potential sources for developing active sites for ORR [44,45,46]. According to studies, the pyridinic-N tends to be the N functional group that is most active in facilitating ORR occurring at low overpotential [47, 48]. However, in their work, D. Guo et al. demonstrated that the carbon atoms near to pyridinic N interact with OH species, causing the pyridinic N to change into pyridonic N. This suggests that the carbon atoms next to the pyridinic N rather than the pyridinic N itself are the active sites [48]. In a theoretical work the ORR was investigated on several different configurations of graphene surfaces containing one or two N atoms. The relationship of the activity of the sites with their absolute position and the type and relative position of N atoms nearby was studied systematically. Regarding the adsorption sites and adsorption energies, multiple options for the construction of active sites were found. That can explain the seemingly contradicting results in literature [49].

Although huge amount of works deals with the use of N-doped carbon materials as ORR electrocatalysts, comparison of the various types of them is rarely found in the literature. The aim of this study was to synthesize and characterize some different N-doped carbonaceous nanomaterials as potential catalyst for ORR. Graphite, graphite oxide (GO), graphene nanoplatelets (GNP) were used as starting materials that have been doped with N. Both solvothermal treatment with ammonia and mechanochemical ball-milling with melamine, as a source of nitrogen, were used to produce them. The samples were characterized by X-ray diffraction (XRD), Raman spectroscopy, nitrogen physisorption, microelemental analysis, X-ray photoelectron spectroscopy (XPS) and wettability measurements. By using Linear Sweep Voltammetry (LSV) measurement, the electrochemical characterization of the catalysts was focused on the assessment of catalytic activity in the ORR in both acidic and alkaline environments. Thus, the effects of precursor carbonaceous materials, synthesis techniques, and electrolytic environment on the qualitative and catalytic properties of the electrocatalysts are compared.

Experimental

Materials

Graphite carbon rod (99.9%) and 2,4,6-triamino-1,3,5-triazine (melamine) precursors were purchased from Merck. GNP (specific surface area (SSA): 750 m2 g−1) was product of Aldrich. 5% Nafion® dispersion (DuPont™ Nafion® PFSA Polymer Dispersions DE 520) was used for catalyst ink preparation. Other chemicals included nitric acid (HNO3, Molar Chemicals, 65%, a.r.), ethanol (Molar Chemicals, 99.55%), 2-propanol (i-C3H5OH, Molar Chemicals, 99.9 V/V%) and KOH (Reanal). Ammonia gas (5.0) was purchased from Linde Gas Hungary. Commercial 20 wt% Pt on Vulcan XC72 support (Pt/C, QuinTech C-20-Pt) was used as a reference electrocatalyst.

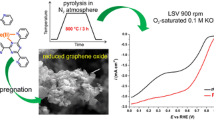

Sample preparation

N-doped multilayer graphene (N-MLG) was prepared as in our previous work [50]. Briefly, 1 g of graphite and 3 g of melamine were loaded in a stainless-steel grinding jar together with 30 grinding balls (10 mm diameter, made of stainless steel) then the mixture was ground at 400 rpm for 24 h. The process was performed at room temperature. Afterward, the materials were washed thoroughly with hot water to remove the un-reacted melamine. Finally, the sample was freeze dried.

Nitrogen doped reduced graphene oxide (N-GO) was prepared by solvothermal treatment [51] of Hummers type of graphite oxide [52]. 25 mL of GO dispersion (1.4 wt% GO in water) was centrifuged for 15 min in order to remove excess amount of water from the dispersion. Then, 15 mL of ammonia (25%) was poured onto the GO dispersion and stirred vigorously with a spatula for 5 min. Thereafter, the GO-ammonia mixture was sonicated for 1 h to delaminate the GO sheets. After that, the solution was transferred to a 60 mL Teflon-sealed autoclave and the reaction system was kept at 160 °C for 12 h and at 180 °C for 2 h (keeping the stirring of reaction mixture via a cross-shaped magnetic stirrer). The next day, the heating was turned off and the system was let to be cooled down naturally up to 45 °C. Then the obtained solution was separated via centrifugation and the resulting solid was washed with DI water (× 4) and ethanol (× 3). In the end, the final material was evaporated at 65 °C for 20 h with continuous stirring and in the following day, it was dried overnight in an oven at 80 °C.

Nitrogen doped graphene nanoplatelets (N-GNP) was prepared similarly to N-GO. 350 mg GNP was dispersed in 20 mL water. 15 mL of ammonia (25%) was poured onto the GNP-water dispersion and the mixture was sonicated for 1 h. Further steps of the preparation of N-GNP were the same as those of the N-GO preparation.

Physicochemical characterization

Elemental composition of CHN of the N-doped samples was determined by Vario EL III. elemental analyzer (Elementar Analysensysteme GmbH) at sample weight ~ 3–3.5 mg and at 950 °C decomposition temperature by use of acetanilide standard.

Nitrogen physisorption measurements were carried out at temperature of liquid nitrogen using Thermo Scientific Surfer automatic volumetric adsorption analyzer (Thermo Fischer Scientific, Berlin, Germany). The specific surface was calculated by the BET method (SBET) in the range of relative pressures from 0.05 to 0.30.

Due to the limited amount of samples, well established methods of contact angle (CA) measurements, such as, e.g., the Washburn method, could not be applied. Instead, a simpler approach [53, 54] was taken, which might not give the true, intrinsic CA of the materials, still, makes possible a meaningful comparison of the wetting properties of the different powder samples. The powder samples were placed in approx. 1 mm thick layers on weighing papers and compacted in a press using a load of 5 tons. Then, the compacted powder samples were placed on the stage of a home-built contact angle goniometer [55]. Ultrapure water (MilliQ, ρ = 18.2 MΩ∙cm) was used as measuring liquid. For each measurement, 1 µL water was disposed from a 25 µL microsyringe equipped with a PTFE-coated 26 s gauge 3 T point style (perpendicular cut) removable needle RN (Hamilton). The microsyringe was operated by a syringe pump (Legato 111, KD Scientific, Holliston, MA, USA). The sample stage was raised manually by turning a micrometre screw to touch the water droplet. A video camera (Sensolytics, Bochum, Germany) and software (IC Capture, The Imaging Source Europe GmbH, Bremen, Germany) was used to capture uncompressed video images at 60 fps time resolution of the water droplets on each sample. The relevant frames of each video have been extracted in free and open source media player VLC 2.24. A free Image J plugin, Low Bond Axisymmetric Drop Shape Analysis [56] was used to determine the CAs from the extracted frames. Further details on the CA measurement conditions and difficulties can be found in the Supplementary Material.

X-ray powder diffraction (XRD) patterns were obtained in a Philips model PW 3710 based PW 1050 Bragg–Brentano parafocusing goniometer using CuKα radiation (λ = 0.15418 nm), graphite monochromator and proportional counter.

Raman spectra were recorded using a JASCO NRS-3300 Raman spectrometer equipped with a CCD detector. The samples were investigated using 514.5 nm laser excitation wavelength; the grating was set at 600 l mm−1 and the slit to 0.1 × 6 mm. The incident laser beam was focused using an Olympus UMPLFL 100× microscope objective lens and the 521 cm−1 peak of the Si was used for the instrument calibration. The experimental Raman data were analyzed with OriginPro 2017 software (OriginLab). Carbon crystallite sizes (La) were calculated using the Tuinstra-Koenig (TK) relation [57, 58].

XPS measurements were performed by using an Omicron EA 125 electron spectrometer in the “Fixed Analyzer Transmission” mode; photoelectrons were excited by non-monochromatized MgKα (1253.6 eV) radiation. The powder samples were dried onto stainless steel sample plates from isopropanol suspensions. After measuring a survey spectrum, high resolution spectra were collected from the regions of interest in the Constant Analyzer Energy mode with a “Pass energy” of 30 eV, providing resolution around 1 eV. The binding energy scale was referenced to the most intense peak of the C 1s envelope arising from sp2 (graphitic) carbon at 284.4 eV binding energy. Spectra were processed with the CasaXPS package [59], while quantitative evaluation of the data was performed with the XPSMultiQuant package [60, 61], during which a homogeneous depth distribution was assumed for all components.

Electrochemical characterization

Activity of the catalyst samples was tested in the ORR by rotating disc electrode (RDE) technique. A RDE is a glassy carbon (GC) working electrode used in a three-electrode system. The rotating speed of the electrode can be controlled, yielding variable diffusion rate of the reactant. The ORR measurements were done either in O2 saturated 0.5 M H2SO4 or 0.1 M KOH solution. Fresh samples were used for measurements in both acidic and alkaline media. The diameter of RDE electrode was d = 0.3 cm (geometric surface area A = 0.0707 cm2). The GC electrode was preliminary polished by means of alumina powder (10 µm in diameter) with the addition of isopropanol in order to remove the impurities from the surface. Subsequently, the polishing alumina powder was removed from the electrode surface by rinsing with distilled water. The sample to be examined was pulverized and an ink was prepared by dispersing 2 mg of the catalyst sample in 2 mL of a mixture of 1.592 mL of MilliQ water, 0.4 mL of isopropanol and 8 µL of 5% Nafion® solution. The suspension was sonicated for 30 min. From this suspension a drop (3.6 μL) was pipetted on to the dry mirror-polished GC and dried at room temperature for 20 min. The reference electrode was a hydrogen electrode immersed in the same electrolyte as the working electrode. All potentials are given on the reversible hydrogen electrode (RHE) scale. Pt was used as counter electrode. All electrochemical measurements were carried out at ambient temperature (25 °C). Solutions were prepared from Millipore MilliQ water; Ar 5.5 gas was used for deoxygenation of the solutions. Prior to the measurements, the electrode was activated by potential cycling for ten times in the range 50 and 1000 mV at a scan rate of 100 mV s−1. Polarization curves were recorded by cathodic scan sweeping the potential between 1000 and 200 mV with 10 mV s−1 sweep rate, rotating the electrode at 225, 400, 625, 900, 1225 and 1600 revolutions/min (rpm).

Results and discussion

Physicochemical characterization

Table 1 summarizes the results of the characterization of N-doped carbonaceous materials obtained from microanalytical and nitrogen physisorption measurements.

The elemental analysis of the nitrogen-doped samples gave an indication about the doping level. Heteroatom concentration of the MLG-derived sample is the highest with 14.6 wt% (see Table 1). In the case of the N-GO and N-GNP samples, both prepared by the same method, the nitrogen content was much lower with the concentration of 7.7 and 2 wt%, respectively. The difference of the N content of two samples prepared by solvothermal treatment can be explained by the fact that a higher level of functionalization in GO leads to a higher rate of doping with heteroatom [62]. GO has much more O-containing functional groups than other members of graphene family have [63, 64].

N2 adsorption–desorption isotherms are shown in Fig. S1. Adsorption isotherm of N-MLG (Fig. S1A) is II type isotherm with H3 type hysteresis loop having some mesoporosity [65]. The adsorption isotherm of N-GO has a hysteresis type H2 (see Fig. S1B), which is indicative of the presence of slit-shaped pores revealing the uniform defects [66]. The nitrogen atoms have the effect of enlarging the defects [39]. However, it must be mentioned that the pore size distribution of N-GO is wide, thus it cannot be characterized with a particular category of pore size. In case of N-GNP, the hysteresis loop is type H3 (Fig. S1C) and the size of the pores is usually bigger, which may make the active sites easily accessible, however there may be present some microporosity as well. The order of SBET values of the samples is in line with the decreasing order of the amount of nitrogen doped and total pore volume values followed a similar trend. However, the declining trend of SSA with increasing doped nitrogen content may not be linked directly, as both of them are determined by the different nature of the starting carbonaceous materials and the different synthesis methods.

To sum up, elemental analysis and N2 physisorption measurements reveal the synthesis of N-doped materials with strongly different morphological parameters.

The contact angle results are summarized in Fig. 1. It is important to emphasize that the measured CAs are not equilibrium CAs, and are definitely not the intrinsic material property CAs of the powders. These CAs are a result of the contribution of several factors, such as: (1) the true, intrinsic CA of the respective material; (2) the effective capillary diameter of the powder samples related to the compactness; (3) the surface roughness of the powder compact, related to the average powder grain size; (4) the porosity of the individual powder grains.

All three samples were hydrophilic, with initial contact angles of 38°, 59° and 51° for N-GNP, N-GO and N-MLG, respectively. All three samples showed an approximately linear decrease of the measured CAs with time. Two of the samples, N-GNP and N-GO, were strongly absorbing, while on the compressed N-MLG powder layer, the water droplet was much more stable. (See also the—compressed—videos in the Supplementary Information and Figs. S2, S3.) Contact angle change in time of all three compacted powder samples is shown in Fig. 2. Expressing this in terms of rate of initial CA change, the values for N-GNP, N-GO and N-MLG were − 17.3, − 26.1, and − 2.9°s−1. According to the aforementioned findings, N-GNP had the maximum wettability, followed by N-GO and N-MLG. Since the interfacial layer of the electrode is where electrochemical reactions occur, the wettability of the electrode frequently contributes to the efficiency [67]. Therefore, the hydrophilicity of these carbon-derived material surfaces in the aqueous phase of the ORR process may be favorable.

Contact angle change in time of compacted powder samples of N-GNP, N-GO and N-MLG. Frames shown here are in 100 ms consecutive steps. A finer time resolution (in 16.67 ms steps) is presented in Fig. 1

The X-ray diffraction (XRD) patterns of the N-doped carbonaceous materials and parent graphite are presented in Fig. 3.

The XRD peaks of all three samples around 2θ = 25–26°, attributed to the (002) diffraction plane of, the graphitic crystal structure, had been broader and their intensity deteriorated compared to that of graphite, implying the successful doping of heteroatom into the carbon nanostructure by both solvothermal synthesis and ball-milling. The peak that was recorded at roughly 2θ = 43° corresponds to the (100) reflection of the graphite [68]. The so-called Scherrer equation had been used to analyze the X-ray diffraction data of the samples in order to determine the average particle size from the broadening of the XRD reflections [69]:

Here D is the crystallite size, k = 0.9 is the Scherrer constant, λ is the wavelength of the X-rays (λ (Cu Kα) = 0.15418 nm), θ is the maximum angle of the reflection band, β1/2 is the full width at half maximum (FWHM) of the diffraction peak. Moreover, by using Bragg’s law the interlayer spacing (d) have been calculated:

The number of layers (Nl) could be determined using Eq. (5) [70]:

The parameters obtained from XRD data of the carbonaceous materials can be found in the Table 2. The primary parameters derived from the XRD data revealed the variations amongst the samples. The size of the crystallites decreased along with the nitrogen content of the samples. Furthermore, the more nitrogen doped material had a smaller number of layers in a crystallite, while there was no trend regarding the interlayer spacing between the layers. However, all three N-doped samples showed much lower D and Nl values than the parent graphite.

Raman spectroscopy is widely used to characterize carbonaceous materials. Raman spectra and calculated parameters are shown in Fig. 4 and Table 2.

The Raman spectrum of graphite is dominated by the typical G, D and 2D bands at 1586, 1356 and 2718 cm−1. The D band belongs to all sp2 hybridized disordered carbon materials and reflects the degree of disorder. The strong G band arising from the in-plane vibration of sp2 hybridized ordered carbon [25] and represents the crystallinity: the more intense the G peak the higher the crystallinity. The intensities of the G bands decreased for all N-doped materials, supporting the effective heteroatom doping process suggested by XRD investigations. The exact peak positions were determined by band fitting with Lorentz functions. The G peak of graphite is positioned at 1586 cm−1, whilst the peaks of N-GNP, N-GO, and N-MLG were detected at 1587, 1600, and 1595 cm−1, correspondingly. This blue shift might be due to the presence of in-plane heteroatoms. As to the N-GO, the higher level of oxidation might also contribute to the shift of the G band [71]. At the same time, the intensity of the D band, associated with structural defects, increased with the nitrogen content [72]. Moreover, another disorder peak, D’ emerged around 1626 cm−1 for N-GNP and N-MLG. The ID/IG ratio, is used to assess the degree of disorder in graphene-like materials. The ID/IG is 0.15 for graphite and it increased in line with increasing N-content (see Table 2). The 2D band around 2703–2018 cm−1 is the overtone of the D band and its frequency and intensity are influenced by the number of graphite layers, too [70]. Due to the reduction in the number of layers (see Table 2), the positions of the 2D band in all N-containing samples were moved towards lower wavenumbers than that of graphite [73]. The N-GO, however, proved to be “tendency-breaker” regarding both 2D intensity and the absence of D′. The oxidized planes of the parent carbon nanomaterial also contribute to the drop in the 2D band intensity by disrupting the stacking order [71]. Furthermore, in this case the intensity of the D + D′ band (also referred as D + G band) in the range of 2928–2944 cm−1 increased [74, 75].

Using the Tuinstra-Koenig (TK) relation [57, 58] the crystallite sizes can be calculated from the Raman spectra:

Here λ is the laser excitation wavelength (514.5 nm). The resulting La values are shown in Table 2. It has been suggested that crystallite size decreases with the increase in the nitrogen doping level because of the defects [62, 74], which is in line with our finding. However, there was certain quantitative discrepancy between D and La values obtained from the analysis of XRD data and Raman spectra.

XPS studies confirmed the successful incorporation of N into the carbonaceous materials. Table 3 summarizes the composition data deduced from XPS for the N-MLG, N-GO and the N-GNP materials expressed in wt%.

Good agreement of the total surface N content obtained by XPS with the bulk N content calculated via the elemental analysis (cf. N data in Table 1, 3) implies the successful and homogeneous doping of nitrogen.

Apart from nitrogen, all samples contain a certain amount of oxygen. While it is not surprising for the GO-derived sample, the oxygen content of the N-MLG and the N-GNP materials indicates slight surface oxidation either before or after the N-doping.

The N 1s core level spectra of the studied materials are depicted in Fig. 5.

The spectrum measured on the N-MLG (curve (a)) is essentially identical to that reported previously in the literature [50]. It can be modeled by two main contributions: a weaker one at 398.3 eV binding energy, arising from pyridinic N and a stronger one at 399.4 eV attributed to pyrrolic N [50] and/or diazine/triazine-like aromatic environments or aromatic amine functionalities [67]. As melamine has indeed a relatively broad N 1s spectrum with its main contribution around 399.4 eV due to its aromatic amines [76] assignation of the 399.4 eV N 1s peak of N-MLG to melamine-related groups rather than to pyrrolic N seems to be more appropriate. Apart from these strong features, a weak band around 405 eV arises from oxidized N species [50]. In case of the N-GO sample (spectrum (b)) the relative intensity of the pyridinic N signal (shifted to slightly lower binding energy at 397.9 eV) was higher than that for the other two materials. The pyrrolic and/or aromatic amine-like peak at 399.3 eV gave still the strongest contribution. At the same time, two new peaks (one at 401.3 eV and one at 403.3 eV) were necessary for adequate fitting, while the high binding energy peak due to oxidized N species at 405.2 eV was still present. The relatively strong 401.3 eV peak is generally attributed to N embedded into the graphite plane [62, 77], while the weaker but clearly visible 403.3 eV peak is probably due to oxidized N atoms. The N 1s spectrum of the N-GNP sample (curve (c)) was adequately modeled by the same features as in the case of N-MLG, although the most intense peak at 399.6 eV probably contains mostly pyrrolic contributions. A broad and relatively intense high binding energy band around 404–405 eV points to somewhat higher extent of N oxidation than in the N-MLG material.

The XPS investigations clearly indicate that several different N-containing functionalities coexist in the electrocatalyst samples. The most diverse N bonding environments are present in the N-GO sample, reflecting the complexity of the starting carbonaceous material.

Electrochemical characterization

According to the results of the cyclic voltammetry in 0.1 M KOH, the gravimetric capacitance (CDL) of the N-doped carbon catalysts was estimated (see Table S1; Figs. S4, S5) based on the literature [78, 79]. CDL was calculated to be approximately 53, 78, and 91 F g−1 for N-MLG, N-GO, and N-GNP, accordingly. These values are in a good agreement with the increasing order of SSA of the carbonaceous materials. Additionally, these values are in the range of gravimetric capacitance of the other doped carbon materials in literature [79].

In order to study the catalytic activity in the ORR, the electrocatalysts were examined after ten cycles of potential cycling conditioning by LSV study using RDE at 225, 400, 625, 900, 1225, and 1600 rpm rotation speeds in both acidic (0.5 M H2SO4) and alkaline (0.1 M KOH) media at scan rate of 10 mVs−1. Both measurement systems with oxygen-rich media underwent potential dynamic polarization. As shown in Fig. 6, a pronounced cathodic ORR peak was observed for all the N-doped carbon-derived electrocatalysts; the commercial Pt/C catalyst was used for comparison. Table 4 summarizes the electro-kinetic characteristics, including the onset potential (calculation of onsets see in Fig. S6), kinetic current density, limiting-diffusion current density and electron transfer number.

Electrochemical characterization of the reference Pt/C and Pt-free N-doped carbonaceous materials by RDE measurements at 900 rpm: N-MLG (line a), N-GO (line b), N-GNP (line c), Pt/C (line d). A ORR curves obtained in O2-saturated 0.5 M H2SO4; B ORR curves obtained in O2-saturated 0.1 M KOH. Recorded at 10 mV s−1, T = 25 °C

The onset potential in acidic media (Eon-ac) for all Pt-free carbon-based catalysts was ≤ 0.5 V (see Table 4; Fig. 6A), which was much lower than that of the commercial Pt/C catalyst (0.96 V [80]). This fact indicates that N-doped carbon-derived materials have limited ORR activity in acidic environments. On the other hand, when ORR activity tests were conducted in alkaline medium, the catalysts displayed moderate activity with limiting current densities (jlim) of 3.1–3.4 mA cm−2 (see Fig. 6B). It should be noted that the Pt/C catalyst showed better performance with jlim = 4.3 mA cm−2 (see Fig. 6B; Table 4). The curves in Fig. S7 demonstrate the anticipated rise in current densities at higher rotational speeds, which corresponds to a quicker diffusion of oxygen onto the catalyst surface. The current density at low potentials clearly depends on the rotation speed, proving that the oxygen reduction is diffusion-limited [80]. For each catalyst, the onset potential—the potential at which the reduction begins—was calculated. The change in the slope of the polarization curve caused by the switch from non-faradaic to faradaic activity was used to identify the onset potential in accordance with the literature. As shown in Fig. 6B, the same onset potentials at 0.83 V were observed for all the catalysts studied with the exception of the onset potential for N-MLG, which was 0.02 V lower.

The Koutecky–Levich (K–L) equation was used to examine the average number of electrons transported per oxygen molecule participating in the ORR [81, 82]. On the basis of the K–L plot for Pt/C and carbon-based catalysts, kinetic parameters such as kinetic current density and the numbers of electrons transferred were calculated at a potential of 0.5 V:

Here j is the current density, jk and jd are the kinetic and diffusion-limiting current densities, respectively. The jd is a function of the rotation speed of the RDE (ω), while B is expressed by the following equation:

Here n is the total electron transfer number for oxygen reduction, D is the diffusion coefficient of oxygen in 0.1 M KOH, F is the Faraday constant, C0 is the bulk concentration of O2, and ν is the kinematic viscosity of the electrolyte. The kinetic study of oxygen reduction had been evaluated using the following parameters: F = 96485 C mol−1, D = 1.9 × 10–5 cm s−1, C0 = 1.2 × 10–6 mol cm−3, υ = 0.01 cm2 s−1 [81, 82]. The plot between 1/j vs. ω−1/2 results in a characteristic straight line (Fig. 7), which denotes first order ORR kinetics with respect to the concentration of dissolved oxygen. Moreover, the linearity of the K–L plots confirms the reliability of the RDE measurements. Since B is equal to the reciprocal of slope and jk is equal to reciprocal of intercept, n and jk can be evaluated from the slope and intercept, respectively. According to the total number of electron transfers determined by K–L slopes, all N-containing carbonaceous materials and the Pt/C catalyst displayed a typical one-step, four-electron ORR route in which oxygen was reduced directly to water molecules, which is most convenient for oxygen reduction in alkaline medium [81, 83] (see Fig. 7). Additionally, only a minor change in the K–L slope observed for all samples at different applied potentials (see Fig. S8) indicate that the ORR proceeds via an overall mechanism leading to the direct formation of H2O [84]. Moreover, the kinetic current densities of the samples (jk) with the highest and lowest N-contents were quite similar ((6.25 ± 0.05) mA cm−2)), whereas the GO-derived catalyst only exhibited half of that (see Table 4). However, as shown in Table 4, the kinetic current densities obtained on N-doped carbonaceous materials were much lower than those of the commercial Pt/C catalyst (41.5 mA cm−2).

Koutecky–Levich representation of ORR measurements obtained at 0.5 V on the (filled circle) N-MLG, (filled triangle) N-GO, (filled square) N-GNP, and (filled diamond) Pt/C electrocatalysts; theoretical two-electron transfer pathway (dash dot), theoretical four-electron transfer pathway (dash dot dot)

It is still debatable which types of nitrogen species contribute the most to ORR. According to certain reports, the graphitic-N has a high propensity to increase ORR activity, whilst the pyridinic-N may tend to decrease ORR activity [85, 86]. Other publications, however, maintain the complete opposite view, arguing that pyridinic nitrogen is ORR active while quaternary/graphitic nitrogen has no effect on the ORR [87]. From this point of view, carbon materials doped with only one kind of C–N bonding configuration are an excellent platform for studying doping effects on the electronic structure and physical/chemical properties. Thus, the two-electron ORR reduction mechanism, which was studied in ref. [88] on CNx graphene with a pure pyridinic N–C bond, showed that the pyridinic N cannot be an effective promoter of ORR activity in carbon materials, as previously expected. No clear dependence of the ORR activity on the content of pyridine-like and pyrrole-like N species in graphene doped with nitrogen using ammonia was observed by Geng et al. [89]. But this study showed that quaternary nitrogen atoms appear to be the most important species for the ORR due to the corresponding relationship between activity and quaternary nitrogen content. However, it should be noted that in the presence of several different types of doped nitrogen species (graphitic N, pyrrolic N, and pyridinic N), it is not always possible to distinguish which type is the most active ORR center [90, 91]. Regarding the pH dependence, it is obvious that the different types of N-containing moieties of N-doped carbonaceous materials behave different way. At pH 1 pyridine moieties are predominantly in the protonated pyridinium form, whereas at pH > 6 the lone pair of Npyridinic sites is mostly deprotonated [92]. Based on the results obtained on model nitrogenated carbon thin film electrodes with controlled both N/C content and Npyridinic/Ngaphitic composition it was concluded that the type and role of the active sites involved in electrocatalysis of the ORR were pH-dependent. The ORR activity in acidic conditions was found to correlate strongly with the concentration of pyridinic nitrogen sites, while graphitic nitrogen sites and a graphitized carbon scaffold determined the ORR behavior at high pH. Accordingly, the density of the pyridinic nitrogen sites does not correlate with ORR activity at high pH region. Close to the pKa of the pyridinium cation (pH of 5.25) an inversion region was observed where pyridine-mediated activity was in competition with graphitic-N mediated activity [92]. However, a study on the pyrolized Fe/N/C catalyst in ref. [93] led to the opposite conclusion, i.e., ORR activity was suppressed when pyridinic N was protonated in an acidic medium.

Since, as shown in Table 1, among the studied N-containing carbonaceous materials, the N–GO catalyst, which had a medium N content but the most diverse distribution of N bonding environments, possessed the lowest kinetic current density and limiting current density (see Table 4), it can be concluded that there is no direct correlation between the N content and the ORR activity, or there are other factors that also have strong effect on the activity. According to a theoretical investigation, model graphene with a greater nitrogen content was more susceptible to Oads poisoning due to the stronger affinity [62, 94]. It should be recalled that the N-GO was synthesized from GO, which was highly functionalized with oxygen containing groups, that may hinder the accessibility of the active sites. Although the N-GNP had the lowest number of doped N atoms (see Table 1), it showed high electrocatalytic activity due to the highest SSA and the structure of pores with large size both facilitating gas and electrolyte diffusion in the ORR. Despite having the lowest SSA, the N-MLG with the highest N concentration demonstrated good electrocatalytic activity. The results presented show that N-doped carbon catalysts active in the ORR can be obtained by both solvothermal and ball-milling syntheses. In addition, it may be inferred that, even if no specific association with any type of N species was discovered, the presence and total content of nitrogen make a significant contribution to the ORR activity of the carbon nanostructures [95]. Moreover, in the development of new catalysts, it is necessary to take into account that, as shown by László et al. [67], an important factor in the electrocatalytic process is not only the nitrogen content, but also the accessibility of the N species.

Conclusions

By using ball-milling and solvothermal syntheses, nitrogen doped carbon nanostructures were created from graphite, GO, and GNP. The production of N-doped carbonaceous materials with diverse specific surface areas and porosities was demonstrated by morphological metrics from nitrogen adsorption. Ball milling of graphite with melamine, a relative simple and eco-friendly preparation method, resulted in a sample with high N-content but low SSA. Contrary, solvothermal treatment of GO and GNP in the presence of NH3 led to higher SSAs due to those of the starting materials. Different N content of two samples prepared by the same solvothermal treatment was explained by the higher level of functionalization in GO resulted in a higher rate of doping. The conducted contact angle measurements proved all three samples were advantageously hydrophilic and had good wettability properties. According to XRD data, a higher nitrogen concentration corresponded to a smaller size of crystallites. The Raman spectroscopy also supported this pattern. Based on deconvoluted bands of N1s XPS spectra, presence of different nitrogen species including pyridinic N, pyrrolic N, graphitic N, and oxidized N ones was suggested. N content determined by surface specific XPS and total N content assessed by elemental analysis were reported to be quite close, indicating homogenous inclusion of N in all three samples. RDE tests revealed that these N-doped materials had lower activity in acidic medium compared to alkaline environment. Although the presence of in-plane N species is regarded to be advantageous for the ORR activity, no particular correlation with any N species was found in these systems. According to Koutecky–Levich analysis, all three N-containing carbonaceous materials and the reference Pt/C catalyst displayed a typical one-step, four-electron ORR route in which oxygen was reduced directly to water. Both ball-milled sample with high N-content but with low SSA and solvothermally treated GNP with low N content but with high SSA showed significant activity in ORR in alkaline medium. It could be concluded that beside the total N content other parameters such as SSA, pore structure, structural defects, wettability were also crucial for attaining high ORR activity for distinct N-containing materials. N–GNP and N–MLG offer great potential for the practical use of fuel cells due to their ease of manufacture, absence of metals, availability, cheapness, and promising activity.

Data availability

The data presented in this study are available on request from the corresponding author.

References

International Energy Agency (2021) Global hydrogen review 2021. Annual report. https://www.iea.org/reports/global-hydrogen-review-2021

Li X (2007) Chapter 1 Thermodynamic performance of fuel cells and comparison with heat engines. Advances in fuel cells. Elsevier, Amsterdem, pp 1–46

Mehta V, Cooper JS (2003) Review and analysis of PEM fuel cell design and manufacturing. J Power Sources 114:32–53. https://doi.org/10.1016/S0378-7753(02)00542-6

Costamagna P, Srinivasan S (2001) Quantum jumps in the PEMFC science and technology from the 1960s to the year 2000: part I. Fundamental scientific aspects. J Power Sources 102:242–252. https://doi.org/10.1016/S0378-7753(01)00807-2

Zhang J (2008) PEM fuel cell electrocatalysts and catalyst layers: fundamentals and applications. Springer, London

Williams MC (2011) Fuel cells. Elsevier, Amsterdem

Breeze P (2017) The alkaline fuel cell. Fuel cells. Elsevier, Amsterdem, pp 23–32

Ferriday TB, Middleton PH (2021) Alkaline fuel cell technology: a review. Int J Hydrogen Energy 46:18489–18510. https://doi.org/10.1016/j.ijhydene.2021.02.203

McLean GF, Niet T, Prince-Richard S, Djilali N (2002) An assessment of AFC technology. Int J Hydrogen Energy 27:507–526

Thiyagarajan N, Janmanchi D, Tsai Y-F et al (2018) A carbon electrode functionalized by a tricopper cluster complex: overcoming overpotential and production of hydrogen peroxide in the oxygen reduction reaction. Angew Chemie 130:3674–3678. https://doi.org/10.1002/ange.201712226

Kodama K, Nagai T, Kuwaki A et al (2021) Challenges in applying highly active Pt-based nanostructured catalysts for oxygen reduction reactions to fuel cell vehicles. Nat Nanotechnol 16:140–147. https://doi.org/10.1038/s41565-020-00824-w

Ma Z, Cano ZP, Yu A et al (2020) Enhancing oxygen reduction activity of pt-based electrocatalysts: from theoretical mechanisms to practical methods. Angew Chemie Int Ed 59:18334–18348. https://doi.org/10.1002/anie.202003654

Jiang Y, Ni P, Chen C et al (2018) Selective electrochemical H2O2 production through two-electron oxygen electrochemistry. Adv Energy Mater 8:17–19. https://doi.org/10.1002/aenm.201801909

Kakaei K, Esrafili MD, Ehsani A (2019) Oxygen reduction reaction. Graphene surfaces: particles and catalysts. Elsevier, Amsterdem

Bredar ARC, Blanchet MD, Burton AR et al (2022) Oxygen reduction electrocatalysis with epitaxially grown spinel MnFe2O4 and Fe3O4. ACS Catal 12:3577–3588. https://doi.org/10.1021/acscatal.1c05172

Shen T, Huang X, Xi S et al (2022) The ORR electron transfer kinetics control via Co–Nx and graphitic N sites in cobalt single atom catalysts in alkaline and acidic media. J Energy Chem 68:184–194. https://doi.org/10.1016/j.jechem.2021.10.027

Xia W, Mahmood A, Liang Z et al (2016) Earth-abundant nanomaterials for oxygen reduction. Angew Chemie Int Ed 55:2650–2676. https://doi.org/10.1002/anie.201504830

Zhang L, Jiang S, Ma W, Zhou Z (2022) Oxygen reduction reaction on Pt-based electrocatalysts: four-electron vs. two-electron pathway. Chinese J Catal 43:1433–1443. https://doi.org/10.1016/S1872-2067(21)63961-X

Li HH, Yu SH (2019) Recent advances on controlled synthesis and engineering of hollow alloyed nanotubes for electrocatalysis. Adv Mater 31:1–23. https://doi.org/10.1002/adma.201803503

Chalk SG, Miller JF, Wagner FW (2000) Challenges for fuel cells in transport applications. J Power Sources 86:40–51. https://doi.org/10.1016/S0378-7753(99)00481-4

Gewirth AA, Thorum MS (2010) Electroreduction of dioxygen for fuel-cell applications: Materials and challenges. Inorg Chem 49:3557–3566. https://doi.org/10.1021/ic9022486

Thorseth MA, Letko CS, Rauchfuss TB, Gewirth AA (2011) Dioxygen and hydrogen peroxide reduction with hemocyanin model complexes. Inorg Chem 50:6158–6162. https://doi.org/10.1021/ic200386d

Ji M, Wei Z (2009) A review of water management in polymer electrolyte membrane fuel cells. Energies 2:1057–1106. https://doi.org/10.3390/en20401057

Wang XX, Swihart MT, Wu G (2019) Achievements, challenges and perspectives on cathode catalysts in proton exchange membrane fuel cells for transportation. Nat Catal 2:578–589. https://doi.org/10.1038/s41929-019-0304-9

Ilnicka A, Kamedulski P, Skorupska M, Lukaszewicz JP (2019) Metal-free nitrogen-rich carbon foam derived from amino acids for the oxygen reduction reaction. J Mater Sci 54:14859–14871. https://doi.org/10.1007/s10853-019-03969-9

Wan X, Liu X, Shui J (2020) Stability of PGM-free fuel cell catalysts: degradation mechanisms and mitigation strategies. Prog Nat Sci Mater Int 30:721–731. https://doi.org/10.1016/j.pnsc.2020.08.010

Cheng F, Chen J (2012) Metal–air batteries: from oxygen reduction electrochemistry to cathode catalysts. Chem Soc Rev 41:2172–2192. https://doi.org/10.1039/c1cs15228a

Zion N, Douglin JC, Cullen DA et al (2021) Porphyrin aerogel catalysts for oxygen reduction reaction in anion-exchange membrane fuel cells. Adv Funct Mater 31:1–7. https://doi.org/10.1002/adfm.202100963

Li H, Wen Y, Jiang M et al (2021) Understanding of neighboring Fe-N4-C and Co-N4-C dual active centers for oxygen reduction reaction. Adv Funct Mater 31:1–13. https://doi.org/10.1002/adfm.202011289

Abbas Q, Raza R, Shabbir I, Olabi AG (2019) Heteroatom doped high porosity carbon nanomaterials as electrodes for energy storage in electrochemical capacitors: a review. J Sci Adv Mater Devices 4:341–352. https://doi.org/10.1016/j.jsamd.2019.07.007

Feng L, Chen Y, Chen L (2011) Easy-to-operate and low-temperature synthesis of gram-scale nitrogen-doped graphene and its application as cathode catalyst in microbial fuel cells. ACS Nano 5:9611–9618. https://doi.org/10.1021/nn202906f

Tang Y, Allen BL, Kauffman DR, Star A (2009) Electrocatalytic activity of nitrogen-doped carbon nanotube cups. J Am Chem Soc 131:13200–13201. https://doi.org/10.1021/ja904595t

Shui J, Wang M, Du F, Dai L (2015) N-doped carbon nanomaterials are durable catalysts for oxygen reduction reaction in acidic fuel cells. Sci Adv 1:1–8. https://doi.org/10.1126/sciadv.1400129

Feng L, Yan Y, Chen Y, Wang L (2011) Nitrogen-doped carbon nanotubes as efficient and durable metal-free cathodic catalysts for oxygen reduction in microbial fuel cells. Energy Environ Sci 4:1892–1899. https://doi.org/10.1039/c1ee01153g

Gong K, Du F, Xia Z et al (2009) Nitrogen-doped carbon nanotube arrays with high electrocatalytic activity for oxygen reduction. Science 323:760–764. https://doi.org/10.1126/science.1168049

Qu L, Liu Y, Baek JB, Dai L (2010) Nitrogen-doped graphene as efficient metal-free electrocatalyst for oxygen reduction in fuel cells. ACS Nano 4:1321–1326. https://doi.org/10.1021/nn901850u

Ju MJ, Jeon IY, Kim JC et al (2014) Graphene nanoplatelets doped with N at its edges as metal-free cathodes for organic dye-sensitized solar cells. Adv Mater 26:3055–3062. https://doi.org/10.1002/adma.201304986

Jeon IY, Choi HJ, Ju MJ et al (2013) Direct nitrogen fixation at the edges of graphene nanoplatelets as efficient electrocatalysts for energy conversion. Sci Rep 3:1–7. https://doi.org/10.1038/srep02260

Du M, Sun J, Chang J et al (2014) Synthesis of nitrogen-doped reduced graphene oxide directly from nitrogen-doped graphene oxide as a high-performance lithium ion battery anode. RSC Adv 4:42412–42417. https://doi.org/10.1039/c4ra05544f

Carrillo-Rodríguez JC, Alonso-Lemus IL, Siller-Ceniceros AA et al (2017) Easy synthesis of N-doped graphene by milling exfoliation with electrocatalytic activity towards the oxygen reduction reaction (ORR). Int J Hydrogen Energy 42:30383–30388. https://doi.org/10.1016/j.ijhydene.2017.08.084

Zhao H, Hui KS, Hui KN (2014) Synthesis of nitrogen-doped multilayer graphene from milk powder with melamine and their application to fuel cells. Carbon NY 76:1–9. https://doi.org/10.1016/j.carbon.2014.04.007

Yadav R, Dixit CK (2017) Synthesis, characterization and prospective applications of nitrogen-doped graphene: a short review. J Sci Adv Mater Devices 2:141–149. https://doi.org/10.1016/j.jsamd.2017.05.007

Chae S, Panomsuwan G, Bratescu MA et al (2019) P-type doping of graphene with cationic nitrogen. ACS Appl Nano Mater 2:1350–1355. https://doi.org/10.1021/acsanm.8b02237

Tran TN, Song MY, Singh KP et al (2016) Iron-polypyrrole electrocatalyst with remarkable activity and stability for ORR in both alkaline and acidic conditions: a comprehensive assessment of catalyst preparation sequence. J Mater Chem A 4:8645–8657. https://doi.org/10.1039/c6ta01543c

Xu P, Chen W, Wang Q et al (2015) Effects of transition metal precursors (Co, Fe, Cu, Mn, or Ni) on pyrolyzed carbon supported metal-aminopyrine electrocatalysts for oxygen reduction reaction. RSC Adv 5:6195–6206. https://doi.org/10.1039/c4ra11643g

Peng H, Liu F, Liu X et al (2014) Effect of transition metals on the structure and performance of the doped carbon catalysts derived from polyaniline and melamine for ORR application. ACS Catal 4:3797–3805. https://doi.org/10.1021/cs500744x

Wu J, Ma L, Yadav RM et al (2015) Nitrogen-doped graphene with pyridinic dominance as a highly active and stable electrocatalyst for oxygen reduction. ACS Appl Mater Interfaces 7:14763–14769. https://doi.org/10.1021/acsami.5b02902

Guo D, Shibuya R, Akiba C et al (2018) Active sites in nitrogen-doped carbon materials for oxygen reduction reaction. Carbon-Based Met Catal Des Appl 1–2:227–249. https://doi.org/10.1002/9783527811458.vol1-ch8

Ganyecz ádám, Kállay M, (2021) Oxygen reduction reaction on N-doped graphene: effect of positions and scaling relations of adsorption energies. J Phys Chem C 125:8551–8561. https://doi.org/10.1021/acs.jpcc.0c11340

Dan M, Vulcu A, Porav S et al (2021) Eco-friendly nitrogen-doped graphene preparation and design for the oxygen reduction reaction. Molecules. https://doi.org/10.3390/molecules26133858

Smith AD, Li Q, Vyas A et al (2019) Carbon-based electrode materials for microsupercapacitors in self-powering sensor networks: present and future development. Sensors. https://doi.org/10.3390/s19194231

Hummers WS, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339. https://doi.org/10.1021/ja01539a017

Dudás Z, Fagadar-Cosma E, Len A et al (2018) Article improved optical and morphological properties of vinyl-substituted hybrid silica materials incorporating a Zn-metalloporphyrin. Materials. https://doi.org/10.3390/ma11040565

Len A, Paladini G, Románszki L et al (2021) Physicochemical characterization and drug release properties of methyl-substituted silica xerogels made using sol–gel process. Int J Mol Sci. https://doi.org/10.3390/ijms22179197

Románszki L, Mohos M, Telegdi J et al (2014) A comparison of contact angle measurement results obtained on bare, treated, and coated alloy samples by both dynamic sessile drop and Wilhelmy method. Period Polytech Chem Eng 58:53–59. https://doi.org/10.3311/PPch.7188

Stalder AF, Melchior T, Müller M et al (2010) Low-bond axisymmetric drop shape analysis for surface tension and contact angle measurements of sessile drops. Colloids Surf A 364:72–81. https://doi.org/10.1016/j.colsurfa.2010.04.040

Caņado LG, Takai K, Enoki T et al (2006) General equation for the determination of the crystallite size la of nanographite by Raman spectroscopy. Appl Phys Lett 88:1–4. https://doi.org/10.1063/1.2196057

Ayyubov I, Vulcu A, Berghian-Grosan C et al (2021) Preparation of Pt electrocatalyst supported by novel, Ti(1−x) Mox O2-C type of composites containing multi-layer graphene. React Kinet Mech Catal. https://doi.org/10.1007/s11144-021-02138-x

Fairley N (2009) CasaXPS manual 2.3.15. Casa Softw Ltd, Devon, pp 1–177

Mohai M (2004) XPS multiquant: multimodel XPS quantification software. Surf Interface Anal 36:828–832. https://doi.org/10.1002/sia.1775

Mohai M (2011) XPS multiquant: multi-model X-ray photoelectron spectroscopy quantification program Version 7.00.92. http://aki.ttk.hu/XMQpages/XMQdownload.php

Wang H, Maiyalagan T, Wang X (2012) Review on recent progress in nitrogen-doped graphene: synthesis, characterization, and its potential applications. ACS Catal 2:781–794. https://doi.org/10.1021/cs200652y

Cataldi P, Athanassiou A, Bayer IS (2018) Graphene nanoplatelets-based advanced materials and recent progress in sustainable applications. Appl Sci. https://doi.org/10.3390/app8091438

Wick P, Louw-Gaume AE, Kucki M et al (2014) Classification framework for graphene-based materials. Angew Chemie Int Ed 53:7714–7718. https://doi.org/10.1002/anie.201403335

Sotomayor F, Quantatec AP, Sotomayor FJ et al (2018) Characterization of micro/mesoporous materials by physisorption: concepts and case studies. Acc Mater Surf Res 3:34–50

Long D, Li W, Ling L et al (2010) Preparation of nitrogen-doped graphene sheets by a combined chemical and hydrothermal reduction of graphene oxide. Langmuir 26:16096–16102. https://doi.org/10.1021/la102425a

Nagy B, Villar-Rodil S, Tascón JMD et al (2016) Nitrogen doped mesoporous carbon aerogels and implications for electrocatalytic oxygen reduction reactions. Microporous Mesoporous Mater 230:135–144. https://doi.org/10.1016/j.micromeso.2016.05.009

Ariharan A, Viswanathan B, Nandhakumar V (2017) Nitrogen doped graphene as potential material for hydrogen storage. Graphene 06:41–60. https://doi.org/10.4236/graphene.2017.62004

Antolini E, Giorgi L, Cardellini F, Passalacqua E (2001) Physical and morphological characteristics and electrochemical behaviour in PEM fuel cells of PtRu/C catalysts. J Solid State Electrochem 5:131–140. https://doi.org/10.1007/s100080000116

Sieradzka M, Ślusarczyk C, Fryczkowski R, Janicki J (2020) Insight into the effect of graphite grain sizes on the morphology, structure and electrical properties of reduced graphene oxide. J Mater Res Technol 9:7059–7067. https://doi.org/10.1016/j.jmrt.2020.05.026

Krishnamoorthy K, Veerapandian M, Yun K, Kim SJ (2013) The chemical and structural analysis of graphene oxide with different degrees of oxidation. Carbon NY 53:38–49. https://doi.org/10.1016/j.carbon.2012.10.013

Graf D, Molitor F, Ensslin K et al (2007) Spatially resolved Raman spectroscopy of single- and few-layer graphene. Nano Lett 7:238–242. https://doi.org/10.1021/nl061702a

Pimenta MA, Dresselhaus G, Dresselhaus MS et al (2007) Studying disorder in graphite-based systems by Raman spectroscopy. Phys Chem Chem Phys 9:1276–1291. https://doi.org/10.1039/b613962k

Coros M, Varodi C, Pogacean F et al (2020) Nitrogen-doped graphene: the influence of doping level on the charge-transfer resistance and apparent heterogeneous electron transfer rate. Sensors 20:1–18. https://doi.org/10.3390/s20071815

Ferrari AC, Basko DM (2013) Raman spectroscopy as a versatile tool for studying the properties of graphene. Nat Nanotechnol 8:235–246. https://doi.org/10.1038/nnano.2013.46

Lee MS, Park M, Kim HY, Park SJ (2016) Effects of microporosity and surface chemistry on separation performances of N-containing pitch-based activated carbons for CO2/N2 binary mixture. Sci Rep 6:1–11. https://doi.org/10.1038/srep23224

Mohai M, László K, Bertóti I (2018) Reduction and covalent modification of graphene-oxide by nitrogen in glow discharge plasma. Surf Interface Anal 50:1207–1212. https://doi.org/10.1002/sia.6411

Nithya VD (2021) A review on holey graphene electrode for supercapacitor. J Energy Storage 44:103380. https://doi.org/10.1016/j.est.2021.103380

Andrade SKS, Bakos I, Dobos G et al (2021) Biomass related highly porous metal free carbon for gas storage and electrocatalytic applications. Materials. https://doi.org/10.3390/ma14133488

Ayyubov I, Tálas E, Salmanzade K et al (2022) Electrocatalytic properties of mixed-oxide-containing composite-supported platinum for polymer electrolyte membrane (PEM) fuel cells. Materials. https://doi.org/10.3390/ma15103671

Roy D, Sarkar S, Bhattacharjee K et al (2020) Site specific nitrogen incorporation in reduced graphene oxide using imidazole as a novel reducing agent for efficient oxygen reduction reaction and improved supercapacitive performance. Carbon NY 166:361–373. https://doi.org/10.1016/j.carbon.2020.05.011

Bo X, Han C, Zhang Y, Guo L (2014) Confined nanospace synthesis of less aggregated and porous nitrogen-doped graphene as metal-free electrocatalysts for oxygen reduction reaction in alkaline solution. ACS Appl Mater Interfaces 6:3023–3030. https://doi.org/10.1021/am405609d

Dhanasekaran P, Vinod Selvaganesh S, Bhat SD (2016) Nitrogen and carbon doped titanium oxide as an alternative and durable electrocatalyst support in polymer electrolyte fuel cells. J Power Sources 304:360–372. https://doi.org/10.1016/j.jpowsour.2015.11.045

Lai L, Potts JR, Zhan D et al (2012) Exploration of the active center structure of nitrogen-doped graphene-based catalysts for oxygen reduction reaction. Energy Environ Sci 5:7936–7942. https://doi.org/10.1039/c2ee21802j

Kim H, Lee K, Woo SI, Jung Y (2011) On the mechanism of enhanced oxygen reduction reaction in nitrogen-doped graphene nanoribbons. Phys Chem Chem Phys 13:17505–17510. https://doi.org/10.1039/c1cp21665a

Nagaiah TC, Kundu S, Bron M et al (2010) Nitrogen-doped carbon nanotubes as a cathode catalyst for the oxygen reduction reaction in alkaline medium. Electrochem Commun 12:338–341. https://doi.org/10.1016/j.elecom.2009.12.021

Chen Z, Higgins D, Tao H et al (2009) Highly active nitrogen-doped carbon nanotubes for oxygen reduction reaction in fuel cell applications. J Phys Chem C 113:21008–21013. https://doi.org/10.1021/jp908067v

Luo Z, Lim S, Tian Z et al (2011) Pyridinic N doped graphene: synthesis, electronic structure, and electrocatalytic property. J Mater Chem 21:8038–8044. https://doi.org/10.1039/c1jm10845j

Geng D, Chen YY, Chen YY et al (2011) High oxygen-reduction activity and durability of nitrogen-doped graphene. Energy Environ Sci 4:760–764. https://doi.org/10.1039/c0ee00326c

Li Y, Li T, Yao M, Liu S (2012) Metal-free nitrogen-doped hollow carbon spheres synthesized by thermal treatment of poly(o-phenylenediamine) for oxygen reduction reaction in direct methanol fuel cell applications. J Mater Chem 22:10911–10917. https://doi.org/10.1039/c2jm30781b

Ouyang W, Zeng D, Yu X et al (2014) Exploring the active sites of nitrogen-doped graphene as catalysts for the oxygen reduction reaction. Int J Hydrogen Energy 39:15996–16005. https://doi.org/10.1016/j.ijhydene.2014.01.045

Behan JA, Iannaci A, Domínguez C et al (2019) Electrocatalysis of N-doped carbons in the oxygen reduction reaction as a function of pH: N-sites and scaffold effects. Carbon NY 148:224–230. https://doi.org/10.1016/j.carbon.2019.03.052

Rauf M, Di ZY, Wang YC et al (2016) Insight into the different ORR catalytic activity of Fe/N/C between acidic and alkaline media: protonation of pyridinic nitrogen. Electrochem commun 73:71–74. https://doi.org/10.1016/j.elecom.2016.10.016

Okamoto Y (2009) First-principles molecular dynamics simulation of O2 reduction on nitrogen-doped carbon. Appl Surf Sci 256:335–341. https://doi.org/10.1016/j.apsusc.2009.08.027

Nagy B, Bakos I, Bertóti I et al (2018) Synergism of nitrogen and reduced graphene in the electrocatalytic behavior of resorcinol: formaldehyde based carbon aerogels. Carbon NY 139:872–879. https://doi.org/10.1016/j.carbon.2018.07.061

Acknowledgements

This research was funded by Project No. RRF-2.3.1-21-2022-00009, titled National Laboratory for Renewable Energy has been implemented with the support provided by the Recovery and Resilience Facility of the European Union within the framework of Programme Széchenyi Plan Plus. Authors thank to Dr. Tamás Szabó (University of Szeged) for providing graphite oxide.

Funding

Open access funding provided by ELKH Research Centre for Natural Sciences.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 446 kb)

Supplementary file2 (MP4 198 kb)

Supplementary file3 (MP4 165 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ayyubov, I., Tálas, E., Berghian-Grosan, C. et al. Nitrogen doped carbonaceous materials as platinum free cathode electrocatalysts for oxygen reduction reaction (ORR). Reac Kinet Mech Cat 136, 125–147 (2023). https://doi.org/10.1007/s11144-022-02331-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-022-02331-6