Abstract

Hydrodesulfurization of thiophene has been studied over alumina supported sulfided molybdena, nickel-promoted molybdena and over nickel (Mo, NiMo and Ni) catalysts. The experiments were carried out with a mixture of thiophene, labeled with radioactive carbon (thiophene-[G-]-14C) and of non-radioactive tetrahydrothiophene (1:1 mol ratio) in a micro catalytic system. It was established, that the main products were tetrahydrothiophene-14C, 1-butene-14C, 2-butene-14C, butane-14C. Tetrahydrothiophene-14C was a major intermediate in the conversion of thiophene—14C in the experimental condition applied. The amounts of converted tetrahydrothiophene on the catalysts were substantially higher than those of thiophene under the same conditions. Hydrothiophene and dihydrothiophene—14C were intermediate products in the hydrodesulfurization of thiophene and tetrahydrothiophene. The hydrodesulphurization of tetrahydrothiophene was paired with dehydrogenation, producing small amounts of thiophene. The experimental results have been considered in the discussion of the mechanism of thiophene and tetrahydrothiophene desulfurization reaction pathway.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The removal of sulfur is crucially important in processing of petroleum feed materials. It is accomplished via hydrodesulfurization (HDS) of the sulfur containing organic compounds. Generally, thiophene (TH) is used as a model reactant to study this process, because it represents the sulfur containing aromatic compounds, that are, in some extent, resistant to desulfurization.

There have been numerous concepts published about the mechanism of HDS of TH [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16] in the literature. As a matter of fact, one of them [2] states that the rupture of the >HC–S– bond is the consequence of the β–C–H dissociation and the hydrogenation of the fragment with other hydrogen molecules. Another concept is based on the direct dissociation of the >C–S bond due to the interaction with outside hydrogen, followed by hydrogenation of the fragments and desorption of the hydrogenated products from the catalysts surface [3]. It has also been proposed [5] that the partial hydrogenation of the >C=C< bonds in TH results in the formation of tetrahydrothiophene (THT), an intermediate of the hydrocarbons produced in HDS of thiophene.

This statement has been confirmed by other study [6], where the conversion rate of thiophene was compared to that of the THT during HDS. The HDS turnover frequencies of TH and THT were compared on catalysts containing Mon+-ions in different oxidation states (n = 2, 4 or 6). The HDS activity was substantially higher on samples with Mo2+, than on with Mo4+ and the activity was the minimal on the samples containing Mo6+. The activity on the silica supported sulfided molybdenum (MoS2) samples showed much higher catalytic activity, than those on the non-sulfided ones.

A simplified model of the HDS of TH (Fig. 1) presents the latter two of the above mentioned mechanisms [5, 6], indicating both the direct and stepwise HDS reactions. Moses et al. [17] compared the two pathways with DFT calculations and presented a detailed overview of the reactions. Not only the presence of both routes of HDS, but also the different role of Mo- and S-sites in HDS on the sulfided catalysts was explained.

The simplified possible ways for HDS of thiophene [5]

The HDS of TH has also been studied by using deuterium isotope on sulfided, alumina supported Mo, Ni and Ni—promoted Mo catalyst [18]. The interaction of TH with D2 and with deuterium containing H2 indicated that the HDS proceeds via the interaction of the TH with external hydrogen and that intermolecular TH conversion with participation of their β-hydrogen atom does not play role in the reaction.

Apart from the detailed studies of sulfur uptake and exchange in a number of laboratories with 35S [19], radiotracer studies on the mechanism of this reaction with 14C labeled sulfur containing compounds have not been carried out [20]. However, the conversion of 14C labeled thiophene was studied by Somorjai and Bussel [21]. They focused on the formation of carbon on the clean and on carbide containing single crystal Mo(100) catalyst, they observed increased HDS activity of the sulfided samples when the sulfur was removed from the surface by evacuation. Our results [22, 23] confirmed their observation: we observed linear correlation between the sulfur exchange capacity and the HDS activity of sulfided, non-promoted and of Ni-, Co-, Pd- and Pt promoted molybdena—alumina, furthermore of Ni—promoted silica—alumina supported tungsten catalysts. The existence of this correlation indicates that the sulfur exchange capacity is similar to the HDS activity of the sulfided catalysts. However, it had been shown in several publications [24, 25], sulfur exchange is not equal to sulfur replacement in the course of thiophene HDS. The correlation observed by the authors relates to sulfur replacement and catalytic activity and is correct only for the catalysts of similar composition. Similar catalysts (NiMo, NiW on Al2O3) were compared in our last study, and the linear correlation between sulfur exchange and catalytic activity was even clearer than in our previous work [26]. Comparison of catalysts differ by carrier nature, active metals etc., may not lead to linear correlation but to more complicated dependence.

We provided a study of the selectivity in TH conversion on three catalysts of substantially different HDS activities observed in our former [27, 28] studies of sulfided Mo-alumina and NiMo-alumina of 0.35 atomic Ni/Mo ratio (Mo and NiMo) and of the alumina supported nickel catalyst (Ni). In the investigation the conversion of a mixture of TH with THT has been studied, whereas the TH was labeled with radioactive carbon (thiophene—14C). In additional experiments, it has been established [16] that THT is not an intermediate at atmospheric pressure but it may be a major intermediate at high pressure and low temperature [8, 9]. Therefore, it was particularly interesting to study the formation of THT and 2,5-dihydrothiophene in conditions of thiophene HDS at atmospheric pressure, different temperature using markedly different catalysts.

There has been used 14C radioisotope in the present study for the answer to these questions and the experiments have been carried out at atmospheric pressure and different temperature in the micro catalytic pulse system applied in our laboratory described in details elsewhere [27,28,29]. Our detailed comments are given on the nature of the conversion products and the elementary steps of the mechanism of thiophene HDS.

Experimental

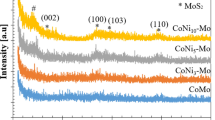

The experiments have been performed on sulfided Mo, NiMo, and Ni samples in conditions, applied before. MoO3/Al2O3 of 12 mass% of (Mo) samples were prepared by impregnation of a Pural-Al2O3 (210 m2/g) with an aqueous solution of ammonium heptamolybdate. The Ni/Al2O3 catalyst (Ni) was prepared by impregnation of the alumina, with an aqueous solution of nickel nitrate calculated for ∼6 mass% of NiO on the catalyst. The wet samples were dried and calcined for 5 h at 723 K. The Ni-promoted molybdena-alumina catalyst (1.75 mass% calculated for Ni) were prepared by impregnation of the dried, (not calcined) Mo sample with aqueous nickel nitrate solution, dried and calcined for 5 h at 773 K temperature. The catalysts samples have been sulfided with a mixture of hydrogen sulfide (H2S) with hydrogen (H2) of 1:1 molar ratio. Table 1 presents the data of the catalysts specific surface area determined by N2 adsorption and their chemical content, calculated from the amounts and correlation of materials applied for preparation [31] and determined [28] by prompt gamma activation analysis (PGAA). There are also presented in Ref. [31] the method of treatment of the samples with mixtures H2S/H2 and detailed data of the irreversible sulfur uptakes determined by their sulfidation in circulation system [22] with H2S, containing radioactive sulfur (H225S). The amount of sulfur uptakes of catalysts were determined from the decrease of the gas phase radioactivity values (GSirr) at circulating of the mixtures H235S + H2 up to the constant gas phase radioactivity values were reached. The amount of irreversible sulfur on the catalysts (SSirr) were determined by the radioactivity of the samples after their treatment in vacuum [31], and calculated also (GSirr), from the amounts of sulfur uptake values by vacuum treated samples determined in their repeated sulfur uptake experiments provided with H225S/H2 presented also in Ref. [31].

The chemicals applied in the experiments were the follows: thiophene and tetrahydrothiophene Merck Co of purity > 98% and ~ 99.9, and hydrogen Messer Hungarogas I.T. of purity 99.5%.

Thiophene—14C was synthesized according to the following procedure: 1.378 g BaCO3 and 1.9 mg Ba14CO3 (of 10.73 GBq/g specific radioactivity) were mixed with barium metal by filling them in a Pyrex tube, and the mixture was heated at 973 K in argon flow, and reduced rapidly to barium carbide—14C at this temperature. The Pyrex tube was broken then to pieces and the barium carbide—14C hydrolyzed by a solution of hydrochloric acid in hydrogen flow in a suitable apparatus. The formed acetylene—14C was purified on pellets of magnesium perchlorate and sodium hydroxide, frozen with liquid nitrogen in a trap and it was connected to a vacuum manifold. The hydrogen was removed, and the amount of expanded acetylene—14C was determined by pressure of that. It was mixed with the amount of hydrogen sulfide required by the stoichiometry for the production of thiophene. The mixture was homogenized and reacted on Al2O3 at 623 K in a circulation process. The formation of thiophene—14C was followed by GC analysis, then the gas mixture was frozen in liquid nitrogen. After the exchange of cooling to – 40 °C the non-reacted acetylene-14C and hydrogen sulfide were separated by freezing in a reservoir. Stopping of the freezing, the formed thiophene-14C was distilled and diluted with non-radioactive thiophene. The chemical purity (99%) and the specific radioactivity (180,750 ± 425 dpm/mg) of the product was determined by GC and LSC, respectively.

The catalytic conversion of non-labeled THT and of its mixtures with thiophene-14C was carried out on sulfided catalyst samples of 10 μl in the pulse catalytic micro system applied in our laboratory described in details elsewhere [29, 30]. The amount of THT and TH conversion products were determined by GC. In experiments with thiophene-14C the fractions were introduced into three different vessels absorbing (i) C4 products, (ii) the non-converted thiophene14C, and (iii) the THT burned by FID, absorbed in solution of 0.1 M sodium-hydroxide. The radioactivity values of these fractions was determined in LSC using Clinisosol liquid scintillation cocktail and calculated the distribution of the radioactivity (%) among the fractions.

The degrees of conversion was calculated from the values of non-reacted THT and TH at injecting pulses of liquids (of 4.3 μl, i.e. 1.71 × 1018 and 1.179 × 1018 molecules of THT and TH). The flow rate of the carrier gas (30 or 40 NTP ml/min of H2) was accepted as equivalent with the low rate of the reactant pulses [32, 33]. The experiments of the reactants conversions have been provided at the temperature range of 593–673 K. The obtained data in the majority of cases indicated definite increase of the conversion rate of THT and TH at increasing temperature. The degree of the THT conversion on the samples, containing NiMo and Ni was very high—near to a total one—at temperatures over 593 K.

On these two catalyst samples the temperature dependence of the THT conversion was determined at a wider—473–673 K—interval of the temperature, and the values of the temperature coefficients—accepted generally, for virtual activation energy values—of the HDS of these compounds were calculated from the conversion data determined at a lower—473–573 K—interval.

Results and discussion

Table 1 presents the characteristic data of the catalyst, used in the experiments. The HDS conversion of the mixtures of thiophene, labeled with radioactive carbon thiophene-14C and not labeled THT (of 1:1 ratio) have been studied in the temperature interval of 593–673 K. Fig. 2 shows the results of chromatographic separation and analysis of the conversion products. Conversion data determined during the HDS of these mixtures can be found in Fig. 3. The results indicating the appearance of THT-14C, besides the C4-hydrocarbon-14C products, minimal amount of 2,5-DHT 14C and 2-HTH-14C. Furthermore, data in these tables indicate substantial radioactivity values of THT, consequently that is a main intermediate of HDS of thiophene-14C at atmospheric pressure. This is different from the observation of Borgna et al. [16] and is connected presumably with the differences in the reaction conditions applied herein.

Distribution of the products of HDS conversion of the mixtures of thiophene, labeled with radioactive carbon thiophene-14C and not labeled THT (of 1:1 ratio) in pulse reactor over MoS2 catalyst at 623 K. The results of chromatographic separation and analysis of the conversion products (a) and the distribution of the radioactivity among the conversion productsproducts (b) (Products: C4, TH thiophene, 2 HT 2-hydrothiophene, 2,5 DHT 2,5 dihydrothiophene, THT tetrahydrothiophene)

Distribution of the radioactivity values (%) among the products at the conversion of the mixture of thiophene-14C + tetrahydrothiophene (molar ratio 1:1) on sulfided catalysts of 10 mg at different temperature and 30 NTP ml/min flow rate of H2(TH:thiophene,DHT: dihydrothiophene, THT:tetrahydrothiophene)

By comparing the data in Fig. 3, it can be seen that the highest radioactivity in the THT obtained on the sulfided Mo catalyst at the flow rate of 30 NTP ml/min at the conversion of the mixtures (thiophene-14C + tetrahydrothiohene). The radioactivity of THT was lower on Ni, and a minimal value was measured on the NiMo catalyst.This is connected with the increase of 14C infiltration at increasing temperature and with the substantially higher amounts of the C4 hydrocarbons, produced from THT on NiMo.

In all other cases the radioactivity values of TH-14C were substantially 3–6 times higher than those of THT-14C. This is the consequence of the much higher extent of HDS and higher degrees of THT conversion, than those of TH, as this was indicated by comparison of the respective data in Fig. 3 with those in Tables 4. Minimal amounts of DHT also formed at the flow rates of 30 NTP ml/min, as that is indicated on tables.

The ratio of the HDS conversion were lower at higher—40 NTP ml/min—flow rates of the mixtures of TH-14C + THT (Fig. 4). The absence of radioactive DHT at the conversion at these flow rates, different from the case of THT-14C, indicated the stepwise HDS of TH. The absence of DTH among the products is connected presumably by substantially higher amounts of the converted THT in comparison with those of TH.

The data of repeated extents and rates (mTH) of the conversion of TH is presented in Table 4, at 673 K on the three catalysts. Measurements by GC indicate the highest ratio of the C1–C2—butenes and butane among them, in agreement with our former observation Table 2. Similar data have been found in the distribution of the radioactivity in C4 (Table 3.) The amount of 2-butene is higher than 1-butene + butane among the C4 products of thiophene conversion wich indicates the hydrogenation of thiophene producing 2-hydrothiophene followed by additional hydrogenation the isomerization of >C=C< resulting the formation of 2,5DHT. There have been observed also minimal amounts of DHT and THT at the conversion. This observation raised the question of stepwise HDS of TH.

This question initiated to perform experiments of the separate conversion of THT on the same catalysts. The determined data are presented in Figs. 5, 6. Comparison of these data with those in Table 4 indicates substantially higher extents of the THT conversion in comparison with those of TH in the same temperature intervals. Total conversion was obtained on the NiMo in the same (593–673 K) temperature range and near total conversion (70–80%) on the Ni, whereas it was substantially lower on the Mo sample. The small temperature dependent amounts of TH among the products on the three catalysts indicated a minimal dehydrogenation of THT.

The calculated temperature coefficients (visual activation energy values) from the “Arrhenius straight” of the TH conversion were definitely higher on Ni than on Mo in agreement with the higher degree of the TH conversion on Mo, as that is seen on Fig. 7. Different from that, no temperature dependence of the TH conversion was observed on the NiMo, and the degree of TH conversion were the highest on this catalyst.

The same temperature dependence of the THT conversion has been also observed on the Mo sample. The conversion rates were substantially higher on the NiMo and Ni, their temperature dependences have been determined from the temperature coefficients at lower—493–553 K—temperature region. The plots of log m vs. 1/T calculated from the “Arrhenius straights” of THT conversion are presented on Fig. 8.

Comparison of the data in Figs. 5, 6 with the respective ones in Table 4 indicates substantially higher degrees of the THT conversion in comparison with those values at the conversion of TH. The temperature coefficients of the THT conversion rates were lower on the Mo and NiMo, than that of determined from the TH conversion rates on the same catalysts. Different from this, the temperature coefficient of the THT conversion on the Ni was substantially higher than that of TH.

This observations raise the question: why the amounts and the rates of THT HDS are substantially higher, in comparison with those values of TH in all respective cases? Our opinion, it is caused by the differences in the bond energy values of the >C–S bonds (QCS), as those are higher in CH2=CH–SH 318 kJ (given as 76.6 kcal in Ref. [33], than in CH3CH2–SH 286 kJ (given as 69 kcal [31]. It follows from the respective bond strengths of C3H7CH2—SH QCS = 304.3 kJ (given as 72.8 kcal [34]), higher than the value of QCS = 251.6 kJ (given as 60.2 kcal [35]) in CH2=CHCH2–SH, that the HDS of 2,5 DHT is higher than that of TH. This approach gives an explanation also for the presence of minimal amounts of 2,5 DHT and 2-HTH among the products of thiophene HDS. The temperature coefficient of the conversion of THT on NiMo is lower substantially, than that on Ni (Fig. 8). This is caused by the substantially (~ three times) higher ratio of the >C–C< bond rupture on Ni in comparison of that at the TH conversion on this NiMo as the determined before [28].

Fig. 9 represents a schematic diagram over the HDS of TH on the sulfided Mo, NiMo, and Ni catalysts. As can be seen in Fig. 2 could be identified in the prehydrogenation step the formation of 2-HTH-14C and 2,5-DHT-14C in the conversion process of TH-14C. It was only possible by the application of pulse microanalytical technique since 2-HTH but also 2,2-DHT have a very short life time before the transformation into THT. The main process was the formation of THT in our dynamic system and over the applied catalysts and followed a rapid scission of both S–C bond because the both bonds are equivalent and they have lower energy values than CH=CH–SH. Our results suggest that butadiene does not form from 2,5-DHT by the elimination of both S–C bond. NiMo catalyst had higher effect on this process.

In the conversion of THT minimal amount of 2,5,-DHT 2—HTH and TH could be also identified (Fig. 7) as a consequence of the minor dehydrogenation process on the catalysts.

We consider that our present study—applying the radiotracer technique and pulse microanalytical method—can contribute to better understanding of the complicated conversion of TH on the different sulfided catalysts.

Conclusions

As our former publication showed [36] the isotope tracer technique is a reliable method for mapping of byproducts of a mechanism. Based on the results of the present study the following statements can be made: the THT is a major intermediate in the conversion of TH on our single sulfided Mo, NiMo, and Ni catalyst at atmospheric pressure in the pulse microanalytical sytem.

Small amount of 2-HTH and 2,5-DHT could be identified in the hydrogenation process of TH. Both intermediates are more reactive because the stability of these species follows the order: THT > 2,5-DHT > 2-HTH. This can provide a good explanation that 2-HTH can hardly observed in the experiment, while THT can be observed easily [37]. The conversion of THT is preferential because both S–C bonds are equivalent and have lower energy value than –CH2=CH–SH. NiMo has higher activity in this process than Mo and, Ni catalysts.

References

Owens PJ, Amberg CH (1961) Thiophene desulfurization by a microreactor technique. Adv Chem 20:182–198

Kolbe S (1969) Catalytic hydrodesulfurization of thiophene. VII. Comparison between thiophene, tetrahydrothiophene, and n-butanethiol. Can J Chem 47:352–355

Milkowsky RJ, Silvestri AJ, Heinemann H (1974) On the mechanism of thiophene desulfurization. J Catal 34:324–326

Houala M, Nag NK, Sapre AV, Broderick DH, Gates BC (1978) Hydrodesulfurization of dibenzothiophene catalyzed by sulfided CoO-MoO3γ-Al2O3: the reaction network. AIChE J 24:1015–1021

Hargreaves AE, Ross JRH (1979) An investigation of the mechanism of the hydrodesulfurization of thiophene over sulfided Co-MoAl2O3 catalysts: II. The effect of promotion by cobalt on the C-S bond cleavage and double-bond hydrogenation/dehydrogenation activities of tetrahydrothiophene and related compounds. J Catal 56:363–376

ZdraŽil M (1982) The chemistry of the hydrodesulphurization process (review). Appl Catal 4:107–123

Pokorny P, Zdrazil M (1981) Single and competitive hydrodesulphurization of thiophene and benzo[b]thiophene on molybdenum catalysts. Collect Czech Chem Commun 46:2185–2196

Vrinat ML (1983) The kinetics of the hydrodesulfurization process-a review. Appl Catal 6:137–158

Schulz H, Do DV (1984) Fast and slow steps of hydrodesulfurization. Bull Soc Chim Belg 93:645–652

McCarty KF, Schrader GL (1984) Reduced Molybdenum states in hydrodesulfurization: investigation using chevrel phase catalysts. In: 8th International congress on catalysis

McCarty KF, Schrader GL (1987) Deuterodesulfurization of thiophene: an investigation of the reaction mechanism. J Catal 103:261–269

Startsev AN (1992) Concerted mechanism of thiophene hydrogenolysis by sulfide HDS catalysts. In: 10th international congress on catalysis, p 585

Leglise J, Gestel V, Duchet J-C (1996) Evidence for H2S as active species in the mechanism of thiophene hydrodesulfurization. In: Occelli ML, Chianelli R (eds) Hydrotreating technology for pollution control. Marcel Dekker Inc., New York, pp 147–157

Topsoe H, Clausen BS, Massoth FE (1996) Hydrotreating catalysis, science and technology. In: Anderson R, Boudart MM (eds) Catalysis, science and technology, vol 11. Springer, Berlin

Schulz H, Schron M, Rahman HM (2000) In: Cerveny L (ed.) Studies in surface science and catalysis. Elsevier, Amsterdam, p 204

Borgna A, Hensen EJM, Coulier L, de Croon MHJM, Schouten JC, van Veen JAR, Niemantsverdriet JW (2003) Intrinsic thiophene hydrodesulfurization kinetics of a sulfided NiMo/SiO2 model catalyst: volcano-type behavior. Catal Lett 90:117–122

Moses PG, Hinnemann B, Topsoe H, Norskov JK (2007) The hydrogenation and direct desulfurization reaction pathway in thiophene hydrodesulfurization over MoS2 catalysts at realistic conditions: a density functional study 248:188–203

Gudkov BS, Gayday NA, Beranek L (1984) Investigation of the mechanism of thiophene hydrodesulphurization by isotopic method. Collect Czech Chem Commun 49:2400–2409

Tétényi P (2006) Use of 35S radiotracer in catalytic studies. In: Hargreaves JSR, Jackson SD, Webb G (eds) Catalytic science series, vol 4. Imperial College Press, London, pp 31–61

Paál Z (2006) Application of 14C radiotracer for the study of heterogeneous catalytic reactions. In: Hargreaves JSR, Jackson SD, Webb G (eds) Catalytic science series, vol 4. Imperial College Press, London, pp 31–61

Bussel ME, Somorjai GA (1987) A radiotracer (14C) and catalytic study of thiophene hydrodesulfurization on the clean and carbided Mo(100) single-crystal surface. J Catal 106:93–104

Koltai T, Massoth FE, Tétényi P (2000) A radioisotope flow-circulation tracer method for determination of sulfur uptake and exchange. Reac Kinet Catal Lett 71:85–92

Massoth FE, Koltai T, Tétényi P (2001) Theoretical analysis of sulfur exchange experiments. J Catal 203:33–40

Kogan VM, Isaguliants GV (2008) The HDS mechanism: which “auxiliary” process takes place—sulfur isotopic exchange or replacement—and why is it important to know it? Catal Today 130:243–248

Kogan VM (1998) Transition metal sulfides. Chemistry and catalysis. In: Weber T, Prins R, van Santen R (eds) NATO ASI Series, Kluwer Academic Publishers, 3. High technology, vol. 60, pp 35–271

Varga Z, Szarvas T, Tétényi P et al (2018) The particular characteristics of the active sites of MoS2, WS2 catalysts in thiophene hydrodesulfurization. Reac Kinet Mech Cat 124:61–74

Tétényi P, Schnörch P, Tellinger O (2009) Promoter effect of nickel in thiophene hydrodesulfurization as monitored by sulfur uptake and cyclohexane conversion. Reac Kinet Catal Lett 97:141–150

Tétényi P, Ollár T, Szarvas T (2012) Sulfur exchange capacity and thiophene hydrodesulfurization activity of sulfided molybdena-alumina catalysts promoted by nickel. Catal Today 181:148–155

Dobrovolszky M, Matusek K, Pál Z, Tétényi P (1993) Conversion of thiophene on molybdena–alumina catalysts containing Group 8–10 metals: effect of H2S uptake. J Chem Soc Farad Trans 89:3137–3142

Koltai T, Galsán V, Tétényi P (1999) Effect of pretreatment of HDS activity of supported NiW and NiMo catalysts. Reac Kinet Catal Lett 67:391–396

Tétényi P, Ollár T, Schay Z, Schnörch P, Szarvas T (2008) Sulfur uptake determination on Ni containing molybdena-alumina samples by radioisotope tracer technique. Appl Radiat Isotopes 66:1190–1195

Pál Z, Koltai T, Matusek K, Manoli J, Potvin C, Muhler M, Wild U, Tétényi P (2001) Sulfur uptake and exchange, HDS activity and structure of sulfided, Al2O3 supported MoOx, PdMoOx and PtMoOx catalysts. Phys Chem Chem Phys 3:1535–1543

Franklin JL, Dillard JG, Rosenstock HM, Herron JT, Draxl K, Field FH (1969) Ionization P, appearance potentials and heats of formation of gaseous positive ionization potentials NSRDS-NBS 26 June Washington. (cited from J.D. Cox, G. Pilcher, thermochemistry of organic and organometallic compounds. London Academic Press, 1970)

Allken PW, Sutton LE (1950) Tables of interatomic distances and molecular configurations obtained by electron diffraction in the gas phase. Acta Cryst Cambridge 3:46–72

Krikorian OJ, Carpenter JH (1965) J Phys Chem 60:4399 (Cited from J.D. Cox, G. Pilcher: Thermochemistry of Organic and Organometallyc Compounds, London Academic Press 1970)

Szarvas T, Eller Z, Kasza T, Ollár T, Tétényi P, Hancsók J (2015) Investigation of radiocarbon (14C) labeled oleic acid hydrotreating over sulfided alumina supported MoP and NiW catalysts. Appl Catal B 165:245–252

Li S, Liu Y, Feng X, Chen X, Yang C (2019) Insights into the reaction pathway of thiophene hydrodesulfurization over corner site of MoS2 catalyst: a density functional theory study. Mol Catal 463:45–53

Funding

Open access funding provided by ELKH Wigner Research Centre for Physics.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tétényi, P., Szarvas, T. & Ollár, T. Experimental proof of thiophene hydrodesulfurization reaction steps by isotope (14C) labeled thiophene. Reac Kinet Mech Cat 134, 697–710 (2021). https://doi.org/10.1007/s11144-021-02086-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-021-02086-6