Abstract

In this work, the results of kinetic studies of Pd(II) chloride complex ion adsorption process on activated carbon are presented. The experiments were conducted for different temperatures, initial concentrations of Pd(II) complex ions as well as for different amount of activated carbon. These results confirmed that the mechanism of the adsorption process is complex and can be described by two step reaction model. A new form of the adsorption isotherm based on kinetic mechanism is suggested and can describe the observed process. Moreover, it was shown that for specific conditions, the proposed isotherm can be transformed into the Freundlich’s isotherm. The activation energies of the subsequent stages of the studied process were determined and are equal to E1 = − 9 ± 9, E2 = − 6 ± 1.4 and E3 = − 85 ± 8.9 J mol−1, respectively. It is also suggested that the observed positive Gibbs energy change during adsorption can be related only to the first step of this process which does not lead to the final product.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

At present, activated carbon is often applied to the heavy metals ions removal form the aqueous solutions. There are two main application areas. The first one, related to recycling of metals [1,2,3,4,5,6,7,8,9,10,11] and the second one, related to the environmental protection [12,13,14,15,16,17]. Our work refers to the first area mentioned above.

The process of Pd(II) chloride complex ions adsorption on activated carbon was described in our previous paper [18]. In the case of acidic solutions containing chloride ions, palladium forms chloride complexes. There are several reports which indicate that during the adsorption process on activated carbon, palladium(II) is reduced to the metallic form [5, 6, 9, 11].

Simonov et al. [11] have investigated the process of palladium(II) chloride complex ions sorption on graphite-like carbon materials. They have shown that in such a system, two processes occur simultaneously. The first one is related to the formation of π-complexes of PdCl2 with fragments of the carbon matrix, and the second one is related to the reduction reaction of Pd(II) to Pd(0).

Consequently, we studied the conditions under which such a recovery process is possible. In our previous work [18], we investigated and described the conditions of Pd(II) ion recovery through adsorption on activated carbon used as the sorbent.

More than a century ago, Herbert Freundlich published the paper [19] in which the isotherm equation describing adsorption process was presented. Since then, the Freundlich isotherm has been one of the most often used equations to describe this process.

We found that Freundlich adsorption isotherm describes the adsorption of Pd(II) complex ions much better then Langmuir equation.

The determined parameters of Freundlich equation are equal to β = 0.035 and 1/p = 0.49, at 294 K, and β = 0.062 and 1/p = 0.53 at 323 K. However, these investigations are time consuming. For example, experiments with desorption at 295 K, took about 10 months.

Moreover, using this description of the experimental data, it has been difficult to clarify the thermodynamics of the adsorption process. The analysis of the adsorption product suggested that PdCl42− adsorbed on the carbon surfaces undergoes irreversible transformation into solid product. However, in the model of the adsorption process suggested by us, thermodynamic considerations were limited only to the first step of the suggested mechanism of adsorption. Thus, there is a question if more information about the process can be drawn from the kinetic data. If this approach may lead to an adsorption isotherm, it would be much faster. Consequently, in this paper, we demonstrate that adsorption isotherm can be derived from the kinetics considerations.

This newly proposed approach gives a direct relationship between the initial concentration of absorbed substance, the amount of the used absorber and equilibrium constant of the adsorption process.

Materials and methods

In all our experiments, commercially available activated carbon, Norit GF40 (AC) in non-modified form was used. Palladium(II) chloride complex was obtained according to the methodology described in our previse paper [18].

The measurements of the rate of Pd(II) chloride complex ions adsorption onto activated carbon were carried out in the cyclic glass reactor kept in the thermostat at constant temperature (± 0.2 °C). After the constant temperature in the system was reached, suitable amount of activated carbon was introduced into the aqueous solution containing fixed concentration of Pd(II) chloride complex ions. The total volume of the solution was equal to 300 mL. The sample of 3 mL of the solution was taken periodically and analyzed spectrophotometrically (Shimadzu, model PC 2501, Japan) to detect changes of Pd(II) chloride ions concentration. The absorbance level was monitored and read out at the wavelength 279 nm. Next, the absorbance level was used to calculate the concentration of Pd(II), assuming molar absorption coefficient equal to 5980 dm3 cm−1 mol−1 [20]. After each UV–Vis analysis, the sample was returned to the cyclic reactor to maintain constant volume of the reagents. The solution was mixed by the glass stirrer dipped into the reactor at ca. 2 cm distance from its bottom. The rotor speed was adjusted and controlled using CAT R-50D stirrer.

The kinetics of the adsorption process was investigated under different conditions. These conditions are specified in Table 1.

After the absorbance measurement, the concentration of Pd(II) complex ions at each instant of time was calculated using earlier determined PdCl42− absorption coefficient [20].

Results

An example of the experimental results is shown in Fig. 1. From the registered absorbance it is possible to calculate concentration changes in time using Beer’s law. The obtained concentration vs time curves for different experimental conditions are shown in Fig. 2.

Concentration versus time curves obtained for different experimental conditions a influence of AC initial concentration, experimental conditions: T = 323 K, [PdCl42−]0 ~ 5 × 10−5 M, Mr = 1200 rpm, b influence of temperature, experimental conditions: [PdCl42−]0 ~ 5 × 10−5 M, Mr = 1200 rpm, [C]0 = 1.67 g/L c influence of mixing rate, experimental conditions: T = 323 K, [PdCl42−]0 ~ 5 × 10−5M, [C]0 = 1.67 g/L, d influence of initial concentration of Pd(II), experimental conditions [C]0 = 1.67 g/L, Mr = 600 rpm, T = 323 K

Having concentration vs time data points registered experimentally, the kinetic curve was determined. Then, the proposed integral form resulting from the assumed model was fitted to the obtained kinetic curve, and respective parameters related to the process were derived.

Taking into account the results obtained earlier [18] it was assumed that the studied process consists of two steps. This assumption is supported by the fact, that calculated Gibbs free energy for assumed single step process is positive. This clearly suggests that the studied process has to consist of at least two steps. Moreover, structural investigation of final product indicates substrates transformation into solid product. The first one is related to the adsorption of Pd(II) chloride complex ions on the surface of the activated carbon. The second step is related to the reaction on the surface.

It was also shown previously [18], that the formation of PdCl2 on the surface was observed, and this chemical compound is the final product of the reaction.

Taking it into account, the following reaction scheme was assumed:

Here n[C]org corresponds to the concentration of functional groups on the surface of applied activated carbon, and kx is the rate constant (where x = 1, 2, 3), and m, n correspond to stoichiometry indexes. The speciation as well as concentration of functional groups at the surface of AC was analyzed in our previous paper [4]. It was shown that the total concentration of acidic forms of functional groups is equal to 17.96 mM/g, where the concentration of alkaline type functional groups are equal to 4.1 mM/g. The main fractions of the acidic groups are carbonylic (13.99 mM/g) and phenolic (2.63 mM/g) [4].

It seems that these groups are responsible for PdCl2 formation in the second stage of adsorption process. Moreover, the activated carbon contains significant amount of functional groups on its surface. Therefore, isolation conditions can be assumed to exist. Under this assumption, the changes in concentration of functional groups can be neglected. Then, in the simplest case assuming m = n = 1, reaction (1) can be rearranged to the following form:

Here k1,obs, k2,obs, and k3,obs are observed rate constants which can be expressed as:

The sequence of first order reactions resulting from simplified scheme of reaction (2) can be put forward in the form of the following differential equation system:

In this equation:

\([PdCl_{4}^{2 - } ]_{soln}\) is concentration of Pd(II) in the solution

The general solution to these equations has the form [21]:

Parameters such as A, B, γ1, γ2 were determined using the TableCurve software by fitting Eq. (7) to all experimental data shown in Fig. 2. Next, parameters corresponding to the observed rate coefficients k1,obs, k2,obs and k3,obs, were calculated using Mathcad software by solving the system of Eqs. (8)–(11). The initial concentration \([PdCl_{4}^{2 - } ]_{0}\) was determined spectrophotometrically, and this value was used during calculations. Having rate coefficients determined from this model, their dependence on various experimental parameters such as AC initial concentration, Pd(II) initial concentration and temperature was analyzed.

Effect of AC initial concentration on the reaction rate

At first, the influence of the applied mass of activated carbon on the rate of Pd(II) chloride complex ions adsorption was investigated. Final results of these experiments are shown in Fig. 3. The obtained data points were fitted with the linear dependence. This fit confirms that assumed earlier observed rate constants (Eqs. 3–5) are in good agreement with the obtained kinetic data. Their dependence on applied mass of AC is linear.

Moreover, it can be seen that fitted equations pass exactly through the origin of the coordinates system. This in turn confirms, that the decrease of absorbance [concentration of Pd(II)] is directly related to the amount of activated carbon present in the solution. Furthermore, it can also be suggested, that the order of the reaction with respect to the concentration of AC = 1. It can also be seen that the k3,obs is in fact independent of AC concentration, which seems to confirm, that the second step (Eq. 4) is related to the transformation step, which is very slow.

Influence of Pd(II) initial concentration on the reaction rate

At first, to determine the reaction order with respect to Pd(II) chloride complex ions initial concentration, the initial rate method was used. In the studied case, this reaction rate can be expressed as:

Under isolation condition, Eq. (12) can be rearranged into the form:

It should be pointed out that at t = 0, initial concentration of \([PdCl_{4}^{2 - } ]_{ads}\) and \([PdCl_{2} ]_{ads}^{{}}\) is equal to 0. Therefore, in Eq. (12), this concentration is not taken into account.

Using logarithmic form of Eq. (13), it is possible to determine the order “α” of the reaction as well as k1,obs from the slope of fitted linear dependence. Experimental data shown in Fig. 2d, were used during this calculations. It was found from the plot shown in Fig. 4 that the order of the reaction is equal to 1.24 ± 0.1. Fractional order of the reaction suggests that the studied process may be complex. However, it should be also noted, that initial rate method is uncertain in case of fast processes, and the result is susceptible to error.

Such linearization methods are outdated now in chemical kinetics, and non-linear least squares fitting to the untransformed original equation should be rather used [22]. Therefore, we determine these parameters by using those two approaches. In the case of fitting the equation in its untransformed form, the order of the reaction was found to be equal to 1.7 ± 0.22.

Therefore, the observed rate coefficients obtained from the solution of equations system (Eq. 8) were also analyzed as a function of initial Pd(II) concentration. The initial rate method yields rate coefficient only for one way irreversible reaction, while the analytical solution corresponds to the steady state which can be different for different initial Pd(II) concentration. Comparing k1obs one can find that taking into account the error bar, the rate coefficients obtained from both methods are of the same order [k1,obs = 0.01299, obtained from initial rate, and k1,obs = 0.01282 from the solution of Eq. (8)].

It can also observed that the increase of Pd(II) initial concentration results in a decrease of Pd(II) observed adsorption rate constant k1,obs, as well as it increases the observed rate constant k2,obs. In case of k3,obs the effect of initial concentration of Pd(II) can be neglected. This is an explanation of fractional value of determined order of the reaction.

Influence of the temperature on the reaction rate

Finally, the influence of the temperature on the rate constants was also investigated. Using Arrhenius dependence, the activation parameters were determined.

Since Arrhenius dependence is written in the following form:

Here R is the gas constant, T is the temperature in kelvin, kx,obs is the observed rate constant of x-th reaction (x = 1, 2, 3), Ex,a is the activation energy of xth reaction, A is the Arrhenius constant.

It is possible to determine the activation energy and Arrhenius constant from the logarithmic plot of Eq. (16). The obtained results, which are the solutions of the system of equations (Eqs. 8–11) are gathered in Table 2 and shown in Fig. 4.

Surprisingly, the activation energy calculated in this way in all three cases has negative values. Such a situation is very rare. However, it was reported in the literature previously [23]. Taking into account error bars, it seems that the process proceeds almost without activation barrier (Fig. 5).

Effect of mixing rate

It is well known, that in case of heterogeneous reaction mass transfer phenomenon may have important impact on the process kinetics [24,25,26]. To investigate this influence, kinetic studies were performed where the mixing rate was varied from 600 to 1200 rpm. The obtained results are shown in Fig. 6.

As it can be seen, there is no visible influence of the mixing rate on the observed rate constants. This suggest, that the process rate is not controlled by the mass transfer phenomenon. Therefore, the influence of this parameter can be neglected in further considerations.

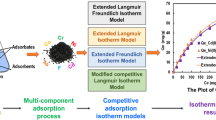

Adsorption isotherm

Having kinetic data, one may attempt to derive adsorption isotherm based on the first step of the reaction scheme represented by Eq. (1). The first part of this equation can be rearranged into the following form:

Taking into account that the results obtained in this work produce fractional order of the reaction, as well as k1obs dependence on initial concentration of Pd(II), the order of elementary step cannot be equal to 1. Therefore, we assumed that at equilibrium state, mPd(II) complexes may react with n[C]org functional groups (active sites). For the steady state, the rate of change of the concentration of ionic species given by Eq. (6) must be zero:

Consequently, from Eq. (15) one obtains:

From this equation, the ratio is:

Since the slowest process in our reaction scheme 2 is described by step 2, i.e., the formation of PdCl2, one can assume that the adsorption stage (i.e., step 1) is at equilibrium, and the ratio of the observed rate constant may in fact correspond to the equilibrium constant.

Considering the above relation, one can further assume that adsorption isotherm should also contain the equilibrium constant. A similar approach was used by Langumir. However, his isotherm was not related to the process in the solvent. Generally speaking, in most cases, the derived isotherms describe only a relation between concentration of absorbent and adsorbed substances, but they do not contain the information about the equilibrium constant.

Then, the relation (18) can be further rearranged in the following way:

The equilibrium concentrations of Pd(II) in the solution can be measured directly spectrophotometrically. The concentration of \(\left[ C \right]_{org,0}\) was determined using Bohem method. The equilibrium concentration of reaction product can be calculated from the mass balance:

Her:\(\left[ {PdCl_{4}^{2 - } } \right]_{\text{soln}}\) is the equilibrium concentration of Pd(II) ions in the solution, \(\left[ {PdCl_{4}^{2 - } } \right]_{0}\) is the initial concentration of Pd(II).

Taking into account that the concentration of acidic functional groups is about \([C]_{org,0}\) = 18 mM, and the initial concentration of Pd(II) as well as the amount of formed product \(\left[ {PdCl_{{4_{{\frac{m}{n},ads}} }} \cdot C_{org} } \right]\) on the surface of AC is of the order 5 × 10−4 M, the changes of [C] org,0 concentration can be neglected.

After the rearrangement of Eq. (18) with the help of Eq. (19), the following relation can be obtained:

In Eq. (20) two parameters i.e., K and m/n are unknown. It is possible to determine those parameters using logarithmic form of Eq. (20):

The above presented equation is in fact a new form of adsorption isotherm equation.

The parameters m and n can’t be determined directly, however m/n ratio can be determined from the slope of fitted line, while from the intercept of fitted line the equilibrium constant can also be calculated.

Fig. 7 shows the equilibrium constant determination using proposed isotherm at two different temperatures 323 and 298 K. Necessary experimental data for these calculations were taken from our previous paper [18] where the influence of the initial concentration of Pd(II) chloride ions on equilibrium concentration was given.

From the slope of the plot \(\log \left( {\frac{{[PdCl_{4}^{2 - } ]_{0} - [PdCl_{4}^{2 - } ]_{\text{soln}} }}{{[C]^{{}}_{org,0} }}} \right)\) versus \(\log \left( {[PdCl_{4}^{2 - } ]_{sol} } \right)\), the \(K = \frac{{k_{1} }}{{k_{2} }}\) value can be determined. The value of \(K = \frac{{k_{1} }}{{k_{2} }}\) at the temperature 323 K is equal to 1.04 ± 0.23 and for temperature 298 K is equal to 0.96 ± 0.4. It is obvious that this ratio \(\frac{{k_{1} }}{{k_{2} }}\) is practically constant. These k ratios can be also derived from kinetic rate constant obtained by solving the system of Eqs. (8)–(11).

The obtained values of equilibrium constant calculated from the kinetic data are gathered in Table 3. This comparison was made for only one temperature 323 K, since kinetic experiments were not conducted at lower temperature 298 K. The obtained value of K is in good agreement with that obtained by fitting proposed isotherm model (Fig. 7).

In the studied case, m/n ratio is equal to 0.52 ± 0.014 and 0.48 ± 0.027 for T = 323 K and T = 298 K.

Discussion

The correctness of the obtained results using proposed kinetic model, can be verified simply. From kinetic measurements, the apparent rate constant k1,obs can be calculated using initial rate method. From Eq. (13):

Obtained values of k1,obs are gathered in Table 4, and compared with those obtained from the system of Eqs. (8)–(11).

It can be seen that there is an insignificant difference between the observed rate coefficients determined from initial rate method and calculated using the proposed model. It should be pointed out, that expected error is higher in case of initial rate method since, this method works well when Δt approaches 0, which is not fulfilled in our case. In the studied case Δt ~ 2 min.

The proposed isotherm contains the equilibrium constant which is defined by the ratio of kxobs. Thanks to that it can be determined from kinetic measurements. The obtained form of Eq. (20) can be easily reduced to Freundlich isotherm, if K ~ β, and \(\frac{m}{n}\sim \frac{1}{n}\). The ratio \(\frac{m}{n}\) as defined by us, corresponds to the number of Pd(II) ions reacted with n number of functional groups (active sites). It is clear (Fig. 7) that the \(\frac{m}{n}\) ratio is not equal to 1 but is ca. 0.5. It may mean that two functional groups are required to immobilize one Pd(II) complex ion.

It is now possible, to explain the observed discrepancy between the formation of stable product and positive \(\Delta G^{0,*}\) calculated for the first elementary step of the reaction 2 [18]. Elusion experiments showed that the product of adsorption can slowly be dissolved. Thus, the second step of our reaction scheme is not irreversible, but it is rather an opposing reaction. Assuming that the reverse reaction (k4,obs) is ca. 10 times slower in comparison with forward one (k3obs), the \(\Delta G^{0,*}\) of total reaction can be calculated as follows:

In this equation:

\(\Delta G_{1}^{0,*}\) was calculated for the first step [18] and is equal to + 795.9 J/mol at 323 K. Next, the \(\Delta G^{0,*}\) can be calculated taking into account Eqs. (24) and (25) as follows:

It can be seen that Gibbs free energy of formation of the final product may have a negative value. This, in turn, confirms that the overall process may be spontaneous and formation of a stable final product is compatible with thermodynamic requirements.

Studies shown by Kalmar et al. [27, 28] were related to the kinetic studies of methylene blue adsorption on quartz substrate. They have shown that kinetic approaches might to be good way to shed light to the equilibrium state.

Conclusions

It was demonstrated that using kinetic studies adsorption isotherm can be derived from the obtained results. The derived Eq. (21) is in fact a new isotherm equation. What is the most important, this equation can be easily transformed to Freundlich isotherm equation. In fact, we have found a kinetic scheme explaining the form of Freundlich equation. This approach seems to be attractive because kinetic studies are faster than typical equilibrium adsorption experiments.

Taking into account the obtained results, the following conclusions can be drawn:

-

The determined value of the equilibrium constant using proposed isotherm is identical with the value of equilibrium constant calculated from kinetic data i.e., rate constants.

-

m and n parameters can be determined only by using a numerical method or by assuming the detailed mechanism of the studied process.

-

Using the assumed kinetic model for two step adsorption reaction it is possible now to explain its positive contribution to \(\Delta G^{0,*}\) obtained in our previous paper [18].

-

The obtained data and proposed isotherm model may find application in designing new technology of precious metals recovery, water purification etc.

-

The proposed isotherm model can be extended into complex system in which several parallel reactions take place.

References

Wojnicki M, Luty-Błocho M, Socha R, Mech K, Pędzich Z, Fitzner K, Rudnik E (2015) Kinetic studies of sorption and reduction of gold(III) chloride complex ions on activated carbon Norit ROX 0.8. J Ind Eng Chem 29:289–297. https://doi.org/10.1016/j.jiec.2015.03.036

Pacławski K, Wojnicki M (2009) Kinetics of the adsorption of gold (III) chloride complex ions onto activated carbon. Arch Metall Mater 54(3):560–853

Wojnicki M, Rudnik E, Luty-Błocho M, Socha RP, Pędzich Z, Fitzner K, Mech K (2016) Kinetic studies of gold recovery from diluted chloride aqueous solutions using activated carbon organosorb 10 CO. Aust J Chem 69(3):254–261. https://doi.org/10.1071/CH15275

Wojnicki M, Pacławski K, Socha RP, Fitzner K (2013) Adsorption and reduction of platinum(IV) chloride complex ions on activated carbon. Trans Nonferrous Met Soc China 23:1147–1156

Wołowicz A, Hubicki Z (2009) Palladium(II) complexes adsorption from the chloride solutions with macrocomponent addition using strongly basic anion exchange resins, type 1. Hydrometallurgy 98:206–212

Simanova SA, Shukarev AV, Lysenko AA, Grebennikov SF, Astashkina OV (2008) Adsorption of palladium, platinum, and gold chloride complexes by carbon fibers with various structures. Fibre Chem 40(4):365–375

Lam KF, Fong CM, Yeung KL (2007) Separation of precious metals using selective mesoporous adsorbents. Gold Bull 40(3):192–198

Cox M, Pichugin AA, El-Shafey EI, Appleton Q (2005) Sorption of precious metals onto chemically prepared carbon from flax shive. Hydrometallurgy 78:137–144

Ageeva LD, Kolpakova NA, Kovyrkina TV, Potsyapun NP, Buinovskii AS (2001) Mechanism and kinetics of the sorption of platinum, palladium, and gold on activated carbon from UV-illuminated chloride solutions. J Anal Chem 56(2):137–139

Els ER, Lorenzen L, Aldrich C (2000) The adsorption of precious metals and base metals on a quaternary ammonium group ion exchange resin. Miner Eng 13(4):401–414

Simonov PA, Romanenko AV, Prosvirin IP, Moroz EM, Boronin AI (1997) On the nature of the interaction of H2PdCl4 with the surface of graphite-like carbon materials. Carbon 35(1):73–82

Machida M, Fotoohi B, Amamo Y, Merciera L (2012) Cadmium(II) and lead(II) adsorption onto hetero-atom functional mesoporous silica and activated carbon. Appl Surf Sci 258:7389–7394

Ünlü N, Ersoz M (2006) Adsorption characteristics of heavy metal ions onto a low cost biopolymeric sorbent from aqueous solutions. J Hazard Mater 136(2):272–280. https://doi.org/10.1016/j.jhazmat.2005.12.013

Šćiban M, Klašnja M, Škrbić B (2006) Modified softwood sawdust as adsorbent of heavy metal ions from water. J Hazard Mater 136(2):266–271. https://doi.org/10.1016/j.jhazmat.2005.12.009

Demirbaş E (2003) Adsorption of cobalt(II) ions from aqueous solution onto activated carbon prepared from hazelnut shells. Adsorpt Sci Technol 21(10):951–963

Uzun I, Guzel F (2000) Adsorption of some heavy metal ions from aqueous solution by activated carbon and comparison of percent adsorption results of activated carbon with those of some other adsorbents. Turk J Chem 24:291–297

Chmielewski AG, Urbański TS, Migdał W (1997) Separation technologies for metals recovery from industrial wastes. Hydrometallurgy 45(3):333–344. https://doi.org/10.1016/S0304-386X(96)00090-4

Wojnicki M, Socha RP, Pędzich Z, Mech K, Tokarski T, Fitzner K (2018) Palladium(II) chloride complex ion recovery from aqueous solutions using adsorption on activated carbon. J Chem Eng Data. https://doi.org/10.1021/acs.jced.7b00885

Freundlich H (1906) Über die adsorption in lösungen. Z Phys Chem 57:385–470

Wojnicki M, Pacławski K, Rudnik E, Fitzner K (2011) Kinetics of palladium(II) chloride complex reduction in aqueous solutions using dimethylamineborane. Hydrometallurgy 110(1–4):56–61

Korobov V, Ochkov V (2011) Chemical kinetics with mathcad and maple. Springer, New York

Lente G (2015) Deterministic kinetics in chemistry and systems biology: the dynamics of complex reaction networks. Springer, New York

Menon A, Sathyamurthy N (1981) Negative activation energy for the Cl(Br)O + NO.fwdarw. Cl(Br) + NO2 reactions. J Phys Chem 85(8):1021–1023. https://doi.org/10.1021/j150608a019

Gomes CP, Almeida MF, Loureiro JM (2001) Gold recovery with ion exchange used resins. Sep Purif Technol 24(1–2):35–57. https://doi.org/10.1016/S1383-5866(00)00211-2

Kasaini H, Mbaya RK (2009) Continuous adsorption of Pt ions in a batch reactor and packed-bed column. Hydrometallurgy 97(1–2):111–118. https://doi.org/10.1016/j.hydromet.2009.02.002

Érdi P, Lente G (2014) Theory and (mostly) systems biological applications. Stochastic chemical kinetics. Springer, New York

Kalmár J, Lente G, Fábián I (2016) Kinetics and mechanism of the adsorption of methylene blue from aqueous solution on the surface of a quartz cuvette by on-line UV–Vis spectrophotometry. Dyes Pigment 127:170–178. https://doi.org/10.1016/j.dyepig.2015.12.025

Kalmár J, Kéri M, Erdei Z, Bányai I, Lázár I, Lente G, Fábián I (2015) The pore network and the adsorption characteristics of mesoporous silica aerogel: adsorption kinetics on a timescale of seconds. RSC Adv 5(130):107237–107246. https://doi.org/10.1039/c5ra21353c

Acknowledgements

Authors thank Mrs. Ewa Zalecka (Brenntag Polska) for kind supply of activated carbon samples. This work was supported by the National Science Center of Poland under Grand Number 2016/23/D/ST8/00668 Sontata 12.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Wojnicki, M., Fitzner, K. Kinetic modeling of the adsorption process of Pd(II) complex ions onto activated carbon. Reac Kinet Mech Cat 124, 453–468 (2018). https://doi.org/10.1007/s11144-018-1412-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-018-1412-2