Abstract

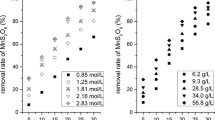

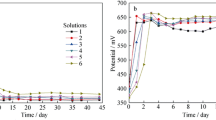

As a byproduct in the pyrolusite leaching process with SO2, the existence of MnS2O6 will decrease the purity of MnSO4 produced by leaching. For obtaining MnSO4 with satisfactory quality, it is beneficial to decrease the formation of MnS2O6 during the leaching process. A study on the formation characteristics of dithionate and sulfate formed in pyrolusite leaching process with SO2 was carried out. The results indicated that \({\text{S}}_{ 2} {\text{O}}_{ 6}^{ 2- }\) formation and mole ratio of \({{{\text{S}}_{ 2} {\text{O}}_{ 6}^{ 2- } } \mathord{\left/ {\vphantom {{{\text{S}}_{ 2} {\text{O}}_{ 6}^{ 2- } } {{\text{SO}}_{ 4}^{ 2- } }}} \right. \kern-0pt} {{\text{SO}}_{ 4}^{ 2- } }}\) increased with increasing initial pH, liquid–solid ratio and SO2 concentration, but was independent of particle size and stirring speed when particle size was less than 200 μm and stirring speed exceeded 400 rpm. The suitable conditions for obtaining MnSO4 product was 45 C and 0.4 mol L−1 H+ concentration with \({\text{S}}_{ 2} {\text{O}}_{ 6}^{ 2- }\) concentration and \({\text{S}}_{ 2} {\text{O}}_{ 6}^{ 2- } /{\text{SO}}_{ 4}^{ 2- }\) ratio were lower than 0.7 g L−1 and 0.02. Besides, the molar ratio of \({\text{S}}_{ 2} {\text{O}}_{ 6}^{ 2- }\) to \({\text{SO}}_{ 4}^{ 2- }\) (R) was put forward as a correlated parameter to evaluate the formation of reaction products, whose kinetics was analyzed in depth. The kinetic equation was related to reaction temperature, H+ and SO2 concentration, and the calculated reaction orders for SO2 concentration and initial H+ were 0.27 and − 0.17, the activation energy was 9696 J mol−1.

Similar content being viewed by others

References

Ogata A, Shimizu T, Komaba S (2007) Crystallization of LiMn2O4 observed with high temperature X-ray diffraction. J Power Sources 174(2):756–760

Yamashita T, Vannice A (1996) No decomposition over Mn2O3 and Mn3O4. J Catal 163(1):158–168

Edwards HW, Harrison RM (1979) Catalysis of nitric oxide decomposition by manganese oxide (Mn3O4). Environ Sci Technol 13(6):673–676

Zhang W, Cheng CY (2007) Manganese metallurgy review. Part I: leaching of ores/secondary materials and recovery of electrolytic/chemical manganese dioxide. Hydrometallurgy 89(3–4):137–159. https://doi.org/10.1016/j.hydromet.2007.08.010

Seo SE, Kang YO, Jung SH, Choi SH (2015) Hydrothermal synthesis of nanostructured MnO2 and gamma radiation effects on rechargeable lithium battery performance. J Nanosci Nanotechnol 15(9):6924–6930

Hu CC, Wu YT, Chang KH (2008) Low-temperature hydrothermal synthesis of Mn3O4 and MnOOH single crystals: determinant influence of oxidants. Chem Mater 20(9):2890–2894

He KJ, Sun WY, Ding SL, Su SJ (2015) Low pollution technology of Mn3O4 preparation by thermal decomposition of MnSO4. Fresen Environ Bull 24(10B):3420–3425

Zhang S, Chen Z, Tan S, Wang J, Jin S (1997) Preparation and microstructure of nanometer-sized Mn2O3. Nanostruct Mater 8(6):719–723

Zheng H, Li L, Lu L, Zhang Q, Xu S (2016) Facile synthesis of porous Mn2O3 microspheres as anode materials for lithium ion batteries. J Nanosci Nanotechno 16(1):698–703

Ning D, Dan ZG (2011) Current status and directions for development of cleaner production technology of electrolytic manganese metal industry in China. J Environ Eng Tech 1(1):75–81 (in Chinese)

Ning D, Wang F, Zhou C, Zhu C, Yu H (2010) Analysis of pollution materials generated from electrolytic manganese industries in China. Resour Conserv Recy 54(8):506–511

Sun WY, Su SJ, Wang QY, Ding SL (2013) Lab-scale circulation process of electrolytic manganese production with low-grade pyrolusite leaching by SO2. Hydrometallurgy 133(2):118–125

Paixdo JMM, Amaral JC, Memória LE, Freitas LR (1995) Sulphation of Carajás manganese ore. Hydrometallurgy 39(1–3):215–222

Li TQ (2008) Technology of low grade pyrolusite ore reduction process and recent advances. Chinas Manganese Ind 26(2):4–14 (in Chinese)

Su H, Wen Y, Wang F, Sun Y, Tong Z (2008) Reductive leaching of manganese from low-grade manganese ore in H2SO4 using cane molasses as reductant. Hydrometallurgy 93(3):136–139

Ali EA, Shahin MA, Ahmed MS, Ibrahim IA (2002) Leaching of low-grade Sinaimanganese ore using lactose as a reductant. Egypt J Chem 45(2):359–374

Acharya C, Kar RN, Sukla LB (2001) Microbial extraction of manganese from low grade manganese ore. T Indian I Metals 54(3):99–103

Naik PK, Sukla LB, Das SC (2000) Aqueous SO2 leaching studies on Nishikhal manganese ore through factorial experiment. Hydrometallurgy 54(2):217–228

Acharya S, Das RP (1987) Kinetics and mechanism of the reductive ammonia leaching of ocean nodules by manganous ion. Hydrometallurgy 19(2):169–186

Lu YZ, Ma HJ, Huang RJ, Yuan AQ, Huang ZW, Zhou ZG (2015) Reductive leaching of low-grade pyrolusite with formic acid. Metall Mater Trans B 46(4):1709–1715

Miller JD, Wan RY (1983) Reaction kinetics for the leaching of MnO2 by sulfur dioxide. Hydrometallurgy 10(2):219–242

Senanayake G, Das GK (2004) A comparative study of leaching kinetics of limonitic laterite and synthetic iron oxides in sulfuric acid containing sulfur dioxide. Hydrometallurgy 72(1–2):59–72. https://doi.org/10.1016/s0304-386x(03)00132-4

Qu B, Deng L, Deng B, He KJ, Liao B, Su SJ (2017) Oxidation kinetics of dithionate compound in the leaching process of manganese dioxide with manganese dithionate. React Kinet Mech Cat 2:1–13

Bassett H, Parker WG (1951) 352. The oxidation of sulphurous acid. J Chem Soc 27(5):1540–1560

Back AE, Ravitz SF, Tame KE (1952) Formation of dithionate and sulphate in the oxidation of sulphur dioxide by manganese dioxide and air. Bureau of Mines RI 4931

Lee JH, Gilje J, Zeitlin H, Fernando Q (2002) Low-temperature interaction of sulfur dioxide with Pacific ferromanganese nodules. Environ Sci Technol 12(13):1428–1431

Bassett H, Henry AJ (1935) The formation of dithionate by the oxidation of sulphurous acid and sulphites. J Chem Soc 210:914–929

Wilkosz I, Mainka A (2008) Mn(II)-catalysed S(IV) oxidation and its inhibition by acetic acid in acidic aqueous solutions. J Atmos Chem 60(1):1–17. https://doi.org/10.1007/s10874-008-9105-2

Qu B, Hu WL, Deng L, Sun WY, Ding SL, Gan ZW, Su SJ (2016) Simultaneous determination of dithionate and sulfate in leaching solution from SO2 leaching pyrolusite by ion chromatography. Energy Fuel 30(10):8561–8566

Yang Qihua ZZ (2012) Thermodynamic analysis and experimental investigation on restraining generation of manganese dithionate in leaching process of MnO2 with SO2. J Chin Soc Rare Earths 30:37–41 (in Chinese)

Lente G, Fábián I (2004) Effect of dissolved oxygen on the oxidation of dithionate ion. Extremely unusual kinetic traces. Inorg Chem 43(13):4019–4025

Petrie LM (1995) Molecular interpretation for SO2 dissolution kinetics of pyrolusite, manganite and hematite. Appl Geochem 10(3):253–267

Acknowledgements

This project was supported by the National Natural Science Foundation of China (NSFC-51374150 and NSFC-51304140) and Science and Technology Plan Projects of Sichuan Province, China (2015HH0067).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

He, Kj., Su, Sj., Ding, Sl. et al. Formation characteristics of dithionate and sulfate ions in the pyrolusite leaching process with SO2. Reac Kinet Mech Cat 123, 757–770 (2018). https://doi.org/10.1007/s11144-018-1365-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-018-1365-5