Abstract

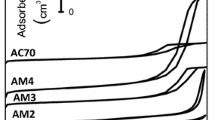

The influence of the porosity of γ-Al2O3 on the performance of CuO–ZnO–Al2O3 catalysts for methanol synthesis from H2 + CO2 mixture was studied. Various types of γ-Al2O3 with different surface areas (from 130 to 280 m2/g) and pore sizes (from 3 to 11 nm) were investigated. N2 adsorption, XRD, TPR studies and grand canonical Monte Carlo simulation were utilized to determine the correlation between their physico-chemical properties and catalytic performance. It was shown that the crystallite size of CuO (determined by XRD) and BET surface area of supports are not the key factors for methanol productivity. The TPR profiles of catalysts demonstrated a direct relationship between CuO–ZnO interaction with their catalytic performance. Interestingly, samples with the uniform pore size of 5 nm exhibit a higher CuO–ZnO interaction and the highest methanol yield. In addition, at this pore size, simulation results showed that the ratio of H2 and CO2 inside the γ-Al2O3 pore was 1.5, which could be an appropriate feed ratio for high methanol productivity.

Similar content being viewed by others

References

Höök M, Tang X (2013) Energy Policy 52:797–809

Heede R, Oreskes N (2016) Glob Environ Chang 36:12–20

Marcos FCF, Assaf JM, Assaf EM (2017) Catal Today 289:173–180

Porosoff MD, Yan B, Chen JG (2016) Energy Environ Sci 9:62–73

Ihm SK, Park YK, Jeon JK, Park KC, Lee DK (1998) Stud Surf Sci Catal 114:505–508

Behrens M (2014) Angew Chem Int Ed 53:12022–12024

Meshkini F, Taghizadeh M, Bahmani M (2010) Fuel 89:170–175

Olah GA, Prakash GKS, Goeppert A (2011) J Am Chem Soc 133:12881–12898

Zangeneh FT, Sahebdelfar S, Ravanchi MT (2011) J Nat Gas Chem 20:219–231

Jadhav SG, Vaidya PD, Bhanage BM, Joshi JB (2014) Chem Eng Res Des 92:2557–2567

Arena F, Mezzatesta G, Zafarana G, Trunfio G, Frusteri F, Spadaro L (2013) J Catal 300:141–151

Fujita S, Moribe S, Kanamori Y, Kakudate M, Takezawa N (2001) Appl Catal A 207:121–128

Guo XJ, Li LM, Liu SM, Bao GL, Hou WH (2007) J Fuel Chem Technol 35:329–333

Wu J, Saito M, Mabuse H (2000) Catal Lett 68:55–58

Lei H, Hou Z, Xie J (2016) Fuel 164:191–198

Fujitani T, Nakamura J (1998) Catal Lett 56:119–124

Choi Y, Futagami K, Fujitani T, Nakamura J (2001) Appl Catal A 208:163–167

Jansen WPA, Beckers J, vd Heuvel JC, vd Gon AD, Bliek A, Brongersma HH (2002) J Catal 210:229–236

Grunwaldt JD, Molenbroek AM, Topsøe NY, Topsøe H, Clausen BS (2000) J Catal 194:452–460

Phongamwong T, Chantaprasertporn U, Witoon T, Numpilai T, Poo-arporn Y, Limphirat W, Donphai W, Dittanet P, Chareonpanich M, Limtrakul J (2017) Chem Eng J 316:692–703

Ahouari H, Soualah A, Le Valant A et al (2013) Reac Kinet Mech Cat 110:131–145

Jeong H, Cho CH, Kim TH (2012) Reac Kinet Mech Cat 106:435–443

Tursunov O, Kustov L, Tilyabaev Z (2017) J Taiwan Inst Chem Eng 78:416–422

Ren H, Xu CH, Zhao HY, Wang YX, Liu J (2015) J Ind Eng Chem 28:261–267

Donphai W, Piriyawate N, Witoon T, Jantaratana P, Varabuntoonvit V, Chareonpanich M (2016) J CO2 Util 16:204–211

Karelovic A, Bargibant A, Fernández C, Ruiz P (2012) Catal Today 197:109–118

Witoon T, Bumrungsalee S, Chareonpanich M, Limtrakul J (2015) Energy Convers Manag 103:886–894

Digne M, Sautet P, Raybaud P, Euzen P, Toulhoat H (2002) J Catal 211:1–5

Plimpton S, Crozier P, Thompson A (2007) LAMMPS-large-scale atomic/molecular massively parallel simulator. Sandia National Laboratories, Albuquerque

Potoff JJ, Siepmann JI (2001) AlChE J 47:1676–1682

Cygan RT, Liang J-J, Kalinichev AG (2004) J Phys Chem B 108:1255–1266

Trinh TT, Vlugt TJ, Hagg MB, Bedeaux D, Kjelstrup S (2013) Front Chem 1:38

Yeh I-C, Lenhart JL, Rinderspacher BC (2015) J Phys Chem C 119:7721–7731

Harris KDM, Tremayne M, Kariuki BM (2001) Angew Chem Int Ed 40:1626–1651

McCusker LB, Von Dreele RB, Cox DE, Louer D, Scardi P (1999) J Appl Crystallogr 32:36–50

Koizumi N, Jiang X, Kugai J, Song C (2012) Catal Today 194:16–24

Nishida K, Atake I, Li D, Shishido T, Oumi Y, Sano T, Takehira K (2008) Appl Catal A 337:48–57

Fierro G, Jacono ML, Inversi M, Porta P, Cioci F, Lavecchia R (1996) Appl Catal A 137:327–348

Bahmani M, Vasheghani Farahani B, Sahebdelfar S (2016) Appl Catal A 520:178–187

Natesakhawat S, Lekse JW, Baltrus JP, Ohodnicki PR Jr, Howard BH, Deng X, Matranga C (2012) ACS Catal 2:1667–1676

Saeidi S, Amin NAS, Rahimpour (2014) J. CO2 Util. 5:66–81

Acknowledgement

This work was carried out at PVPro, VPI and supported by Vietnam National Oil and Gas Group (03/NCCB(PVPro)/2012/HĐ-NCKH) and the Ministry of Industry and Trade of Vietnam (DT.03.12/NLSH).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Le-Phuc, N., Van Tran, T., Thuy, P.N. et al. Correlation between the porosity of γ-Al2O3 and the performance of CuO–ZnO–Al2O3 catalysts for CO2 hydrogenation into methanol. Reac Kinet Mech Cat 124, 171–185 (2018). https://doi.org/10.1007/s11144-017-1323-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-017-1323-7