Abstract

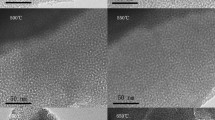

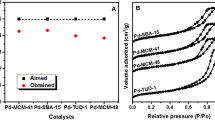

A series of SiO2 supports were prepared with the sol–gel method. Bimodal mesoporous Co/SiO2 catalysts with different pore size distributions were prepared. The samples were characterized by means of N2 adsorption–desorption, powder X-ray diffraction, H2-chemisorption, H2 temperature programmed reduction and Raman spectroscopy. The catalysts were employed in Fischer–Tropsch synthesis under the reaction conditions of 240 °C, 2 MPa and 1,000 h−1 to investigate their catalytic performance with different pore diameters. The experimental results revealed that the bimodal catalysts contain high specific surface area contributed from the formation of smaller mesopores during sol–gel process. Small Co particles of bimodal catalyst are able to be highly dispersed and behave moderate metal-support interaction without formation of hardly reducible species, which favors the production of sufficient active centers, contributing to the high catalytic activity. Moreover, increasing the pore size of the larger pores in bimodal mesoporous catalysts will facilitate the transportation of primary products and inhibit the hydrocracking to generate light hydrocarbons, promoting the production of heavy hydrocarbons with high C5+ selectivity.

Similar content being viewed by others

References

Font Freide JJHM, Gamlinb TD, Graham C, Hensman JR, Nay B, Sharp C (2003) Top Catal 26(1-4):3–12

Gy Pölczmann, Valyon J, Szegedi Á, Mihályi RM, Hancsók J (2011) Top Catal 54(16–18):1079–1083

Yamashita K, Barreto L (2005) Energy 30(13):2453–2473

Honsho T, Kitano T, Miyake T, Suzuki T (2012) Fuel 94:170–177

Park SJ, Bae JW, Oh JH, Chary KVR, Sai Prasad PS, Jun KW, Rhee YW (2009) J Mol Catal A 298(1–2):81–87

Schultz H (1999) Appl Catal A 186(1–2):3–12

Bromfield TC, Vosloo AC (2003) Macromol Symp 193(1):29–34

Park JY, Lee YJ, Karandikar PR, Jun KW, Ha KS, Park HG (2012) Appl Catal A 411–412:15–23

Wang YL, Hou B, Li DB, Chen JG, Sun YH (2012) Reac Kinet Mech Cat 106(1):217–224

Oukaci R, Singleton AH, Goodwin JG (1999) Appl Catal A 186(1–2):129–144

Jacobs G, Das TK, Zhang YQ, Li JL, Racoillet G, Davis BH (2002) Appl Catal A 233(1–2):263–281

Saib AM, Claeys M, van Steen E (2002) Catal Today 71(3–4):395–402

Khodakov AY, Griboval-Constant A, Bechara R, Zholobenko VL (2002) J Catal 206(2):230–241

Iglesia E (1997) Appl Catal A 161(1–2):59–78

Shinoda M, Zhang Y, Yoneyama Y, Hasegawa K, Tsubaki N (2004) Fuel Process Technol 86(1):73–85

Ooi YS, Zakaria R, Mohamed AR, Bhatia S (2005) Energy Fuels 19(3):736–743

Cooper CA, Lin YS (2007) J Mater Sci 42(1):320–327

Xu BL, Fan YN, Zhang Y, Tsubaki N (2005) AIChE J 51(7):2068–2076

Zhang Y, Koike M, Tsubaki N (2005) Catal Lett 91(3–4):193–198

Schanke D, Vada S, Blekkan EA, Hilmen AM, Hoff A, Holmen A (1995) J Catal 156(1):85–95

Jones RD, Bartholomew CH (1988) Appl Catal 39:77–88

Jones VK, Neubauer LR, Bartholomew CH (1986) J Phys Chem 90(20):4832–4839

Khodakov AY, Bechara R, Griboval-Constant A (2003) Appl Catal A 254(2):273–288

Jongsomjit B, Panpranot J, Goodwin JG (2001) J Catal 204(1):98–109

Iglesia E, Reyes SC, Madon RJ, Soled SL (1993) Adv Catal 39:221–302

Zhang Y, Koike M, Yang RQ, Hinchiranan S, Vitidsant T, Tsubaki N (2005) Appl Catal A 292:252–258

Li HL, Li JL, Ni HK, Song DC (2006) Catal Lett 110(1–2):71–76

Madon RJ, Reyes SC, Iglesia E (1991) J Phys Chem 95(20):7795–7804

Fan L, Yokota K, Fujimoto K (1995) Top Catal 2(1–4):267–283

Acknowledgments

This work was supported by National Natural Science Foundation of China (20876113).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, C., Wu, Y. & Zhan, J. Study on bimodal mesoporous Co/SiO2 catalysts for the Fischer–Tropsch synthesis. Reac Kinet Mech Cat 109, 497–508 (2013). https://doi.org/10.1007/s11144-013-0570-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-013-0570-5