Abstract

Silver linden (Tilia tomentosa Moench, TtM) flowers possess several health-promoting properties, especially at the neurological level, such as intestinal relaxation activity associated with specific flavonols, particularly quercetin and kaempferol derivatives. However, such molecules are susceptible to degradation upon different triggers like heat, light and extreme pH values. To overcome the scarce stability of TtM flowers bioactive molecules and make them suitable for developing functional food and supplements, we applied microencapsulation. Spray-drying microencapsulation of TtM flowers extract was performed using three starch-derived wall materials: maltodextrin 12 DE (MD12) and 19 DE (MD19), and OSA-modified starch (OSA-S). The stability of total phenols, flavanols, and antioxidant capacity was monitored for 70 days under accelerated stress conditions (40 °C/70% RH) by HPLC and spectrophotometric methods, and the intestinal contractile activity was tested in a murine model. In comparison to MD12 and MD19, OSA-S stood out for the higher encapsulation efficiency of quercetin and kaempferol glycosides (+ 36–47% compared to MD12 and + 18–24% compared to MD19) and stability thereof (half-life on average + 30% compared to MD12 and + 51% compared to MD19). The intestinal contractile activity of OAS-S powders resulted comparable to the original extract, indicating that flavonols were biologically active and accessible. Our results underly the potential advantages of OSA-S encapsulated formulation as a functional ingredient for the development of nutraceutical products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Tilia tomentosa Moench (TtM), also known as silver linden, is a deciduous tree belonging to the Malvaceae family [1]. TtM dried inflorescences are traditionally used as a popular remedy against cough, sore throat (tonsillitis and/or pharyngitis) [2], cold, and bronchitis [3]. Tilia flowers are also used as diaphoretic, diuretic, and antispasmodic agents [4]. In recent years, numerous studies confirmed the anti-inflammatory [3], hepatoprotective [5], antinociceptive [6], anxiolytic [7], and antispasmodic properties of Tilia extracts [8]. These properties are frequently associated with the presence of specific flavonols, i.e., phenolic compounds belonging to the broader group of flavonoids acknowledged for their numerous biological properties [9]. In particular, the most active flavonols recognized in TtM flowers are glycosides of quercetin and kaempferol, like tiliroside, isoquercitrin, rutin, and astragalin [4]. TtM flowers are used worldwide in the form of infusions, decoctions, or tinctures. The composition of extracts and their biological activity may depend on the extraction technique and the solvent used [3]. Recent finding also suggest that Tilia flower extracts can positively modulate human gut microbiota and this could contribute to the mentioned anti-inflammatory properties [9].

The chemical instability typical of phenolic compounds, the scarce solubility in aqueous solutions of some flavonoids (e.g., quercetin), and the pronounced organoleptic properties (such as taste and smell) represent issues [10] that can limit food and nutraceutical applications of TtM flowers. These problems could be overcome by using microencapsulation, i.e., the process of entrapping target molecules with one or more wall (or coating) materials to protect them and improve their functionalities. Spray-drying is a largely employed microencapsulation technology by which it is possible to convert liquid extracts into powders with enhanced stability, ease of manipulation and integration into different types of functional foods and supplements [9]. Existing literature on the spray-drying of TtM flower extracts is limited to one study [11] based on maltodextrin 13–17 DE (dextrose equivalents) as the wall material, and no data about the stability over time and the efficacy of the encapsulated bioactive molecules are available.

Recently, we described the biological activity in vitro of a commercial TtM flower extract, providing a molecular basis for the use of TtM for the treatment of functional gastrointestinal disorders [8]. In the present study, we aimed at evaluating the effects of spray-drying encapsulation of the same extract using different starch-derived wall materials, i.e., two maltodextrins with different DE, i.e., MD12 and MD19, and octenyl succinic anhydride (OSA) modified starch (OSA-S), comparing their impact on the stability of TtM flower flavonols, and finally confirming the pharmacological properties of the microencapsulated powders (TtMP) on intestinal neuromuscular activity.

Materials and Methods (Reported in the Supplementary Material #1)

Results and Discussion

TtME Characterization

TtME presented a TPC of 11.22 ± 0.68 mg GAE/mL, a TFC of 0.72 ± 0.03 mg QE/mL, and AOC of 19.70 ± 0.92 mg TE/mL (see Table S1 reported in the Supplementary Material #2). Since the extract was produced using a drug/solvent ratio of 1:1, the calculated value can also be expressed per gram of dry weight (dw) plant material.

Similar results can be found in previous works. Demiray et al. [12] quantified the phenolic content of TtM flower extract using three different solvents: 70% acetone solution, 100% water, 100% methanol. The best levels were obtained with acetone, with a polyphenolic content of 18.3 mg GAE/g dw plant, while water was the less efficient extractor with a TPC of 5.4 mg GAE/g dw. The antioxidant activity was 14.7 mg ascorbic acid equivalent/g dw plant using ABTS. Marrassini et al. [13], working on Tilia x viridis, obtained a greater TPC extracting with ethanol and hydroalcoholic mixtures, i.e., 30 mg/g dw. Akyuz et al. [14], using methanol at 60 °C as an extraction solvent for Tilia rubra subsp. Caucasica flowers obtained a TPC of 17.37 mg GAE/g dw and a TFC of 0.04 mg QE/g dw. It is interesting to note that the TFC reported by the authors is more than 10 times lower in comparison to what was found in the present work, although the TPC content was 1.6 times greater. It is likely that the discrepancy lies in the different studied plant species since, for instance, no kaempferol was detected by the authors, while in our case, this flavonol was represented by more than one derivative [8].

It is well known that the main molecules associated with the biological activity of Tilia flower extract, and in particular with its effects on the nervous system, are mainly kaempferol and quercetin glycosides [7, 15, 16]. For this reason, the extract was analyzed by RP HPLC-DAD focusing the detection to flavonols as recently described [8]. Briefly, the analysis of the hydrolyzed extract allowed us to identify quercetin and kaempferol as the dominant aglycones (Fig. S1 reported in the Supplementary Material #2). Based on these results, the quantitative data were reported as equivalents of these two flavonols. The contents of quercetin and kaempferol were 399 µg/mL ± 2.1 and 252 µg/mL ± 1.7 , respectively as recently found by Cerantola et al. [8]. These values are in good accordance with the TFC of the extract, confirming that the protocol of Pekal et al. [17] here adopted is suitable for quantifying the flavonols present in TtME. Indeed, flavanols like catechins, ordinarily present in Tilia ssp. extracts [18] are not detected by the adopted procedure [17].

Encapsulation of TtME

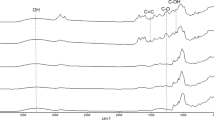

We applied spray-drying technology to improve the stability of TtME phenolic compounds to degradation/oxidation and make them easier to manipulate. Spray-drying is a relatively cheap, simple, and scalable process that allows the dehydration of extracts and slurries in combination with specific hydrophilic polymers to form powders. We compared the performance of three different polymers as wall materials, i.e., OSA-S, MD12, and MD19. The chromatograms of the flavonols extracted from the three TtMPs are presented in Fig. S2, panels b, c, and d. Although phenolic compounds underwent a high temperature during spray-drying, no distinct qualitative differences were appreciable.

Table 1 presents the quantitative data of the three formulations in terms of total and surface phenolic compounds calculated by Folin-Ciocalteu assay (i.e., TPC and SPC) and by HPLC (i.e., TQC and SQC for quercetin, and TKC and SKC for kaempferol). Even though the three TtMPs gave similar TPC, MD19 was characterized by higher SPC, indicating a lower capacity of this material to bind phenolic compounds. HPLC analysis of Q and K partially confirmed these results: indeed, both MDs exhibited higher surface flavonols, but MD12 was characterized by the highest SQC and SKC. OSA-S displayed the best encapsulating properties showing a higher capacity of establishing stronger interactions with flavonols. This is probably due to the octenyl succinic groups that give the starch molecule surface-active properties, enhancing the interactions with flavonols that are less water-soluble than other phenols like hydroxycinnamic and phenolic acids.

These results translate into different encapsulation efficiency profiles (Fig. 1). When it comes to total phenols, no significant differences were found among the three materials, with EE ranging from 88.8 to 96.6%, not far from what Alaşalvar et al. [11] obtained using MD 13–17 DE (97.4%). On the contrary, OSA-S stood out as the best wall material to encapsulate TtM flavonols compared to MDs (Fig. 1). This is the first report of the encapsulation efficiency of specific TtM flavonoids. The fact that different maltodextrin DE performed differently is not new: previously published data highlighted the different binding capacities of MD for phenolic compounds as a function of their DE [19]. The higher amount of flavonoids on the particle surface should correlate with their faster degradation being less protected by the wall materials.

The AOC of the TtMPs did not show significant differences. This result was expected since the AOC was measured only for total phenols extracted from the powders, which did not exhibit differences in terms of TPC, TQC, and TKC. Concerning Aw and moisture content, no significant differences were observed between the three different TtMPs. Even the encapsulation yield (EY), a parameter strongly associated with the profitability of the process, did not significantly vary, showing values close to what Alasavar et al. [11] observed.

Stability of Spray-dried Phenolic Compounds Over Time

Despite their potential health benefits, phenolic compounds are susceptible to degradation upon heating and UV light exposure, drastically reducing their biological activity [20]. To study the stability of the encapsulated phenols, TtMPs were subjected to an accelerated stability test under controlled temperature (40 °C) and humidity (75% RH) conditions in the absence of light. Figure 3 shows the storage effect on TPC, TQC, TKC, and AOC, for the three TtMPs. We observed that the content of flavonols, in terms of quercetin and kaempferol equivalents, decreased following 1st-order kinetics (Fig. 2b and c). This result agrees with previously published data about the thermal degradation of flavonoids [21, 22]. Kinetic parameters of Q and K are presented in Table 2 and confirm that flavonols could be better protected by using OSA-S, in accordance with the higher encapsulation efficiency of this shell material (Fig. 1). Indeed, the t1/2 of OSA-S samples was on average 30 and 51% higher than the t1/2 of MD 12 and MD 19 samples, respectively. The greater stability of kaempferol compared to quercetin is probably related to the number of -OH groups, i.e., five for quercetin and four for kaempferol, which leads to considering the latter as the less reactive, hence more stable [23].

Effect of TtMP on small intestine contractility. (A) Ileal inhibitory neuromuscular response induced by TtMP or TtME. (B) Ileal neuromuscular excitatory response induced by 10 Hz electrical field stimulation after 15 min-incubation with TtMP or TtME. Data are reported as mean ± SE. n = 12/experimental group. *** p < 0.001; TtMP: Tilia tomentosa Moench powder; TtME: Tilia tomentosa Moench extract

The behaviour of TPC (Fig. 2a) and AOC (Fig. 2d) was different in comparison to flavonols: in particular, we could not appreciate a net decrease of these values that, on the contrary, showed an increase after 15 days of storage with a final reduction (only for DPPH) in the last time intervals. One explanation for this phenomenon is that during the degradation of phenolic compounds, obtained products bearing new hydroxyl groups or characterized by structures capable of better delocalizing unpaired electrons or donating hydrogen atoms are formed, and this could affect the chemical reactions underlying the Folin-Ciocalteu and DPPH assays [24]. Consequently, the AOC lost during the thermal degradation of phenolic compounds could be compensated to different extents by the antioxidant capacity of the degradation products as already observed for microparticles [25, 26] and model flavonoids [27].

However, these data do not agree with previously published results on spray-drying particles of açai (Euterpe oleracea Mart.) extract [19]. The AOC of the powders obtained with MD, starch, and gum arabic showed a clear and net decrease of anthocyanins following a 1storder kinetics. Explanations for this discrepancy might lie in the different temperature and humidity conditions (35 °C x 52.3% RH) applied by the authors and in the different composition of the extract. Results similar to what Tonon et al. [19] described were observed by Lago and Norena [28] with respect to the total phenolic content on Smallanthus sonchifolius microparticles. The development of mathematical models could help understand the factors responsible for these discrepant results and predict the degradation kinetics of the phenolic content or the antioxidant capacity of microencapsulates [29].

TtMP I n Vitro Activity on Intestinal Preparations

The activity of TtMP was assessed on isolated ileal segments by performing the organ bath technique. This assay allows the analysis of the influence of xenobiotics or receptor ligands or endogenous factors on intestinal contractility. Firstly, the direct effect of TtMP on ileal motor response was evaluated. As shown in Fig. 3a, TtME and TtMP determined a comparable inhibitory effect on ileal motor function. Moreover, ileal specimens preincubated with TtME or TtMP showed a comparable reduction of ileal contraction induced by 10 Hz EFS (electrical field stimulation)-induced contraction (Fig. 3b). Indeed, both TtM formulations exerted an inhibitory effect on basal ileal contractility as well as on cholinergically mediated responses evoked by EFS, that determines the release of endogenous neuronal acetylcholine, which interacts primarily with cholinergic receptors, expressed mainly on smooth muscle cells [8].

Conclusions

Our findings prove that the spray-drying process of TtM flower extract through OSA-S is characterized by the best encapsulation efficiency, allowing to stabilize quercetin and kaempferol derivatives for longer times in comparison to MDs. OSA-S powder showed pharmacological effects on ileal motor functions similar to the one of TtME, suggesting that flavonols are not affected by the microencapsulation process and are accessible to the specific receptors. OSA-S TtMP thus represents a functional ingredient for the development of nutraceutical products ensuring the maintenance of the relaxation effect induced by TtM per se.

Data Availability

All data generated or analysed during this study are included in this published article and its supplementary information files.

Abbreviations

- AOC:

-

Antioxidant capacity

- DE:

-

Dextrose equivalent

- K:

-

Kaemferol

- MD:

-

Maltodextrin

- OSA-S:

-

Octenyl succinic anhydride-modified starch

- Q:

-

Quercetin

- SKC:

-

Surface kaempferol content

- SPC:

-

Surface phenolic content

- SQC:

-

Surface quercetin content

- TFC:

-

Total flavanoid content

- TKC:

-

Total kaempferol content

- TPC:

-

Total phenolic content

- TQC:

-

Total quercetin content

- TtM :

-

Tilia tomentosa Moench

- TtME :

-

TtM extract

- TtMP :

-

TtM powder

References

Frezza C, De Vita D, Spinaci G, Sarandrea M, Venditti A, Bianco A (2020) Secondary metabolites of Tilia tomentosa Moench inflorescences collected in Central Italy: chemotaxonomy relevance and phytochemical rationale of traditional use. Nat Prod Res 34(8):1167–1174. https://doi.org/10.1080/14786419.2018.1550487

Czerwinska ME, Dudek MK, Pawlowska KA, Prus A, Ziaja M, Granica S (2018) The influence of procyanidins isolated from small-leaved lime flowers (Tilia cordata Mill.) on human neutrophils. Fitoterapia 127:115–122. https://doi.org/10.1016/j.fitote.2018.02.018

Oniszczuk A, Podgorski R (2015) Influence of different extraction methods on the quantification of selected flavonoids and phenolic acids from Tilia cordata inflorescence. Ind Crop Prod 76:509–514. https://doi.org/10.1016/j.indcrop.2015.07.003

Sroka Z, Belz J (2009) Antioxidant Activity of hydrolyzed and non-hydrolyzed extracts of the inflorescence of linden (Tiliae inflorescentia). Adv Clin Exp Med 18(4):329–335

Matsuda H, Ninomiya K, Shimoda H, Yoshikawa M (2002) Hepatoprotective principles from the flowers of Tilia argentea (Linden): structure requirements of tiliroside and mechanisms of action. Bioorg Med Chem 10(3):707–712. https://doi.org/10.1016/s0968-0896(01)00321-2

Martinez AL, Gonzalez-Trujano ME, Aguirre-Hernandez E, Moreno J, Soto-Hernandez M, Lopez-Munoz FJ (2009) Antinociceptive activity of Tilia americana var. mexicana inflorescences and quercetin in the formalin test and in an arthritic pain model in rats. Neuropharmacology 56(2):564–571. https://doi.org/10.1016/j.neuropharm.2008.10.010

Herrera-Ruiz M, Roman-Ramos R, Zamilpa A, Tortoriello J, Jimenez-Ferrer JE (2008) Flavonoids from Tilia americana with anxiolytic activity in plus-maze test. J Ethnopharmacol 118(2):312–317. https://doi.org/10.1016/j.jep.2008.04.019

Cerantola S, Faggin S, Annaloro G, Mainente F, Filippini R, Savarino EV, Piovan A, Zoccatelli G, Giron MC (2021) Influence of Tilia tomentosa Moench extract on mouse small intestine neuromuscular contractility. Nutrients 13(10):3505. https://doi.org/10.3390/nu13103505

Kruk A, Granica S, Popowski D, Malinowska N, Piwowarski JP (2022) Tiliae flos metabolites and their beneficial influence on human gut microbiota biodiversity ex vivo. J Ethnopharmacol 294:115355

Li Q, Duan M, Hou D, Chen X, Shi J, Zhou W (2021) Fabrication and characterization of Ca(II)-alginate-based beads combined with different polysaccharides as vehicles for delivery, release and storage of tea polyphenols. Food Hydrocoll 112:106274. https://doi.org/10.1016/j.foodhyd.2020.106274

Alaşalvar H, Çam M (2019) Process for production of ready to drink iced teas from sage (Salvia officinalis L.) and linden (Tilia cordata): pressurized hot water extraction and spray drying. Food Sci Biotechnol 28(3):779–785. https://doi.org/10.1007/s10068-018-0538-3

Demiray S, Pintado M, Castro P (2009) Evaluation of phenolic profiles and antioxidant activities of Turkish medicinal plants: Tilia argentea, Crataegi folium leaves and Polygonum bistorta roots. World Acad Sci Eng Technol 54:312–317

Marrassini C, Anesini C, Ferraro G (2011) HPLC fingerprint of a flower extract of Tilia x viridis and correlation with antiproliferative and antioxidant activity. Phytother Res 25(10):1466–1471. https://doi.org/10.1002/ptr.3444

Akyuz E, Sahin H, Islamoglu F, Kolayli S, Sandra P, MS/MS (2014) Evaluation of phenolic compounds in Tilia rubra Subsp Caucasica by HPLC-UV and HPLC-UV. Int J Food Prop 17(2):331–343. https://doi.org/10.1080/10942912.2011.631252

Cardenas-Rodriguez N, Gonzalez-Trujano ME, Aguirre-Hernandez E, Ruiz-Garcia M, Sampieri A, Coballase-Urrutia E, Carmona-Aparicio L (2014) Anticonvulsant and antioxidant effects of Tilia americana var. mexicana and flavonoids constituents in the pentylenetetrazole-induced seizures. Oxid Med Cell Longev 2014:329172. https://doi.org/10.1155/2014/329172

Viola H, Wolfman C, Destein ML, Wasowski C, Pena C, Medina JH, Paladini AC (1994) Isolation of pharmacologically active benzodiazepine receptor ligands from Tilia Tomentosa (Tiliaceae). J Ethnopharmacol 44(1):47–53. https://doi.org/10.1016/0378-8741(94)90098-1

Pekal A, Pyrzynska K (2014) Evaluation of aluminium complexation reaction for flavonoid content assay. Food Anal Method 7(9):1776–1782. https://doi.org/10.1007/s12161-014-9814-x

Ziaja M, Pawlowska KA, Jozefczyk K, Prus A, Stefanska J, Granica S (2020) UHPLC-DAD-MS/MS analysis of extracts from linden flowers (Tiliae flos): differences in the chemical composition between five Tilia species growing in Europe. Ind Crop Prod 154:112691

Tonon RV, Brabet C, Hubinger MD (2010) Anthocyanin stability and antioxidant activity of spray-dried acai (Euterpe oleracea Mart.) juice produced with different carrier agents. Food Res Int 43(3):907–914. https://doi.org/10.1016/j.foodres.2009.12.013

Parisi OI, Puoci F, Restuccia D, Farina G, Iemma F, Picci N (2014) Polyphenols and their formulations: different strategies to overcome the drawbacks associated with their poor stability and bioavailability. In: Watson RR, Preedy VR, Zibadi S (eds) Polyphenols in human health and disease. Elsevier, pp 29–45

Chen JY, Du J, Li ML, Li CM (2020) Degradation kinetics and pathways of red raspberry anthocyanins in model and juice systems and their correlation with color and antioxidant changes during storage. LWT-Food Sci Technol 128:109448. https://doi.org/10.1016/j.lwt.2020.109448

Wang J, Zhao XH (2016) Degradation kinetics of fisetin and quercetin in solutions affected by medium pH, temperature and co-existing proteins. J Serb Chem Soc 81(3):243–253. https://doi.org/10.2298/JSC150706092W

Xiao JB, Hogger P (2015) Stability of dietary polyphenols under the cell culture conditions: avoiding erroneous conclusions. J Agr Food Chem 63(5):1547–1557. https://doi.org/10.1021/jf505514d

Nicoli MC, Anese M, Parpinel M (1999) Influence of processing on the antioxidant properties of fruit and vegetables. Trends Food Sci Technol 10(3):94–100. https://doi.org/10.1016/S0924-2244(. 99)00023 – 0

Flores FP, Singh RK, Kong FB (2014) Physical and storage properties of spray-dried blueberry pomace extract with whey protein isolate as wall material. J Food Eng 137:1–6. https://doi.org/10.1016/j.jfoodeng.2014.03.034

Bellumori M, De Marchi L, Mainente F, Zanoni F, Cecchi L, Innocenti M, Mulinacci N, Zoccatelli G (2021) A by-product from virgin olive oil production (pâté) encapsulated by fluid bed coating: evaluation of the phenolic profile after shelf-life test and in vitro gastrointestinal digestion. Int J Food Sci Technol 56:3773–3783. https://doi.org/10.1111/ijfs.15068

Ioannou I, Chekir L, Ghoul M (2020) Effect of heat treatment and light exposure on the antioxidant activity of flavonoids. Processes 8(9):1078. https://doi.org/10.3390/pr8091078

Lago CC, Norena CPZ (2017) Thermodynamic and kinetics study of phenolics degradation and color of yacon (Smallanthus sonchifolius) microparticles under accelerated storage conditions. J Food Sci Tech Mys 54(13):4197–4204. https://doi.org/10.1007/s13197-017-2887-y

Bassani A, Carullo D, Rossi F, Fiorentini C, Garrido GD, Reklaitis GV, Bonadies I, Spigno G (2022) Modeling of a spray-drying process for the encapsulation of high-added value extracts from food by-products. Comput Chem Eng 161:107772. https://doi.org/10.1016/j.compchemeng.2022.107772

Acknowledgements

This research was funded by: Regione Veneto, Italy, grant number POR-FESR 2014–2020, ASSE 1, AZIONE 1.1.4 - Project 3S_4H – Safe, Smart, Sustainable food for Health (ID 10065201). This study was carried out on the mouse isolated small intestine under approved guidelines by the Animal Care and Use Ethics Committee of the University of Padova and by the Italian Ministry of Health (authorization number: 41451.N.NRD) and was performed in compliance with national and EU guidelines for the handling and use of experimental animals. We are grateful to Dr. Francesco Piazzi for his technical assistance.

Funding

Open access funding provided by Università degli Studi di Verona within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mainente, F., Piovan, A., Zanoni, F. et al. Spray-drying Microencapsulation of an Extract from Tilia tomentosa Moench Flowers: Physicochemical Characterization and in Vitro Intestinal Activity. Plant Foods Hum Nutr 77, 467–473 (2022). https://doi.org/10.1007/s11130-022-00995-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11130-022-00995-y