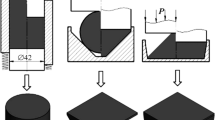

The evolution of stress-strain state and the distribution of temperature and relative density throughout a porous workpiece subjected to hot extrusion forging to produce axisymmetric parts with an axial hole was studied by computer simulation. The hot forging process was modeled using the finite element method employing the DEFORM 2D/3D software package. Analysis of the simulation results showed that the region of strains, stresses, and relative densities formed under the conical protrusions of the punches in the initial stages of the process, and these parameters decreased radially from the center of the workpiece to its periphery. As the axial strain increased with further deformation, the region of elevated stresses and densities extended deeper into the material, spreading from the center of the workpiece to its periphery. In the final stage, after the die cavity was filled with the forged material, the relative densities and stress intensities averaged over the workpiece, while the strain intensity noticeably decreased in the radial direction from the center to the periphery following additional compaction. This was explained by the deformation that occurred in the final stage when the forged material filled the pore volume in the additional compaction process after the die cavity was filled. The forging force increased sharply when the die cavity was filled fully and the material underwent additional compaction but increased monotonically in the initial stages of the process.

Similar content being viewed by others

References

A. Upadhyaya and G.S. Upadhyaya, Powder Metallurgy: Science, Technology, and Materials, 1st ed., Universities Press, India (2011), p. 536.

O.N. Sizonenko, A.I. Ivliev, and G.A. Baglyuk, Advanced Processes for Producing Powder Materials [in Russian], Nats. Univ. Korablestr., Nikolaev (2014), p. 376.

V.V. Savich and S.A. Oglezneva, Powder Metallurgy: Current State and Development Prospects [in Russian], Izd. Perm. Nats. Issled. Politekh. Univ., Perm (2021), p. 695.

G.G. Serdyuk and L.I. Svistun, Powder Metallurgy Technology: Part 3. Sintering and Additional Processing: Handbook [in Russian], Izd. GO UVPO Kuban. Gos. Tekhnol. Univ., Krasnodar (2005), p. 241.

H.F. Fischmeister, B. Arén, and K.E. Easterling, “Deformation and densification of porous preforms in hot forging,” Powder Metall., 14, Issue 27, 144–163 (2014).

W. Brian James, “Powder forging,” Rev. Part. Mater., 2, 173–214 (1994).

Yu.G. Dorofeev, B.G. Gasanov, V.Yu. Dorofeev, V.N. Mishchenko, and V.I. Miroshnikov, Industrial Hot Pressing Technology for Powder Parts [in Russian], Metallurgiya, Moscow (1990), p. 206.

Kh.A. Kun, “Main principles of forging powder billets,” in: Powder Metallurgy of Special-Purpose Materials [in Russian], Metallurgiya, Moscow (1977), pp. 143–158.

V.M. Gorokhov, E.A. Doroshkevich, A.M. Efimov, and E.V. Zvonarev, Bulk Forming of Powder Materials [in Russian], Navuka Tekhnika, Minsk (1993), p. 272.

A.A. Hendrickson, P.M. Machmeier, and D.W. Smith, “Impact forging of sintered steel preforms,” Powder Metall., 43, No. 4, 327–344 (2000).

G.G. Serdyuk, “Plastic strain of powder component in unclosed volumes,” Powder Metall. Met. Ceram., 34, No. 5–6, 247–252 (1995).

E.A. Doroshkevich, V.M. Gorokhov, I.N. Ryabin, and E.V. Zvonarev, “Finding an optimum shape of a porous blank in hot forging,” Powder Metall. Met. Ceram., 27, No. 4, 269–272 (1988).

G.A. Baglyuk, “Improving the densification of porous billets by intensification of shear strains,” in: Rheology, Structure, and Properties of Powder and Composite Materials: Collected Papers [in Ukrainian], Red. Vyd. Lutsk Derzh. Tekh. Univ., Lutsk (2004), pp. 35–48.

V.A. Pavlov and M.I. Nosenko, “Effect of the stress-strain state on the densification of metal powders (powder preforms) during hot forging,” Powder Metall. Met. Ceram., No. 2, 31, 103–107 (1992).

G.A. Baglyuk, “Effect of deformation parameters on the structure and properties of hot-forged powder materials,” Obrab. Mater. Davl., No. 1 (26), 139–145 (2011).

Y.A. Shishkina, G.A. Baglyuk, V.S. Kurikhin, and D.G. Verbylo, “Effect of the deformation scheme on the structure and properties of hot-forged aluminum-matrix composites,” Powder Metall. Met. Ceram., 55, No. 1–2, 5–11 (2016).

V.Yu. Dorofeev and S.N. Egorov, Interparticle Splicing in Producing Hot-Worked Materials [in Russian], Metallurgizdat, Moscow (2003), p. 152.

V.A. Pavlov and M.I. Nosenko, “An investigation of the processes of hot deformation of porous blanks of titanium, copper, and aluminum and optimization of them,” Powder Metall. Met. Ceram., 32, No. 9–10, 768–772 (1994).

V.A. Pavlov and M.I. Nosenko, “Effect of hot working on the formation of structure and properties in sintered metals,” Powder Metall. Met. Ceram., 27, No. 2, 103–107 (1988).

R.C. Buckingham, C. Argyrakis, M.C. Hardy, and S. Birosca, “The effect of strain distribution on microstructural developments during forging in a newly developed nickel base superalloy,” Mater. Sci. Eng. A, 654, 317–328 (2016).

V.M. Grishin and D.V. Grishin, “Improving the extrusion of hollow axisymmetric parts,” Kuznech. Shtamp. Proizv., No. 6, 12–15 (1996).

V.L. Kalyuzhny and A.M. Potyatinik, “Analysis of cold extrusion of hollow axisymmetric parts,” Nauk. Not., No. 59, 137–143 (2017).

V.L. Kalyuzhny, V.N. Gornostay, A.A. Gulyuk, and Ya.S. Oleksandrenko, “Hot forging of hollow parts from high-strength aluminum alloy with metal structure processing by plastic deformation,” Obrab. Mater. Davl., No. 1 (44), 137–142 (2017).

E.I. Semenov (ed.), Forging and Stamping: Handbook in 3 Volumes [in Russian], Mashinostroenie, Moscow (1986), Vol. 2, Hot Bulk Forging, p. 592.

Shiro Kobayashi, Soo-Ik Oh, and Taylan Altan, Metal Forming and the Finite-Element Method, Oxford Series on Advanced Manufacturing, Oxford University Press, Oxford, New York (1989), p. 377.

S. Shima and M. Oyane, “Plasticity theory for porous metal,” Int. J. Mech. Sci., 18, 285–291 (1976).

A.R. Khoei, Computational Plasticity in Powder Forming Processes, Elsevier Science (2005), p. 449.

V.G. Kononeko (ed.), High-Speed Low-Waste Metal Forging [in Russian], Vyshcha Shkola. Izd. Khark. Univ., Kharkiv (1985), p. 176.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 61, Nos. 9–10 (547), pp. 23–34, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bagliuk, G.A., Kyryliuk, S.F. Evolution of the Stress–Strain State of Porous Workpieces in Hot Extrusion Forging to Produce Axisymmetric Parts with an Axial Hole. Powder Metall Met Ceram 61, 504–513 (2023). https://doi.org/10.1007/s11106-023-00340-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-023-00340-1