Traditionally, the soldering process was carried out, applying mainly lead-based solder materials. However, the prohibition against using lead (Pb) in electronic equipment under the Restriction of Hazardous Substances Directive (RoHS) shifted the focus of research towards developing lead-free alloys. At the same time, tin (Sn) and tin-based alloys became viable alternatives. The development of solder alloys for long-term industrial applications necessitates a methodical characterization of material properties. Thermophysical properties are essential for modeling, designing, and employing lead-free solders to obtain strong joints. Such thermophysical properties as viscosity and density become more and more important as the research in advanced hybrid materials moves forward. This study presents an examination of density and dynamic viscosity in common lead-free solder materials, namely, pure Sn, Sn–3.5Ag, and Sn–3Ag–0.5Cu. The focus of research essentially moved onto the tin-based materials as it has a relatively low melting point and, thus, can serve as an alternative to lead in solder alloy research area and applications. Hence, Sn, Sn–3.5Ag and Sn–3Ag–0.5Cu were selected as research objects. A detailed literature review on the available models for theoretical evaluation of the above materials’ density and dynamic viscosity is provided. The available scientific efforts on dynamic viscosity assessment are extensive, but no specific model was described in the literature as more beneficial than the other. This study allows evaluating the density and dynamic viscosity using different models with the subsequent comparison of the results. Comparative analysis ensures a better model assessment for calculating thermophysical properties and contributes to high-quality modeling and designing of lead-free solder alloys.

Similar content being viewed by others

References

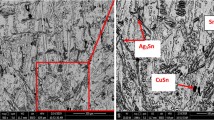

Manoj Kumar Pal, Gréta Gergely, Dániel Koncz-Horváth, and Zoltán Gácsi, “Investigation of the Electroless Nickel Plated SiC Particles in SAC305 Solder Matrix,” Powder Metallurgy and Metal Ceramics, 58, No. 9–10, 529–537 (2020).

P.M. Kumar, G. Gergely, D.K. Horváth, and Z. Gácsi, “Investigating the microstructural and mechanical properties of pure lead-free soldering materials (SAC305 & SAC405),” Powder Metall. Progr., 18, No. 1, 49–57 (2018).

M.K. Pal, G. Gergely, D. Koncz-Horváth, Z. Gácsi, “Characterization of the interface between ceramics reinforcement and lead-free solder matrix,” Surf. Interf., 20, 100576 (2020).

M.P. Kumar, G. Gergely, D. Koncz-Horvath, and Z. Gacsi, “Influence of ceramic particles on the microstructure and mechanical properties of SAC305 lead-free soldering material,” Arch. Metall. Mater., 64, 603–606 (2019).

D. Koncz-Horvath, A. Molnar, G. Gergely, M.K. Pal, and Z. Gacsi, “Examination the effect of thermal shock test on SAC solder joints fabricated by THRS and multiwave soldering techniques,” Resolut. Discovery, 4, No. 1, 1–6 (2019).

Z. Guo, M. Hindler, W. Yuan, and A. Mikula, “The density and surface tension of In–Sn and Cu–In–Sn alloys,” Monatshefte für Chemie-Chemical Monthly, 142, No. 6, 579–584 (2011).

T. Gancarz, “Physicochemical properties of Sb–Sn–Zn alloys,” J. Electron. Mater., 43. No. 12, 4374–4385 (2014).

J. Brillo and I. Egry, “Density determination of liquid copper, nickel, and their alloys,” Int. J. Thermoph. 24, No. 4, 1155–1170 (2003).

P. Fima, “Surface tension and density of liquid Sn–Ag–Cu alloys,” Int. J. Mater. Research., 103, No. 12, 1455–1461 (2012).

J. Brillo and I. Egry, “Density and excess volume of liquid copper, nickel, iron, and their binary alloys,” Zeitschrift für Metallkunde, 95, No. 8, 691–697 (2004).

H. Kobatake, J. Schmitz, and J. Brillo, “Density and dynamic viscosity of ternary Al–Cu–Si liquid alloys,” J. Mater. Sci., 49, No. 9, 3541–3549 (2014).

A. Dogan and H. Arslan, “Thermophysical properties of Cu–In–Sn liquid Pb-free alloys: dynamic viscosity and surface tension,” Philosophical Magazine, 98, No. 1, 37–53 (2018).

A. Dogan and H. Arslan, “Theoretical calculation of surface tension and its temperature coefficient associated with liquid Cu–Ti alloys,” Philosophical Magazine, 98, No. 27, 2529–2542 (2018).

A. Dogan and H. Arslan, “An investigation of influencing of Sb and Bi contents on surface tensions associated with Pb-free Sn–Zn–Sb–Bi quaternary and sub-quaternary solder alloys,” Philosophical Magazine, 99, No. 15, 1825–1848 (2019).

G. Kaptay, Proc. of MicroCAD Conference, Section of Metallurgy, University of Miskolc (2003), pp. 23–28.

R.I.L. Guthrie and T. Iida, “Thermodynamic properties of liquid metals,” Mater. Sci. Eng.: A, 178, No. 1–2, 35–41 (1992).

L.Ya. Kozlov, L.M. Romanov, and N.N. Petrov, “Prediction of viscosity of multicomponent metal melts,” Izv. Vysch. Uch. Zav., Chern. Metall., 3, No. 7, 7–11 (1983).

M. Kucharski, “The viscosity of multicomponent systems,” Z. Metallkd., 77, 393 (1986).

D. Sichen, J. Bygd’En, and S. Seetharaman, “A model for estimation of viscosities of complex metallic and ionic melts,” Metall. Mater. Trans. B, 25, No. 4, 519–525 (1994).

X.M. Zhong, Y.H. Liu, K.C. Chou, X.G. Lu, D. Zivkovic, and Z. Zivkovic, “Estimating ternary dynamic viscosity using the thermodynamic geometric model,” J. Phase Equilibria, 24, No. 1, 7–11 (2003).

S. Morioka, “Evaluation of the dynamic viscosity for binary and ternary liquid alloys,” Mat. Sci. Eng. A, 362, 223–227 (2003).

D. Zvivković, “Estimation of the dynamic viscosity for Ag–In and In–Sb liquid alloys using different models,” Zeitschrift für Metallkunde, 97, No.1, 89–93 (2006).

D.J. Steinberg, “A simple relationship between the temperature dependence of the density of liquid metals and their boiling temperatures,” Metall. Trans., 5, No. 6, 1341–1343 (1974).

J. Brillo, I. Egry, and I. Ho, “Density and thermal expansion of liquid Ag–Cu and Ag–Au alloys,” Int. J. Thermoph., 27, No. 2, 494–506 (2006).

C. Lüdecke and D. Lüdecke, Thermodynamik, Springer, Heidelberg (2000), p. 506.

X.M. Zhong, K.C. Chou, Y. Gao, X. Guo, and X. Lan, “Estimating ternary dynamic viscosity in terms of Moelwyn-Hughes’ model,” Calphad., 25, No. 3, 455–460 (2001).

A. Takeuchi, A. Inoue, T. Shindo, and Y. Waseda, “Enthalpies in alloys,” Mater. Trans. JIM, 41, No. 11, 1372–1378 (2000).

I. Budai, M.Z. Benkő, and G. Kaptay, “Analysis of literature models on dynamic viscosity of binary liquid metallic alloys on the example of the Cu–Ag system,” Mater. Sci. Forum, 473, 309–314 (2005).

G. Kaptay, “The exponential excess Gibbs energy model revisited,” Calphad, 56, 169–184 (2017).

G. Kaptay, “On the interfacial energy of coherent interfaces,” Acta Mater., 60, No. 19, 6804–6813 (2012).

A. Dinsdale, “SGTE data for pure elements,” Calphad, 15, No. 4, 317–425 (1991).

I. Budai, M.Z. Benkő, and G. Kaptay, “Comparison of different theoretical models to experimental data on dynamic viscosity of binary liquid alloys,” Mater. Sci. Forum., 537, 489–496 (2007).

S. Seetharaman and D. Sichen, “Estimation of the viscosities of binary metallic melts using Gibbs energies of mixing,” Metall. Mater. Trans. B, 25, No. 4, 589–595 (1994).

G. Kaptay, “A unified equation for the dynamic viscosity of pure liquid metals,” Zeitschrift für Metallkunde, 96, No. 1, 24–31 (2005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkova Metallurgiya, Vol. 60, Nos. 7–8 (540), pp. 143–153, 2021.

Rights and permissions

About this article

Cite this article

Varanasi, D., Pal, M.K. Density and Dynamic Viscosity of Sn, Sn–Ag, and Sn–Ag–Cu Liquid Lead-Free Solder Alloys. Powder Metall Met Ceram 60, 504–512 (2021). https://doi.org/10.1007/s11106-021-00262-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00262-w