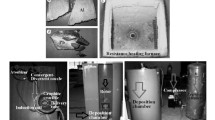

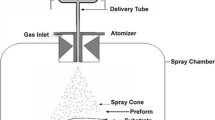

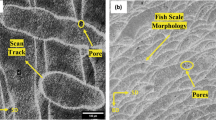

In this study, Al–6Si alloys with various Pb content (0, 10, 20, and 30 wt.%) were prepared by the spray deposition technique. Gaussian or bell-shaped spray deposits were obtained for different Al–6Si–xPb alloys at a pressure of 10 bar, at a nozzle to substrate distance of 450 mm, delivery tube with a diameter of 4 mm with a substrate inclination angle of 0°. Spray deposited Al–6Si–xPb alloys with variable Pb content were subjected to different rolling deformation. For the hardness measurements, samples were cut from the central and peripheral regions of the deposit containing different percentages of lead content. This paper examines the effect of deformation degree during different rolling reductions and the lead content of the spray deposited aluminum-silicon alloy on hardness behavior through the linear regression technique. A factorial design analysis was conducted to study the effect of different parameters, such as percentage of rolling deformation, variation of the lead composition, and preform distance from center to the periphery of the spray deposit. The influence of different rolling deformation on hardness values was more pronounced relative to that of the distance from the center to the peripheral region of the aluminum-silicon spray deposit with lead content. The hardness largely depends on the rolling deformation degree. Hardness values of the deposits were noted to increase with a higher deformation degree of the deposit, but it decreased as the Pb content increased.

Similar content being viewed by others

References

Mauduit Damien, Gilles Dusserre, and Thierry Cutard, “Influence of temperature cycles on strength and microstructure of spray-deposited Si–Al CE9F alloy,” Mechan. Mater., 131, 93–101 (2019).

Wang Yongxiao, Guoqun Zhao, Xiao Xu, Xiaoxue Chen, and Cunsheng Zhang, “Constitutive modeling, processing map establishment and microstructure analysis of spray deposited Al–Cu–Li alloy 2195,” J. Alloys Compd., 779, 735–751 (2019).

M. Goudar Dayanand, V.C. Srivastava, G.B. Rudrakshi, K. Raju, and S.N. Ojha, “Effect of tin on the wear properties of spray formed Al–17Si alloy, Transac. Indian Institute of Metals, 68, No. 1, 3–7 (2015).

B.V.R. Reddy, R. Mittal, S.R. Maity, and K.M. Pandey, “Investigation on metallurgical, tribological, hardness properties of spray deposited and warm rolled Al–18Pb, Al–22Pb alloys,” J. Mater. Research Technol., 8, No. 6, 5687–5697 (2019).

F.R. Milhorato and E.M. Mazzer, “Effects of aging on a spray-formed Cu–Al–Ni–Mn–Nb high temperature shape memory alloy,” Mater. Sci. Eng.: A, 753, 232–237 (2019).

Ran Guang, Jing-En Zhou, Shengqi Xi, and Pengliang Li, “Microstructure and morphology of Al–Pb bearing alloy synthesized by mechanical alloying and hot extrusion,” J. Alloys Compd., 419, No. 1–2, 66–70 (2006).

V.C. Srivastava, K.B. Surreddi, S. Scudino, M. Schowalter, V. Uhlenwinkel, A. Schulz, A. Rosenauer, H-W. Zoch, and J. Eckert, “Spray forming of bulk Al85Y8Ni5Co2 with co-existing amorphous, nano- and micro-crystalline structures,” Transac. Indian Institute of Metals, 62, No. 4–5, 331–335 (2009).

K. Raju, A.P. Harsha, and S.N. Ojha, “Microstructural features, wear, and corrosion behaviour of spray cast Al–Si alloys. Proc. of the Institution of Mechanical Engineers,” J. Eng. Tribol., 225, No. 3, 151–160 (2011).

Rashmi Mittal and Devendra Singh, “Effect of cold rolling on the mechanical properties of spray cast Al–6Si–20Pb alloys,” Adv. Mater. Res., 585, 402–406 (2012).

Reddy Bandi Venkata Ramana, Saikat Ranjan Maity, and Krishna Murari Pandey, “Characterization of spray formed Al-alloys—A Review,” Reviews Adv. Mater. Sci., 58, No. 1, 147–158 (2019).

W. Xiangdong, P. Qinglin, L. Lili, X. Shangwu, W. Weiyi, L. Jianping, S. Yuanwei, and H. Zhiqi, “Characterization of hot extrusion and heat treatment on mechanical properties in a spray formed ultra-high strength Al–Zn–Mg–Cu alloy,” Mater. Character., 144, 131–140 (2018).

Tomar Aruna, Rashmi Mittal, and Devendra Singh, “Strength and elongation of spray formed Al–Si–Pb alloys,” Int. J. Minerals, Metallurgy, and Materials, 21, No. 12, 1222–1227 (2014).

Kaur Kamalpreet and O.P. Pandey, “Microstructural characteristics of spray formed zircon sand reinforced LM13 composite,” J. Alloys Compd., 503, No. 2, 410–415 (2010).

D.P. Mondal and S. Das, “High stress abrasive wear behavior of aluminum hard particle composites: Effect of experimental parameters, particle size and volume fraction,” Tribology Int., 39, No. 6, 470–478 (2006).

Manas R. Tripathy, Ravindra K. Dube, Satish C. Koria, “Rolling behaviour of steel backed spray deposited Al–Sn strip,” J. Mater. Proc. Technol., 190, No. 1–3, 342–349 (2007).

D. Singh and S. Dangwal, “Effects of process parameters on surface morphology of metal powders produced by free fall gas atomization,” J. Mater. Sci., 41, No. 12, 3853–3860 (2006).

Y.C. Suh and Z.H. Lee, “Nucleation of liquid Pb-phase in hypermonotectic Al–Pb melt and the segregation of Pb-droplets in melt-spun ribbon,” Scr. Metall. Mater., 33, No. 8, 1231–1237 (1995).

Kaur Kamalpreet and O.P. Pandey, “Microstructural characteristics of spray formed zircon sand reinforced LM13 composite,” J. Alloys Compd., 503, No. 2, 410–415 (2010).

Evans Mark, Optimization of Manufacturing Processes: A Response Surface Approach, Maney Publishing, 791 (2003).

M.M. Pariona, C. Bolfarini, R.J.D. Santos, and C.S. Kiminami, “Application of mathematical simulation and the factorial design method to the optimization of the atomization stage in the spray forming of a Cu–6% Zn alloy,” J. Mater. Proc. Technol., 102, 221–229 (2000).

Rizzi Paola, Habib A., Alberto Castellero, and Livio Battezzati, “Constrained deformation of an Al based amorphous alloy by cold rolling,” J. Alloys Compd., 509, S275–S278 (2011).

P.K. Rohatgi, Y. Riu, and S. Ray, Friction, Lubrication and Wear Technology, American Society for Metals, Metals Park, OH, 85 (1992).

F. Yu, D.S. Dwarakadasa, and S. Ranganathan, “Microstructure and mechanical properties of spray formed Al–Si–Pb alloys,” J. Mater. Proc. Technol., 137, 164–167 (2003).

C.N. Panagopoulos and E.P. Georgiou, “Cold rolling and lubricated wear of 5083 Aluminium alloy,” Mater. Des. 31, 1050–1055 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkova Metallurgiya, Vol. 60, Nos. 3–4 (538), pp. 46–57, 2021.

Rights and permissions

About this article

Cite this article

Mittal, R., Reddy, B.V.R. Studying the Influence of Rolling Deformation Degree and Pb Content on the Hardness of Spray Deposited Al–6Si Alloy Using Linear Regression Analysis. Powder Metall Met Ceram 60, 164–173 (2021). https://doi.org/10.1007/s11106-021-00224-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00224-2