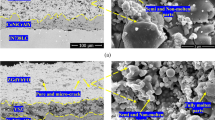

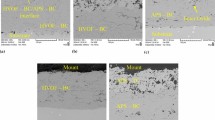

The world’s experience in using hafnium in two important parts of high-temperature thermal barrier coatings, such as the top thermal barrier layer and bond coat layer, was analyzed. In the top thermal barrier layer, hafnium is present as HfO2 completely or partially stabilized by yttria (or other rare-earth oxides). Another approach is to use hafnium dioxide as an addition to conventional coatings based on ZrO2 stabilized completely or partially. Electron-beam physical vapor deposition (EB-PVD) and air plasma spray process (APS) are most common techniques for applying thermal barrier coatings containing hafnium dioxide. Magnetron sputtering turned out to be successful as well. Compared to the 8YSZ coating, the 7.5YSH coating showed reduced Young’s modulus, 30% lower thermal conductivity (decreased to 0.5–1.1 W/(m · K)) at high temperatures for HfO2 stabilized with 27 wt.% Y2O3, and higher sintering resistance and heat resistance. Doping of ZrO2 and HfO2 by several stabilizers proved to be promising: specifically, doping by a mixture of one trivalent ion larger than Y3+ and another trivalent ion smaller than Y3+, preserving the metastable structure of the t′ phase. The importance of phase diagrams for a correct choice of the top coat composition and doping elements for the bond coat is shown. Doping the bond coat with a small amount (up to 1 wt.%) of hafnium improved its cyclic oxidation resistance and increased the adhesion of the thermally grown oxide layer to the bond coat and strength of the latter.

Similar content being viewed by others

References

D.R. Clarke and C.G. Levi, “Materials design for the next generation thermal barrier coatings,” Annu. Rev. Mater. Res., 33, 383–417 (2003).

S.M. Lakiza, M.I. Grechanyuk, O.K. Ruban, V.P. Redko, M.S. Glabay, O.B. Myloserdov, O.V. Dudnik, and S.V. Prokhorenko, “Thermal barrier coatings: current status, search, and analysis,” Powder Metall. Met. Ceram., 57, No. 1–2, 82–113 (2018).

D.R. Clarke, “Materials selection guidelines for low thermal conductivity thermal barrier coatings,” Surf. Coat. Technol., 163–164, 67–74 (2003).

C.G. Levi, “Emerging materials and processes for thermal barrier systems,” Curr. Opin. Solid State Mater. Sci., 8, 77–91 (2004).

R.W. Scheidecker, O. Hunter Jr., and F.W. Calderwood, “Elastic properties of partially-stabilized HfO2 compositions,” J. Mater. Sci., 14, 2284–2288 (1979).

M. Noor-A-Alam, A.R. Choudhuri, and C.V. Ramana, “Effect of composition on the growth and microstructure of hafnia–zirconia based coatings,” Surf. Coat. Technol., 206, No. 7, 1628–1633 (2011).

K. Matsumoto, Y. Itoh, and T. Kameda, “EB-PVD process and thermal properties of hafnia-based thermal barrier coating,” Sci. Technol. Adv. Mater., 4, 153–158 (2003).

J. Singh, D.E. Wolfe, R.A. Miller, J.I. Eldridge, and D. Zhu, “Tailored microstructure of zirconia and hafnia-based thermal barrier coatings with low thermal conductivity and high hemispherical reflectance by EB–PVD,” J. Mater. Sci., 39, 1975–1985 (2004).

M. Peters, B. Saruhan-Brings, and U. Schulz, Proc. CEAS 2009 European Air and Space Conf. (October 2009), Manchester, UK (2009), pp. 1–9.

U. Schulz, B. Saruhan, K. Fritscher, and Ch. Leyens, “Review on advanced EB-PVD ceramic topcoats for TBC applications,” Int. J. Appl. Ceram. Technol., 1, No. 4, 302–315 (2004).

M. Noor-A-Alam and C.V. Ramana, “Structure and thermal conductivity of yttria-stabilized hafnia ceramic coatings grown on nickel-based alloy,” Ceram. Int., 38, 2957–2961 (2012).

D. Zhu and R.A. Miller, “Sintering and creep behavior of plasma-sprayed zirconia- and hafnia-based thermal barrier coatings,” Surf. Coat. Technol., 108–109, 114–120 (1998).

D. Zhu and R.A. Miller, “Development of advanced low thermal conductivity thermal barrier coatings,” Int. J. Appl. Ceram. Technol., 1, No. 1, 86–94 (2004).

D. Zhu, D.S. Fox, N.P. Bansal, and R.A. Miller, Advanced Oxide Material Systems for 1650°C Thermal and Environmental Barrier Coating Applications, NASA/TM-2004–213219, National Aeronautics and Space Administration, Washington DC (2004).

C.V. Ramana, M. Noor-A-Alam, J.J. Gengler, and J.G. Jones, “Growth, structure, and thermal conductivity of yttria-stabilized hafnia thin films,” ACS Appl. Mater. Interfaces, 4, 200–204 (2012).

E.J. Rubio, G. Martinez, M. Noor-A-Alam, S.W. Stafford, V. Shutthanandan, and C.V. Ramana, “Microstructure and thermal oxidation behavior of yttria-stabilized hafnia nanostructured coatings deposited on alumina,” Surf. Coat. Technol., 236, 142–148 (2013).

H. Ibegazene, S. Alperine, and C. Diot, “Yttria-stabilized hafnia-zirconia thermal barrier coatings: the influence of hafnia addition on TBC structure and high-temperature behavior,” J. Mater. Sci., 30, 938–951 (1995).

M.D. Gorman, I. Spitsberg, B.A. Boutwell, R. Darolia, R.W. Bruce, V.S. Venkataramani, A.M. Thompson, and A. Mogro-Campera, Ceramic Compositions for Low Conductivity Thermal Barrier Coatings, US Patent 6,858,334 (2005).

A.V. Shevchenko, L.M. Lopato, V.D. Tkachenko, and A.K. Ruban, “Interaction of hafnium and zirconium dioxide,” Izv. Akad. Nauk SSSR, 23, No. 2, 259−263 (1987).

M. Matsumoto, T. Kato, N. Yamaguchi, D. Yokoe, and H. Matsubara, “Thermal conductivity and thermal cycle life of La2O3 and HfO2 doped ZrO2–Y2O3 coatings produced by EB-PVD,” Surf. Coat. Technol., 203, 2835–2840 (2009).

M.R. Winter and D.R. Clarke, “Thermal conductivity of yttria-stabilized zirconia–hafnia solid solutions,” Acta Mater., 54, 5051–5059 (2006).

J. Gild, M. Samiee, J.L. Braun, T. Harrington, H. Vegab, P.E. Hopkins, K. Vecchio, and J. Luo, “High-entropy fluorite oxides,” J. Eur. Ceram. Soc., 38, No. 10, 3578–3584 (2018).

D. Chen, Q. Wang, Y. Liu, and N. Xianjin, “Investigation of ternary rare earth oxide-doped YSZ and its high temperature stability,” J. Alloys Compd., 806, No. 25, 580–586 (2019).

A.J. Wright, Q. Wang, C. Huang, A. Nieto, R. Chen, and J. Luo, “From high-entropy ceramics to compositionally-complex ceramics: A case study of fluorite oxides,” J. Eur. Ceram. Soc., 40, No. 5, 2120–2129 (2020).

A.J. Wright, Q. Wang, S-T. Ko, K.M. Chung, R. Chen, and J. Luo, “Size disorder as a descriptor for predicting reduced thermal conductivity in medium- and high-entropy pyrochlore oxides,” Scr. Mater., 181, 76–81 (2020).

K. Ren, Q. Wang, G. Shao, X. Zhao, and Y. Wang, “Multicomponent high-entropy zirconates with comprehensive properties for advanced thermal barrier coating,” Scr. Mater., 178, 382–386 (2020).

D.L. Poerschke and C.G. Levi, “Effects of cation substitution and temperature on the interaction between thermal barrier oxides and molten CMAS,” J. Eur. Ceram. Soc., 35, 681–691 (2015).

J. Stringer, M. Allam, and D.P. Whittle, “The high temperature oxidation of Co–Cr–Al alloys containing yttrium or hafnium additions,” Thin Solid Films, 45, No. 2, 377–384 (1977).

I.M. Allam, D.P. Whittle, and J. Stringer, “The oxidation behavior of CoCrAI systems containing active element additions,” Oxid. Met., 12, No. 1, 35–66 (1978).

I.M. Allam, D.P. Whittle, and J. Stringer, “Improvements in oxidation resistance by dispersed oxide addition: Al2O3-forming alloys,” Oxid. Met., 13, No. 4, 381–401 (1979).

R. Pendse and J. Stringer, “The influence of alloy microstructure on the oxide peg morphologies in a Co–10% Cr–11% Al alloy with and without reactive element additions,” Oxid. Met., 23, No. 1–2, 1–16 (1985).

A.S. Khanna, C. Wasserfuhr, W.J. Quadakkers, and H. Nickel, “Addition of yttrium, cerium and hafnium to combat the deleterious effect of sulphur impurity during oxidation of an Ni–Cr–Al alloy,” Mater. Sci. Eng. A, 120, 185−191 (1989).

J.A. Haynes, B.A. Pint, K.L. More, Y. Zhang, and I.G. Wright, “Influence of sulfur, platinum, and hafnium on the oxidation behavior of CVD NiAl bond coatings,” Oxid. Met., 58, No. 5–6, 513–544 (2002).

B.A. Pint, I.G. Wright, W.Y. Lee, Y. Zhang, K. Prüßne, and K.B. Alexander, “Substrate and bond coat compositions: factors affecting alumina scale adhesion,” Mater. Sci. Eng.: A, 245, No. 2, 201–211 (1998).

C. Leyens, B.A. Pint, and I.G. Wright, “Effect of composition on the oxidation and hot corrosion resistance of NiAl doped with precious metals,” Surf. Coat. Technol., 133–134, 5–22 (2000).

B.A. Pint, K.L. More, and I.G. Wright, “Effect of quaternary additions on the oxidation behavior of Hf-doped NiAl,” Oxid. Met., 59, No. 3–4, 257–283 (2003).

B.A. Pint, “The role of chemical composition on the oxidation performance of aluminide coatings,” Surf. Coat. Technol., 188–189, 71–78 (2004).

B.A. Pint, J.A. Haynes, and T.M. Besmann, “Effect of Hf and Y alloy additions on aluminide coating performance,” Surf. Coat. Technol., 204, 3287–3293 (2010).

T. Izumi, N. Mu, L. Zhang, and B. Gleeson, “Effects of targeted γ-Ni + γ′-Ni3Al-based coating compositions on oxidation behavior,” Surf. Coat. Technol., 202, 628−631 (2007).

B.A. Pint, “Optimization of reactive-element additions to improve oxidation performance of alumina-forming alloys,” J. Am. Ceram. Soc., 86, No. 4, 686–695 (2003).

B.A. Pint and J.H. Schneibel, “The effect of carbon and reactive element dopants on oxidation lifetime of FeAlp,” Scr. Mater., 52, No. 4, 1199–1204 (2005).

B.M. Warnes, “Reactive element modified chemical vapor deposition low activity platinum aluminide coatings,” Surf. Coat. Technol., 146–147, 7–12 (2001).

G.Y. Kim, L.M. He, J.D. Meyer, A. Quintero, J.A. Haynes, and W.Y. Lee, “Mechanisms of Hf dopant incorporation during the early stage of chemical vapor deposition aluminide coating growth under continuous doping conditions,” Metall. Mater. Trans. A, 35, 3581–3593 (2004).

S. Naveos, G. Oberlaender, Y. Cadoret, P. Josso, and M.-P. Bacos, “Zirconium modified aluminide by a vapor pack cementation process for thermal barrier applications: Formation mechanisms and properties,” Mater. Sci. Forum, 461–464, 375–382 (2004).

J.P. Stacy, Y. Zhang, B.A. Pint, J.A. Haynes, B.T. Hazel, and B.A. Nagaraj, “Synthesis and oxidation performance of Al-enriched γ + γ′ coatings on Ni-based superalloys via secondary aluminizing,” Surf. Coat. Technol., 202, 632–636 (2007).

R. Darolia, J.D. Rigney, and R.J. Grylls, Nickel Aluminide Alloys with Cr and Zr for Adherent Coating or Interlayer on Superalloy Turbine Parts, US Patent 6,291,084 B1 (2001).

J.D. Rigney, R. Darolia, W.S. Walston, and R.R. Corderman, Nickel Aluminide Coating and Coating Systems Formed Therewth, US Patent 6,153,313 (2000).

B. Saint Ramond and J.R. Nicholls, Method of Making a Protective Coating Forming a Thermal Barrier with Bonding Underlayer on a Superalloy Substrate, and a Part Obtained Thereby, US Patent 6,645,351 B2 (2003).

C. Mercer, S. Faulhaber, N. Yao, K. McIlwrath, and O. Fabrichnaya, “Investigation of the chemical composition of the thermally grown oxide layer in thermal barrier systems with NiCoCrAlY bond coats,” Surf. Coat. Technol., 201, 1495–1502 (2006).

B.W. Veal, A.P. Paulikas, B. Gleeson, and P.Y. Hou, “Creep in α-Al2O3 thermally grown on β-NiAl and NiAlPt alloys,” Surf. Coat. Technol., 202, 608–612 (2007).

U. Schulz, K. Fritscher, and A. Ebach-Stahl, “Cyclic behavior of EB-PVD thermal barrier coating systems with modified bond coats,” Surf. Coat. Technol., 203, 449–455 (2008).

W.O. Soboyejo, P. Mensah, R. Diwan, J. Crowe, and S. Akwaboa, “High temperature oxidation interfacial growth kinetics in YSZ thermal barrier coatings with bond coatings of NiCoCrAlY with 0.25% Hf,” Mater. Sci. Eng. A, 528, 2223–2230 (2011).

H. Guo, L. Sun, H. Li, and S. Gong, “High temperature oxidation behavior of hafnium modified NiAl bond coat in EB-PVD thermal barrier coating system,” Thin Solid Films, 516, 5732–5735 (2008).

D. Li, H. Guo, H. Peng, Sh. Gong, and H. Xu, “Improved alumina scale adhesion of electron beam physical vapor deposited Dy/Hf-doped NiAl coatings,” Appl. Surf. Sci., 283, 513–520 (2013).

R. Darolia, “Thermal barrier coatings technology: critical review, progress update, remaining challenges and prospects,” Int. Mater. Rev., 58, No. 6, 315–348 (2013).

Y.Q. Wang and M. Suneson, “Oxidation behavior of Hf-modified aluminide coatings on Haynes-188 at 1050°C,” Surf. Coat. Technol., 215, 7–15 (2013).

D. Wang, H. Peng, Sh. Gong, and H. Guo, “NiAlHf/Ru: Promising bond coat materials in thermal barrier coatings for advanced single crystal superalloys,” Corros. Sci., 78, 304–312 (2014).

H. Zhang, L. Guo, Y. Ma, H. Peng, H. Guo, and Sh. Gong, “Thermal cycling behavior of (Gd0.9Yb0.1)2Zr2O7/8YSZ gradient thermal barrier coatings deposited on Hf-doped NiAl bond coat by EB-PVD,” Surf. Coat. Technol., 258, 950–955 (2014).

R.W. Jackson, D.M. Lipkin, and T.M. Pollock, “Thermal barrier coating adherence to Hf-modified B2 NiAl bond coatings,” Acta Mater., 80, 39–47 (2014).

R.W. Jackson, D.M. Lipkin, and T.M. Pollock, “The oxidation and rumpling behavior of overlay B2 bond coats containing Pt, Pd, Cr and Hf,” Surf. Coat. Technol., 221, 12–21 (2013).

L. Wei, H. Peng, F. Jia, L. Zheng, Sh. Gong, and H. Guo, “Cyclic oxidation behavior of Hf/Zr co-doped EB-PVD β-NiAl coatings at 1200°C,” Surf. Coat. Technol., 276, 721–725 (2015).

A.U. Munawar, U. Schulz, and M. Shahid, “Microstructure and lifetime of EB-PVD TBCs with Hf-doped bond coat and Gd-zirconate ceramic top coat on CMSX-4 substrates,” Surf. Coat. Technol., 299, 104–112 (2016).

Y.F. Yang, C.Y. Jiang, H.R. Yao, Z.B. Bao, S.L. Zhu, and F.H. Wang, “Preparation and enhanced oxidation performance of a Hf-doped single-phase Pt-modified aluminide coating,” Corros. Sci., 113, 17–25 (2016).

J.M. Saldana, U. Schulz, G.C. Mondragon Rodrigues, L.A. Caceres-Dias, and H. Lau, “Microstructure and lifetime of Hf or Zr doped sputtered NiAlCr bond coat/7YSZ EB-PVD TBC systems,” Surf. Coat. Technol., 335, 41–51 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 60, Nos. 1–2 (537), pp. 99–112, 2021.

Rights and permissions

About this article

Cite this article

Lakiza, S., Hrechanyuk, M., Red’ko, V. et al. The Role of Hafnium in Modern Thermal Barrier Coatings. Powder Metall Met Ceram 60, 78–89 (2021). https://doi.org/10.1007/s11106-021-00217-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00217-1