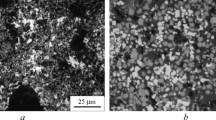

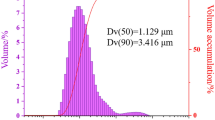

The structure and phase composition of Fe–Ti–Ni–C alloys produced in situ by thermal synthesis at 1200°C using TiH2, Fe, graphite, and Ni powder mixtures have been studied. The synthesized alloys represent a skeleton of titanium carbide grains of different stoichiometry, with sizes varying from 0.5 to 16 μm, surrounded by metal reinforcement layers. The starting mixtures without nickel or with 5% Ni have coarse TiC grains. When Ni content of the mixture increases to 10–20%, the maximum grain size sharply decreases to 6–7 μm. The microhardness of the synthesized alloys decreases when nickel amount in the mixture increases to 15% but becomes somewhat higher at 20% Ni. The phase composition of the alloys substantially depends on the amounts of starting mixture components and includes titanium carbide, Fe3C cementite, α-iron solid solution, and intermetallic FeNi3 (for ironcontaining mixtures) and Ni3Ti and Ni4Ti (for nickel-containing mixtures). When Ni content of the starting mixture increases to 10–20%, the lattice parameter and stoichiometry of TiCx slightly decrease and carbide particles noticeably refine. The thermally synthesized alloys have been ground to produce reinforced steel composite powders, which can find extensive application in depositing wear-resistant coatings and fabricating bulky parts by compaction followed by sintering, hot pressing, or hot forging.

Similar content being viewed by others

References

K.I. Parashivamurthy, R.K. Kumar, S. Seetharamu, and M.N. Chandrasekharaiah, “Review on TiC reinforced steel composites,” J. Mater. Sci., 36, 4519–4530 (2001).

M. Razavi, M.S. Yaghmaee, M.R. Rahimipour, and S.S. Tousi, “The effect of production method on properties of Fe–TiC composite,” Int. J. Miner. Process., 94, 97–100 (2010).

Zhi Wang and Tao Lin, “Microstructure and properties of TiC-high manganese steel cermet prepared by different sintering processes,” J. Alloys Compd., 650, 918–924 (2015).

Yu.G. Gurevich, V.K. Narva, and N.R. Frage, Sintered Carbide Steels [in Russian], Metallurgiya, Moscow (1988), p. 144.

J. Kübarsepp, Hard Alloy with Steel Bonding [in Russian], Valgus-TTU, Tallinn (1991).

I.M. Martins, M. Oliveira, and H. Carvalhinhos, “Wear resistant high-speed steel matrix composites,” Adv. Powder Metall. Part. Mater., 6, 213–218 (1992).

M.V. Deshpande, J.P. Saxena, and P. Rumar, “Toughness cermeted carbide material with iron-rich binder for steel turning,” Int. J. Refract. Met Hard Mater., 15, No. 1–3, 157–162 (1997).

M. Oliveira and D. Bolton, “Effect of ceramic particles on the mechanical properties of M3/2 high speed steel,” Int. J. Powder Metall., 32, No. 1, 37–49 (1996).

G.A. Baglyuk, L.O. Poznyak, and S.V. Tikhomirov, Method of Producing Articles from Powder Composite Materials [in Ukrainian], Ukrainian Patent 47662 A, July 15 (2002), Bulletin No. 7.

G.A. Baglyuk and D.A. Goncharuk, “Structural and phase analysis of carburized steel powders produced by reaction synthesis,” in: Powder Metallurgy: Surface Engineering, New Powder Composites, and Welding [in Russian], Minsk (2011), pp. 68–73.

Z. Mei, W. Yana, and K. Cui, “Effect of matrix composition on the microstructure of in situ synthesized TiC particulate reinforced iron-based composites,” Mater. Lett., 57, 3175–3181 (2003).

L.S. Zhong, Y.H. Xu, M. Hojamberdiev, J.B. Wang, and J. Wang, “In situ fabrication of carbide particulates-reinforced iron matrix composites,” Mater. Des., 32, 3790–3795 (2011).

B.H. Li, Y. Liu, H. Cao, L. He, and J. Li, “Rapid fabrication of in situ TiC particulates reinforced Fe-based composites by spark plasma sintering,” Mater. Lett., 63, 2010–2012 (2009).

J. Wang and Y.S. Wang, “In-situ production of Fe–TiC composite,” Mater. Lett., 61, 4393–4395 (2007).

G.A. Baglyuk, I.D. Martyukhin, T.M. Pavligo, G.G. Serdyuk, and V.M. Tkach, “Structural features of hotforged carbide steel (high-speed steel–titanium carbide),” Powder Metall. Met. Ceram., 48, No. 1–2, 34–37 (2009).

S.-H. Chang, T.-P. Tang, K.-T. Huang, and F.-C. Tai, “Effects of sintering process and heat treatments on microstructures and mechanical properties of VANADIS 4 tool steel added with TiC powders,” Powder Metall., 54, No. 4, 507–512 (2011).

O.M. Ivasyshyn, A.N. Demidik, and D.G. Savvakin, “Use of titanium hydride for the synthesis of titanium aluminides from powder materials,” Powder Metall. Met. Ceram., 38, No. 9–10, 482–487 (1999).

O.M. Ivasyshyn, G.A. Baglyuk, O.O. Stasyuk, and D.G. Savvakin, “Structurization in the sintering of TiH2–TiB2 powder mixtures,” Fiz. Khim. Tverd. Tela, 18, No. 1, 15–20 (2017).

G.A. Baglyuk, O.M. Ivasyshyn, O.O. Stasyuk, and D.G. Savvakin, “The effect of charge component composition on the structure and properties of titanium matrix sintered composites with high-modulus compounds,” Powder Metall. Met. Ceram., 56, No. 1–2, 45–52 (2017).

N.P. Lyakishev (ed.), Phase Diagrams of Binary Metallic Systems [in Russian], Mashinostroenie, Moscow (1997), p. 1024.

S.T. Li, H.Y. Wang, S.J. Lü, S.L. Sun, D. Li, and Q.C. Jiang, “Fabrication of steel matrix composite locally reinforced with in situ TiC particulate via SHS reaction of (Ti, Fe)–C system during casting,” ISIJ Int., 48, No. 9, 1293–1298 (2008).

O.M. Shevchenko, “Carburized steels. Types and production methods (overview),” Tek. Probl. Fiz. Materialoved. Ser Fiz. Khim. Osn. Tekhnol. Poroshk. Mater., Issue 20, 51–64 (2011).

A.G. Buklakov, Tribotechnical Characteristics of a Composite with Titanium Carbide for Equipping Centering Support Devices [in Russian], Author’s Abstract of PhD Thesis, Moscow (2015), p. 24.

V.V. Pashinskii and M.G. Subbotina, “Effect of heat treatment on the structure and properties of sintered TiC–Ti–Ni and TiC–Ni–Fe alloys,” Vost. Evrop. Zh. Pered. Tekhnol., No. 5(5), 39–45 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 59, Nos. 3–4 (532), pp. 69–79, 2020.

Rights and permissions

About this article

Cite this article

Bagliuk, G., Maksimova, G., Mamonova, A. et al. The Structure and Phase Composition Acquired by Fe–Ti–Ni–C Alloys in Thermal Synthesis. Powder Metall Met Ceram 59, 171–178 (2020). https://doi.org/10.1007/s11106-020-00149-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00149-2