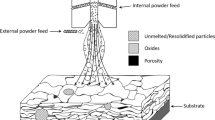

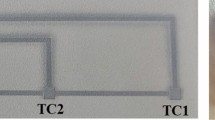

A method is developed for determining the temperature of the substrate in the area of electrospark deposition. The method is employed during experiments on deposition of two types of electrodes onto steel substrates: carbon steel electrodes and hard-alloy electrodes based on tungsten carbide with 6 wt.% cobalt. It is established that the dependence of substrate temperature on deposition time is defined by the initial structure of the substrate, electrode material, and pressing force on the electrode. Analysis of the data shows that cathode jets are the main working element of the electrospark deposition process.

Similar content being viewed by others

References

Kh. Ts. Zayatuev, “Electrical current and heat exchange on arc cathodes,” in: Low-Temperature Plasma. Vol. 20. Generation of Low-Temperature Plasma and Plasma Technologies. Challenges and Prospects, Novosibirsk (2004), pp. 86–105.

G. A. Mesyats and S. A. Barengolts, “Mechanism of generating abnormal ions in vacuum arc,” Usp. Fiz. Nauk, 172, No. 10, 1113–1129 (2002).

V. D. Belik, R. V. Litvin, and M. S. Kovalchenko, “Effect of pulse duration and size of interelectrode interval on electric-spark spraying. I. Effect of pulse duration and size of interelectrode interval on rate of electric-spark transfer,” Powder Metall. Met. Ceram., 45, No. 11–12, 593–598 (2006).

B. G. Semiletenko and V. N. Uskov, “Experimental dependences determining the position of shock waves in a jet impinging an obstacle perpendicular to its axis,” Inzh. Fiz. Zh., 23, No. 3, 453–458 (1972).

V. D. Belik, R. V. Litvin, M. S. Kovalchenko, et al., “Effect of pulse duration and size of interelectrode interval on electrospark spraying. II. Effect of pulse duration and size of interelectrode interval on composition and mechanical properties of coatings,” Powder Metall. Met. Ceram., 46, No. 1–2, 95–99 (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 50, No. 11–12 (482), pp. 29–36, 2011.

Rights and permissions

About this article

Cite this article

Belik, V.D., Litvin, R.V. & Kovalchenko, M.S. Effect of substrate temperature on the electrospark deposition, structure, and mechanical properties of coatings. I. Kinetics of substrate heating during electrospark deposition. Powder Metall Met Ceram 50, 698–703 (2012). https://doi.org/10.1007/s11106-012-9377-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-012-9377-6