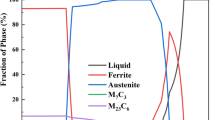

The effect of sintering temperature (900–1300°C) on the interaction of Cr3C2 with a Kh17N2 steel matrix is studied. It is shown that complex iron–chromium carbide of (Cr, Fe) x C y type forms during sintering. With increasing temperature, it undergoes a number of phase transformations. The following mechanism of Cr3C2 dissolution in the steel matrix is established: Cr3C2 → 900°C (Cr, Fe)2C → 1050°C (Cr, Fe)7C3 → 1200°C (Cr, Fe)23C6 → 1300°C (Cr, Fe)2C.

Similar content being viewed by others

References

A. A. Bondar, V. A. Maslyuk, T. Ya. Velikanova, and A. V. Grytsiv, “Phase equilibria in the Cr–Ni–C system and their use for developing physicochemical principles for design of hard alloys based on chromium carbide,” Powder Metall. Met. Ceram., 36, No. 5–6, 242–252 (1997).

V. A. Maslyuk and S. G. Napara-Volgina, “Wear-resistant and corrosion-resistant carbide-steel-type materials having different matrices,” Powder Metall. Met. Ceram., 38, No. 9–10, 521–525 (1999).

G. A. Baglyuk and L. A. Poznyak, “Powder metallurgy wear-resistant materials based on iron. Part 1. Materials prepared by sintering and infiltration,” Powder Metall. Met. Ceram., 40, No. 1–2, 34–39 (2001).

S. G. Napara-Volgina, L. N. Orlova, A. A. Mamonova, and V. P. Dzeganovskii, “Structure formation processes in sintering of stainless-steel-base heterophase materials 1. Sintering of austenitic stainless-steelbase materials with additions of Cr3C2,” Powder Metall. Met. Ceram., 36, No. 1–2, 93–100 (1997).

S. G. Napara-Volgina, L. N. Orlova, A. A. Mamonova, and V. P. Dzeganovskii, “Structure formation processes in sintering of stainless steel-base heterophase materials. II. Structure formation processes in sintering of type Kh18N15 stainless steel-base materials with additions of Cr3C2 and MoS2,” Powder Metall. Met. Ceram., 36, No. 9–10, 548–553 (1997).

V. A. Maslyuk, S. G. Napara-Volgina, and V. K. Kud’, “Sintered composites based on stainless steel,” Powder Metall. Met. Ceram., 39, No. 11–12, 549–553 (2000).

R. Z. Vlasyuk, A. N. Gripachevskii, and I. D. Radomyselskii, “Changes in the chemical and phase compositions of a Cr3C2 particle in contact with an iron matrix during sintering,” Powder Metall. Met. Ceram., 23, No. 8, 597–602 (1984).

I. B. Borovskii (ed.), Electron Probe Microanalysis [Russian translation], Mir, Moscow (1974), p. 260.

N. S. Tsikunov, V. A. Batyrev, A. N. Gripachevskii, et al., Software Package for Processing the Results from Quantitative Electron Probe Microanalysis with ZAF Method Using Mini PC [in Russian], Preprint 81.16, Inst. Metallofiz, AN USSR, Kiev (1981), p. 40.

H. J. Goldschmidt, Interstitial Alloys, Butterworths, London (1967).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 50, No. 3–4 (478), pp. 75–83, 2011.

Rights and permissions

About this article

Cite this article

Yakovenko, R.V., Maslyuk, V.A., Gripachevskii, A.N. et al. Dissolution of chromium carbide Cr3C2 in Kh17N2 steel during sintering. Powder Metall Met Ceram 50, 182 (2011). https://doi.org/10.1007/s11106-011-9316-y

Received:

Published:

DOI: https://doi.org/10.1007/s11106-011-9316-y