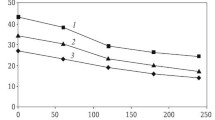

The behavior of coarse and fine pore channels and closed pores (pore space components) in temperature ranges of intensive (900–1150°C) and less active (1150–1400°C) sintering of a sample pressed from nanosized powder of tetragonal zirconia solid solution is examined. The change in the volume of the sample in the temperature range of intensive sintering is determined by approximately equal decrease in the volume of coarse and fine pore channels, which originate from channels between agglomerates and between aggregates in the powder agglomerates. Closed pores of the sample originating from closed pores of the powder make a minor contribution to the decrease in volume since they contain air. In the temperature range of less active sintering, all fine (200–300 nm) and coarse (0.8–1 μm) pore channels are broken and new closed pores are formed.

Similar content being viewed by others

References

M. Mazaheri, A. Simchi, and F. Golestani-Fard, “Densification and growth of nanocrystalline 3Y-TZP during two-step sintering,” J. Eur. Ceram. Soc., 28, 2933–2939 (2008).

M. Trunec and K. Maca, “Compaction and pressureless sintering of zirconia nanoparticles,” J. Am. Ceram. Soc., 90, 2735–2740 (2007).

K. Matsui, H. Yoshida, and Y. Ikahara, “Grain-boundary structure and microstructure development mechanism in 2–8 mol.% yttria-stabilized zirconia polycrystals,” Acta Mater., 56, 1315–1325 (2008).

G. Bernard-Granger and C. Guizard, “Spark plasma sintering of a commercially available granulated zirconia powder,” Acta Mater., 55, 3493–3504 (2007).

S. V. Gabelkov, R. V. Tarasov, N. S. Poltavtsev, et al., “Sintering of tetragonal zirconia,” Vest. NTU KhPI, Thematic Issue: Chemistry, Chemical Technology, and Ecology, No. 39, 136–144 (2008).

A. V. Ragulya and V. V. Skorokhod, Consolidated Nanostructured Materials [in Russian], Naukova Dumka, Kiev (2007).

S. V. Gabelkov, R. V. Tarasov, N. S. Poltavtsev, at al., “Synthesis, morphology and compactibility of tetragonal zirconia nanopowder,” Func. Mat., 14, No. 2, 187–191 (2007).

S. V. Gabelkov, V. V. Makarenko, A. G. Mironova, et al., “Determining the volume of pore channels in porous materials by evaporated water,” Ogneup. Tekh. Keram., No. 12, 41–47 (2006).

S. V. Gabelkov, R. V. Tarasov, A. G. Mironova, and L. M. Litvinenko, “Evolution of structural organization of xerogel in producing nanosized zirconia powder,” Nanosyst., Nanomater., Nanotekhnol., 6, No. 4, 1315–1330 (2008).

S. V. Gabelkov, R. V. Tarasov, A. G. Mironova, and L. M. Litvinenko, “Evaluation of structural organization of nanosized zirconia powder during grinding and pressing,” Fiz. Tekh. Vys. Davl., 18, No. 2, 98–110 (2008).

S. V. Gabelkov, R. V. Tarasov, and A. G. Mironova, “Change in pore space during sintering of magnesium–aluminum spinel,” Voprosy Atom. Nauki Tekh., Ser. Vakuum, Chist. Met. Sverkhprov., No. 6, 221–226 (2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Translated from Poroshkovaya Metallurgiya, Vol. 50, No. 3–4 (478), pp. 35–43, 2011.

Rights and permissions

About this article

Cite this article

Gabelkov, S.V., Tarasov, R.V. & Mironova, A.G. Change in pore structure of yttria-stabilized zirconia during sintering. Powder Metall Met Ceram 50, 151 (2011). https://doi.org/10.1007/s11106-011-9312-2

Received:

Revised:

Published:

DOI: https://doi.org/10.1007/s11106-011-9312-2