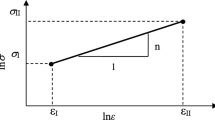

The paper discusses the main topics of the plenary report given at the 49th International Conference “Relevant Problems of Strength” (Kiev, June 14–17, 2010) dedicated to the 80th anniversary of Academician Trefilov’s birth. Special attention is paid to strengthening in transition from micro- to nanosizes. It is shown that S-functions can be used to obtain a generalized equation for the dependence of the yield strength on grain size with regard to changes in mechanisms of strengthening in polycrystals in the vicinity of grains with critical sizes dcr1 and dcr2. This equation can describe softening in transition to nanostructures (inverse Hall–Petch relation) and abrupt strengthening under increased intergranular cohesion.

Similar content being viewed by others

References

Proc. 49th Int. Conf. Relevant Problems of Strength for the 80th Birth Anniversary of Trefilov, Academician of the National Academy of Sciences and Russian Academy of Sciences [in Russian], Inst. Probl. Materialoved., NAN Ukrainy, Kiev (2010), p. 290.

S. A. Firstov, “Seventieth Birthday of Viktor Ivanovich Trefilov,” Powder Metall. Met. Ceram., 39, No. 7–8, 325–330 (2000).

V. I. Trefilov, Life and Activity (Selected Papers) [in Russian], in 2 Vols., Akademperiodika, Kiev (2005).

V. I. Trefilov, “Plastic deformation and fracture of metals,” in: Physics of Strength and Plasticity of Metals [in Russian], Metallurgizdat., Moscow (1963), pp. 190–254.

V. N. Gridnev, Yu. Ya. Meshkov, S. P. Oshkaderov, and V. I. Trefilov, Physics of Electrothermal Hardening of Steel [in Russian], Naukova Dumka, Kiev (1973), p. 236.

V. N. Gridnev and V. I. Trefilov, “Reversibility of martensitic transformations in heating of iron–carbon alloys,” DAN SSSR, 96, No. 4, 741–743 (1954).

V. N. Gridnev and V. I. Trefilov, “Structural changes in steel during electrotempering,” Izv. AN SSSR, Ser. Metall. Toplivo, No. 2, 62–69 (1959).

V. N. Gridnev, V. I. Trefilov, S. A. Firstov, et al., Phase and Structural Transformations into Metastable States in Metals [in Russian], Naukova Dumka, Kiev (1988), p. 264.

V. N. Gridnev, V. N. Minakov, and V. I. Trefilov, “Method of high-speed x-ray photography,” in: Study of Steels and Alloys [in Russian], Nauka, Moscow (1964), pp. 384–388.

V. N. Gridnev, V. N. Minakov, and V. I. Trefilov, “Mechanism of austenite formation in high-speed heating,” DAN SSSR, 154, 675–678 (1964).

V. V. Burdin, N. M. Grabenko, V. N. Gridnev, et al., “Formation of austenite below the phase equilibrium temperature in high-speed heating of carbon steels,” Fiz. Met. Metalloved., 35, No. 3, 5–9 (1973).

V. V. Burdin, V. N. Gridnev, V. N. Minakov, et al., “Phase transformations in iron and carbon steels,” in: Metal Physics [in Russian], Issue 55, Naukova Dumka, Kiev (1974), pp. 3–8.

V. V. Burdin, V. N. Gridnev, V. N. Minakov, et al., “Formation of intermediate phases in (α ↔ γ) transformation in iron and carbon steels,” DAN SSSR, 217, 1045–1048 (1974).

V. I. Trefilov, “Role of the type of interatomic bond in brittle fracture,” in: Physics of Brittle Fracture of Metals [in Russian], Naukova Dumka, Kiev (1965), pp. 22–58.

Yu. V. Mil’man and V. I. Trefilov, “Physical nature of the temperature dependence of yield stress,” in: Metal Fracture Mechanism [in Russian], Naukova Dumka, Kiev (1966), pp. 59–76.

V. I. Trefilov, Yu. V. Mil’man, and S. A. Firstov, Strength Physics of Refractory Metals [in Russian], Naukova Dumka, Kiev (1975), p. 314.

V. I. Trefilov and V. F. Moiseev, Disperse Particles in Refractory Metals [in Russian], Naukova Dumka, Kiev (1978), p. 235.

V. I. Trefilov, Yu. V. Mil’man, R. K. Ivaschenko, et al., Structure, Texture, and Mechanical Properties of Deformed Molybdenum Alloys [in Russian], Naukova Dumka, Kiev (1983), p. 232.

V. I. Trefilov, V. F. Moiseev, É. P. Pechkovskii, et al., Strain Hardening and Fracture of Polycrystalline Metals [in Russian], Naukova Dumka, Kiev (1989), p. 156.

M. M. Ristic, V. I. Trefilov, Yu. V. Mil’man, et al., Structure and Mechanical Properties of Sintered Materials [in Russian], Serbian Academy of Sciences and Arts, Belgrade (1992), p. 254.

S. A. Firstov, “The main tendencies in elaboration of materials with high specific strength,” in: Metallic Materials with High Specific Strength, Kluwer Academic Publishers, Netherlands (2004), pp. 33–44.

O. O. Bilous, N. I. Tsyganenko, M. P. Burka, et al., “Titanium-boride eutectic materials: effects of vanadium and niobium on high-temperature strength,” High Temp. Mat. Proc., 25, No. 1–2, 83–96 (2006).

S. A. Firstov, S. V. Tkachenko, and N. N. Kuz’menko, “Titanium cast iron and titanium steel,” Metalloved. Term. Obrab., No. 1 (634), 14–20 (2009).

Yu. V. Mil’man and I. V. Goncharova, “Nanoquasicrystals. Structure, mechanical properties, and application,” in: L. D. Merson (ed.), Advanced Materials. Technical and Medical Nanomaterials: Textbook [in Russian], Vol. 3, TGU MISIS, Moscow (2009), pp. 5–54.

Yu. V. Milman, “Mechanical behavior of nanostructured aluminum alloys containing quasicrystalline phase,” Mater Sci. Forum, 482, 77–82 (2005).

O. D. Neikov, Yu. V. Milman, D. B. Miracle, et al., “Properties of rapidly solidified powder aluminum alloys for elevated temperatures produced by water atomization,” Adv. Powder Metall. Partic. Mat., 7, 14–27 (2002).

V. A. Manilov, V. G. Tkachenko, V. I. Trefilov, and S. A. Firstov, “Electron microscopy of structural changes in chromium deformation and softening,” Izv. AN SSSR. Metally, No. 2, 114–121 (1967).

V. I. Trefilov, S. A. Firstov, A. Lyuft, and K. Shlyaubitts, “Dislocation-structure evolution in bcc metals,” in: Problems in Solid-State Physics and Materials Science [in Russian], Nauka, Moscow (1976), pp. 97–121.

S. A. Firstov, “Structurization and changes in mechanical properties of bcc metals under plastic deformation,” in: Collective Deformation Processes and Localization of Deformation [in Russian], Naukova Dumka, Kiev (1989), pp. 196–219.

G. F. Sarzhan and S. A. Firstov, “Dislocation structure and strain hardening of bcc metals,” Izv. Vysh. Uzeb. Zaved. Fiz., No. 3, 23–34 (1991).

A. N. Vergazov, V. A. Likhachev, and V. V. Rybin, “Analysis of fragmented structure in molybdenum formed under active plastic deformation,” Fiz. Met. Materialoved., 42, No. 6, 1240–1246 (1976).

V. V. Rybin, Extensive Plastic Deformations and Fracture of Metals [in Russian], Metallurgiya, Moscow (1986), p. 224.

R. Z. Valiev and I. V. Aleksandrov, Nanostructured Materials Produced by Severe Plastic Deformation [in Russian], Logos, Moscow (2000), p. 272.

R. Z. Valiev, A. V. Korznikov, and R. R. Mulyukov, “Structure and properties of ultra-fine-grained materials produced by severe plastic deformation,” Mat. Sci. Eng. A, 168, 141–148 (1993).

S. A. Firstov, T. G. Rogul, V. T. Marushko, and V. A. Sagaidak, “Structure and microhardness of polycrystalline chromium produced by magnetron sputtering,” Probl. Mat. Sci., No. 1, 201–204 (2003).

S. A. Firstov, T. G. Rogul, and S. N. Dub, “Grain boundary engineering of nanostructured chromium films,” in: Innovative Superhard Materials and Sustainable Coatings for Advanced Manufacturing, Springer, Dordrecht (2005), pp. 225–232.

S. A. Firstov, “Deformation and fracture of micro- and nanocrystalline materials,” in: Advanced Materials and Technologies [in Russian], in 2 Vols., Akademperiodika, Kiev (2003), pp. 610–630.

Yu. F. Lugovskii and S. A. Firstov, “Effect of microstructure on the strength of composite materials under static and cyclic loading,” in: Electron Microscopy and Strength of Materials [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kiev (2008).

S. A. Firstov, T. G. Rogul’, and O. A. Shut, “Hardening of polycrystals in transfer from micro- to nanostructured state,” Fiz. Khim. Mekh. Mat., No. 6, 5–12 (2009).

S. A. Firstov, T. G. Rogul, and O. A. Shut, “Transition from microstructures to nanostructures and ultimate hardening,” Functional Materials, 16, No. 4, 364–373 (2009).

R. A. Andrievskii and A. M. Glezer, “Size effects in nanocrystalline materials. II. Mechanical and physical properties,” Fiz. Met. Materialoved., 89, No. 1, 91–112 (2000).

H. Gleiter, “Nanostructured materials,” Prog. Mat. Sci., 33, 223–315 (1989).

H. Gleiter, “Materials with ultrafine microstructures: retrospectives and perspectives,” Nanostruct. Mat., 1, 1–19 (1992).

V. G. Gryaznov and L. I. Trusov, “Size effects in micromechanics of nanocrystals,” Prog. Mat. Sci., 37, 289–401 (1993).

K. S. Kumar, S. Suresh, M. F. Chisholm, et al., “Deformation of electrodeposited nanocrystalline nickel,” Acta Mat., 51, 387–392 (2003).

S. Takeuchi, “The mechanism of the inverse Hall–Petch relation of nanocrystals,” Scripta Mat., 44, 1483–1487 (2001).

S. Veprek, “A concept for the design of novel superhard materials,” J. Vac. Sci. Technol., A17, No. 5, 2401–2420 (1999).

A. S. Drachinskii, V. F. Moiseev, and V. I. Trefilov, “Transfer from intercrystalline to transcrystalline fracture in molybdenum,” in: Mechanism of Plastic Deformation [in Russian], Naukova Dumka, Kiev (1965), pp. 42–53.

A. S. Drachinskii, V. F. Moiseev, and V. I. Trefilov, “Dependence on the type of plastic deformation (slip, twinning) on grain size of polycrystalline iron,” DAN SSSR, 154, No. 5, 1078–1081 (1964).

G. Langford and M. Cohen, “Strain hardening of iron by severe plastic deformation,” Transactions of the ASM, 62, No. 3, 623–638 (1969).

A. W. Thompson, “Substructure strengthening mechanisms,” Met. Trans., 8A, No. 6, 833–842 (1977).

A. H. Cottrell, “Discontinuous flow,” in: The Relation between the Structure and Mechanical Properties of Metals, Her Majesty’s Stationery Office, London (1963).

M. Yu. Gutkin and I. A. Ovid’ko, Physical Mechanics of Deformable Structures [in Russian], Vol. 1, Saint-Petersburg (2003), p. 194.

G. A. Malygin, “Effect of grain size distribution on the strength and plasticity of nanocrystalline materials,” Fiz. Tverd. Tela, 50, No. 6, 1013–1017 (2008).

V. A. Pozdnyakov and A. M. Glezer, “Structural fracture mechanisms nanocrystalline materials,” 47, No. 5, Fiz. Tverd. Tela, 793–800 (2005).

R. A. Masumura, P. M. Hazzledine, and C. S. Pande, “Yield stress of fine grained materials,” Acta. Mat., 46, No. 13, 4527–4534 (1998).

E. É. Glikman, “Equilibrium segregation at grain boundaries and intercrystallite cold brittleness of solid solutions,” in: Metal Physics [in Russian], Issue 43, 42–51 (1972).

S. A. Firstov and T. G. Rogul’, “Theoretical (ultimate) strength,” Dokl. NAN Ukrainy, No. 4, 110–116 (2007).

S. A. Firstov, T. G. Rogul, V. F. Gorban, and E. P. Pechkovsky, Ultimate strengthening, theoretical and limit tool hardness,” Key Eng. Materials, 409, 128–136 (2009).

S. A. Firstov, V. F. Gorban’, É. P. Pechkovskii, and N. A. Mameka, “Indentation equation,” Dokl. NAN Ukrainy, No. 12, 100–106 (2007).

S. A. Firstov, V. F. Gorban’, and É. P. Pechkovskii, New Methodology for Processing and Analyzing the Results of Automatic Materials Indentation [in Russian], Logos, Kiev (2009), p. 83.

Inoue Akihisa, “High strength bulk amorphous alloys with low critical cooling rates (Overview),” Mat. Trans., 36, No. 7, 866–875 (1995).

Yu. K. Kovneristyi, “Bulk-decrystallizing metal alloys and nanostructured materials on their basis,” Metalloved. Term. Obrab. Met., No. 7 (601), 14–17 (2005).

S. N. Grigor’ev, A. A. Andreev, and V. M. Shulaev, “Nanostructured wear-resistant coatings obtained by physical deposition in vacuum,” Uprochn. Tekhnol. Pokryt., No. 9, 57–71 (2005).

O. A. Rozenberg, N. V. Novikov, S. E. Sheikin, et al., “Formation of gradient nanostructure on parts by plastic deformation,” Metallofiz. Noveish. Tekhnol., 26, No. 11, 1493–1500 (2004).

M. Danylenko, V. Gorban, Yu. Podrezov, et al., “Gradient structure formation by severe plastic deformation,” in: Zenji Horita (ed.), Nanomaterials by Severe Plastic Deformation, Trans. Tech. Publications, Zurich (2005), pp. 787–792.

I. Gornaya, K. Gorpenko, M. Bulanova, et al., “Influence of zirconium on phase composition, structure and mechanical properties of as-cast alloys of Ti–Al–Si system,” J. High Temp. Mat. Proc., Special Issue, No. 1–2, 59–66 (2006).

I. D. Gorna, K. O. Gorpenko, O. Yu. Koval’, et al., “Structure and mechanical properties of Ti–Si–X alloys,” Fiz. Khim. Mekh. Mat., No. 3, 35–42 (2008).

I. D. Gorna, K. O. Gorpenko, M. D. Bega, et al., “Effect of boron on the structure, phase composition, and mechanical properties of Ti–Si–X eutectic alloys,” Metallofiz. Noveish. Tekhnol., 28, Special Issue, 175–182 (2006).

G. He and M. Hagiwara, “Bimodal structured Ti-base alloy with large elasticity and low Young’s modulus,” Mater. Sci. Eng. C, 25, 290–295 (2005).

W. Yeh, S. K. Chen, and S. J. Lin, “Nanostructured high-entropy alloys with multiprincipal elements-novel alloy design concepts and outcomes,” Adv. Eng. Mater., 6, 299–314 (2004).

X. F. Wang, Y. Zhang, Y. Qiao, and G. L. Chen, “Novel microstructure and properties of multicomponent CoCr–CuFeNiTix alloys,” Intermetallics, 15, No. 3, 357–370 (2007).

C. Li, J. C. Li, M. Zhao, et al., “Microstructure and properties of AlTiNiMnBx high entropy alloys,” Mat. Sci. Technol., 24, No. 3, 376–378 (2008).

S. A. Firstov, V. F. Gorban’, N. A. Krapivka, et al., “Mechanical properties of multicomponent titanium alloy,” Probl. Prochn., No. 5, 178–189 (2010).

S. A. Firstov, V. F. Gorban’, N. A. Krapivka, et al., “Mechanical properties of high-entropy alloys at high temperatures,” Vest. Sam. GTU, Ser. Fiz. Mat. Nauki, Samara (2009), pp. 1–6.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 49, No. 7–8 (474), pp. 19–33, 2010.

Rights and permissions

About this article

Cite this article

Firstov, S.A. Trefilov and strength physics today. Powder Metall Met Ceram 49, 386–396 (2010). https://doi.org/10.1007/s11106-010-9249-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-010-9249-x