Abstract

Background and Aims

Wet processed alfalfa-based products can provide high-quality concentrated protein, also contain nutrients and phytochemicals. Agronomic fortification can increase selenium (Se) incorporation into green biomass. For this reason, the aim was to investigate how different forms of Se are incorporated into the green biomass of multiple-harvest alfalfa and how they affect the chemical quality of the processed product candidates.

Methods

In this research, alfalfa was enriched with three forms of selenium at different concentrations [selenate (Se(VI)); selenite (Se(IV)); and red elemental Se (Se0)]. The fortified green biomass was fractionated into leaf protein concentrate (LPC), fiber and phytoserum, and changes in selenium content and speciation, protein and phytochemical composition were determined.

Results

Total Se content in alfalfa fractions drastically reduced within the four consecutive harvests, particularly for Se(VI) and Se(IV) forms, and significantly varied according to the Se treatments. Selenomethionine (SeMet) was the predominant organic Se species in LPC (35.7–246.0 µg g −1 DW) and fiber (9.0- 47.7 µg g −1 DW) fractions. Se-fortification induced considerable changes in the crude protein of LPC, which varied between 29—45 (m/m)%. Phytochemical composition markedly varied among Se-treatments. Besides several flavonoids, aglycones and glycosyl derivatives, apigenin glucuronide, and apigenin were the most abundant with a concentration up to 170.85 µg g −1 DW. Medicagenic acid concentration was below 1.86 µg g −1 DW in LPC.

Conclusions

Se-enhanced alfalfa green biomass could provide functional products, such as LPC, for human and animal consumption with enhanced nutritional value, including Se, protein, and phytochemical contents.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Potential of alfalfa in human consumption has been emerged with the increase in the demand for green food, protein source (Mielmann 2013). The lower production cost of alfalfa compared to animal protein has special importance in developed countries. Depending on the processing methods of green biomass, alfalfa can be used to obtain food such as croquettes or casseroles (Martínez-González and Sánchez-Villegas 2016). Leaf protein has also been considered by the FAO for human consumption as a nutritious and valuable source of protein (Xie et al. 2008). However, the acceptance of alfalfa greens is limited by consumers due to its sensory attributes. As a result of efforts to process alfalfa in a product-oriented way, alfalfa leaf protein concentrate (LPC) has been authorized in the EU, USA and some other countries as food supplements (European Food Safety Authority (EFSA), 2009). The production of LPC from either alfalfa or other green biomass can be part of the technological realization of green biorefining. Hence, the concept of "Green Biorefinery" encompasses this ambition, as it aims to produce food, feed and industrially valuable products from green biomass using novel biotechnological and chemical methods, maximizing the energy efficiency and minimizing the greenhouse gases emissions (Kamm et al. 2016; Asgharipour et al. 2016). Alfalfa (Medicago sativa L.) is the most common raw material for green biorefineries (El-Ramady et al. 2020). It provides 3–10 times higher yield than seed based protein plants (oilseeds, grain, legumes) (Popp et al. 2016). Another benefit of alfalfa cultivation that cannot be overlooked is the carbon sequestration as a result of the low emission of CO2, as alfalfa does not require extensive plowing and tillage like most crops. More than 30 million hectares of alfalfa are cultivated worldwide (Barros et al. 2019). Wet fractionation offers alternative utilization of alfalfa designing mobile small-scale biorefineries and operating in climate-smart way (Fathollahi et al. 2018; Ait Sair et al. 2021).

Following the processing steps of a green biorefining, it usually starts with the physical fractionation of green biomass into green juice and fiber fractions. Subsequently, the green juice fraction, liberated from cell walls, is coagulated by chemical or physical methods. Heat coagulation is the most commonly used method converting green juice into LPC and phytoserum (brown juice) fractions (Pietrzak 2014). Besides protein, LPC contains photosynthetic pigments, phytonutrients, carbohydrates and fatty acids, which can be separated from phytoserum by filtration (Bákonyi et al. 2020). The three fractions (LPC, fiber, phytoserum) can be final products or platform materials for further industrial development depending on utilization purposes. For instance, LPC is considered a suitable food and/or feed protein source according to its protein content and phytochemical composition; furthermore, LPC could also serve as a raw material for high-value industries (e.g. cosmetics). Also, fiber fraction could be utilized as suitable feedstock for ruminants, platform source for biogas and cellulose-based bioethanol production; moreover, it could be directed towards paper or construction industry after further processing steps (Takkellapati et al. 2018). Phytoserum may serve as complex growing medium for microorganisms or growth stimulant for crop production (Bákonyi et al. 2020). Economic interest in these green biomass-derived products is continually growing (Popp et al. 2021). However, nutrichemical composition and thus the quality of alfalfa fractions may be affected in response to various biotic/abiotic stress factors; out of these, Se biofortification has a special consideration.

Selenium is a key trace element in humans and other mammals, forasmuch 25 encoded selenoproteins are known in the human genome, which are typically selenophosphate synthetases, glutathione peroxidases, thioredoxin reductases and iodothyronine deiodinases in addition due to its pivotal position in oxidation–reduction homeostasis, regulation of thyroid hormone metabolism, promotion of DNA synthesis (Zhou et al. 2021).

Considering its health effect, the absence or low contents of Se in some regions around the world gives a cause for concern. Hence, several methods of Se supplementation are used in human consumption, including tablets, capsules containing selenium in organic form or as inorganic salts. Since Se can enter the food chain through plants, so Se fortification may be an obvious natural way of meeting Se requirements. Selenium foliar application as a method of agronomical fortification has practical difficulties and risks of uneven distribution. The Se content of agro-food can also be increased by soil fertilization of Se. Within crops biofortification strategy, Se-enriched forage crops have an important role to meet feed quality necessity in animal nutrition (Petković et al. 2019). For instance, Se-enriched alfalfa does not require external Se supplementation in feedlot diets. Along with, it is important to keep in mind that alfalfa is a multi-harvestable crop. Hence the success of fortification is influenced by the absorption, translocation, distribution and transformation dynamics of Se in re-growing green biomass (Kovács et al. 2021).

Besides improving Se content, the biofortification can also influence the quantitative and qualitative parameters, including stimulated phenolic compound synthesis, extended antioxidant capacity and increased nitrogen and sulfur metabolism as reported in some crops species (Schiavon et al. 2013; Malagoli et al. 2015; Groth et al. 2020). With all this knowledge, it is possible to produce healthier, fortified foods in agriculture.

The present study focuses on qualitative analysis of LPC, fiber and phytoserum fractions as product candidates and intermediates of processed alfalfa which fortified by different selenium forms. In particular, we investigate how Se supply affect the crude protein content, amino acid composition, and bioactive components of fractions comparing two ionic Se forms and a red elemental Se. Also, the uptake and transformation dynamics of inorganic selenium forms to organic form from processed alfalfa are observed, together with nutrition values considering four consecutive harvests.

Materials and methods

Soil sampling and seed sowing

Surface-soil (0–25 cm) was gathered from the Demonstration garden at the University of Debrecen, Hungary (47° 32 ′ 0"; 21° 38′ 0" E). Soil samples were air-dried and homogenised before seed sowing. Physical and chemical traits of experimental soil are shown in Table S1 (Supplementary materials). Soil samples were sifted through a 4 mm sieve and placed into polyethylene pots (without holes) at a rate of 8 kg soil per pot. Each pot received 0.29 g seed of alfalfa (Medicago sativa L. var. Tápiószelei 1).

Experimental installation and Se treatments

The experimental layout was the Randomized Complete Block Design (RCBD) with seven replicates. Selenium treatments included selenate [Se(VI)] and selenite [Se(IV)] as an ionic forms, which prepared from Na2SeO4 (sodium selenate) and Na2SeO3 (sodium selenite), respectively, and red elemental selenium (red Se0) prepared by reduction of sodium selenite using ascorbic acid (Kovács et al. 2021). The application rate of the ionic forms was 1, 10, and 50 mg kg−1 soil, while red Se0 was added at a rate of 10 and 50 mg L−1. Selenium was as soil application and the calculated Se quantity per pot was dissolved in 1 L distilled water to remain below the saturation percentage (SP) of soil (SP = 360 mL water kg−1 dry soil). Control pots were watered with the same volume of distilled water. Soil moisture content was retained at 75% of SP within the entire period of the experiment using tap water. Pots were placed under greenhouse conditions. The aboveground green biomass was harvested in the early morning to avoid protein degradation and quality deterioration and quickly transported to the laboratory in ice box for further wet fractionation. The harvest was carried out four consecutive times during year 2018 growth season when green buds were initiated and before turning into purple flowers.

Wet fractionation fresh green alfalfa biomass

Harvested fresh green alfalfa biomass was pressed by a twin-screw juicer (Angel Juicer 5500, Angel Ltd, South Korea) generating green juice and fiber fractions. Next, green juice was coagulated by microwave radiation at 80 ± 2 °C to precipitate the soluble proteins (Fári and Domokos-Szabolcsy 2018). Thereafter, the coagulated leaf protein (LPC) was separated from phytoserum (in other words, brown juice) employing cloth filtration (Kaszás et al. 2020). After recording the fresh mass of fractions, samples were placed in the freezer at -20 °C. The LPC and fiber fractions were dehydrated using a lyophiliser (Alpha 1–4 LSC basic, Martin Christ Ltd., Germany) and dry mass was measured. Freeze-dried samples were powdered and homogenized using a stainless steel grinder and kept in polyethylene bags at -20 °C for further analyses. The phytoserum was stored at -80 °C.

Determination of crude protein and amino acid composition

Determination of crude protein content was performed according to the ISO 5983–2:2009 international standard method. Briefly, 1 g lyophilized sample (for LPC and fiber) or 1 mL (for phytoserum) was placed in a 150 mL Kjeldahl tube with 15 mL concentrated sulfuric acid (99% Avantor Ltd., USA). Later, samples were placed into a Tecator Digestion unit (VELP scientifica Ltd., Italy) and digestion temperature was set to 420 °C for 1.5 h. The content of total N was measured using acid–base titration method. Crude protein content was computed by the following formula:

Amino acid composition was determined after ISO 13903:2005 standard. The sample size varied according to N content to match the content of 25 mg N per sample. Samples were hydrolysed in a hydrolysis vessel using 6 M HCl under an inert environment of N2 gas. The sealed vessels were heated to 110 ± 1 °C for 24 h. Hydrolysed samples were filtered and vacuum evaporated to remove surplus acid; deionised water was added twice during the evaporation process. Syrup-like samples were transferred into plastic centrifuge tubes and dissolved in citrate buffer (pH 2.2). Amino acid analyser (INGOS AAA500; Ingos Ltd., Czech Republic) was applied for quantification of amino acids. The elution of 17 proteinogenic amino acids was implemented by pH gradient based on ionic exchange chromatography. Detection was performed by post-column ninhydrin derivatization and optical sensing at 440/570 nm.

Determination of total Se content

The content of total Se in the LPC, fiber, and phytoserum fractions was measured as follows: 20 mg powdered sample (for LPC and fiber) or 1 mL (for phytoserum) was transferred into a 150 mL Kjeldahl tube, then tubes were kept in a Tecator Digestion unit (VELP Digester model DK 42/26, VELP scientifica Ltd., Italy). Samples were digested by 3 mL concentrated nitric acid (HNO3) for 60 min at 120 °C. After cooling, samples received 2 mL of 30% hydrogen peroxide (H2O2) and then heated at 150 °C for an additional 60 min. For the reduction of selenate into selenite, additional digestion step was carried by adding 20 mL 6 M HCl to cooled sample and then heated up to 100 °C for 60 min. Using Milli-Q water, the final volume of digested samples was brought up to 50 mL. The content of total Se was measured by hydride generation atomic fluorescent spectrometer (PSA 10.055 Millennium Excalibur System, PS Analytical Ltd., United Kingdom). Sodium borohydride (1.4 m/v%) was used as reducing agent to generate volatile hydrogen selenide (H2Se).

Selenium speciation measurements

Identification of different Se forms was performed in water and enzymatic extracts of LPC, fiber, and phytoserum. Briefly, 200 mg of freeze-dried powdered sample (LPC and fiber) was mixed with 9 mL MQ water (Millipore, Molsheim, France). Liquid phytoserum was considered as water extract. Water extraction was enhanced with 10 min ultrasonic bath. Supernatants were collected in a clean centrifuge tube by centrifuge samples at 9000 × g for 10 min and then placed in a freezer at -80 °C. Pellets were enzymatically digested as follows: each sample was digested by 40 mg protease XIV (Sigma-Aldrich, Budapest, Hungary), which suspended in 9 mL 100 mM TRIS (pH 8). Digestion lasted overnight at 37 °C in a water bath shaker. In the next morning, each sample received an extra 40 mg protease XIV (for complete hydrolysis of the proteins), which dissolved in 1 mL TRIS bringing the total volume to 10 mL and it was shaken for additional 6 h at 37 °C. Samples were then centrifuged at at 9000 × g for 10 min to collect the supernatants, which were stored in clean Falcon tubes at -80 °C. Besides the samples, a reference material (SELM-1; LGC Standards Ltd., Germany) was processed as mentioned above. The contents of selenate [Se(VI)] and selenomethionine (SeMet) were determined in water and enzyme extracts by the High-Performance Liquid Chromatography linked to an Inductively Coupled Plasma Mass Spectrometry system (SAX HPLC-ICP-MS). Before injection, samples were syringe filtered (hydrophilic PTFE, 0.22 µm), and to prevent the oxidation, 0.01% dithiothreitol was added. The column used was PRP-X100 SAX (250 mm × 4.1 mm, 10 µm; Hamilton, Reno, NV) with an injection volume of 100 µL, at 1.9 mL min−1 flow rate and ammonium-acetate eluents (buffer A: 10 mM; buffer B: 300 mM, pH 5.5) in anion exchange chromatography. The Thermo Spectra System P4000 HPLC pump (Thermo Fisher Scientific, Waltham, MA, USA) was coupled to the Thermo Scientific X-Series II ICP-MS for the detection of 78Se and 80Se from the eluted samples.

Qualification and quantification of phytochemicals in alfalfa fractions

Bioactive components in LPC, fiber, and phytoserum fractions were extracted by water: methanol (30:70 ratio). Mixtures were stirred at 150 rpm for 2 h at room temperature in dark. Extracts were filtered using syringe filters (PTFE, 0.22 µm) and stored at -20 °C until further measurements. Determination of phytochemical was conducted by the UHPLC-ESI–MS. For chromatography, a Dionex Ultimate 3000RS UHPLC system (Thermo Fisher Scientific Ltd., USA) was served with a Thermo Accucore C18 analytical column (2.1 mm × 100 mm, 2.6 µm particle size). Gradient elution was performed at 0.2 mL min−1 flow rate with methanol and water eluents.

Hyphenated analytical system was set up with a Thermo Q Exactive Orbitrap hybrid mass spectrometer equipped with electrospray ionization (Thermo Fisher Scientific Ltd., USA). Samples were analyzed in positive and negative ionization mode. Retention time and fragmentation pattern data was analyzed using Thermo Trace Finder 2.1 software. For identification self-collected and online databases were applied. For quantification external calibration curves were generated. The processed data were manually examined using Thermo Xcalibur 4.0 software. Quantitative determination was made taking into account the following selected standard compounds: apigenin (≥ 95.0%); apigenin-7-O-glucuronide (primary reference standard); luteolin (≥ 98%); quercetin (≥ 95.0%); isoquercitrin (a. s); naringenin (≥ 95.0%); liquiritigenin (≥ 97%); medicagenic acid (phyproof Reference Substance). All the standards were purchased from Sigma-Aldrich (Darmstadt, Germany).

Statistical evaluation of the experimental data

Normality and homoscedasticity of dependent variables were examined and corrected as necessary. Data analysis was conducted using Microsoft Excel 2016 and the IBM SPSS 25.0 software package (SPSS Inc., Chicago, IL, USA). One-way ANOVA was used to evaluate the differences between either Se treatments or harvest times. Separation of means was executed by post-hoc test (Tukey’s test), and significant differences were accepted at the levels p < 0.05. The data were presented as mean ± standard deviation.

Results

Fresh yield of Se-biofortified alfalfa fractions

The fiber fraction represented 35–49% of the fractionated fresh biomass. Within the four harvests, Se application did not influence the yield of the obtained fractions. The percentage distribution of the fractions (LPC, fiber, phytoserum) was strongly influenced by the pressing and protein coagulation techniques. In this experiment, the average distribution of fiber, phytoserum and LPC fractions, during the 4 harvests, was 40%, 38% and 20%, respectively (Fig. 1A).

(A) The percentage of the fresh yield of fiber, phytoserum, and leaf protein concentrate (LPC) fractions; (B) dry matter content (%) of LPC; and (C) dry matter content (%) of fiber fractions originated from fresh green biomass of alfalfa fortified with different Se forms [Se(VI), Se(IV), and red elemental Se (Se0)] and concentrations [1 and 10 mg kg-1 for Se(VI); 1, 10, and 50 mg kg-1 for Se(IV); and 10 and 50 mg L-1 for Se0] during four consecutive harvests. Control (0Se) received no Se.

Dry matter content of LPC and fiber fractions

The dry matter content of the LPC ranged from 16.5–31% over the four harvests, with an average of 25.4% (Fig. 1B). The treatments of 1Se (IV) and 50Se0 showed similar dry matter content as control. However, increasing the concentration of ionic Se forms drastically reduced the dry matter content. In terms of ratios, the dry matter content of LPC of 10Se(VI) treatment was 79% of the control and 82% of the 50Se(IV).

Total Se content of fortified alfalfa fractions

The LPC fraction showed the highest total Se content, followed by fiber and phytoserum (Table 1). The absorption and building up of Se in the LPC fraction significantly varied in response to the harvest times. The total Se concentration in LPC of alfalfa grown on the ionic Se forms drastically decreased from the 1st harvest to the 4th harvest, except for the 1Se(IV) and 10Se(IV) treatments, which showed a slight increase in the total Se content during the 4th harvest compared to the 3rd harvest. Fortification of alfalfa using red Se0 displayed a different impact on the absorption and building up of Se into plant tissues compared with the ionic Se forms. Applying red Se0, regardless of its concentration, showed a small reduction in the total Se content from the 1st harvest to the 2nd harvest, and then Se content begun to increase during the 3rd and 4th harvests (Table 1). Moreover, the ionic Se forms demonstrated a higher decrease in the total Se concentration from the 1st to the 4th harvest than the red Se0. For example, the 10Se(VI) treatment displayed a reduction of 94.3% in the total Se concentration from the 1st to the 4th harvest, and the 50Se(IV) treatment showed a decrease of 76.2%, while the 50 Se0 treatment revealed only 49.5% decrease in the total Se concentration. Increasing the concentration of the applied Se elevated the total Se content in the LPC, regardless of the Se forms. Overall, the Se(VI) form was the most absorbed Se form and it showed the highest total Se concentration in the LPC fraction, particularly during the 1st harvest, followed by the Se(IV) and red Se0, respectively.

Similarly, the total Se content in the fiber fraction largely depended on the concentration and chemical form of applied Se and the harvest times (Table 1). While deposition of Se in the fiber of plants treated with the ionic Se forms considerably dropped down from the 1st to the 4th harvest, red Se0 treatments showed a decrease in the bioconcentration of Se from the 1st to the 2nd harvest, followed by an elevation in the total Se concentration of fiber fraction during the 3rd and 4th harvests. Furthermore, the total Se content in fiber dropped down from the 1st to the 4th harvest by 96.0% (for the 10Se(VI)), 81.1% (for the 50Se(IV)), and 41.0% (for the 50Se0). Considering the same Se form, increasing the application rate increased the total Se content within the four consecutive harvests. Yet, the highest fiber total Se content corresponded to the treatment of 10Se(VI) in the 1st, 2nd harvests and 50Se(IV) treatment in the 3rd, 4th harvests. The variation in the total Se content of the fiber fraction among the different harvests was not substantial for plants grown on red Se0.

Although the phytoserum fraction had the lowest total Se concentration compared to the LPC and fiber fractions, it showed almost the same response to Se-fortification and harvest time. The total Se content decreased considerably from the 1st to the 4th harvest, except for the red Se0 treatments. The red Se0 treatments (10Se0 and 50Se0) displayed a hesitating Se content during the four successive harvests. The 50Se0 treatment showed the lowest decrease in the total Se content from the 1st harvest to the 4th harvest, recording a decrease of 74.9%, while the two ionic Se forms, i.e., Se(VI) and Se(IV), revealed a higher reduction of 96.8 and 88.4%, respectively. The total Se content shows a dose–response relationship to the applied Se, regardless of the applied Se form. The Se(VI) resulted in the highest Se content, followed by Se(IV) and red Se0, respectively.

Selenium species in processed alfalfa fractions

The possible Se species in the LPC, fiber and phytoserum fractions originated from Se-fortified alfalfa were quantified in the highest Se treatments (10Se(VI), 50Se(IV), and 50Se0) during three harvests (e.g., 1st, 2nd, and 4th). Selenium species were determined in two extracts, i.e., water and enzymatic extracts.The standard reference material was a Se-enriched yeast (SELM-1) sample with 80.4% Se recovery for selenomethionine (SeMet). Recovery was used to compensate the SeMet concentration in the enzymatic extracts.

The Se(VI) form was the predominant Se species in the water extract of the LPC, fiber, and phytoserum fractions within the three harvests, while the SeMet was the most plentiful Se species in enzymatic extract of the LPC and fiber fractions. The Se(VI) and SeMet content in the LPC, fiber, and phytoserum fraction linearly reduced from the 1st to the 4th harvest, particularly for the 10Se(VI) and 50Se(IV) treatments. Despite the results of the 50Se0 treatment were similar to those of the ionic Se treatments, some exceptions were reported. The treatment of 10Se(VI) revealed the highest Se(VI) and SeMet concentrations in all fractions during the 1st and 2nd harvests, whereas the 50Se(IV) treatment displayed the highest content of Se(VI) and SeMet species in the 4th harvest. The decrease in the Se(VI) and SeMet concentration from the 1st to the 4th harvest was drastically for the 10Se(VI) and 50Se(IV) treatments; nevertheless, fortification of alfalfa with 50Se0 showed lower variations in the content of Se(VI) and SeMet species during the different harvests of alfalfa biomass (Table 1). The LPC fraction displayed higher Se(VI) and SeMet contents during the three harvests than the fiber fraction, while the phytoserum fraction exhibited the lowest contents.

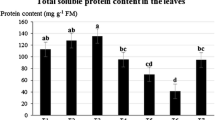

Crude protein content of fractions

The crude protein content significantly varied upon the Se treatments, harvest times, and alfalfa fractions (Fig. 2). Considering the alfalfa fractions, the LPC showed the highest crude protein content, while the phytoserum displayed the lowest crude protein quantity.The crude protein content of the LPC was negatively affected by the Se fortification, especially at the high Se concentrations. The LPC derived from control plants revealed the highest LPC crude protein content during the four harvests, except for the 3rd harvest, where the treatment of 50Se0 showed the highest LPC crude protein content (40.1 m/m%). High concentrations of ionic forms of Se, i.e., 10Se(VI), 50Se(VI), and 50Se(IV), caused a reduction in the crude protein content of LPC. Nevertheless, during the 3rd and 4th harvests, these treatments showed higher crude protein contents of LPC compared with the 1st and the 2nd harvest. Otherwise, low concentrations of Se ionic forms displayed high crude protein content of LPC, particularly during the 1st, 2nd, and 3rd harvests. Interestingly, applying red Se0, regardless of its concentration, increased crude protein content of LPC from the 1st to the 3rd harvest.

Crude protein content (m/m %) in leaf protein concentrate LPC (A), fiber (B), and phytoserum (C) fractions obtained from fresh green biomass of alfalfa fortified with different Se forms [Se(VI), Se(IV), and red elemental Se (Se0)] and concentrations [1 and 10 mg kg−1 for Se(VI); 1, 10, and 50 mg kg−1 for Se(IV); and 10 and 50 mg L−1 for Se0] during four consecutive harvests. Control (0Se) received no Se. Different letters on the same bars are significant according to the Tukey’s test (p ≤ 0.05). Data are Means ± SD and n = 3

The crude protein content of the fiber displayed a similar results to the LPC, where the control treatment (0Se) revealed the highest crude protein content of fiber during the first two harvests. The highest fiber crude protein content in the 3rd and 4th harvests corresponded to the treatment of 10Se(IV) and 50Se0, respectively. Moreover, increasing the concentration of the Se(VI) and Se(IV) decreased the fiber crude protein content within the four harvests. Likewise, red Se0 decreased the fiber crude protein content when its concentration was elevated from 10 to 50 mg L−1, except at the 2nd harvest. However, the fiber crude protein content increased from the 1st to the 3rd harvest when plants were treated with red Se0.

The crude protein content in the phytoserum showed a different response to the Se fortification and harvesting times, despite its being the lowest content compared to the LPC and fiber fractions. The 1st and 4th harvests displayed higher crude protein content than the 2nd and 3rd harvests. Also, Se-treated plants revealed higher phytoserum crude protein content than the control. Moreover, increasing the concentration of ionic Se forms (Se(VI) and Se(IV)) and red Se0 resulted in higher crude protein content during the four harvest times, except for the 50Se(IV) treatment, which showed lower content in the 1st and 4th harvests. The treatments of 1Se(IV) and 10Se(IV) displayed the highest phytoserum crude protein content, regardless of the harvest times.

Amino acid composition

Proteinogenic amino acids were quantified in the LPC and fiber fractions of the 1st and 4th harvests (Table S2 and S3; Supplementary materials). Overall, the LPC fraction showed higher amino acid composition than the fiber fraction in both harvests. The trends between the amount of incorporated Se and the protein content were also observed for the amino acid results. The sum of amino acids in fractions from plants treated with high concentrations of ionic forms showed the lowest amino acid yield at the 1st harvest. This was correlated with high incorporated Se content and low crude protein value, because by the 4th harvest, when the Se content decreased, the amino acid content was similar to the control. The fractions of plants treated at lower concentrations had similar amino acid content to the control. Amino acid composition of the fiber was less affected by any Se treatment than the LPC.

Phytochemical composition of Se-fortified alfalfa fractions

Qualitative analysis of bioactive components in alfalfa fractions

Qualitative analysis of the possibly co-existing bioactive compounds in the LPC, fiber, and phytoserum fractions originated from fresh green biomass of alfalfa using the LC–MS revealed no substantial differences between the Se-fortified alfalfa and control (0Se). Therefore, screening analysis results of the LPC, fiber, and phytoserum fractions derived from the control are shown in Table 2. Overall, the profiles of the phytochemicals in all the fractions were almost similar. Among organic compounds, flavonoids were the most abundant in all hydro-alcoholic extracted alfalfa fractions (Table 2). Out of 37 identified flavonoids, aglycones and glycosyl derivatives were detected from flavanone, flavonol, flavone, isoflavone, and chalcone classes. Among flavonoids, flavones are the most diverse group, including several hydroxyflavones and glycosyl derivatives. The sugar chain of flavonoids was not exclusively glucuronic acid; glucose and xylose were also identified in apigenin, naringenin, and quercetin. For instance, vicenin-1 (Apigenin-8-C-glucoside-6-C-xyloside) with [M + H]+ ion at m/z 565.15574 and vicenin-3 (Apigenin-6-C-glucoside-8-C-xyloside) ([M + H]+ ion at m/z 565.15574), as minor components, were detected in the LPC fraction.

Quantification of important bioactive components in Se-fortified alfalfa fractions

Based on the quantitative analysis of hydro-alcoholic extracted alfalfa fractions, the apigenin glucuronide and apigenin (4'0.5.7-Trihydroxyflavone) aglycones were the most abundant flavonoids within the four harvests (Table 3). The fiber fraction displayed the highest concentration of apigenin-7-O- glucuronide, ranging between 90.82–170.85 µg g−1 DW, while the LPC and phytoserum fractions exhibited 33.31–68.10 µg g−1 DW and 376.13–1098.88 ng mL−1, respectively (Table 3). Apigenin was the second most abundant of the selected quantified flavonoids ranging between 7.97–72.93 µg g−1 DW. In contrast to apigenin-7-O-glucuronide, apigenin showed a slight range of 13–24 µg g−1 DW in the LPC and fiber fractions, except for the 4th harvest, recording an average of 67 µg g−1 DW in the fiber fraction, regardless of the Se form and concentration. The form and concentration of applied Se to alfalfa induced the changes in apigenin (4'0.5.7-trihydroxyflavone) and apigenin-7-O-glucuronide content. The concentration of both flavones increased upon adding Se in the form of Se(IV) and Se(VI), especially during the 1st harvest, while the red Se0 displayed lower values compared with the control, regardless of Se concentration (Table 3).

The other hydroxyflavones, luteolin (3'0.4'0.5.7-Tetrahydroxyflavone) and its derivatives, i.e., luteolin-7-O-glucuronide, luteolin-di-O-glucuronide, luteolin-4'-O-glucuronide-7-O-[feruloyl-(→ 2)-glucuronyl-(1 → 2) glucuronide] were quantified in the phytoserum fraction; yet, some of them were absent in the fiber and LPC fractions. The concentration of luteolin aglycone was markedly lower (0.71 – 5.10 µg g−1 DW) than the apigenin in all alfalfa fractions (Table 3). The concentration of luteolin in the fiber fraction did not exceed 2.25 µg g−1 DW, whereas in the LPC fraction, it displayed a 20–30% increase compared to the fiber fraction. The luteolin concentration shows a dose–response correspondence to the applied Se concentration during the four consecutive harvests, as well as it varied according to the applied chemical Se form; however, some exceptions were reported. In addition to hydroxyflavones, methoxy-hydroxyflavones were also detected in significant quantities. Quantitative analysis of tricin (3'0.5'-Dimethoxy-4'0.5.7-trihydroxyflavone) confirmed a concentration of 14.5 µg g−1 DW (on average) in the LPC and fiber fractions and about ~ 160 ng mL−1 in the phytoserum. However, tricin didn’t show considerable dependence on Se treatments. Among the identified phytochemicals, several other flavonoids were also quantified. Regardless of the applied Se treatments and harvest times, quercetin, isoquercitrin, naringenin, liquiritigenin, and genkwanin were detected in trace amounts up to ≤ 10.00 µg g−1 DW (for the LPC and fiber, on average) or 14. 86 ng mL−1 (for the phytoserum, on average). The LPC and fiber fractions showed similar content of the minor flavonoids (Table 3). Furthermore, two soy sapogenol B derivatives were recognized only in the LPC fraction, along with several unknown saponin aglycones that were detectable in one or more fractions (Table 3).

Variations in medicagenic acid and formononetin content in Se-fortified alfalfa fractions

Among isoflavones, four compounds were identified (Table 2) and from these the concentration of formononetin (7-Hydroxy-4'-methoxyisoflavone) ranged between 0.34–8.39 µg g−1 DW in the LPC and fiber fractions and 3.16–80.04 ng mL−1 in the phytoserum (Table 4). The treatments of 1Se(IV) and 10Se0 showed similar formononetin content to control. Contrarily, high Se concentrations of Se(VI), Se(IV), or red Se0 resulted in lower formononetin content within the three fractions. The other isoflavone, biochanin A (4'-Methylgenistein) displayed lower concentration ranging between 0.11–0.63 µg g−1 DW in the LPC and fiber and 0.35–3.88 ng mL−1 in the phytoserum.

Among pterocarpans, medicarpin (3-Hydroxy-9-methoxypterocarpan) ([M + H]+ ion at m/z 271.09704) and methylnissolin (3-Hydroxy-9,10-dimethoxypterocarpan) ([M + H]+ ion at m/z 301.1076) were recognized in all alfalfa fractions. Regardless of the Se treatment, medicagenic acid and its combinations with either short or long sugar chains of mono-, bi-, or tridesmoides were the most abundant saponins in all alfalfa fractions (Table 4). The concentration of medicagenic acid ranged between 0.11–1.86 µg g−1 DW in the LPC and fiber fractions and 0.72–32.72 ng mL−1 in the phytoserum fraction during the four successive harvests of alfalfa. The treatments of 10Se(IV), 50Se(VI), and 50Se0 increased the concentration of medicagenic acid in the LPC, fiber, and phytoserum fractions, particularly during the 1st harvest (Table 4). Nevertheless, during the next harvests, the concentration of medicagenic acid did not clearly depend on the Se treatments.

Discussion

In the green biorefining concept, fresh green biomass can be processed using modern technologies to produce feedstock for industrial purposes. Alfalfa, as a traditional fodder crop with good protein content, is an ideal feedstock for green biorefineries. Leaf protein concentrate (LPC), which can be obtained from processed green biomass using various coagulation methods, represents the greatest value, which is an alternative feed protein source in addition to seed-based soy (Pietrzak 2014; Kaszás et al. 2020). Along with this, the value-added utilization of fiber and phytoserum fractions as by-products has also great importance due to the economical and sustainable maintenance of the green biorefinery system. In addition to protein, processed alfalfa-based products are also a source of different macro- and micronutrients and phytochemicals. The composition and concentration of these chemical components can be influenced by genetic tools and the growing conditions. Among the microelements, selenium has received special attention in recent times due to its essential role in humans and farm animals. For this reason, as a member of the feed/food supply chain, enhancing the selenium content of plants is a widely researched area (Schiavon et al. 2013; Ros et al. 2016); (Shalaby et al. 2017); Groth et al. 2020). In this complex study, the linkage between green biorefining and agronomic Se fortification was investigated. To the best of our knowledge, we are the first to investigate the dynamics of selenium accumulation in alfalfa-based processed products considering the major Se speciations and the changes of phytochemical patterns comparing three inorganic forms of selenium during 4 consecutive harvests. We did this because alfalfa is special in that the green leafy stem can be harvested 4 to 6 times during a growing season. And the appropriate fortification method is important in order to achieve green biomass with balanced selenium supply during consecutive harvests.

Alfalfa plants grown in pots under greenhouse conditions were fortified with three Se forms, including Se(VI), Se(IV), and red Se0 and applied at different concentrations.

The uptake and incorporation of Se into different alfalfa fractions significantly varied according to the harvest times, applied form, and concentration of Se. Among all alfalfa fractions, the LPC fraction demonstrated the highest total Se content, followed by the fiber fraction, whereas the lowest Se content belonged to the phytoserum. According to the United States Department of Agriculture (USDA), alfalfa is considered a facultative Se-accumulating crop, where it can accumulate Se at a concentration of 50 mg kg−1 DW. Nevertheless, in the present study, the 10Se(VI) and 50Se(IV) treatments resulted in total Se content above 50 mg kg−1 in all the fractions during the 1st harvest (Table 1). The results showed that the two tested ionic forms of Se were the most readily absorbed by the alfalfa, as they showed a high total Se content in all the fractions during the 1st harvest, followed by a rapid decrease in the following harvest times.

Although Se(VI) is the cheapest and most readily available form of Se, its rapid allocation in soil–plant systems and tissues may be an unfavorable attribute for perennial crops such as alfalfa. In contrast to the ionic Se forms, the results showed that the red Se0 was gradually absorbed and built up into plant tissues, where it displayed a steady total Se content, particularly during the last three harvests. It is probably due to the transformation of red Se0 into ionic forms depending on soil conditions. Thus, the red Se0 could serve as a low release Se fertilizer, providing the growing alfalfa with a steady Se content during the entire growing season. Hu et al. (2022) distinguished three assimilation pathways of Se(IV) sprayed on leaves: 1) it can enter the stems via vascular tissues, 2) it can be excreted from the plant as volatile Dimethyl Selenide (DMSe) by gas exchange, or 3) it can be incorporated into proteins, non-specifically as Selenocysteine (SeCys) and SeMet.

Foliar application is one of the most effective ways for agronomic fortification of microelements such as Se, through enhancing the Se availability and its uptake by plants due to the direct contact with plant leaves (Motesharezadeh et al. 2020). The foliar fertilization of the multiple-harvested perennial crops such as alfalfa is a labor-intensive task during the growing season. Therefore, a long-release soil Se fertilization with an appropriate dose could be more effective and beneficial for the formation of valuable SeMet form compared to fast-absorbing and depleting foliar fertilization (Peng et al. 2021).

The Se species in the processed alfalfa LPC, fiber, and phytoserum fractions were quantified using the highest Se treatments, i.e., 10Se(VI), 50Se(IV), and 50Se0, where they displayed the highest total Se content. The Se speciation was detected in the 1st, 2nd, and 4th harvests to explore the uptake dynamics and building up Se into the plant tissues. The main selenium species were Se(VI) as the inorganic form and SeMet as the organic form, regardless of the selenium form used in the treatment. In addition, we also detected some minor unknown components in the brown juice and fiber fraction.Based on our standards selenomethylselenocysteine (SeMetSeCys); gamma-Glutamyl-selenomethyl-selenocysteine (γGlu-SeMe-SeCys) and selenite Se(IV) were below detection limits in all fractions. Despite the inability to measure the volatile forms of Se in the experimental setup, the formation of the volatile forms in the soil–plant complex system was confirmed, as the characteristic odor of DMSe, dimethyl diselenide, and other gaseous species were noticed during plant growth. Results revealed that the Se(VI) was the most plentiful Se form found in the water extract, while the SeMet was the main species quantified in the enzymatic extract of alfalfa fractions during the three selected harvests. Organic Se species are more efficiently metabolized by mammals and Se-containing proteins and peptides are known to have antioxidant, hepatoprotective, and immune-enhancing effects. (Pecoraro et al. 2022; Zhang et al. 2020).

The SeMet is the prevalent organic Se form in plant-based foods and feeds (Tamás et al. 2010). Its importance lies in the fact that it does not stress the body's redox defense system as Se ionic forms do. However, the results also illustrated a saturation capacity of building ionic Se forms into organic forms like SeMet, where applying more Se did not result in higher SeMet yield. Moreover, the Se(VI) form displayed the highest SeMet yield in the 1st harvest, whereas the Se(IV) resulted in the highest SeMet during the 2nd and the 4th harvests in all the fractions.

The crude protein content of alfalfa LPC ranged between 40–60%, as reported earlier by several pieces of literature (European Food Safety Authority (EFSA), 2009; Domokos-Szabolcsy et al. 2020; El-Ramady et al. 2020). In the current study, high applied Se concentrations significantly reduced the crude protein content compared to the control (0Se). Similar results were reported for the fiber and phytoserum fractions. Concerning the crude protein content in the phytoserum, the measured values are mainly derived from oligopeptides, free amino acids, and biogenic amines. No real proteins could be detected (data not shown). Being the most readily absorbed Se form, Se(VI) can quickly reach toxic levels in the living organism. In addition, the decrease in the crude protein content might also be ascribed to the strong oxidative stress-inducing feature of Se(VI) in actively metabolizing cells (Ečimović et al. 2018).

In their study on the Se-tolerant Melilotus indica L. growing on Se-contaminated soil Guo and Wu (1998) cited no correlation between Se content and the amount of sulfur-containing and non-sulfur amino acids. Moreover, they reported SeMet as the most abundant free selenoamino acid. Yet, in the present study, SeMet was largely quantified in the enzymatic extract compared to the water extract, indicating that the SeMet was integrated into alfalfa proteins rather than being in the free form. The SeMet yield was about 2–5% of the methionine content in the LPC during the 1st harvest. For instance, the SeMet content was 247 and 158 mg kg−1 in the treatments of 10Se(VI) and 50Se(IV), respectively, during the 1st harvest, while the methionine content in the same treatments was 9000 and 2900 mg kg−1, respectively.

Among secondary metabolites, flavonoids are of importance because of their potential health benefits for humans and domestic animals. Indeed, flavonoids in the human diet are partially bioavailable and possibly involved in still incompletely understood mechanisms related to protection from chronic diseases such as cancers and cardiovascular diseases. Even though these mechanisms have still not been revealed entirely, most of them are related to some fundamental properties of flavonoids; for example, reducing capacity (antioxidant characteristics by electron or H-atom donation), capability to interact with proteins, and chelating effect (Heim et al. 2002, Andersen and Markham 2005).

The non-nutritional phytochemical composition is a relevant question from the point of view of experimental product development. Hence more attention has been paid to qualitative and quantitative analyses of phytochemicals of alfalfa green biomass-derived LPC, fiber, and phytoserum fractions, in the context of Se fortification. The results of the UHPLC-ESI–MS analysis revealed that flavonoids were the major identified organic phytochemicals. The absence of some expected bioactive compounds in some alfalfa fractions could be attributed to the strictness of the identification method. Identification of phytochemicals was acceptable if the retention time, molecular weight, and MS(n) fragment characteristics were all in agreement with the standard references.

Synthesis of flavonoids is primarily localized to the cytoplasmic surface of the endoplasmic reticulum (ER); however, chloroplasts have long been reported to be capable of flavonoid biosynthesis and accumulation. Also, the nuclear localization of some key enzymes of flavonol synthesis was confirmed. The transportation and accumulation of ER-derived flavonoids in vacuoles is a pivotal issue, as it is a pre-requisite for their biosynthesis, which can be altered by severe stress (Agati et al. 2012). Following our product-oriented process of alfalfa biomass, the flavonoids of phytoserum and LPC are derived from the released soluble part of disrupted vacuoles, cytoplasm, and chloroplasts. The third fraction is the fiber partly made up of the cell wall remnants of squeezed cells; the other route of flavonoids transport to the cell wall. Phenylpropanoids contribute to cell wall formation through esterification with complex carbohydrates.

The presence of glycosyl derivatives of flavonoids is frequent in plants. Twenty flavonoid glycosides were identified in the LPC, fiber, and phytoserum originating from Se-treated alfalfa fresh green biomass and control. Glucuronic acid is the only compound presented in a unbracnched or branched sugar chain of alfalfa flavonoids (Rafińska et al. 2017; Tava et al. 2022). However, our results showed different sugar chains that bind to aglycons, such as apigenin-8-C-glucoside-6-C-xyloside, apigenin-6-C-glucoside-8-C-xyloside, and quercetin-3.4'-di-O-glucoside in the fractionated alfalfa biomass. To our knowledge, it is the first time to detect apigenin-C-glucoside-C-xylosides in alfalfa biomass. Among the quantified flavonoids, apigenin-7-O-glucuronide and apigenin were the most abundant, followed by tricin (3'0.5'-Dimethoxy-4'0.5.7-trihydroxyflavone), in all three processed alfalfa fractions. Tricin and apigenin glycosides were previously quantified in high concentrations from alfalfa shoots by Rafińska et al. (2017). The acylated derivatives of ferulic acid, including apigenin-7-O-[feruloyl-(→ 2)-[glucuronyl-(1 → 3)]-glucuronyl-(1 → 2)]glucuronide, apigenin-4'-O-glucuronide-7-O-[feruloyl-(→ 2)-glucuronyl-(1 → 2)-glucuronide], and tricin-7-O-[feruloyl-(→ 2)-glucuronyl-(1 → 2)-glucuronide], were detected in alfalfa (Goławska and Łukasik 2012). The importance of flavone acylation, in the context of UVB, is due to shifting the absorption maxima with a simultaneous increase in the molar absorption coefficient protecting the cells against harmful UV effects (Rafińska et al. 2017). Alfalfa is well-known as a source of phytoestrogens, including isoflavones and coumestans. These compounds are of interest due to their ambiguous on animal health. Isoflavones in a feed show positive impacts on weight gain in lambs and milk production in cows (Rodrigues et al. 2014). On the other hand, the consumption of feed enriched with high concentrations of formononetin and coumestrol causes temporary or permanent reproductive problems in some ruminants, mainly sheep and cattle (Tucak et al. 2020). Similar to results reported by Tava et al. (2022), isoflavones formononetin (7-Hydroxy-4'-methoxyisoflavone) and its glycoside ononin (Formononetin 7-O-glucoside), alfalone (4'0.7-Dimethoxy-6-hydroxyisoflavone), and biochanin A (5,7-dihydroxy-4'-Methoxyisoflavone) were identified in all alfalfa fractions. Although Tucak et al. (2020) quantified 836.5 µg g−1 DW of genistein as the most abundant phytoestrogens in 20 observed alfalfa populations, in the present study, no genistein was detected in either control or Se-fortified alfalfa. Coumstrol, the phytoestrogen-like phytochemical belonging to the coumestans, was also identified in the LPC, fiber, and phytoserum fractions ranging between 0.27–7.81 µg g−1 DW. However, Martin et al. (2006) cited a higher concentration of coumestrol (99 µg g−1 DW) in alfalfa. Among saponins, medicagenic acid is the most abundant in alfalfa (Rafińska et al. 2017). In addition, the present phytochemical analysis revealed that among the saponins, medicagenic acid and its glycosyl derivatives were present in the largest number in both the control and Se-enriched alfalfa fractions. The glucose, xylose, rhamnose, glucuronic acid, and galactose were presented as sugar moieties of the side chains. Tava et al. (2022) reported that the sugar moieties link at the C-3 position of the triterpenic aglycone and, additionally, at the C-28 position in most cases. The concentration of medicagenic acid, which possessed hemolytic activity, did not exceed the 1.26 µg g−1 DW in the LPC and fiber fractions and 37.72 ng mL−1 in the phytoserum fraction. However, a higher concentration (550 µg g−1 DW) was reported by Rafińska et al. (2017). By contrast, no hederagenin or zahnic acid was detected in the alfalfa fractions, although the literature suggests them as the most abundant sapogenins after medicagenic acid. Soysapogenol B glycosyl derivative was also an identified saponin that did not show hemolytic activity. However, soyasapogenol presented at lower concentrations in the LPC fractions.

Conclusion

This study aimed to improve the quality of one of the most famous forage plants (alfalfa) through agronomic fortification using different Se forms and concentrations within four consecutive harvests. In the shadow of the circular economy concept, the Se-fortified alfalfa green biomass was fractionated into three fractions (LPC, fiber, and phytoserum) with added-economic value and possible direction toward the human and animal consumption.

We have drawn the following most important consequences from our extensive investigations: In the case of alfalfa, as a multi-harvest plant, red elemental selenium is more suitable for enrichment purposes than ionic forms, since a more balanced accumulation of selenium can be achieved with it during successive harvests in any processed fraction (LPC, fiber, phytoserum) under culture vessel conditions. Regarding the applied concentrations, treatment with 50 mg L−1 Se0 was found to be beneficial from the point of view of selenium enrichment, hence it caused a continuous, significant increase, without negatively affecting the distribution of alfalfa-based fractions and their dry matter content. Among the fractions, leaf protein concentrate (LPC) should be highlighted, as it is a fraction that can be used directly as an alternative protein feed. Treatment with 50 mg L−1 Se0 resulted in the conversion of 48.1–73.6% of the Se accumulated in the LPC to the organic form SeMet, which is important for the bioavailability of the animals. However, taking into account the hesitating results of the quantity of major and minor flavonoid components and the significant decreases in crude protein content it is recommended to investigate a wider range of red Se0 concentrations.

Along with, more investigations about the uptake mechanism, transportation, and transformation of red Se0, in addition to its building up in organic molecules, such as proteins and sugars, are required. Also, monitoring within a long-term investigation will be crucial to explain the uptake dynamics and explore the climatic effects. Lastly, studying the soil–plant-microbes interactions regarding the red Se0 will help understanding the positive influences of red Se0 on plant growth, agricultural products, and soil ecosystem.

Data Availability

All data generated or analysed during this study are included in this published article [and its supplementary information files]. However more detailed information corresponding to this current study are available from the corresponding author on reasonable request.

References

Agati G, Azzarello E, Pollastri S, Tattini M (2012) Flavonoids as antioxidants in plants: Location and functional significance. Plant Sci 196:67–76. https://doi.org/10.1016/j.plantsci.2012.07.014

Ait Sair A, Kansou K, Michaud F, Cathala B (2021) Multicriteria Definition of Small-Scale Biorefineries Based on a Statistical Classification. Sustainability 13:7310. https://doi.org/10.3390/su13137310

Andersen O.M., Markham, K.R. (Eds.), 2005. Flavonoids: Chemistry, Biochemistry and Applications, 0 ed. CRC Press. https://doi.org/10.1201/9781420039443

Asgharipour MR, Mousavinik SM, Enayat FF (2016) Evaluation of energy input and greenhouse gases emissions from alfalfa production in the Sistan region Iran. Energy Reports 2:135–140. https://doi.org/10.1016/j.egyr.2016.05.007

Bákonyi N, Kisvarga S, Barna DO, Tóth I, El-Ramady H, Abdalla N, Kovács S, Rozbach M, Fehér C, Elhawat N, Alshaal T, Fári MG, (2020) Chemical Traits of Fermented Alfalfa Brown Juice: Its Implications on Physiological, Biochemical, Anatomical, and Growth Parameters of Celosia. Agronomy 10, 247https://doi.org/10.3390/agronomy10020247

Barros J, Temple S, Dixon RA (2019) Development and commercialization of reduced lignin alfalfa. Current Opinion in Biotechnology, Food Biotechnology • Plant Biotechnology 56, 48–54. https://doi.org/10.1016/j.copbio.2018.09.003

Domokos-Szabolcsy É, Kovács Z, Kaszás L, Koroknai J, Fári M (2020) Green biomass of perennial crops as valuable source of protein and phytonutrients. Presented at the XVII. Nemzetközi Tudományos Napok : online konferencia, Eszterházy Károly Egyetem – Gyöngyösi Károly Róbert Campus

Ečimović S, Velki M, Vuković R, Štolfa Čamagajevac I, Petek A, Bošnjaković R, Grgić M, Engelmann P, Bodó K, Filipović-Marijić V, Ivanković D, Erk M, Mijošek T, Lončarić Z (2018) Acute toxicity of selenate and selenite and their impacts on oxidative status, efflux pump activity, cellular and genetic parameters in earthworm Eisenia andrei. Chemosphere 212:307–318. https://doi.org/10.1016/j.chemosphere.2018.08.095

El-Ramady H, Abdalla N, Kovacs S, Domokos-Szabolcsy E, Bákonyi N, Fari M, Geilfus C-M (2020) Sustainable Biorefinery and Production of Alfalfa (Medicago sativa L.). Egypt. J Bot. 0, 0–0. https://doi.org/10.21608/ejbo.2020.37749.1532

European Food Safety Authority (EFSA), 2009. Opinion on the safety of ‘Alfalfa protein concentrate’ as food. EFS2 7. https://doi.org/10.2903/j.efsa.2009.997

Fári MG, Domokos-Szabolcsy É (2018) Növényifehérje-koagulum előállítására szolgáló eljárás. Method for Producing Plant Protein Coagulum Hungarian Patent P1800041/40

Fathollahi H, Mousavi-Avval SH, Akram A, Rafiee S (2018) Comparative energy, economic and environmental analyses of forage production systems for dairy farming. J Clean Prod 182:852–862. https://doi.org/10.1016/j.jclepro.2018.02.073

Goławska S, Łukasik I (2012) Antifeedant activity of luteolin and genistein against the pea aphid, Acyrthosiphon pisum. J Pest Sci 85:443–450. https://doi.org/10.1007/s10340-012-0452-z

Groth S, Budke C, Neugart S, Ackermann S, Kappenstein F-S, Daum D, Rohn S (2020) Influence of a Selenium Biofortification on Antioxidant Properties and Phenolic Compounds of Apples (Malus domestica). Antioxidants 9:187. https://doi.org/10.3390/antiox9020187

Guo X, Wu L (1998) Distribution of Free Seleno-amino Acids in Plant Tissue ofMelilotus indicaL. Grown in Selenium-Laden Soils. Ecotoxicol Environ Saf 39:207–214. https://doi.org/10.1006/eesa.1997.1628

Heim KE, Tagliaferro AR, Bobilya DJ (2002) Flavonoid antioxidants: chemistry, metabolism and structure-activity relationships. J Nutr Biochem 13:572–584. https://doi.org/10.1016/S0955-2863(02)00208-5

Kamm B, Schönicke P, Hille Ch (2016) Green biorefinery – Industrial implementation. Food Chem 197:1341–1345. https://doi.org/10.1016/j.foodchem.2015.11.088

Kaszás L, Alshaal T, El-Ramady H, Kovács Z, Koroknai J, Elhawat N, Nagy É, Cziáky Z, Fári M, Domokos-Szabolcsy É (2020) Identification of Bioactive Phytochemicals in Leaf Protein Concentrate of Jerusalem Artichoke (Helianthus tuberosus L.). Plants 9, 889. https://doi.org/10.3390/plants9070889

Kovács Z, Soós Á, Kovács B, Kaszás L, Elhawat N, Bákonyi N, Razem M, Fári MG, Prokisch J, Domokos-Szabolcsy É, Alshaal T (2021) Uptake Dynamics of Ionic and Elemental Selenium Forms and Their Metabolism in Multiple-Harvested Alfalfa (Medicago sativa L.). Plants 10, 1277. https://doi.org/10.3390/plants10071277

Malagoli M, Schiavon M, dall’Acqua S, Pilon-Smits EAH (2015) Effects of selenium biofortification on crop nutritional quality. Front. Plant Sci. 6. https://doi.org/10.3389/fpls.2015.00280

Martin LM, Castilho MC, Silveira MI, Abreu JM (2006) Liquid Chromatographic Validation of a Quantitation Method for Phytoestrogens, Biochanin-A, Coumestrol, Daidzein, Formononetin, and Genistein, in Lucerne. J Liq Chromatogr Relat Technol 29:2875–2884. https://doi.org/10.1080/10826070600961076

Martínez-González MA, Sánchez-Villegas A (2016) Food patterns and the prevention of depression. Proc Nutr Soc 75:139–146. https://doi.org/10.1017/S0029665116000045

Melinda Tamás, Zsolt Mándoki, Melinda Márton, Sándor Mészáros, Szabolcs Lányi, János Csapó (2010) Correlations study between the selenium content of wheat grass (Triticum aestivum L.) and wheat seeds grown on different soil types. Acta agrar. Debr. 117–121. https://doi.org/10.34101/actaagrar/41/2691

Mielmann A (2013) The utilisation of lucerne ( Medicago sativa ): a review. British Food Journal 115:590–600. https://doi.org/10.1108/00070701311317865

Motesharezadeh B, Ghorbani S, Alikhani HA (2020) The effect of selenium biofortification in alfalfa ( Medicago sativa ). J Plant Nutr 43:240–250. https://doi.org/10.1080/01904167.2019.1676900

Pecoraro BM, Leal DF, Frias-De-Diego A, Browning M, Odle J, Crisci E (2022) The health benefits of selenium in food animals: a review. J Animal Sci Biotechnol 13:58. https://doi.org/10.1186/s40104-022-00706-2

Peng Q, Zhang Z, Su R, Zhang X, Lambers H, He H (2021) Phosphorus and selenium uptake, root morphology, and carboxylates in the rhizosheath of alfalfa (Medicago sativa) as affected by localised phosphate and selenite supply in a split-root system. Functional Plant Biol 48:1161. https://doi.org/10.1071/FP21031

Petković K, Manojlović M, Lombnæs P, Čabilovski R, Krstić Đ, Lončarić Z, Lombnæs P (2019) FOLIAR APPLICATION OF SELENIUM, ZINC AND COPPER IN ALFALFA (Medicago sativa L.) BIOFORTIFICATION. Turkish J Field Crops 81–90. https://doi.org/10.17557/tjfc.569363

Pietrzak K, G.E., (2014) Production Technology, Chemical Composition and Use of Alfalfa Protein-Xanthophyll Concentrate as Dietary Supplement. J Food Process Technol 5. https://doi.org/10.4172/2157-7110.1000373

Popp J, Kovács S, Oláh J, Divéki Z, Balázs E (2021) Bioeconomy: Biomass and biomass-based energy supply and demand. New Biotechnol 60:76–84. https://doi.org/10.1016/j.nbt.2020.10.004

Popp J, Szakály Z, Polereczki Z, Oláh J (2016) Substitution of soybean with alternative sources of protein for feed in the EU. Hungarian Agric Res 25:4–9

Rafińska K, Pomastowski P, Wrona O, Górecki R, Buszewski B (2017) Medicago sativa as a source of secondary metabolites for agriculture and pharmaceutical industry. Phytochem Lett 20:520–539. https://doi.org/10.1016/j.phytol.2016.12.006

Rodrigues F, Almeida I, Sarmento B, Amaral MH, Oliveira MBPP (2014) Study of the isoflavone content of different extracts of Medicago spp. as potential active ingredient. Ind Crops Prod 57:110–115. https://doi.org/10.1016/j.indcrop.2014.03.014

Ros GH, van Rotterdam AMD, Bussink DW, Bindraban PS (2016) Selenium fertilization strategies for bio-fortification of food: an agro-ecosystem approach. Plant Soil 404:99–112. https://doi.org/10.1007/s11104-016-2830-4

Schiavon M, dall’Acqua S, Mietto A, Pilon-Smits EAH, Sambo P, Masi A, Malagoli M (2013) Selenium Fertilization Alters the Chemical Composition and Antioxidant Constituents of Tomato (Solanum lycopersicon L.). J Agric Food Chem. 61, 10542–10554https://doi.org/10.1021/jf4031822

Shalaby T, Bayoumi Y, Alshaal T, Elhawat N, Sztrik A, El-Ramady H (2017) Selenium fortification induces growth, antioxidant activity, yield and nutritional quality of lettuce in salt-affected soil using foliar and soil applications. Plant Soil 421:245–258. https://doi.org/10.1007/s11104-017-3458-8

Takkellapati S, Li T, Gonzalez MA (2018) An overview of biorefinery-derived platform chemicals from a cellulose and hemicellulose biorefinery. Clean Techn Environ Policy 20:1615–1630. https://doi.org/10.1007/s10098-018-1568-5

Tava A, Biazzi E, Ronga D, Pecetti L, Avato P (2022) Biologically active compounds from forage plants. Phytochem Rev 21:471–501. https://doi.org/10.1007/s11101-021-09779-9

Tucak M, Čupić T, Horvat D, Popović S, Krizmanić G, Ravlić M (2020) Variation of Phytoestrogen Content and Major Agronomic Traits in Alfalfa (Medicago sativa L.) Populations. Agronomy 10, 87. https://doi.org/10.3390/agronomy10010087

Xie Z, Huang J, Xu X, Jin Z (2008) Antioxidant activity of peptides isolated from alfalfa leaf protein hydrolysate. Food Chem 111:370–376. https://doi.org/10.1016/j.foodchem.2008.03.078

Zhang X, He H, Xiang J, Yin H, Hou T (2020) Selenium-Containing Proteins/Peptides from Plants: A Review on the Structures and Functions. J Agric Food Chem 68:15061–15073. https://doi.org/10.1021/acs.jafc.0c05594

Zhou F, Peng Q, Wang M, Liu N, Dinh QT, Zhai H, Xue M, Liang D (2021) Influence of processing methods and exogenous selenium species on the content and in vitro bioaccessibility of selenium in Pleurotus eryngii. Food Chemistry 338, 127661. https://doi.org/10.1016/j.foodchem.2020.127661

Acknowledgements

This research has been implemented with the TKP2021-EGA-20 support provided from the National Research, Development and Innovation Fund of Hungary, financed under the TKP2021-EGA funding scheme.

The present work is also supported by the GINOP-2.2.1-15-2017-00051 project which is co-financed by the European Union and the European Regional Development Fund. Éva Domokos-Szabolcsy was supported by the János Bolyai Research Scholarship of the Hungarian Academy of Sciences. The authors would like to thank Mihály Dernovics for his help with the HPLC-ICP-MS measurements.

Funding

Open access funding provided by University of Debrecen.

This work was supported by TKP2020-IKA-04 program provided by the National Research, Development and Innovation Fund of Hungary under the 2020–4.1.1-TKP2020.

The authors have no relevant financial or non-financial interests to disclose.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Dr. Áron Soós, Dr. Béla R. Kovács, László Kaszás, Dr Nevien Elhawat, Mutasem Razem, Dr. Szilvia Veres, Dr. Miklós G. Fári, Judit Á. Koroknai, Dr. Tarek Alshaal and Dr. Éva Domokos-Szabolcsy. The first draft of the manuscript was written by Zoltán Kovács and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Corresponding author

Additional information

Responsible Editor: Yongchao Liang.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kovács, Z., Soós, Á., Kovács, B. et al. Nutrichemical alterations in different fractions of multiple-harvest alfalfa (Medicago sativa L.) green biomass fortified with various selenium forms. Plant Soil 487, 173–195 (2023). https://doi.org/10.1007/s11104-023-05917-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11104-023-05917-8