Abstract

Purpose

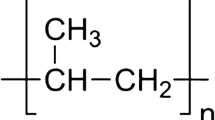

To analyze the influence of inherent densification and deformation properties of paracetamol on the mathematical parameters derived from Heckel, Walker, Kawakita, and Adams equations and to correlate these with single particle nominal fracture strength and bulk compression parameters using confined compression on a fully instrumented rotary tablet press.

Materials and Methods

Force–displacement data were captured during in-die compression for four different particle size fractions (150–250, 300–450, 500–650, and 700–1,000 μm) of paracetamol each at compression force of 5.2, 8.6, and 17.3 kN. Nominal single particle fracture strength was obtained by micro tensile testing.

Results

Apparent mean yield pressure (Py) from Heckel analysis was significantly affected by the applied pressure, and was influenced by elastic energy and Young’s modulus. The single particle fracture strength correlated to parameters obtained from Heckel, Walker, Kawakita, and Adams equations. Results obtained from bulk compression and single particle measurements were consistent with, and polynomially related to Py, Kawakita (1/b), and Adams parameter (τ 0′).

Conclusions

Values of Py, 1/b, and τ 0′ obtained from Heckel, Kawakita, and Adams equations, respectively, can be interpreted as a measure of single particle nominal fracture strength during confined compression loading. Walker and Adams parameters were less affected, than Heckel and Kawakita parameters, by the applied pressure.

Similar content being viewed by others

References

H. Rumpf. The strength of granules and agglomerates. In W. A. Knepper (ed.), Agglomeration, Interscience, London, 1962, pp. 379–418.

M. J. Adams, M. A. Mullier, and J. P. K. Seville. Agglomerate strength measurement using a uniaxial confined compression test. Powder Technol. 78:5–13 (1994).

E. E. Walker. The properties of powder. Part VI. The compressibility of powders. Trans. Faraday Soc. 19:73–82 (1923).

I. Shapiro. Ph.D. Thesis, University of Minnesota (1944).

R. W. Heckel. Density–pressure relationships in powder compaction. Trans. Metall. Soc. AIME 221:671–675 (1961).

R. W. Heckel. An analysis of powder compaction phenomena. Trans. Metall. Soc. AIME 221:1001–1008 (1961).

K. Kawakita and K. H. Lüdde. Some considerations on powder compression equations. Powder Technol. 4:61–68 (1971).

K. Kawakita, I. Hattori, and M. Kishigami. Characteristic constants in Kawakita’s powder compression equation. J. Powder Bulk Solids Technol. 1:3–8 (1977).

P. Paronen. Using Heckel equation in the compression studies of pharmaceuticals. In Proc. 4th Int. Conf. Pharmaceutical Technology, Paris 301–307 (1986).

R. J. Roberts and R. C. Rowe. The compaction of pharmaceutical and other model materials—a pragmatic approach. Chem. Eng. Sci. 42:903–911 (1987).

C. M. Gabaude, M. Guillot, J. C. Gautier, P. Saudemon, and D. Chulia. Effects of true density, compacted mass, compression speed, and punch deformation on the mean yield pressure. J. Pharm. Sci. 88:725–730 (1999).

J. M. Sonnergaard. Impact of particle density and initial volume on mathematical compression models. Eur. J. Pharm. Sci. 11:307–315 (2000).

J. M. Sonnergaard. A critical evaluation of the Heckel equation. Int. J. Pharm. 193:63–71 (1999).

A. Hassanpour and M. Ghadiri. Distinct element analysis and experimental evaluation of the Heckel analysis of bulk powder compression. Powder Technol. 141:251–261 (2004).

F. Nicklasson and G. Alderborn. Analysis of the compression mechanics of pharmaceutical agglomerates of different porosity and composition using the Adams and Kawakita equations. Pharm. Res. 17:949–954 (2000).

L. E. Holman. The compaction behavior of particulate materials. An elucidation based on percolation theory. Powder Technol. 66:265 (1991).

W. Chen and S. G. Malghan. Investigation of compaction equations for powders. Powder Technol. 81:75–81 (1994).

R. Panelli and A. Filho. A study of a new phenomenological compacting equation. Powder Technol. 114:255–261 (2001).

J. M. Sonnergaard. Investigation of a new mathematical model for compression of pharmaceutical powders. Eur. J. Pharm. Sci. 14:149–157 (2001).

K. M. Picker. A new theoretical model to characterize the densification behavior of tableting materials. Eur. J. Pharm. Biopharm. 49:267–273 (2000).

J. S. M. Garr and M. H. Rubinstein. An investigation into the capping of paracetamol at increasing speeds of compression. Int. J. Pharm. 72:117–122 (1991).

O. F. Akande, M. H. Rubinstein, P. H. Rowe, and J. L. Ford. Effect of compression speeds on the compaction properties of a 1:1 paracetamol–microcrystalline cellulose mixture prepared by single compression and by combinations of pre-compression and main-compression. Int. J. Pharm. 157:127–136 (1997).

E. Joiris, P. Di Martino, C. Berneron, A. M. Guyot-Hermann, and J. C. Guyot. Compression behavior of orthorhombic paracetamol. Pharm. Res. 15:1122–1130 (1998).

R. J. Oates and A. G. Mitchell. Calculation of punch displacement and work of powder compaction on a rotary tablet press. J. Pharm. Pharmacol. 41:517–523 (1989).

C. Matz, A. Bauer-Brandl, T. Rigassi, R. Schubert, and D. Becker. On the accuracy of a new displacement instrumentation for rotary tablet presses. Drug Dev. Ind. Pharm. 25:117–130 (1999).

M. Haisa, S. Kashino, R. Kawai, and H. Maeda. The monoclinic form of p-hydroxyacetanilide. Acta Crystallogr. B. 32:1283–1285 (1976).

P. Espeau, R. Ceolin, J. L. Tamarit, M. A. Perrin, J. P. Gauchi, and F. Leveiller. Polymorphism of paracetamol: relative stabilities of the monoclinic and orthorhombic phases inferred from topological pressure–temperature and temperature–volume phase diagrams. J. Pharm. Sci. 94:524–539 (2005).

N. A. Armstrong and R. F. Haines-Nutt. Elastic recovery and surface area changes in compacted powder systems. J. Pharm. Pharmacol. 24:135P–136P (1972).

O. Antikainen and J. Yliruusi. Determining the compression behavior of pharmaceutical powders from the force–distance compression profile. Int. J. Pharm. 252:253–261 (2003).

P. York. Particle slippage and rearrangement during compression of pharmaceutical powders. J. Pharm. Pharmacol. 30:6–10 (1978).

M. Duberg and C. Nystrom. Studies on direct compression of tablets XI. Evaluation of methods for the estimation of particle fragmentation during compaction. Acta Pharm. Suec. 19:421–436 (1982).

M. Duberg and C. Nystrom. Studies on direct compression of tablets XVII. Porosity–pressure curves for the characterization of volume reduction mechanism in powder compaction. Powder Technol. 46:67–75 (1986).

C. Sun and D. J. Grant. Influence of elastic deformation of particles on Heckel analysis. Pharm. Dev. Technol. 6:193–200 (2001).

J. E. Rees and K. D. Tsardaka. Some effects of moisture on the viscoelastic behavior of modified starch during powder compaction. Eur. J. Pharm. Biopharm. 40:193–197 (1994).

P. Konkel and J. B. Mielck. Associations of parameters characterizing the time course of the tableting process on a reciprocating and on a rotary tableting machine for high-speed production. Eur. J. Pharm. Biopharm. 45:137–148 (1998).

P. J. Denny. Compaction equations: a compression of the Heckel and Kawakita equations. Powder Technol. 127:162–172 (2002).

M. J. Adams and R. McKeown. Micromechanical analyses of the pressure–volume relationships for powders under confined uniaxial compression. Powder Technol. 88:155–163 (1996).

Acknowledgments

Authors wish to thank Arbro Pharmaceuticals Ltd., New Delhi, India for gift sample of paracetamol. Aditya M. Kaushal would like to acknowledge CSIR, India for providing senior research fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Patel, S., Kaushal, A.M. & Bansal, A.K. Effect of Particle Size and Compression Force on Compaction Behavior and Derived Mathematical Parameters of Compressibility. Pharm Res 24, 111–124 (2007). https://doi.org/10.1007/s11095-006-9129-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-006-9129-8