Purpose

Pharmaceutical tablets are generally produced by compacting a mixture of several ingredients, including active drugs and excipients. It is of practical importance if the properties of such tablets can be predicted on the basis of the ones for constituent components. The purpose of this work is to develop a theoretical model which can predict the tensile strength of compacted multi-component pharmaceutical mixtures.

Methods

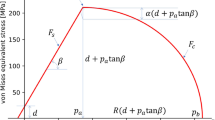

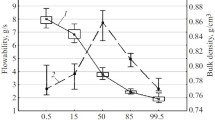

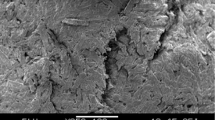

The model was derived on the basis of the Ryshkewitch‐Duckworth equation that was originally proposed for porous materials. The required input parameters for the model are the relative density or solid fraction (ratio of the volume of solid materials to the total volume of the tablets) of the multi-component tablets and parameters associated with the constituent single-component powders, which are readily accessible. The tensile strength of tablets made of various powder blends at different relative density was also measured using diametrical compression.

Results

It has been shown that the tensile strength of the multi-component powder compacts is primarily a function of the solid fraction. Excellent agreement between prediction and experimental data for tablets of binary, ternary and four-component blends of some widely used pharmaceutical excipients was obtained.

Conclusion

It has been demonstrated that the proposed model can well predict the tensile strength of multi-component pharmaceutical tablets. Thus, the model will be a useful design tool for formulation engineers in the pharmaceutical industry.

Similar content being viewed by others

References

C. Y. Wu, O. Ruddy, A. C. Bentham, B. C. Hancock, S. M. Best, and J. A. Elliott. Modelling the mechanical behaviour of pharmaceutical powders during compaction. Powder Technol. 152(1–3):107–117 (2005).

C. Y. Wu and A. C. F. Cocks. Flow behaviours of powders during die filling. Powder Metall. 47(2):127–136 (2004).

C. Y. Wu, L. Dihoru, and A. C. F. Cocks. The flow of powder into simple and stepped dies. Powder Technol. 134(1–2):24–39 (2003).

G. Alderborn and C. Nystrom. Pharmaceutical Powder Compaction Technology, Marcel Dekker Inc., New York, 1996.

B. C. Hancock, J. T. Colvin, M. P. Mullarney, and A. V. Zinchuk. The relative densities of pharmaceutical powders, blends, dry granulations, and immediate-release tablets. Pharm. Technol. 27:64–80 (2003).

J. T. Fell and J. M. Newton. Determination of tablet strength by the diametrical compression test. J. Pharm. Sci. 59:688–691 (1970).

H. Vromans, A. H. De Boer, G. K. Bolhuis, C. F. Lerk, K. D. Kussendrager, and H. Bosch. Studies on tableting properties of lactose. 2. Consolidation and compaction of different types of crystalline lactose. Pharm. Weekbl., Sci. Ed. 7(5):186–193 (1985).

A. H. De Boer, H. Vromans, C. F. Lerk, G. K. Bolhuis, K. D. Kussendrager, and H. Bosch. Studies on tableting properties of lactose. 3. The consolidation behavior of sieve fractions of crystalline alpha-lactose monohydrate. Pharm. Weekbl., Sci. Ed. 8(2):145–150 (1986).

M. Eriksson and G. Alderborn. The effect of original particle size and tablet porosity on the increase in tensile strength during storage of sodium chloride tablets in a dry atmosphere. Int. J. Pharm. 113(2):199–207 (1995).

H. Olsson and C. Nystrom. Assessing tablet bond types from structural features that affect tablet tensile strength. Pharm. Res. 18(2):203–210 (2001).

T. Sebhatu and G. Alderborn. Relationships between the effective interparticulate contact area and the tensile strength of tablets of amorphous and crystalline lactose of varying particle size. Eur. J. Pharm. Sci. 8:235–242 (1999).

L. W. Wong and N. Pilpel. Effect of particle shape on the mixing of powders. J. Pharm. Pharmacol. 42:1–6 (1990).

D. Poquillon, V. Baco-Carles, Tailhades, and E. Andrieu. Cold compaction of iron powders—relations between powder morphology and mechanical properties. Part II. Bending tests: results and analysis. Powder Technol. 126(1):75–84 (2002).

C. K. Tye, C. Sun, and G. E. Amindon. Evaluation of the effects of tabletting speed on the relationships between compaction pressure, tablet tensile strength, and tablet solid fraction. J. Pharm. Sci. 94(3)465–472 (2005).

C. Y. Wu, S. M. Best, A. C. Bentham, B. C. Hancock, and W. Bonfield. A simple predictive model for the tensile strength of binary tablets. Eur. J. Pharm. Sci. 25:331–336 (2005).

J. T. Fell and J. M. Newton. The prediction of tensile strength of tablets. J. Pharm. Pharmacol. 22:247–248 (1970).

K. A. Riepma, C. F. Lerk, A. H. De Boer, G. K. Bolhuis, and K. D. Kussendrager. Consolidation and compaction of powder mixtures. 1. Binary-mixtures of same particle-size fractions of different types of crystalline lactose. Int. J. Pharm. 66(1–3):47–52 (1990).

K. A. Riepma, J. Veenstra, A. H. De Boer, G. K. Bolhuis, K. Zuurman, C. F. Lerk, and H. Vromans. Consolidation and compaction of powder mixtures. 2. Binary-mixtures of different particle-size fractions of α-lactose monohydrate. Int. J. Pharm. 76(1–2):9–15 (1991).

W. E. Jetzer. Compaction characteristics of binary-mixtures. Int. J. Pharm. 31(3):201–207 (1986).

H. Leuenberger. The compressibility and compactibility of powder systems. Int. J. Pharm. 12(1):41–55 (1982).

D. C.-H. Cheng. The tensile strength of powders. Chem. Eng. Sci. 23:1405–1420 (1968).

S. Y. Chan, N. Pilpel, and D. C.-H. Cheng. The tensile strengths of single powders and binary mixtures. Powder Technol. 34:173–189 (1983).

M. Kuentz and H. Leuenberger. A new theoretical approach to tablet strength of a binary mixture consisting of a well and a poorly compactable substance. Eur. J. Pharm. Biopharm. 49:151–159 (2000).

N. Ramírez, L. M. Melgoza, M. Kuentz, H. Sandoval, and I. Caraballo. Comparison of different mathematical models for the tensile strength-relative density profiles of binary tablets. Eur. J. Pharm. Sci. 22:19–23 (2004).

E. Ryshkewitch. Compression strength of porous sintered alumina and zirconia. J. Am. Ceram. Soc. 36:65–68 (1953).

W. Duckworth. Discussion of ryshkewitch paper. J. Am. Ceram. Soc. 36:68 (1953).

R. Steendam and C. F. Lerk. Poly(dl-lactic acid) as a direct compression excipient in controlled release tablets. Part I. Compaction behaviour and release characteristics of poly(dl-lactic acid) matrix tablets. Int. J. Pharm. 175:33–46 (1998).

J. E. Barralet, T. Gaunt, A. J. Wright, I. R. Gibson, and J. C. Knowles. Effect of porosity reduction by compaction on compressive strength and microstructure of calcium phosphate cement. J. Biomed. Materi. Res. 63:1–9 (2002).

U. Gbureck, O. Grolms, J. E. Barralet, L. M. Grover, and R. Thull. Mechanical activation and cement formation of β-tricalcium phosphate. Biomaterials 24:4123–4131 (2003).

H. S. Shin, S. K. Lee, and B. K. Lee. Aggregate and necking force in Mn–Zn ferrite. Mater. Lett. 57:1467–1470 (2003).

H. Vromans, G. K. Bolhuis, C. F. Lerk, and K. D. Kussendrager. Studies of tabletting properties of lactose. 9. The relationship between particle structure and compactibility of crystalline lactose. Int. J. Pharm. 39(3):207–212 (1987).

I. H. Moon and J. S. Choi. Dependence of green strength on contact area between powder particles for spherical copper-powder compacts. Powder Metall. 28(1):21–26 (1985).

Acknowledgments

This work is supported by Pfizer Global Research and Development. We thank Dr. C.K. Tye for kindly providing the experimental data published in (14).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, CY., Best, S.M., Bentham, A.C. et al. Predicting the Tensile Strength of Compacted Multi-Component Mixtures of Pharmaceutical Powders. Pharm Res 23, 1898–1905 (2006). https://doi.org/10.1007/s11095-006-9005-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-006-9005-6