Abstract

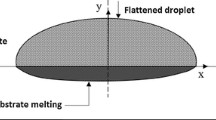

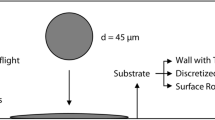

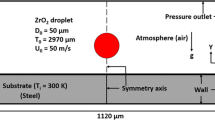

The fluid–solid coupling model is developed to simulate substrate melting and deformation during molten droplet impact. In this model, the liquid and solid parts of splat and substrate are governed by the SPH formulations of the Navier–Stokes equations and the conservation equations of continuum mechanics, respectively. This is the first time that the fluid–solid coupling by the SPH method is applied to simulation of the interaction between droplet and substrate during thermal spray coating. The simulation results on formation of the crater are presented to study the Ni droplet impacting onto the Sn substrate, and Mo droplet impacting onto the Steel, Al, and Brass substrates, respectively. It is found that the initial temperatures and thermal properties of droplet and substrate have great effects on the substrate melting and the morphologies of the splat and the substrate.

Similar content being viewed by others

Abbreviations

- c p :

-

Specific heat (J/kg K)

- d :

-

Droplet diameter (m)

- D :

-

Parameter in the form of the repulsive force

- f :

-

Force (N)

- g :

-

Gravity force (N)

- G :

-

Shear modulus (Pa)

- h :

-

Smoothing length (m)

- I :

-

Unit tensor

- J 0 :

-

Yield stress (Pa)

- Ja :

-

Jakob number (= c pl (T m −T B )/L f )

- k :

-

Thermal conductivity (W/m K)

- K :

-

Permeability (m2)

- L :

-

Latent heat (J/kg)

- m :

-

Particle mass (kg)

- p :

-

Pressure (Pa)

- R :

-

Rotaotion rate tensor

- Re:

-

Reynolds number (= ρVd/μ)

- t :

-

Time (s)

- T :

-

Temperature (K)

- u :

-

Internal energy (J/kg)

- U :

-

Velocity (m/s)

- \( \vec{v} \) :

-

Particle velocity vector (m/s)

- W :

-

Smoothing function (m−3)

- r :

-

Particle position (m)

- δ :

-

Dirac notation

- ε :

-

Strain rate tensor

- μ :

-

Viscosity coefficient (kg/m s)

- ρ :

-

Particle density (kg/m3)

- τ :

-

Viscous stress tensor, deviatoric stress tensor

- ∇ :

-

Gradient operator

- α, β :

-

Coordinate direction

- i,j :

-

Particle index

- m:

-

Melting

- l :

-

Liquid

- s :

-

Solid

References

Heimann RB (1996) Plasma-spray coating. VCH

Armster SQ (2002) Thermo-fluid mechanisms controlling droplet based materials processes. Int Mater Rev 47(4):169–190

Escure C, Vardelle M, Fauchais P (2003) Experimental and theoretical study of the impact of alumina droplets on cold and hot substrates. Plasma Chem Plasma Process 23(2):185–221

Mundo C, Sommerfeld M, Tropea C (1995) Droplet-wall collisions—experimental studies of the deformation and breakup process. Int J Multiph Flow 21(2):151–173

Stow CD, Hadfield MG (1981) An experimental investigation of fluid-flow resulting from the impact of a water drop with an unyielding dry surface. Proc Royal Soc Lond Ser A-Math Phys Eng Sci 373(1755):419–441

Zhang MY, Zhang H, Zheng LL (2007) Application of smoothed particle hydrodynamics method on free surface and solidification problems. Numer Heat Transf, Part A: Appl 52(4):299–314

Zhang MY, Zhang H, Zheng LL (2008) Simulation of droplet spreading, splashing and solidification using smoothed particle hydrodynamics method. Int J Heat Mass Transf 51:3410–3419

Sun DW, Xu J, Zhang H, Wan YP, Prasad V, Wang GX (2000) Effect of contact resistance and substrate melting on thermal spray coating. thermal spray: surface engineering via applied research. ASM International, Materials Park

Xu L, Zhang WW, Nagel SR (2005) Drop splashing on a dry smooth surface. Phys Rev Lett 94:18

Zhang H (1999) Theoretical analysis of spreading and solidification of molten droplet during thermal spray deposition. Int J Heat Mass Transf 42(14):2499–2508

Bussmann M, Mostaghimi J, Chandra S (1999) On a three-dimensional volume tracking model of droplet impact. Phys Fluids 11(6):1406–1417

Bussmann M, Chandra S, Mostaghimi J (2000) Modeling the splash of a droplet impacting a solid surface. Phys Fluids 12(12):3121–3132

Pasandideh-Fard M, Chandra S, Mostaghimi J (2002) A three-dimensional model of droplet impact and solidification. Int J Heat Mass Transf 45(11):2229–2242

Mostaghimi J, Pasandideh-Fard M, Chandra S (2002) Dynamics of splat formation in plasma spray coating process. Plasma Chem Plasma Process 22(1):59–84

Jiang XY, Wan YP, Wang XY, Zhang H, Goswami R, Herman H, Sampath S (2000) Investigation of splat/substrate contact during Molybdenum thermal spraying. Thermal spray: surface engineering via applied research, ASM International. Berndt, C. C. Materials Park, 729–36

Wang SP, Wang GX, Matthys EF (1999) Deposition of a molten layer of high melting point material: substrate melting and solidification. Mater Sci Eng A 262:25–32

Zhang H, Wang XY, Zheng LL, Jiang XY (2001) Studies of splat morphology and rapid solidification during thermal spraying. Int J Heat Mass Transf 44(24):4579–4592

Li L, Wang XY, Wei G, Vaiday A, Zhang H, Sampath S (2004) Substrate melting during thermal spray splat quenching. Thin Solid Films 468:113–119

Nugent S, Posch HA (2000) Liquid drops and surface tension with smoothed particle applied mechanics. Phys Rev E 62(4):4968–4975

Cleary PW, Monaghan JJ (1999) Conduction modelling using smoothed particle hydrodynamics. J Comput Phys 148(1):227–264

Liu GR, Liu MB (2003) Smoothed particle hydrodynamics—A Meshfree Particle Method. World Scientific

Cleary PW, Prakash M, Ha J (2006) Novel applications of smoothed particle hydrodynamics (SPH) in metal forming. J Mater Process Technol 177:41–48

Monaghan JJ (1994) Simulating free surface flows with SPH. J Comput Phys 110(2):399–406

Acknowledgment

The first author acknowledges the support from National Natural Science Foundation of China (Grant No. 10742002 and 10802011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, M., Zhang, H. & Zheng, L. Numerical Investigation of Substrate Melting and Deformation During Thermal Spray Coating by SPH Method. Plasma Chem Plasma Process 29, 55–68 (2009). https://doi.org/10.1007/s11090-008-9158-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-008-9158-7