Abstract

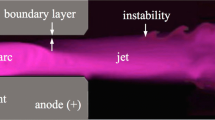

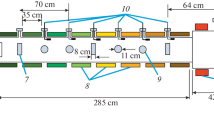

The behavior of plasma flow, generated by a D.C. plasma spraying gun, is simulated in a time-dependent 3 D. design. The high-temperature and high-velocity plasma plume is generated by a simple model based on Joule effect. The criterion of validation is the thermal efficiency while the only adjustment parameter is the length of the plasma column inside the anode. The transient plasma flow issuing in air atmosphere is reproduced. The plasma behavior is quite similar to that observed by fast-image video. Moreover, the centerline plasma plume properties are in agreement with experiment measurements, especially close to the torch exit and downstream the laminar-to-turbulent transition.

Similar content being viewed by others

Abbreviations

- S ef :

-

Thermal source by Joule effect (W)

- Q conv :

-

Losses by convection (W)

- \( \ifmmode\expandafter\vec\else\expandafter\vec\fi{u} \) :

-

Velocity vector (m/s)

- E:

-

Global energy (W)

- k:

-

Thermal conductivity (W/m K)

- \( \ifmmode\expandafter\vec\else\expandafter\vec\fi{J}_{j} \) :

-

Diffusion flux of the j specie (kg/m2 s)

- ε:

-

Turbulent dissipation rate (m2/s3)

- u i :

-

Velocity component along direction i (m/s)

- G k :

-

Turbulent kinetic energy production source term

- Prt :

-

Turbulent PRANDTL number

- C1ε :

-

Constant for k–ε model

- σ k :

-

Turbulent PRANDTL number for k

- Cμ :

-

Constant for k–ε model

- μ:

-

Dynamic viscosity (kg/m s)

- U:

-

Average arc voltage (V)

- L m :

-

Average plasma column length (m)

- V1 :

-

First heating zone volume (m3)

- P1 :

-

Electrical power generated in V1 volume (W)

- l1 :

-

Constant length of the heating zone V1 (m)

- γ:

-

Rotating angle of the V2 area (degree)

- f :

-

Frequency of the arc voltage fluctuation (hz)

- lmin :

-

Shortest global heating zone length (m)

- p :

-

Pressure (Pa)

- Q rad :

-

Losses by radiation (W)

- ρ:

-

Density (kg/m3)

- T :

-

Temperature (K)

- h j :

-

Specific enthalpy of the j specie (J/kg)

- \( \overline{\overline \tau } _{{eff}} \cdot \ifmmode\expandafter\vec\else\expandafter\vec\fi{u} \) :

-

Viscous dissipation term (W/m2)

- κ:

-

Turbulent kinetic energy (m2/s3)

- g i :

-

Gravitation vector component along the i direction

- G b :

-

Turbulence production rate due to natural convection

- β :

-

Volume dilatation coefficient (1/K)

- C 2ε :

-

Constant for k-ε model

- σ ε :

-

PRANDTL turbulent number for ε

- μt :

-

Turbulent viscosity (kg/m s)

- Pm :

-

Average input power (W)

- I:

-

Arc current intensity (A)

- η :

-

Thermal efficiency rate (%)

- V2 :

-

Second heating zone volume (m3)

- P2 :

-

Electrical power generated in V2 volume (W)

- l2(t):

-

Time-dependent length of the heating zone V2 (m)

- V(t):

-

Time-dependent arc voltage (V)

- α :

-

Constant angle of the truncated cornet of the V2 area (degree)

- lmax :

-

Longest global heating zone length (m)

References

Wutzke SA, Pfender E, Eckert ERG (1967) Study of electric arc behaviour with superimposed flow. AIAA J 5:707–714

Janisson S, Vardelle A, Coudert JF, Fauchais P, Meillot E (1999) Analysis of the stability of DC plasma gun operating with Ar–He–H2 gas mixtures. Ann NY Acad Sci 891:407–416

Duan Z, Heberlein J (2002) Arc instabilities in a plasma spray torch. J Thermal Spray Technol 11(1):44–57

Baudry C, Vardelle A, Mariaux G, Delalondre C, Meillot E (2004) Three-dimensional and time-dependent model of the dynamic behaviour of the arc in a plasma spray torch. Proceedings of international thermal spray conference 2004, Osaka, Japan. German Welding Society Editor, Full DVD, reference 036.pdf

Colombo V, Ghedini E (2005) Time dependent 3-D simulation of a DC non-transferred arc plasma torch: anode attachment and downstream region effects. Proceedings of International Symposium on Plasma Chemistry, Toronto, Canada, University of Toronto Editor, Full DVD, reference ID229.pdf

Hang P, Chen X (2001) Modelling of the subsonic or supersonic flow and heat transfer in a D.C. Arc Plasma Torch, 0272-4324/01/0600-0249, Ed. Plenum Publishing Corp

Eichert P, Imbert M, Coddet C (1998) Numerical study of an Ar/H2 gas mixture flowing inside and outside a D.C. plasma torch. J Thermal Spray Technol 7(4):505–512

Remesh K, Yu SCM, Ng HW, Berndt CC (2003) Computational study and experimental comparison of the in-flight particle behaviour for an external injection plasma spray process. J Thermal Spray Technol 12(4):508–522

Mariaux G, Vardelle A (2005) 3-D time-dependent modelling of the plasma spray process. Part 1: flow modelling. Int J Thermal Sci 44:357–366

Fluent user’s manual, http://www.fluentusers.com, Version 6.2, 2005-06-01

Bolot R, Li J, Coddet C (2005) Some key advices for the modelling of plasma jets using FLUENT, Proceedings of International Thermal Spray Conference 2005, Basel, Switzerland, Editor E. Lugscheider, Full DVD, paper n° 1367

Wilke CR (1950) A viscosity equation for a gas mixture. J Chem Phys 18(4):517–519

Mason EA, Saxena SC (1958) Approximate formula for the thermal conductivity of gas mixture. Phys Fluid 1(5):361–369

Boulos M, Fauchais P, Pfender E (1995) Thermal plasmas fundamentals and applications, Vol. 1, Ed. Plenum Press, New York

Westhoff R, Dilawari AH, Szekely J (1991) A mathematical representation of transport phenomena inside a plasma Torch, Mat. Res. Soc. Symp. Proc., Vol. 190, Mater Res Soc

Spores R, Pfender E (1989) Flow structure of a Turbulent Thermal Plasma Jet. Surf Coat Technol 37(3):251–432

Morsi SA, Alexander AJ (1972) An investigation of particle trajectories in two-phase flow systems. J Fluid Mech 55:193–208

Kang CW, Ng HW, Yu SCM (2006) Comparative study of plasma spray flow fields and particle behaviour near to flat inclined substrates. Plasma Chem Plasma Process 26:149–175

Naghizadeh-Kashani Y, Cressault Y, Gleizes A (2002) Net emission coefficient of air thermal plasmas. J Phys D: Appl Phys 35:2925–2934

Fauchais P (2004) Understanding plasma spraying. J Phys D: Appl Phys 37:R86–R108

Coudert JF, Planche MP, Fauchais P (1996) Characterization of D.C. plasma torch voltage fluctuations. Plasma Chem Plasma Process 16(1 Suppl):2115–2275

Planche MP (1995) Experimental study of fluctuating plasma jets, Ph.D. Thesis University of Limoges, France

Betoule O (1994) Relationships between the distributions of particle velocity and temperature and coating properties, Ph.D. Thesis, University of Limoges, France

Balmigere G, Vincent S, Meillot E, Caltagirone JP, Simulation numérique de l’interaction entre un jet plasma et un jet aqueux., Proceedings of Société Française de Physique Congress, Hyeres, France, May 2007

Meillot E, Guenadou D (2004) Thermal plasma flow modeling: a simple model for gas heating and acceleration. Plasma Chem Plasma Process 24:2

Meillot E, Guenadou D, Bourgeois C (2006) Effect of time-dependent D.C. plasma flow on particle treatment. In: Fauchais P, Amouroux J (eds) Proceedings of HTPP 9, St Petersburg, Russia, Journal of High Temp Mater Process, May10, 2006

Meillot E, Guenadou D, Saget A (2005) Time-dependent D.C. plasma flow modelling, Proceedings of International Symposium on Plasma Chemistry, Toronto, Canada, University of Toronto Editor, Full DVD, ID221.pdf

Lagnoux O (1999) Study of particle oxidation under plasma spraying conditions, Ph.D. Thesis, University of Limoges, France

Guenadou D, Meillot E, Saget A, Particle treatment modelling in a time-dependent D.C. plasma flow, Proceedings of International Thermal Spray Conference 2005, Thermal Spray Connects: Explore its surface potentials. Ed. E. LUGSCHEIDER, May 2nd-5th, 2005, BASEL, SWITZERLAND

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meillot, E., Guenadou, D. & Bourgeois, C. Three-Dimension and Transient D.C. Plasma Flow Modeling. Plasma Chem Plasma Process 28, 69–84 (2008). https://doi.org/10.1007/s11090-007-9108-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-007-9108-9