Abstract

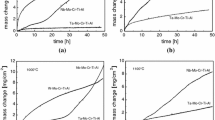

Refractory high-entropy alloys (RHEA) are considered as potential candidates for new-generation energy-related high-temperature applications. However, the poor high-temperature oxidation resistance of RHEAs, resulting in phenomena such as significant weight gain, scale spallation, pesting, and even complete oxidation, limits their applications. In this study, the oxidation behavior of AlxHfNbTiVY0.05 (x = 0.75; 1; 1.25) high-entropy alloys was investigated at 700–900 °C. The isothermal oxidation tests showed that the oxidation resistance of AlxHfNbTiVY0.05 RHEA is strongly influenced by temperature and time. In addition, accelerated oxidation, known as pesting, was observed to occur at 700 °C for all alloys; while, partial spallation was observed at 800 °C for the Al1 and Al1.25 alloys. Detailed analyses of oxidation kinetics have been carried out for the oxidation test series at 900 °C. The mechanism behind disintegration was investigated and attributed to accelerated internal oxidation followed by the formation of voluminous Nb2O5, TiNb2O7, and fast-growing AlNbO4, and is also thought to be related to the partial evaporation of V2O5.

Similar content being viewed by others

References

O. N. Senkov, S. V. Senkova, D. M. Dimiduk, C. Woodward, and D. B. Miracle, Journal of Materials Science 47, 6522 (2012). https://doi.org/10.1007/s10853-012-6582-0.

T. M. Pollock and S. Tin, Journal of Propulsion and Power 22, 361 (2006). https://doi.org/10.2514/1.18239.

Y. Yan, K. A. McGarrity, D. J. Delia, C. Fekety, and K. Wang, Corrosion Science 204, 110377 (2022). https://doi.org/10.1016/j.corsci.2022.110377.

R. A. MacKay, T. P. Gabb, J. L. Smialek, and M. V. Nathal, Alloy Design Challenge : Development of Low Density Superalloys for Turbine Blade Applications. (NASA TM 2009-215819, 2009), p. 1.

J. W. Yeh, S. K. Chen, S. J. Lin, J. Y. Gan, T. S. Chin, T. T. Shun, et al., Advanced Engineering Materials 6, 299 (2004). https://doi.org/10.1002/adem.200300567.

B. Cantor, I. T. H. Chang, P. Knight, and A. J. B. Vincent, Materials Science and Engineering A 375–377, 213 (2004). https://doi.org/10.1016/j.msea.2003.10.257.

O. N. Senkov, G. B. Wilks, J. M. Scott, and D. B. Miracle, Intermetallics 19, 698 (2011). https://doi.org/10.1016/j.intermet.2011.01.004.

O. N. Senkov, J. M. Scott, S. V. Senkova, D. B. Miracle, and C. F. Woodward, Journal of Alloys and Compounds 509, 6043 (2011). https://doi.org/10.1016/j.jallcom.2011.02.171.

O. N. Senkov, G. B. Wilks, D. B. Miracle, C. P. Chuang, and P. K. Liaw, Intermetallics 18, 1758 (2010). https://doi.org/10.1016/j.intermet.2010.05.014.

O. N. Senkov and C. F. Woodward, Materials Science and Engineering A 529, 311 (2011). https://doi.org/10.1016/j.msea.2011.09.033.

O. N. Senkov, S. V. Senkova, D. B. Miracle, and C. Woodward, Materials Science and Engineering A 565, 51 (2013). https://doi.org/10.1016/j.msea.2012.12.018.

Z. Lei, X. Liu, Y. Wu, H. Wang, S. Jiang, S. Wang, et al., Nature 563, 546 (2018). https://doi.org/10.1038/s41586-018-0685-y.

S. Wei, S. J. Kim, J. Kang, Y. Zhang, Y. Zhang, T. Furuhara, et al., Nature Materials 19, 1175 (2020). https://doi.org/10.1038/s41563-020-0750-4.

B. Gorr, S. Schellert, F. Müller, H. J. Christ, A. Kauffmann, and M. Heilmaier, Advanced Engineering Materials (2021). https://doi.org/10.1002/adem.202001047.

B. Gorr, F. Müller, M. Azim, H. J. Christ, T. Müller, H. Chen, et al., Oxidation of Metals 88, 339 (2017). https://doi.org/10.1007/s11085-016-9696-y.

T. M. Butler and K. J. Chaput, Journal of Alloys and Compounds 787, 606 (2019). https://doi.org/10.1016/j.jallcom.2019.02.128.

O. A. Waseem, U. Auyeskhan, H. M. Lee, and H. J. Ryu, Journal of Materials Research 33, 3226 (2018). https://doi.org/10.1557/jmr.2018.241.

K. C. Lo, H. Murakami, J. W. Yeh, and A. C. Yeh, Intermetallics 119, 106711 (2020). https://doi.org/10.1016/j.intermet.2020.106711.

C. M. Liu, H. M. Wang, S. Q. Zhang, H. B. Tang, and A. L. Zhang, Journal of Alloys and Compounds 583, 162 (2014). https://doi.org/10.1016/j.jallcom.2013.08.102.

T. Maruyama and K. Yanagihara, Materials Science and Engineering A 239–240, 828 (1997). https://doi.org/10.1016/s0921-5093(97)00673-4.

S. Sheikh, M. K. Bijaksana, A. Motallebzadeh, S. Shafeie, A. Lozinko, L. Gan, et al., Intermetallics 97, 58 (2018). https://doi.org/10.1016/j.intermet.2018.04.001.

C. H. Chang, M. S. Titus, and J. W. Yeh, Advanced Engineering Materials 20, 1 (2018). https://doi.org/10.1002/adem.201700948.

D. Ouyang, Z. Chen, H. Yu, K. C. Chan, and L. Liu, Corrosion Science 198, 110153 (2022). https://doi.org/10.1016/j.corsci.2022.110153.

F. Muhammad, E. A. Basuki, A. A. Korda, Z. Zulhan, and D. H. Prajitno, Journal of Non-Crystalline Solids 613, 122392 (2023). https://doi.org/10.1016/j.jnoncrysol.2023.122392.

C. W. Bale, E. Bélisle, P. Chartrand, S. A. Decterov, G. Eriksson, A. E. Gheribi, et al., Calphad 54, 35 (2016). https://doi.org/10.1016/j.calphad.2016.05.002.

O. N. Senkov, D. B. Miracle, K. J. Chaput, and J. P. Couzinie, Journal of Materials Research 33, 3092 (2018). https://doi.org/10.1557/jmr.2018.153.

Y. K. Mu, Y. D. Jia, L. Xu, Y. F. Jia, X. H. Tan, J. Yi, et al., Materials Research Letters 7, 312 (2019). https://doi.org/10.1080/21663831.2019.1604443.

M. K. Meyer and M. Akinc, Journal of the American Ceramic Society 79, 938 (1996). https://doi.org/10.1111/j.1151-2916.1996.tb08528.x.

V. K. Tolpygo and H. J. Grabke, Scripta Metallurgica et Materiala 28, 747 (1993). https://doi.org/10.1016/0956-716X(93)90047-V.

T. C. Chou and T. G. Nieh, Journal of Materials Research 8, 214 (1993). https://doi.org/10.1557/JMR.1993.0214.

J. H. Westbrook and D. L. Wood, Journal of Nuclear Materials 12, 208 (1964). https://doi.org/10.1016/0022-3115(64)90142-4.

P. J. Meschter, Metallurgical Transactions A 23, 1763 (1992). https://doi.org/10.1007/BF02804369.

C. G. McKamey, P. F. Tortorelli, J. H. DeVan, and C. A. Carmichael, Journal of Materials Research 7, 2747 (1992). https://doi.org/10.1557/JMR.1992.2747.

D. A. Berztiss, R. R. Cerchiara, E. A. Gulbransen, F. S. Pettit, and G. H. Meier, Materials Science and Engineering: A 155, 165 (1992). https://doi.org/10.1016/0921-5093(92)90324-T.

G. Mi, K. Yao, P. Bai, C. Cheng, and X. Min, Metals (Basel) 7, 226 (2017). https://doi.org/10.3390/met7060226.

M. Esmaily, Y. Qiu, S. Bigdeli, M. B. Venkataraman, A. Allanore, and N. Birbilis, npj Materials Degradation 4, 25 (2020). https://doi.org/10.1038/s41529-020-00129-2.

N. Yurchenko, E. Panina, S. Zherebtsov, G. Salishchev, and N. Stepanov, Oxidation Materials 11, 2526 (2018). https://doi.org/10.3390/ma11122526.

A. S. Gandhi and C. G. Levi, Journal of Materials Research 20, 1017 (2005). https://doi.org/10.1557/JMR.2005.0133.

H. Jiang, M. Hirohasi, Y. Lu, and H. Imanari, Scripta Materialia 46, 639 (2002). https://doi.org/10.1016/S1359-6462(02)00042-8.

C. Leyens, Journal of Materials Engineering and Performance 10, 225 (2001). https://doi.org/10.1361/105994901770345259.

A. Ralison, F. Dettenwanger, and M. Schütze, Materials and Corrosion 51, 317 (2000). https://doi.org/10.1002/(SICI)1521-4176(200005)51:5%3c317::AID-MACO317%3e3.0.CO;2-W.

S. C. Parida, N. K. Gupta, K. Krishnan, G. A. Rama Rao, and B. K. Sen, Metallurgical and Materials Transactions A 39, 2020 (2008). https://doi.org/10.1007/s11661-008-9548-8.

V. Gauthier, C. Josse, J. P. Larpin, and M. Vilasi, Oxidation of Metals 54, 27 (2000). https://doi.org/10.1023/a:1004694327812.

P. Pérez, V. A. C. Haanappel, and M. F. Stroosnijder, Materials Science and Engineering: A 284, 126 (2000). https://doi.org/10.1016/S0921-5093(00)00754-1.

Y. Ogawa and E. Miura-Fujiwara, Materials Transactions 60, 2204 (2019). https://doi.org/10.2320/matertrans.MT-M2019136.

C. Liu, P. Luo, Y. Feng, W. Gong, and F. Zhang, Ceramics International 49, 30471 (2023). https://doi.org/10.1016/j.ceramint.2023.06.311.

R. S. Roth, Progress in Solid State Chemistry 13, 159 (1980). https://doi.org/10.1016/0079-6786(80)90003-5.

N. Birks, G. H. Meier, and F. S. Pettit, Introduction to the High Temperature Oxidation of Metals, 2nd ed (Cambridge University Press, Cambridge, 2006), https://doi.org/10.1017/CBO9781139163903.

E. M. Savitskii and G. S. Burkhanov, Physical Metallurgy of Refractory Metals and Alloys, (Springer US, 1995). https://doi.org/10.1007/978-1-4684-1572-8.

K. T. Jacob, C. Shekhar, M. Vinay, and Y. Waseda, Journal of Chemical and Engineering Data 55, 4854 (2010). https://doi.org/10.1021/je1004609.

P. M. Woodward, P. Karen, J. S. O. Evans, and T. Vogt, Solid State Materials Chemistry, (Cambridge University Press, 2021). https://doi.org/10.1017/9781139025348.

P. Stone, R. A. Bennett, and M. Bowkery, New Journal of Physics 1999. https://doi.org/10.1088/1367-2630/1/1/008.

B. Voglewede, V. R. Rangel, and S. K. Varma, Corrosion Science 61, 123 (2012). https://doi.org/10.1016/j.corsci.2012.04.029.

L. Korb and D. Olson, ASM Metals Handbook: Corrosion, vol. 13. (ASM international, 1992),.

G. Geramifard, C. Gombola, P. Franke, and H. J. Seifert, Corrosion Science 177, 108956 (2020). https://doi.org/10.1016/j.corsci.2020.108956.

B. A. Pint, K. L. More, and I. G. Wright, Oxidation of Metals 59, 257 (2003). https://doi.org/10.1023/A:1023087926788.

B. A. Pint, Journal of the American Ceramic Society 86, 686 (2003). https://doi.org/10.1111/j.1151-2916.2003.tb03358.x.

Acknowledgements

The financial support of the ITB International Research Program 2022, grant no. LPPM.PN-10-34-2022 is gratefully acknowledged. A part of this work was carried out at the Thermodynamics and Modelling Research Group of the Department of Chemical and Metallurgical Engineering, School of Chemical Engineering, Aalto University. This work utilized the Academy of Finland’s RawMatTERS Finland Infrastructure (RAMI) based at Aalto University, GTK Espoo, and VTT Espoo.

Author information

Authors and Affiliations

Contributions

F.M. contributed to conceptualization, investigation, methodology, software, data curation, writing—original draft and editing. D.S. contributed to methodology, validation, and writing—review. L.K. contributed to methodology, validation, writing—review and editing. D.S. was involved in methodology, validation, writing—review and editing. E.A.B contributed to methodology, supervision, validation, funding acquisition, and writing—review. D.L. contributed to methodology, software, supervision, validation, and writing—review. P.T. contributed to methodology, supervision, validation, writing—review and editing. All other authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Muhammad, F., Sukhomlinov, D., Klemettinen, L. et al. Oxidation Behavior of AlxHfNbTiVY0.05 Refractory High-Entropy Alloys at 700–900 °C. High Temperature Corrosion of mater. (2024). https://doi.org/10.1007/s11085-024-10243-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11085-024-10243-0