Abstract

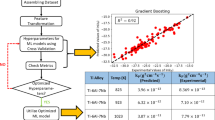

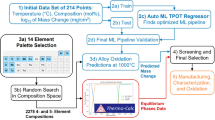

Predictive modelling of cyclic oxidation (CO) behavior is challenging. CO is dependent on several factors including time, temperature, atmosphere (composition, pressure) and alloy composition. The machine learning algorithm CatBoost is used to model, for the first time, CO of binary Fe-(10–20)% Cr alloys and ternary Fe-(16–20) %Cr-(10–30)%Ni alloys using published data. The CO conditions were 650 °C and 800 °C under air + 10% water vapor atmosphere. The CatBoost model was successfully trained and tested using 80:20% of the data with the composition, temperature and cycle time as input variables and mass change as the output. The five-fold cross-validation showed that the model had an average accuracy of 0.98 (R2). The CatBoost algorithm was also used as a classifier that, given a composition, predicts if the alloy will form protective oxide scale, oxidize rapidly or undergo spallation after 100 h of CO, accurately.

Graphical Abstract

Similar content being viewed by others

Data Availability

The raw data have been extracted from [5]. Our curated data can be shared based on an appropriate request from any researcher.

Code Availability

The CatBoost model code is available here: https://github.com/sree369nidhi/Artificial-Intelligence-approach-to-predict-elevated-temperature-cyclic-oxidation-of-Fe-Cr-and-Fe-Cr.git

References

J. L. Smialek, 461–464, 2004 (663).

C. E. Lowell, C. A. Barrett, R. W. Palmer, V. Judith, and H. B. Probst, Oxidation of Metals 36, 1991 (81).

D. Poquillon and D. Monceau, Oxidation of Metals 59, 2003 (409).

J. L. Smialek, Acta Materialia 51, 2003 (469).

R. Peraldi and B. A. Pint, Oxidation of Metals 61, 2004 (463).

E. Kavlakoglu. AI vs. Machine Learning vs. Deep Learning vs. Neural Networks: What’s the Difference? .(https://www.ibm.com/cloud/blog/ai-vs-machine-learning-vs-deep-learning-vs-neural-networks AI vs. Machine Learning vs. Deep Learning vs. Neural Networks: What’s the Difference?)

H. K. D. H. Bhadeshia, ISIJ International 39, 1999 (966–979).

H. K. D. H. Bhadeshia, R. C. Dimitriu, S. Forsik, J. H. Pak, and J. H. Ryu, Materials Science and Technology 25, 2009 (504–510).

M. P. Phaniraj and A. K. Lahiri, Materials Science and Technology. 20, 2004 (14).

M. P. Phaniraj and A. K. Lahiri, Journal of Materials Processing Technology 141, 2003 (219–227).

J. Peng, R. Pillai, M. Romedenne, et al., NPJ Materials Degradation 5, 2021 (1–8).

R. Pillai, M. Romedenne, J. Peng, et al., Oxidation of Metals 97, 2022 (51–76).

L. Prokhorenkova, G. Gusev, A. Vorobev, A. V. Dorogush, and A. Gulin, Advances in Neural Information Processing Systems 2018, 2018 (6638–6648).

L. Diao, D. Niu, Z. Zang, C. Chen, Short-term weather forecast based on wavelet denoising and catboost. Chinese Control Conf. CCC. 2019, 3760 (2019).

J. T. Hancock and T. M. Khoshgoftaar, Journal of Big Data 7, 2020 (1–45).

S. Lee, T. P. Vo, H. T. Thai, J. Lee, and V. Patel, Structural Engineering 238, 2021 (112109).

S. H. Kong, D. Ahn, B. Kim, et al., JBMR Plus. 4, 2020 (1–9).

H. C. Yi, Z. H. You, and Z. H. Guo, Frontiers in Genetics 10, 2019 (1–10).

Ali M. PyCaret: An pen source low code machine learning library in Python. 2020 Available at: https://www.pycaret.org/about.

CatBoost: Multiclassification. Available at: https://catboost.ai/en/docs/concepts/loss-functions-multiclassification#objectives-and-metrics.

James G, Hastie DWT, Tibshirani R. Ml and Statistics (Springer); 2013.

N. Birks, G. H. Meier, and F. S. Pettit, Introduction to the High-Temperature Oxidation of Metals, (Cambridge University Press, Cambridge, 2006).

Author information

Authors and Affiliations

Contributions

MKA contributed to formal analysis, software, methodology. MSI contributed to formal analysis, software. PHAD contributed to project administration. MPP contributed to conceptualization, data curation, writing—original draft, review and editing.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Anirudh, M.K., Iyengar, M.S., Desik, P.H.A. et al. Artificial Intelligence Approach to Predict Elevated Temperature Cyclic Oxidation of Fe–Cr and Fe–Cr–Ni Alloys. Oxid Met 98, 291–303 (2022). https://doi.org/10.1007/s11085-022-10123-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-022-10123-5