Abstract

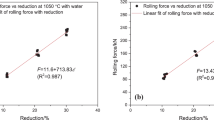

The formation and performance of oxide scale on a low-alloy steel were investigated during hot rolling at 850 and 950 °C under various lubrication conditions, including benchmarks (dry condition and water) and water-based nanolubricants containing various concentrations of nano-TiO2 from 1.0 to 8.0 wt%. The results showed that the addition of nano-TiO2 particles in the lubricant significantly reduced the thickness of oxide scale and surface oxide roughness. The reduction reached the maximum when the concentration of TiO2 was 4.0 wt%. Detailed oxide phase characterisation and oxide component fraction determination revealed that hot rolling destroyed the conventional multi-layer oxide scale and promoted magnetite and haematite formation because of easy access of oxygen from the deformed structure. The effect of TiO2 was explained by the decrease in the rolling force, which led to a higher fraction of dense retaining wustite and therefore reduced the extent of further oxidation. Increasing temperature did not change the trend of lubrication effect but raised the rate of steel oxidation in general.

Similar content being viewed by others

References

L. Suárez, Y. Houbaert, X. V. Eynde, and R. Colás, Corrosion Science 51, 309 (2009).

X. Cheng, Z. Jiang, D. Wei, L. Hao, J. Zhao, and L. Jiang, Tribology International 84, 61 (2015).

T. Jia, Z. Y. Liu, H. F. Hu, and G. D. Wang, ISIJ International 51, 1468 (2011).

X. Yu, Z. Jiang, J. Zhao, D. Wei, C. Zhou, and Q. Huang, Corrosion Science 90, 140 (2015).

X. Yu, Z. Jiang, J. Zhao, D. Wei, C. Zhou, and Q. Huang, Wear 332–333, 1286 (2015).

Z. Y. Jiang, J. Tang, W. Sun, A. K. Tieu, and D. Wei, Tribology International 43, 1339 (2010).

X. Cheng, Z. Jiang, J. Zhao, D. Wei, L. Hao, J. Peng, M. Luo, L. Ma, S. Luo, and L. Jiang, Wear 338–339, 178 (2015).

P. A. Munther and J. G. Lenard, Journal of Materials Processing Technology 88, 105 (1999).

L. Luong and T. Heijkoop, Wear 71, 93 (1981).

H. Utsunomiya, T. Nakagawa, and R. Matsumoto, Procedia Manufacturing 15, 46 (2018).

R. Y. Chen and W. Y. D. Yuen, Oxidation of Metals 56, 89 (2001).

S. Birosca, D. Dingley, and R. L. Higginson, Journal of Microscopy 213, 235 (2004).

S. Garber and G. Sturgeon, (1959).

H. Wriedt, Binary Alloy Phase Diagrams, 2nd edn, ed. B. Massalski 2, (1990).

X. Yu, Z. Jiang, J. Zhao, D. Wei, C. Zhou, and Q. Huang, Corrosion Science 85, 115 (2014).

X. L. Yu, Z. Y. Jiang, J. W. Zhao, D. B. Wei, and C. L. Zhou, Applied Mechanics and Materials 395–396, 273 (2013).

D. B. Lee and J. W. Choi, Oxidation of Metals 64, 319 (2005).

F. H. Stott, G. C. Wood, and J. Stringer, Oxidation of Metals 44, 113 (1995).

K. Dohda, C. Boher, F. Rezai-Aria, and N. Mahayotsanun, Friction 3, 1 (2015).

H. Wu, F. Jia, J. Zhao, S. Huang, L. Wang, S. Jiao, H. Huang, and Z. Jiang, Wear 426–427, 792 (2019).

H. Xie, S. Dang, B. Jiang, L. Xiang, S. Zhou, H. Sheng, T. Yang, and F. Pan, Applied Surface Science 475, 847 (2019).

S. Du, J. Sun, and P. Wu, Carbon 140, 338 (2018).

A. S. He, S. Q. Huang, J. H. Yun, H. Wu, Z. Y. Jiang, J. Stokes, S. H. Jiao, L. Z. Wang, and H. Huang, Tribology Letters 65, 40 (2017).

Y. Bao, J. Sun, and L. Kong, Tribology International 114, 257 (2017).

Y. Meng, J. Sun, P. Wu, C. Dong, and X. Yan, Nanomaterials 8, 111 (2018).

H. Wu, J. Zhao, L. Luo, S. Huang, L. Wang, S. Zhang, S. Jiao, H. Huang, and Z. Jiang, Lubricants 6, 57 (2018).

H. Wu, J. Zhao, W. Xia, X. Cheng, A. He, J. H. Yun, L. Wang, H. Huang, S. Jiao, L. Huang, S. Zhang, and Z. Jiang, Journal of Manufacturing Processes 27, 26 (2017).

H. Wu, J. Zhao, W. Xia, X. Cheng, A. He, J. H. Yun, L. Wang, H. Huang, S. Jiao, L. Huang, S. Zhang and Z. Jiang, Tribology International 109, 398 (2017).

H. Wu, J. Zhao, X. Cheng, W. Xia, A. He, J.-H. Yun, S. Huang, L. Wang, H. Huang, S. Jiao and Z. Jiang, Tribology International 117, 24 (2018).

B. G. R. K. Singh Raman, and D. J. Young, Materials Science and Technology 14, 373 (1998).

K. Lee, Y. Hwang, S. Cheong, Y. Choi, L. Kwon, J. Lee and S. H. Kim, Tribology Letters 35, 127 (2009).

X. Tao, Z. Jiazheng and X. Kang, Journal of Physics D: Applied Physics 29, 2932 (1996).

R. Dwyer-Joyce, R. Sayles and E. Ioannides, Wear 175, 133 (1994).

S. Mrowec and K. Przybylski, Oxidation of Metals 11, 383 (1977).

M. H. Davies, M. T. Simnad and C. E. Birchenall, Jom 3, 889 (1951).

R. Y. Chen and W. Y. D. Yeun, Oxidation of Metals 59, 433 (2003).

D. P. Burke and R. L. Higginson, Scripta Materialia 42, 277 (2000).

Z.-F. Li, G.-M. Cao, F. Lin, H. Wang and Z.-Y. Liu, Oxidation of Metals 90, 337 (2018).

J. Tominaga, K.-Y. Wakimoto, T. Mori, M. Murakami and T. Yoshimura, Transactions of the Iron and Steel Institute of Japan 22, 646 (1982).

W. Sun, A. K. Tieu, Z. Jiang, H. Zhu and C. Lu, Journal of Materials Processing Technology 155–156, 1300 (2004).

S. Hayashi, K. Mizumoto, S. Yoneda, Y. Kondo, H. Tanei and S. Ukai, Oxidation of Metals 81, 357 (2014).

Y. Shizukawa, S. Hayashi, S. Yoneda, Y. Kondo, H. Tanei and S. Ukai, Oxidation of Metals 86, 315 (2016).

S. Yoneda, S. Hayashi, Y. Kondo, H. Tanei, and S. Ukai, Oxidation of Metals 87, 125 (2017).

X. Yu, Z. Jiang, D. Wei, C. Zhou, Q. Huang, and D. Yang, Wear 302, 1286 (2013).

K. Mori and D. Ito, CIRP Annals 58, 267 (2009).

P. Liu, L. Wei, S. Ye, H. Xu, and Y. Chen, Surface and Coatings Technology 205, 3582 (2011).

Acknowledgements

The authors acknowledge the financial supports from Baosteel-Australia Joint Research and Development Center (BAJC) under the Project of BA17004 and Australian Research Council (ARC) under Linkage Project Program (LP150100591). The authors are grateful to Mr. Suoquan Zhang at Baosteel Research Institute for the provision of steel samples. We would like to thank the technicians in the workshop of SMART Infrastructure Facility at University of Wollongong for their kind help on samples machining. We also wish to extend special thanks to A/Prof. Buyung Kosasih and Mr. Long Wang for their great supports on the ultrasonic treatment of applied lubricants. Thanks also go to Drs. Lin Wang and Chun Yu who participated in some oxide analyses when they were working at UNSW.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, H., Jiang, C., Zhang, J. et al. Oxidation Behaviour of Steel During hot Rolling by Using TiO2-Containing Water-Based Nanolubricant. Oxid Met 92, 315–335 (2019). https://doi.org/10.1007/s11085-019-09924-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-019-09924-y