Abstract

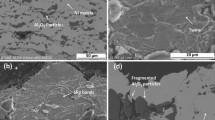

Surface characteristics, such as topography and roughness (R a), are important in affecting the isothermal oxidation behavior of MCrAlY coatings. In this study, the effect of sandblasting on the oxidation behavior of HVOF thermal-sprayed MCrAlY coatings was investigated. Oxidation tests were conducted under isothermal conditions at 1050 °C for different periods. The R a of the bondcoat was approximately 12 μm. Before and after oxidation, the thermally-grown scale composition and morphology were analyzed using scanning electron microscope (SEM/EDX) and X-ray diffraction. The results showed that the oxide scale that formed on the as-sprayed coatings was a mixture of Al2O3 and spinel, while the oxide formed on the sandblasted coating was composed mainly of Al2O3. In addition, with increasing R a of the bondcoat, the oxidation rate progressively decreased and the amount of Al2O3 increased compared with the as-sprayed coating. Scanning electron microscope analysis showed that the thickness of the scale layer on the sandblasted CoNiCrAlY coating at 1050 °C was much thinner than that on the as-sprayed one.

Graphical Abstract

Isothermal oxidation kinetics of HVOF CoNiCrAlY coatings with different surface modifications at 1050 °C. This figure indicates the effect of the surface process on the oxidation kinetics of the CoNiCrAlY coating at the temperature of 1050 °C. As it can be observed, in both samples, oxidation rate is initially high and gradually lowers with the passage of time. The reason for this reduction in the longer times is the formation of a uniform and dense oxide layer at the beginning of the process within which the rate of oxygen penetration reduces and gets harder with lasting oxidation time. The type of oxidation kinetics of these coatings is parabolic. According to the results obtained, the oxidation rate constant (Kp) for the coating in the as-sprayed and sandblasted states equals 1.75 × 10−13 and 0.63 × 10−13 mg/cm2, respectively. The reduction in the oxidation rate signifies the effect of the surface morphology on the oxidation behavior of these coatings.

Similar content being viewed by others

References

F. Gao, X. Huang, Q. Yang and R. Liu, Oxidation of Metals, 1 (2015). doi:10.1007/s11085-015-9604-x.

T. Gheno, G. H. Meier and B. Gleeson, Oxidation of Metals 84, 185 (2015). doi:10.1007/s11085-015-9550-7.

H. M. Tawancy, L. M. Al-Hadhrami, A. I. Mohammed, F. K. Alyousef and H. Dafalla, Oxidation of Metals 83, 417 (2015). doi:10.1007/s11085-014-9525-0.

H. Lan, P. Y. Hou, Z.-G. Yang, Y.-D. Zhang and C. Zhang, Oxidation of Metals 75, 77 (2010). doi:10.1007/s11085-010-9221-7.

A. Fossati, M. D. Ferdinando, A. Lavacchi, A. Scrivani, C. Giolli and U. Bardi, Coatings 1, 3 (2010). doi:10.3390/coatings1010003.

D. Mercier (2009). http://digitool.Library.McGill.CA/R/-?func=dbin-jump-full&object_id=86775.

T. S. Hille, S. Turteltaub and A. S. J. Suiker, Engineering Fracture Mechanics 78, 2139 (2011). doi:10.1016/j.engfracmech.2011.04.003.

A. G. Evans, D. R. Mumm, J. W. Hutchinson, G. H. Meier and F. S. Pettit, Progress in Materials Science 46, 505 (2001). doi:10.1016/S0079-6425(00)00020-7.

Y. Bai, et al., Ceramics International 39, 4437 (2013). doi:10.1016/j.ceramint.2012.11.037.

Y. Li, Y. Xie, L. Huang, X. Liu and X. Zheng, Ceramics International. 38, 5113 (2012). doi:10.1016/j.ceramint.2012.03.014.

Y. Li, C.-J. Li, Q. Zhang, L.-K. Xing and G.-J. Yang, Journal of Thermal Spray Technology 20, 121 (2010). doi:10.1007/s11666-010-9590-0.

Z.-H. Zhou, S.-K. Gong, H.-F. Li, H.-B. Xu, C.-G. Zhang and L. Wang, Chinese Journal of Aeronautics 20, 145 (2007). doi:10.1016/s1000-9361(07)60022-3.

L. Ni and C. Zhou, Progress in Natural Science: Materials International 22, 237 (2012). doi:10.1016/j.pnsc.2012.04.007.

F. Tang, L. Ajdelsztajn, G. E. Kim, V. Provenzano and J. M. Schoenung, Surface and Coatings Technology 185, 228 (2004). doi:10.1016/j.surfcoat.2003.11.020.

A. Gil, V. Shemet, R. Vassen, M. Subanovic, J. Toscano, D. Naumenko, L. Singheiser and W. J. Quadakkers, Surface and Coatings Technology 201, 3824 (2006). doi:10.1016/j.surfcoat.2006.07.252.

W. Brandl, G. Marginean, D. Maghet and D. Utu, Surface and Coatings Technology 188–189, 20 (2004). doi:10.1016/j.surfcoat.2004.07.111.

L.-Y. Ni and Z.-L. Wu, Progress in Natural Science: Materials International 21, 173 (2011). doi:10.1016/s1002-0071(12)60052-5.

A. C. Karaoglanli, K. M. Doleker, B. Demirel, A. Turk and R. Varol, Applied Surface Science (2015). doi:10.1016/j.apsusc.2015.06.113.

M. Chen, M. Shen, S. Zhu, F. Wang and X. Wang, Corrosion Science 73, 331 (2013). doi:10.1016/j.corsci.2013.04.022.

N. Espallargas, in Future Development of Thermal Spray Coatings, ed. N. Espallargas (Woodhead Publishing, Cambridge, 2015), p. 1.

J. He and J. M. Schoenung, Materials Science and Engineering: A 336, 274 (2002). doi:10.1016/S0921-5093(01)01986-4.

K. Tao, X.-L. Zhou, H. Cui and J.-S. Zhang, Transactions of Nonferrous Metals Society of China 19, 1151(2009). doi:10.1016/S1003-6326(08)60421-5.

D. Toma, W. Brandl and U. Köster, Surface and Coatings Technology 120–121, 8 (1999). doi:10.1016/S0257-8972(99)00332-1.

Q. Wei, Z. Yin and H. Li, Applied Surface Science 258, 5094 (2012).

S. R. J. Saunders, M. Monteiro and F. Rizzo, Progress in Materials Science 53, 775 (2008). doi:10.1016/j.pmatsci.2007.11.001.

Z. Xu, G. Huang, L. He, R. Mu, K. Wang and J. Dai, Journal of Alloys and Compounds 586, 1 (2014). doi:10.1016/j.jallcom.2013.09.210.

A. Hesnawi, H. Li, Z. Zhou, S. Gong and H. Xu, Surface and Coatings Technology 201, 6793 (2007). doi:10.1016/j.surfcoat.2006.09.076.

A. C. Karaoglanli, K. M. Doleker, B. Demirel, A. Turk and R. Varol, Applied Surface Science (2015). doi:10.1016/j.apsusc.2015.06.113.

K. Ma and J. M. Schoenung, Surface and Coatings Technology 205, 5178 (2011). doi:10.1016/j.surfcoat.2011.05.025.

X. C. Zhang, B. S. Xu, H. D. Wang and Y. X. Wu, Materials & Design 27, 989 (2006). doi:10.1016/j.matdes.2005.02.008.

Acknowledgments

The authors are grateful to the Poudr afshan Company for financial support and their assistance with the HVOF spraying.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naeimi, F., Rahimipour, M.R. & Salehi, M. Effect of Sandblasting Process on the Oxidation Behavior of HVOF MCrAlY Coatings. Oxid Met 86, 59–73 (2016). https://doi.org/10.1007/s11085-016-9619-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-016-9619-y