Abstract

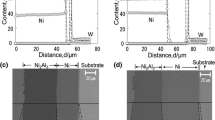

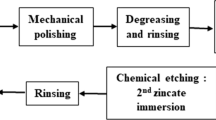

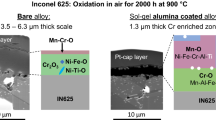

The formation of a coating layer consisting of Ni-aluminide containing Hf on a Ni–10at.%Cr–8at.%Al alloy substrate was attempted by the electrodeposition of Hf, Ni, and Al. The cyclic-oxidation resistance for the alloy covered with this coating was then evaluated in air at 1,423 K. Ni was deposited by aqueous solution electrolysis. Hf and Al were deposited by molten-salt electrolysis. For the sample first treated with the Hf-deposition, subsequently treated with the Ni-deposition, followed by Al-deposition, a coating consisting of Ni2Al3 of about 40-μm thickness was uniformly formed on the alloy. At the center region of this coating, a Hf-concentration layer was formed. The cyclic-oxidation test showed that, for the untreated sample and the sample with only Ni and Al depositions, a mass reduction due to spallation of a scale took place during the initial oxidation period. On the contrary, for the sample with Hf, Ni, and Al depositions, a mass reduction due to spallation of a scale scarcely took place. The cross-sectional observation using SEM showed that, for the sample with Hf, Ni, and Al depositions after the oxidation test, an adhesive scale having a spiked shape was formed. This scale mainly consisted of α-Al2O3, and contained HfO2 particles. It was postulated that, for this sample, the Hf in the Hf-concentration layer diffused into the surface region of the Ni-aluminide layer, contributing to improvement in the exfoliation resistance of the scale.

Similar content being viewed by others

References

T. Narita, M. Shoji, Y. Hisamatsu, D. Yoshida, M. Fukumoto, and S. Hayashi, Materials at High Temperatures 18(S), 245 (2001).

J. L. Smialek, Metallurgical Transactions A: Physical Metallurgy and Material Science 9A, 309 (1978).

A. S. Kahn, C. E. Lowell, and C. A. Barrett, Journal of the Electrochemical Society 127, 670 (1980).

T. T. Chang, Y. C. Pan, and T. H. Chuang, Journal of Alloys and Compounds 243, 126 (1996).

B. A. Pint, Oxidation of Metals 45, 37 (1996).

J. A. Haynes, B. A. Pint, K. L. More, Y. Zhangand, and I. G. Wright, Oxidation of Metals 58, 513 (2002).

S. Taniguchi and T. Shibata, Oxidation of Metals 25, 201 (1986).

M. Fukumoto, M. Hara, and T. Nagataki, Oxidation of Metals 61, 1 (2004).

M. Fukumoto, R. Yamashita, and M. Hara, Oxidation of Metals 62, 309 (2004).

M. Fukumoto, T. Yokota, and M. Hara (to be submitted).

B. Lustman, Transactions of the Metallurgical Society of AIME 188, 995 (1950).

H. Hindam and D. P. Whittle, Journal of the Electrochemical Society 129, 1147 (1982).

J. K. Tien and F. S. Pettit, Metallurgical Transactions 3, 1587 (1972).

Acknowledgments

The investigation was carried out with financial support for Specially Promoted Research, No. 16001004, from a Grant-in-Aid for Scientific Research, Ministry of Education, Culture, Science and Technology, Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hara, M., Matsuda, Y., Fukumoto, M. et al. Formation of Ni-aluminide Coating Containing Hf by Molten-Salt Electrodeposition and Cyclic-Oxidation Resistance. Oxid Met 70, 295–306 (2008). https://doi.org/10.1007/s11085-008-9122-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-008-9122-1