Abstract

Laser corneal reshaping is an eye surgery utilizes UV lasers to modify a targeted corneal surface to correct vision disorders such as myopia, hyperopia and astigmatism. The most commonly used laser type in such treatment is a pulsed gas laser namely argon fluoride (ArF) excimer laser (193 nm). A mixture of Argon, Fluorine and high percentage of Neon gas is utilized for producing the required laser. However, the availability of Neon gas is currently very limited due to the existent Russian-Ukraine war as this region is considered the main supplier of pure Neon gas. The present work provides a novel alternative system for the commercially available corneal reshaping eye surgery devices with a special opening for entering the operational laser beam from external sources. The proposed system is a flying spot platform coupled with a solid state laser, that is a forth harmonic of Nd: YAG laser. The aperture in the system’s design enables it to take in the generated UV-laser beam (266 nm) from the external Nd: YAG laser source. The beam is then modified and directed at the treatment area. The device was tested for hyperopia laser profile algorithm on different targets. Furthermore, the hyperopia profile procedure was also applied to the ex-vivo rabbit eye to investigate the ablation effect on the corneal tissues. The obtained results showed an appropriate ablation effect for hyperopic correction via a complete corneal reshaping platform. Although, the device’s current state may not be appropriate for immediate clinical use. It holds significant value as a training and educational platform.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cornea accounts for more than 65% of the total refractive power in the eye. Consequently, any distortion in its shape significantly impacts visual acuity (Maier et al. 2019). Among various ophthalmologic procedures, laser refractive eye-surgery has been widely utilized for correcting common vision defects (Joffe 2021). Laser eye-surgery employs UV-laser pulses to achieve a photoablation effect on a targeted part of the cornea to modify its curvature (Kane et al. 2017). LASIK (Laser-Assisted in Situ Keratomileusis) is a popular refractive surgical procedure that treats nearsightedness, farsightedness, and astigmatism (Kahuam-López et al. 2020). It entails producing a thin corneal flap with a microkeratome or femtosecond laser (Netto et al. 2007). An excimer laser is then used to remodel the underlying corneal tissue and rectify the refractive defect. Finally, the corneal flap is adjusted. Excimer lasers, microkeratomes, and femtosecond lasers are all LASIK-related tools.

PRK (Photorefractive Keratectomy) is another laser eye surgery technique for correcting refractive problems. Unlike LASIK, PRK requires removing the cornea’s thin outer layer (epithelium) before using an excimer laser to reshape the cornea (Tomás-Juan et al. 2015). Excimer lasers are critical components in laser eye-surgeries. These lasers use ultraviolet light to accurately remove small amounts of tissue from the cornea and reshape it to cure refractive defects. The applied laser appropriately has a few nanosecond pulse duration and 107-108 W/cm2 irradiance to make the desired effect on the corneal tissue (Pidro et al. 2019). The polypeptide bond between amino acids in the collagen fibers of the stromal layer is the primary chromophore in corneal tissue (Yu et al. 2019). Accordingly, the utilized UV-laser wavelength and applied energy control the acquired ablation depth (Abdelhalim et al. 2021a; Manns et al. 2002).

Various gas lasers have been introduced for this type of eye-surgery such as krypton chloride (KCl) at 223 nm and krypton fluoride (KF) at 248 nm excimer lasers (Atezhev et al. 2016). However, the most successfully utilized type is the 193-nm ArF excimer laser. This laser wavelength (193 nm) is highly absorbed by the proteins, glycosaminoglycans, and nucleic acids of the cornea owing to its adequate photon energy (6.4 eV) and precision. Therefore, ArF excimer laser is broadly used in most commercial laser eye-surgery devices (Vossmerbaeumer 2010). However, the hazardous active medium, unsafe electrical pumping method, complex maintenance, and expensive cost are some drawbacks of the ArF excimer laser (Abdelkawi et al. 2010; Lubatschowski et al. 1994). A typical excimer laser is composed of two gases: a noble gas and a halogen, usually stable in their normal low states. The gas composition utilized in the laser system determines the excimer laser’s specific wavelength (Görtler and Strowitzki 2005). About 70% of the world’s exports of Neon gas (which is the main part for 193-nm ArF excimer laser) come from Ukraine. However, the availability of pure neon gas is currently severely constrained because of the ongoing Russian-Ukrainian war (Mbah and Wasum 2022). Therefore, developing alternative laser sources is highly in demand.

Although some solid-state UV-laser sources have been developed and evaluated for corneal reshaping such as fourth harmonic Ti: sapphire (210 nm) and fifth harmonic Nd: YAG (213 nm) lasers (Shah and Piovella 2013), the applicable commercial devices are still utilizing the ArF excimer laser. The present paper introduces and evaluates a novel design for a solid-state laser eye surgery device that can receive an external laser beam (Abdelhalim and Hamdy 2022). The proposed system (namely, i-ablation device) enables examining the effect of applying different laser types/wavelengths on the cornea with ablation algorithms similar to those found in the commercial laser eye-surgery devices.

The device was deliberately constructed to have dimensions comparable to commercial equipment. However, it includes a number of other characteristics that add to its distinctiveness. One noteworthy feature is the presence of a magnified-live view screen, which improves surgical visibility and precision during the surgery. This real-time visualization capacity distinguishes the i-ablation device from conventional methods. The i-ablation device addresses the issue of corneal debris formed during the laser ablation process with its integrated debris removal technology. This function ensures a clear viewing field while minimizing the risk of problems caused by debris interference.

To reduce the possibility of corneal overheating, the device includes a robotic arm fitted with a cooled air blower. This cooling mechanism is essential addition since it helps to maintain an ideal corneal temperature throughout treatment to assure patient safety and reducing potential thermal damage. Another remarkable feature of our device is the ability to modify both software and hardware. This adaptability enables future enhancements and changes in response to new technology developments. For performance evaluation, a fourth harmonic Nd: YAG laser source (266 nm) was generated and utilized as the incident UV-laser (Abdelhalim et al. 2021b). Furthermore, the functionality of the device hyperopic correction was tested on different objects including paper sheet, poly-methyl-methacrylate (PMMA) target, and ex-vivo rabbit eye. It is essential to emphasize that the present research is an experimental study, not a clinical trial. The study’s specific aims were to improve the laser platform’s scanning capabilities, visualization systems, and control features. To accomplish these objectives, we proposed a combination of engineering and technical approaches. The modifications were assessed using laboratory experiments and proof-of-concept demonstrations.

2 Materials and methods

2.1 System design

The main components of the i-ablation system are shown in Fig. 1. The prescribed device is a class 4 laser with a door interlock, emergency switch, key switch, video output connector, Ethernet connection, huge sponge dust cover, and air intake opening to protect the optics from dust. There are also two USB connectors, auxiliary laser controls, a license card slot, a joystick, a wireless mouse, and a keyboard on the user panel. The flying spot delivery technique used by most commercial devices is employed to provide the optical path for the proposed device (Shraiki and Arba-mosquera 2011).

The modifications we have proposed in our study are intended to enhance the capabilities and functionality of laser eye surgery platforms. While the feasibility of implementing these modifications within existing platforms may vary depending on the specific design and architecture of each platform, we believe that our proposed modifications can be adapted to complement and improve existing systems. The improvements have been developed to be compatible with the core ideas and elements of platforms used in laser eye surgery. Our priorityes had been to incorporate more control capabilities and enhance the visualisation system. Moreover, we have taken into account the scalability of the proposed modifications.

Our intention was to develop enhancements that can be incorporated into different laser eye surgery platforms, considering variations in laser sources, scanning systems, and control interfaces. Additionally, We have considered the practical aspects of implementing the proposed modifications. Our intention is to provide practical solutions that can be feasibly implemented within the constraints of existing laser eye surgery platforms. We have taken into account factors such as space requirements, compatibility with existing components and ease of integration.

2.2 The added features

The proposed “i-ablation” system is constructed to receive the laser beam from outside sources through a certain port. Such opening is intended to allow entry of the UV laser beam from an external light source to be used in the treatment procedures (i.e. photoablation) as illustrated in Fig. 2.

Enabling the examination of various UV lasers seeks to increase scanning capabilities may result in better refractive outcomes and visual acuity for individuals undergoing hyperopic correction. The decision to position the laser outside the installation is based on the nature of our research device. As a research device, it offers the flexibility to explore different configurations and setups. The ability to house the laser either outside or inside the installation provides an added value in terms of adaptability and versatility. While increasing the optical path length and introducing additional air flows can potentially impact system stability, we have taken measures to mitigate these effects. Through careful design considerations and implementation of appropriate optical components, we aim to maintain stable and reliable performance despite the extended optical path. Furthermore, by locating the laser outside the installation, we can explore variations in laser placement and optimize the device’s overall design. This approach allows for easier access to the laser system, facilitates maintenance and upgrades, and provides opportunities for future enhancements and modifications.

Moreover, the i-ablation device is provided by an automatic debris removal system that carries the vacuum and blower hoses ended with nozzles directed to the target to remove the debris and fumes developed during the treatment process. A robotic arm controls the movement of that debris removal system toward the treatment area (see Fig. 3).

The automatic debris removal system, equipped with vacuum and blower hoses plays a crucial role in maintaining a clear treatment area. By efficiently removing debris and fumes generated during the procedure, the modification minimizes potential obstructions that could impede the surgeon’s view and interfere with the accuracy of the treatment. A clear treatment area enhances surgical precision and reduces the risk of complications, ultimately contributing to improved outcomes for patients undergoing hyperopic correction. Additionally, a cooled air blower equipped with a Peltier element is used to rapidly cool the attached copper pipes during the procedure to prevent cornea overheating. By preventing corneal overheating, this modification helps mitigate the risk of thermal damage to the cornea during the hyperopic correction procedure. Maintaining optimal corneal temperature throughout the treatment is critical for preserving corneal integrity and reducing the potential for postoperative complications. Thus, this modification can contribute to improved patient safety and better clinical outcomes.

Our proposed platform features a user interface that prioritizes simplicity and ease of use. By combining all of the essential controls into a single screen, we substantially reduced the complexity generally associated with conventional systems’ graphical user interfaces (GUIs). This design strategy ensures that surgeons may immediately become acquainted with the system, minimizing the need for significant training to use the GUI. Our primary goal in creating this platform was to provide a user-friendly tool for education and research, while also optimizing the surgical workflow potentially shortening procedure times. An intuitive computer interface is used to control and modify the acquired medical procedure’s operational settings as presented in Fig. 4.

The nine key elements of the system’s computer interface are the system control, laser joystick, laser source control, video control, system feedback, reference laser control, treatment control, treatment type selection, and eye tracker. The device’s various modules, including the buzzer, blower system, targeting beam, shutter, and firing laser, are enabled and monitored by the system control. The primary beam’s location on the target is adjusted via the laser joystick. If the device uses an internal UV-laser source instead of an external one, the laser source control handles the internal laser. The selection of the treatment procedure is provided by “the treatment type selection” with the provision of different diopters. Besides, the video control offers a live view of the surgery and allows for visual representation, laser beam centralization, and the capture of videos or images.

The monitoring module also shows a light alarm and feedback from several modules. The reference lasers needed for treatment, centralization, and alignment are produced by reference lasers control. Displaying the treatment’s progress or cancellation is possible using “the treatment control”. Lastly, the eye tracker enables tracing the eye site throughout the surgery. These advancements in the visualization system can provide surgeons with better real-time feedback during the procedure. It is worth noting that the total manufacturing expenses of the designed laser system is approximately $2500 excluding the external laser source used for ablation. It is crucial to note that this cost is substantially lower than current laser eye surgery systems which generally cost hundreds of thousands of dollars (Joffe 2021).

2.3 The generated UV-laser (266 nm)

A Q-switched Nd: YAG laser source (1064 nm) produces a second harmonic (532 nm) with 3–5 ns pulse duration, 14-mJ pulse energy, and 3-mm spot size diameter. The laser beam is directed to Barium Borate crystal (BBO) to generate the forth-harmonic Nd: YAG laser beam at 266 nm (Abdelhalim et al. 2023b). A harmonic separator mirror reflects the 266-nm beam and transmits the other wavelengths (i.e. 1064 and 532 nm), which are further blocked by the field stop. The reflected 266-nm beam is directed to the i-ablation device port using another mirror. Inside the i-ablation device, a shutter controls the entrance of the external laser beam. The device contains an optical breadboard with a pinhole to block any possible reflected wavelengths (1064 and 532 nm).

To perform the predefined treatment algorithm, a positive lens is employed to focus the beam on the target through X-Y galvo scanners equipped with appropriate mirrors. The 266-nm beam is then bent toward the target using an additional mirror. Four LEDs are used to illuminate the target, while a camera and four first-surface periscope mirrors (i.e. hot mirror) allow the live view documentation system. Finally, two additional lasers are used: an axillary pulsed laser (635 nm & frequency 3 Hz) serving as the fixation laser and a visible laser (532 nm) to determine the focusing level. The laser energy reached the target for the 266-nm beam is 1 mJ, the spot diameter is 0.5 mm, and the laser linewidth is 5 nm. The distance between the device and the target is 26 ± 1 cm; therefore, the operating area is relatively large. Moreover, the device’s laser transmission from the laser coupler to the target is 77%. Fig. 5 shows the block diagram of the entire optical configurations.

To evaluate beam quality, we used the following method: A black paper sheet was exposed to a sequence of laser pulses starting with one and gradually increasing by one until the diameter of the resulting spot remained constant. This stabilization point was identified after five laser pulses allowing us to estimate the effective spot size and shape. Then, the Size Estimation Transparency Chart was used in conjunction with an optical microscope to accurately determine spot size. The gradual increase in laser pulses provided insights on spot size convergence, allowing us to examine the laser beam’s consistency and reproducibility. This approach was used as an initial stage in our research to get a basic understanding of beam quality. Future investigations will include further in-depth examinations and measurements of the laser beam’s characteristics.

We conducted our investigation using a specific laser source available at our institute. This laser source despite its relatively low frequency (15 Hz) enables us to demonstrate the feasibility and concept of using the 266-nm wavelength for corneal reshaping. It is important to note that our laser source’s low frequency does not accurately reflect its entire capability or the variety of possibilities that can be attained with other laser sources. One limitation we encountered relates to the scanning speed which is dependent on the laser source utilized. In our current implementation, we had to reduce the scanner’s speed to ensure synchronization with the frequency of the laser source. The reduction in scanning speed may have implications for overall procedure time and efficiency. However, a new high-speed laser source can address this limitation and improve the scanning speed of our system. It is important to note that while this limitation affects the scanning speed, we have taken measures to mitigate its impact and have successfully demonstrated the effectiveness of our system for hyperopic correction. However, we recognize the need to further optimize and refine the methodology to overcome this limitation and improve its practicality for clinical applications.

In a prior paper, we reported that using fluence of 6.82 mJ/mm2 and 9.09 mJ/mm2 resulted in an adequate ablation outcome with minimum thermal effect. These data demonstrated that our modified platform produced the necessary ablation effect while minimizing heat damage.

Furthermore, we employed the comet assay to compare DNA damage resulting from our proposed 266-nm solid-state laser versus a commercially available 193-nm ArF excimer laser. The results showed that the DNA damage caused by our laser system was nearly identical to that caused by the standard ArF excimer laser, demonstrating the safety and efficacy of our method (Abdelhalim et al. 2023b).

It is worth noting that the laser source used in our study can be replaced with alternative sources should the need arise. This flexibility allows for adjustments in scan speed and the potential incorporation of laser sources with different performance parameters, thus expanding the possibilities and optimizing the laser system for corneal reshaping applications. In the present study, we specifically chose to employ a 266-nm laser source for corneal reshaping purposes. The 266-nm solid-state laser was selected due to its safety profile particularly for patients with pacemakers or sensitivity to ozone. Unlike the 193-nm gas laser which requires optics replacements and additional maintenance, the soild-state 266-nm laser offers advantages in terms of operational ease and reduced safety concerns. Furthermore, the 266-nm laser source used in our study offers the benefit of utilizing a non-toxic active medium, eliminating the potential risks associated with high-pressure and hazardous gases commonly found in other laser sources. Table 1 presents a comparison outlining the characteristics of the 4th harmonic Nd: YAG laser vs. other potential sources.

Additionally, the technical specifications of our proposed platform in comparison with existing platforms are presented in Table 2. The table highlights key technical parameters such as pulse energy, spot size, and other relevant factors that contribute to the effectiveness of our platform in hyperopic correction.

It is essential to highlight that our system is intended to support a variety of laser sources, giving flexibility for future applications and allowing for the investigation of different wavelengths and performance factors. This versatility ensures that the device can be optimized for individual criteria, such as safety, cost-effectiveness, and practicality.

2.4 Hyperopia laser profile algorithm

The device is integrated with three Arduino platforms to control the majority of its modules and a processing IDE-built GUI to run the device’s essential functions. To implement the treatment profile algorithm, each galvo scanner is fed by a specific sinusoidal wave which controls deflection in the angles of the galvo scanners as demonstrated in (Fig. 6). The galvo scanner generates line-shaped spots if the two sine waves have the same amplitude and phase (Fig. 6a). In addition, an ellipse shape will be formed if the phase shift is not 90° (Fig. 6b). On the other hand, two sine waves with the same amplitude and a 90° phase shift produce a circle shape (Fig. 6c).

The hyperopia treatment algorithm requires laser spots as circles with various diameters as shown in Fig. 7(a). In our treatment procedures for hyperopia, some circles will be repeated more than others, depending on the type of required treatment. For example, in Fig. 7(b) and 7(c), the red circle is repeated more than the orange, followed by the yellow circle, and finally, the blue circle achieves the deepest ablation.

When the ablation algorithm is applied, the expected result is to steep the corneal tissue, as presented in Fig. 8 (a). The red ring creates the maximum ablation depth, while the blue ring produces the minimum effect (Fig. 8b). Consequently, the focusing point will be shifted from F1 to F2, as shown in Fig. 8(c). The stepped structure depicted in Fig. 8 was created only to highlight the disparity in depth necessary for addressing the hyperopic profile. It is worth noting that the actual applied profile exhibits a considerably smoother appearance due to the inherent smoothing effect of the Gaussian laser pulse ablation. This ablation process induces a gradual and continuous removal of tissue resulting in a more uniform and smooth shape of the ablated area.

2.5 Device testing and validation

To evaluate the device basic operation, the illumination reached the target was measured with a LUX meter (TOTAL model TETUO1, China), and the debris removal blower efficiency was measured by an anemometer (UNI-T model UT363, China). Moreover, the temperature of cooled air blower was measured by an infrared thermometer (CROWN model CT44037, Switzerland). Moreover, the generated UV- laser (266 nm) was confirmed via spectrometer (Photontec-Firefly4000, Germany). The scanner’s efficiency and the laser profile were initially tested on black paper sheets. Furthermore, the hyperopia algorithm profile of + 1 is applied on PMMA plates and measured by lensometer (Huvitz model32-AXIS221, South Korea). Ex-vivo rabbit eyes were examined under the optical microscope (OPTECH model LFZT, Germany) to investigate the ablation effect using a rotating Scheimpflug camera (WaveLight model allegro oculyzer II, Germany) for thickness evaluation after treatment.

2.6 Ex-vivo rabbit eyes preparation

Ex-vivo rabbit eyeballs were bought from nearby butcher shops and treated within 15 min after the animal was slaughtered. Mechanical epithelial debridement was performed before laser application. The applied experimental procedures and animal protocols were approved by Cairo University-the Institutional Animal Care and Use Committee (CU-IACUC) with approval number: CU/ I/ F/ 9/ 22).

3 Results

3.1 Target illumination and external UV-laser

The measured illumination on the target surface was 410 lx which provides an excellent visualization on the screens. The airflow efficiency of the blower was 1.1 m/s revealing rapid debris removal. Moreover, the recorded temperature of the cooled air blower of copper air pipes was less than the room temperature by 7 °C resulting in a decrease in the temperature of the examined cornea. The wavelength of the generated forth-harmonic Nd: YAG laser that entered the device via its opening was confirmed with the spectrometer showing a sharp peak at 266 nm with total elimination of the other wavelengths (i.e. 1064 and 532 nm).

3.2 Evaluating the device’s basic operation

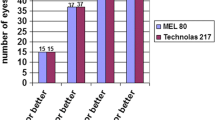

We conducted scanner excursion testing using black photo paper as a means to assess the movement and positioning accuracy of the laser beam. By examining the scanning profile on the black photo paper, we were able to evaluate the precision of the laser system in terms of its ability to deliver accurate and uniform laser pulses. Black paper sheets were subjected to 5 laser pulses (the minimum number of pulses to obtain the full-width at half maximum (FWHM), producing a circular spot on the paper sheet. The spot size was 500 μm (measured with Film Dot Gauge Spot meter), as presented in Fig. 9(a). To test the scanner excursion, four laser shoots were directed to the paper sheet at coordinates (x, y), (-x, y), (x,-y), and (-x,-y) resulting in the equal vertical and horizontal distances (see Fig. 9(b). Such a test was performed to avoid unneeded cylinder correction (Wu 2002). Additionally, executing perpendicular lines and full circle were successfully tested as illustrated in Fig. 9(c) and (d), respectively.

3.2.1 Hyperopia profile test

The ablation profile for hyperopia correction was applied on black paper sheets and PMMA as shown in Fig. 10(a) and (b), respectively. The presented images were captured via an optical microscope. The recorded correction on the PMMA targets was 0.9063 ± 0.1294 diopters with 8 mm optical zone. The numerical value and the indicated error is an average and the standard division of ten measurements taken via lensometer. PMMA is a commonly used material with known optical properties similar to the cornea (Arba-Mosquera and Triefenbach 2012), and the lensometer is a device used to measure the power of eyeglass lenses (Cordero 2016). By verifying the readings on the lensometer against the known properties of the PMMA, we could evaluate the accuracy of the laser system in measuring and delivering the intended energy levels.

Furthermore, the same algorithm was applied to ex-vivo rabbit eyes. The optical microscope image after the application of the ablation profile shows an obvious ablation effect on the cornea as shown in Fig. 11(a). The laser spots are made in the peripheral region rather than the central region for the hyperopia treatment protocol (Mimura et al. 2008).

After applying the laser treatment, the ex-vivo rabbit eyes were investigated via a rotating Scheimpflug camera. The tomographic image obtained by the rotating Scheimpflug camera showed a laser haze effect (marked by a red circle in Fig. 11(b). This haze effect results from the laser pulses on the cornea. A similar effect is usually observed with 193 nm ablation (Deshmukh et al. 2020; Mohan et al. 2008).

The results of the study demonstrate distinct ablation patterns during hyperopic treatment as illustrated in Fig. 11(a). The central region of the cornea exhibits minimal ablation, while gradual ablation is observed in the outer periphery. This distribution of ablation is consistent with the designed hyperopic profile discussed in Fig. 7 which highlights the stepping effect applied to the cornea by commercial devices for treating hyperopia. Furthermore, Fig. 11(b) presents tomography imaging of a sliced cornea which confirming the presence of the stepping effect resulting from the device’s ablation. The areas of corneal tissue ablation align with the marked red regions, thus validating the application and efficacy of the device in achieving the intended ablation profile. These findings provide empirical evidence supporting the successful implementation of the proposed ablation profile for hyperopic correction, demonstrating its compatibility with commercial devices and its ability to induce the desired changes in corneal shape. Consequently, the i-ablation device can replicate the ablation patterns commonly employed in commercial devices for hyperopic treatment. The ability to reproduce these patterns is crucial in ensuring the device’s compatibility with established treatment protocols and its potential for effective hyperopia correction.

Our research focuses mostly on hyperopic correction with the redesigned platform. While we have shown encouraging outcomes in this specific context, it is crucial to note that the platform’s application to other eye diseases or surgical procedures may require further studies. Future research may investigate the platform’s efficacy and safety across a broader set of indications. Moreover, long-term stability and reliability of the modified platform must be evaluated by extensive follow-up research. This includes assessing the platform’s long-term performance, component durability, and any dangers connected with prolonged use. More study is needed to ensure the platform’s consistent performance and safety over long periods. In addition, our current implementation of the modified system relies on a stranded ablation concept which does not provide direct customization choices for specific patient needs based on specific anatomical characteristics. However, we emphasize the necessity of adjusting for changes in corneal curvature, pupil size, and other anatomical characteristics that might have a major impact on treatment outcomes. Accordingly, we are currently pursuing additional research and development to incorporate customized ablation techniques into our system.

To further enhance the practicality and applicability of our device, we have identified several key areas that require improvement in its installation. Firstly, the scanning capabilities of the laser platform can be enhanced by incorporating advanced scanning technologies (such as high-speed galvanometer scanners) to improve the precision and speed of laser beam delivery (Luo et al. 2017; Moskal et al. 2023). Additionally, the visualization systems can be upgraded to include real-time imaging modalities such as optical coherence tomography (OCT) to provide accurate and detailed visualization of the ocular structures during the surgical procedure (Zeppieri et al. 2023). Moreover, the control features of the platform can be optimized by implementing intelligent algorithms and feedback mechanisms to enable adaptive control of laser parameters based on real-time tissue responses (Rakhmatulin et al. 2024). These enhancements are required to integrate our technology with the most recent advances in ophthalmology and assure its relevance for future use in clinical practice.

The current article focuses primarily on the technological development and evaluation of the modified laser eye surgery platform. Certification is an essential requirement for any medical equipment used in clinical practice including ophthalmic systems. The certification process assures that the device is safe, effective, and compliant with regulatory criteria, eventually evaluating its suitability for widespread clinical use. However, the main points to be considered for certification include tge regulatory considerations, safety and efficacy assessments and quality Assurance & manufacturing standards. To investigate the prospect of certification, we intend to perform more research and development activities. These activities will be focused on fulfilling the specific regulatory criteria and standards applicable to ophthalmic equipment, particularly laser eye surgery platforms. We plan to thoroughly review and adhere to the regulatory norms and requirements that apply to our propsed platform.

Although the proposed modification shows promise in improving outcomes, further clinical validation through well-designed studies and trials is necessary. Robust evidence demonstrating the clinical benefits, safety, and superiority of the modified system compared to existing approaches is essential to support its widespread adoption and acceptance within the medical community. For the current stage, the proposed device serves as a hands-on learning tool allowing trainees to explore and familiarize themselves with the intricate workings of ophthalmic systems. This educational aspect is an essential component of our research with the intention of nurturing the skills and knowledge of future ophthalmologists and medical professionals.

4 Conclusions

We have introduced a novel laser ablation system for eye surgery applications. The proposed corneal reshaping device (i-ablation) is analogous to other commercially available systems in the market that employ gas lasers (ArF laser at 193 nm) but with the ability to receive external laser beam through special design opening. Additionally, the device also has other advances such as fast debris removal system and a simple multifunctional user interface. The combination of the automatic debris removal system and the cooled air blower with a Peltier element addresses key challenges in hyperopic correction procedures, namely maintaining a clear treatment area and preventing corneal overheating. By providing effective solutions to these challenges, the proposed modification can enhance surgical accuracy, reduce the risk of adverse effects, and ultimately improve patient outcomes. Fourth harmonic Nd: YAG solid-state laser (266 nm) was experimentally generated to be used as the external laser beam. The solid-state lasers should be preferred due to the shortage of Neon gas required to operate the alternative gas lasers used in commercial devices. The photoablation effect of this particular UV wavelength (266 nm) was investigated using different samples, including PMMA targets and ex-vivo rabbit corneas. The promising ablation findings reveal that 266-nm wavelength has the potential to take the place of the typical 193-nm wavelength used in refractive eye surgery. For initial device testing, we investigated the laser ablation effect on the ex-vivo corneal tissues as a pilot study in hyperopia correction. For future investigations, further detailed in-vivo examinations are required for other refractive disorders, including myopia and astigmatism. Although the current state of the device may not be suitable for immediate clinical use. It holds significant value as a training and educational platform. By providing a comprehensive understanding of the underlying technologies and components it can contribute to the future development and enhancement of off-the-shelf ophthalmic systems.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Abdelhalim, I., Hamdy, O.: A low-cost and easy-to-use laser corneal reshaping device for educational, research and training purposes. In: Proceedings of the 2022 Design of Medical Devices Conference. pp. 3–6. ASME (2022)

Abdelhalim, I., Hamdy, O., Hassan, A.A., Elnaby, S.H.: Nd:YAG fourth harmonic (266-nm) generation for corneal reshaping procedure: An ex-vivo experimental study. PLoS ONE. 16(11), 16–e0260494 (2021). https://doi.org/10.1371/journal.pone.0260494 (b)

Abdelhalim, I., Hamdy, O., Hassan, A.A., Elnaby, S.H.: Assessing the local temperature of human cornea exposed to surface ablation by different laser refractive-surgery devices: A numerical comparative study. Lasers Med. Sci. 36, 1725–1731 (2021a). https://doi.org/10.1007/s10103-021-03347-5 (a)

Abdelhalim, I., Hamdy, O., Hassan, A.A., Abdelkawi, S., Elnaby, S.H.: A modified model for laser-cornea interaction following the ablation effect in the laser eye-surgery. Beni-Suef Univ. J. Basic. Appl. Sci. 12(1–14) (2023). https://doi.org/10.1186/s43088-023-00426-0 (a)

Abdelhalim, I., Hamdy, O., Khattab, M.A., Abdelkawi, S., Hassab Elnaby, S., Hassan, A.A.: Evaluating the efficacy of nd:YAG fourth harmonic (266 nm) in comparison with ArF excimer (193 nm) in laser corneal reshaping: Ex vivo pilot study. Int. Ophthalmol. 43, 3087–3096 (2023b). https://doi.org/10.1007/s10792-023-02708-z (b)

Abdelkawi, S.A., Ghoneim, D.F., Atoat, W., Badr, Y.A.: 193 nm ArF excimer laser and the potential risk for cataract formation. J. Appl. Sci. Res. 6, 796–805 (2010)

Arba-Mosquera, S., Triefenbach, N.: Analysis of the cornea-to-PMMA ablation efficiency rate. J. Mod. Opt. 59, 930–941 (2012). https://doi.org/10.1080/09500340.2012.683823

Atezhev, V.V., Barchunov, B.V., Vartapetov, S.K., Zav, A.S.: Laser technologies in ophthalmic surgery. Laser Phys. 26, 1–20 (2016). https://doi.org/10.1088/1054-660X/26/8/084010

Cordero, I.: Understanding and caring for a lensmeter. Community Eye Health J. 29, 37 (2016)

Deshmukh, R., Reddy, J.C., Rapuano, C.J., Vaddavalli, P.K.: Phototherapeutic keratectomy: Indications, methods and decision making. Indian J. Ophthalmol. 68, 2856–2866 (2020). https://doi.org/10.4103/ijo.IJO

Görtler, A., Strowitzki, C.: Excimer lasers – the powerful light source in the UV and VUV. Laser Tech. J. 2, 46–50 (2005). https://doi.org/10.1002/latj.200790037

Joffe, S.N.: The 25th anniversary of laser vision correction in the United States. Clin. Ophthalmol. 15, 1163–1172 (2021). https://doi.org/10.2147/OPTH.S299752

Kahuam-López, N., Navas, A., Castillo-Salgado, C., Graue-Hernandez, E.O., Jimenez-Corona, A., Ibarra, A.: Laser-assisted in-situ keratomileusis (LASIK) with a mechanical microkeratome compared to LASIK with a femtosecond laser for LASIK in adults with myopia or myopic astigmatism (review). Cochrane Database Syst. Reviews. 7, 1–63 (2020). https://doi.org/10.1002/14651858.CD012946.pub2.www.cochranelibrary.com

Kane, S.N., Mishra, A., Dutta, A.K.: Pulsed UV laser technologies for ophthalmic surgery. Journal of Physics: Conference Series. 793, 1–12 (2017). https://doi.org/10.1088/1742-6596/793/1/012022

Lubatschowski, H., Kermani, O., Often, C., Haller, A., Schmiedt, K.C., Ertmer, W.: ArF-excimer laser–induced secondary radiation in photoablation of biological tissue. Lasers Surg. Med. 14, 168–177 (1994). https://doi.org/10.1002/1096-9101(1994)14:2<168::AID-LSM1900140210>3.0.CO;2-1

Luo, X., Li, J., Lucas, M.: Galvanometer scanning technology for laser additive manufacturing. In: Proc. of SPIE, Laser 3D Manufacturing IV. pp. 1009512-1-8 (2017)

Maier, P., Reinhard, T., Kohlhaas, M.: Corneal Collagen Cross-linking in the stabilization of Keratoconus. Deutsches Arzteblatt Int. 116 (2019). https://doi.org/10.3238/arztebl.2019.0184

Manns, F., Milne, P., Parel, J.M.: Ultraviolet corneal photoablation. J. Refract. Surg. 18, S610–S614 (2002). https://doi.org/10.3928/1081-597X-20020901-22

Mbah, R.E., Wasum, D.F.: Russian-Ukraine 2022 War: A review of the Economic Impact of Russian-Ukraine Crisis on the USA, UK, Canada, and Europe. Adv. Social Sci. Res. J. 9, 145–153 (2022). https://doi.org/10.14738/assrj.93.12005

Mimura, T., Amano, S., Yokoo, S., Uchida, S., Usui, T., Yamagami, S.: Isolation and distribution of rabbit keratocyte precursors. Mol. Vis. 14, 197–203 (2008)

Mohan, R.R., Stapleton, W.M., Sinha, S., Netto, M.V., Wilson, S.E.: A novel method for generating corneal haze in anterior stroma of the mouse eye with the excimer laser. Exp. Eye Res. 8, 235–240 (2008). https://doi.org/10.1016/j.exer.2007.10.014.A

Moskal, D., Martan, J., Honner, M.: Scanning strategies in laser surface texturing: A review. Micromachines. 14, 1–24 (2023). https://doi.org/10.3390/mi14061241

Netto, M.V., Mohan, R.R., Medeiros, F.W., Dupps, W.J., Sinha, S., Krueger, R.R., Stapleton, W.M., Rayborn, M., Suto, C., Wilson, S.E.: Femtosecond laser and microkeratome corneal flaps: Comparison of stromal wound healing and inflammation. J. Refract. Surg. 23, 667–676 (2007). https://doi.org/10.3928/1081-597x-20070901-05

Pallikaris, I., Papadaki, T.: History of LASIK. (2002)

Pidro, A., Biscevic, A., Pjano, M.A., Mravicic, I., Bejdic, N., Bohac, M.: Excimer lasers in refractive surgery. Acta Informatica Med. 27, 278–283 (2019). https://doi.org/10.5455/aim.2019.27.278-283

Rakhmatulin, I., Risbridger, D., Carter, R.M., Esser, M.J.D., Erden, M.S.: A review of automation of laser optics alignment with a focus on machine learning applications. Opt. Lasers Eng. 173, 1–10 (2024). https://doi.org/10.1016/j.optlaseng.2023.107923

Shah, S., Piovella, M.: Solid-State Laser Platforms: Two Reviews the Benefits of Using the Pulzar Z1 and LaserSoft Technologies, pp. 26–30. Cataract & Refractive Surgery Today EUROPE (2013)

Shah, T.J., Moshirfar, M., Hoopes, P.C.: Safety of the excimer laser in LASIK and PRK for patients with implantable cardiac devices: Our clinical experience in the past two decades. J. Ophthalmic Vis. Res. 14, 530–531 (2019). https://doi.org/10.18502/jovr.v14i4.5473

Shraiki, M., Arba-mosquera, S.: Simulation of the impact of refractive surgery ablative laser pulses with a Flying-Spot Laser Beam on Intrasurgery corneal temperature. Investig. Ophthalmol. Vis. Sci. 52, 3713–3722 (2011). https://doi.org/10.1167/iovs.10-6706

Tomás-Juan, J., Murueta-Goyena Larrañaga, A., Hanneken, L.: Corneal regeneration after photorefractive keratectomy: A review. J. Optometry. 8, 149–169 (2015). https://doi.org/10.1016/j.optom.2014.09.001

Vossmerbaeumer, S.: Application principles of excimer lasers in ophthalmology. Med. Laser Appl. 25, 250–257 (2010). https://doi.org/10.1016/j.mla.2010.08.004

Wu, H.K.: Astigmatism and LASIK. Curr. Opin. Ophthalmol. 13, 250–255 (2002). https://doi.org/10.1097/00055735-200208000-00012

Yu, D., Brown, E.B., Huxlin, K.R., Knox, W.H.: Tissue effects of intra-tissue refractive index shaping (IRIS): Insights from two-photon autofluorescence and second harmonic generation microscopy. Biomedical Opt. Express. 10, 855 (2019). https://doi.org/10.1364/boe.10.000855

Zeppieri, M., Marsili, S., Enaholo, E.S., Shuaibu, A.O., Uwagboe, N., Salati, C., Spadea, L., Musa, M.: Optical coherence tomography (OCT): A brief look at the uses and Technological Evolution of Ophthalmology. Medicina. 59, 1–18 (2023). https://doi.org/10.3390/medicina59122114

Acknowledgements

The authors would like to thank the ophthalmologist Dr. Assem Zahran, the founder of Zahran Eye Center, for his invaluable support and assistance with the required equipment. We also would like to thank optometrists Mohamed Koura and Essam Ahmed for their insightful comments that improved the manuscript.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

IA and AAH were involved in conceptualization and validation. IA curated the data. OH and SA carried out the formal analysis. IA, and OH conducted the investigation. OH, and SA were responsible for visualization. SH participated in supervision. IA wrote the original draft. OH, SA, AAH and SH contributed to writing—reviewing and editing.

Corresponding author

Ethics declarations

Ethical approval

Sample collection and preparation methods were approved by Cairo University-the Institutional Animal Care and Use Committee (CU-IACUC), number: CU/ I/ F/ 9/ 22).

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abdelhalim, I., Hassan, A.A., Abdelkawi, S. et al. A modified flying-spot laser eye-surgery platform for hyperopic correction. Opt Quant Electron 56, 1268 (2024). https://doi.org/10.1007/s11082-024-07152-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-024-07152-6