Abstract

High refractive index contrast gratings (HCGs) with their extraordinary optical properties are very interesting candidates to substitute Distributed Bragg Reflectors as mirrors in optoelectronic semiconductor devices. In this work we present results of optical examination of a large scale HCG structure fabricated by focused-ion beam etching technique. The measured reflectance spectra exhibit a strong dependence on polarization of incident light, which confirms theoretical predictions. We also studied optical properties of a cavity formed by the HCG stacked on a wafer containing a VECSEL-like epitaxial structure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, distributed Bragg reflectors (DBRs) are in widespread use in technology of surface-normal emitting lasers like VCSELs and VECSELs Calvez et al. (2009). Despite very high reflectivity of such kind of mirrors, we must be aware of their limitations. The choice of materials of suitable high contrast of values of refractive index and the similar lattice constants is already a big challenge, however the most important problem is the heat management Calvez et al. (2009), Chernikov et al. (2011). For example optically pumped vertical-cavity lasers suffer from strong heating of their active media caused by high power density of a pumping laser beam. Therefore, the output power of the device is limited by thermal effects occurring within the active region. One of the common solutions is to use a top heat spreader (a plate of a high thermal conductivity material, e.g. sapphire or diamond) in order to redistribute the heat laterally and thus transport the heat more effectively down to a copper heat sink. Further improvement of the heat management can be obtained by eliminating the multilayer Bragg mirror from the semiconductor structure. This can be practically realised considering the extraordinary properties of high refractive index contrast gratings (HCGs) Mateus et al. (2004a), Mateus et al. (2004b). With this approach it is possible to substitute DBR for a heat spreader embodying this kind of structure as a mirror Huang et al. (2007), Chang-Hasnain and Yang (2012).

The goal of this work was to study the HCG structure fabricated by FIB etching to confirm its extraordinary properties and to verify applicability of FIB milling technique for its fabrication. Focused Ion Beam (FIB) systems have become very useful tools used in the micro- and nanotechnology because they provide easy prototyping Łaszcz et al. (2014) or post-processing customization of individual devices Czerwinski et al. (2015). The important advantage of FIB etching method is a possibility to fabricate the nanophotonics structures much faster compared with standard patterning approaches, like lithography or imprint techniques. We investigated polarization dependence of the HCG reflectance spectra and their agreement with calculated results. We also attempted to study optical properties of the cavity formed by the HCG combined with a VECSEL-like epitaxial structure.

2 High contrast grating

High refractive index contrast grating is a single layer photonic structure composed of periodically repeated stripes made of high refractive index material and low refractive index material gaps between them. It has to be surrounded by low refractive index media. Additionally to the ratio of the refractive indices of the materials which a HCG is made of, its optical properties depend significantly on geometric parameters of the grating. The most important ones are a grating period L, fill factor F (defined as the ratio of the stripe LF to the period L) and a layer thickness \(h_{HCG}\) (Fig. 1).

The schematic view of an HCG structure Gębski et al. (2015)

Although the design of this small planar structure seems to be very simple, it has extraordinary properties. It has been shown that HCG can be designed to have almost 100 % reflectivity for surface-normal incidence light Mateus et al. (2004b). This feature, together with significant polarization discrimination and sub-micron thickness, makes HCG very interesting in context of application in photonic devices.

The explanation for such a high reflectivity of HCG is associated with suppression of all apart from zeroth and first higher order waveguide modes excited in the structure upon vertically incident light. By tunning the grating thickness, an interference condition is met at the grating interfaces—either both modes interact destructively and cancel each other (high reflectance) or interact constructively (high transmission). The polarization dependence of HCG reflectivity is due to one-dimentional character of the structure Lee et al. (2009), Wan et al. (2011).

Such a structure can be realized using combination of photo or electron-beam lithography and etching Gebski et al. (2015). An alternative approach is to use the focused-ion beam (FIB) Kim et al. (2012) etching technique.

3 Experimental details

High contrast grating, studied in this work, is designed for maximal reflectivity at \(\lambda =980\,\hbox {nm}\). The structure was prepared by FIB etching of a 75 nm-thickness thin layer of amorphous silicon deposited on sapphire substrate. The size of the whole structure is 100 \(\upmu \hbox {m}\times 100\,\upmu \hbox {m}\), the period is 550 nm and the fill factor is 0.44. The \(h_{HCG}\) parameter is equal to the thickness of the amorphous silicon layer, because inside the grooves between the high index stripes all of the material has been etched. During the FIB etching process the preview in secondary electron mode of the milled region was applied to control if the layer of amorphous Si was completely removed.

The HCG pattern was made using the grid pattern created in the form of a bitmap and then imported into the FIB-system control program. FIB experiments were performed with a FEI Helios Nanolab 600 FIB using a ion (Ga+) beam energy of 30 keV and a beam current of 0.92 nA at chamber vacuum <2.6 \(\cdot 10^{-6}\) mbar. Preparation time was about 18 min for presented HCG. Due to the fact that the HCG is made on insulating substrate, to avoid charging effect the FIB charge neutralizer (flood gun) has been activated during the FIB experiment.

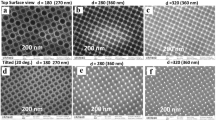

To verify the accuracy of the fabrication process, the structure dimensions were checked using Scanning Electron Microscopy (SEM) (Fig. 2). Although such a large scale structure is uncommon for the FIB etching technique, it can be seen that this method allows to maintain dimensional regime also in this case. Slight differences in comparison with the design are associated only with the cross-sectional shape of the strips. The small rounding of the edges is observed. However, receiving a very good quality of edges is a problem that occurs in greater or lesser extent in all nanoscale fabrication methods.

For the purpose of optical characterisation of the HCG structures, a micro-reflectance (\(\upmu \hbox {R}\)) setup was implemented. The schematic view of the measurement system is shown in Fig. 3.

A tungsten halogen lamp is used as a source of white light. The light beam is dispersed by a monochromator before reaching the sample surface. Next to the monochromator there is a pinhole and a lens which allow to form near collimated light beam. To ensure high spatial resolution of measurements a microscope objective is used to focus the incident light on the sample surface. Part of the light reflected from the sample is collected by the same objective and then directed to an InGaAs photodetector. A polarizer mounted before the detector allows for polarization dependent measurements. Since optical features of the investigated sample strongly depend on the angle of incidence of the light, an iris diaphragm is applied below the objective to reduce the solid angle of the collected light. An additional CCD camera is used to control the light spot size and its position on the sample. In order to improve signal-to-noise ratio we applied a chopper and a lock-in amplifier.

In case of reflectance measurements, the sample with HCG on its bottom surface is directly laying on the translation stage. To provide a surrounding of the grating by a low refractive index medium (air in this case), a special hole in the table is designed. On the other hand, in situation of optical investigation of the cavity, the sapphire plate with the HCG on its top surface lays on the VECSEL-like epitaxial structure (Fig. 4). The VECSEL chip applied for this part of investigation is a 8xQW InGaAs/GaAs epitaxial structure. The bottom DBR consists 27 repeated pairs of low/high refractive index material. The structure emits at 971 nm. As a result of the applied configuration of the structures, an optical cavity is formed between the bottom DBR of VECSEL chip and the investigated HCG. We measured the reflectance spectra of the HCG structure and the same HCG combined with VECSEL. We took into account the effect of sapphire layer on obtained spectra. All of the measurements were also performed for various polarization of incident light. For all the obtained results, both for the HCG and the optical cavity, a reflectance of a gold mirror was used as a reference. The details of numerical calculation of HCG reflectance spectra were presented elsewhere Gębski et al. (2015).

4 Results and discussion

We investigated polarization dependence on reflectance spectra of the studied HCG structure. A significant difference in the spectra obtained for TE (the non-zero component of the vector E parallel to the grating stripes) and TM (the non-zero component of the vector E perpendicular to the grating stripes) polarization of the incident light was observed for wavelength longer than 950 nm, whereas for shorter wavelengths the spectra were very similar (Fig. 5). This increases of the reflectance for TE polarized light confirm theoretical predictions, however the maximum value of reflectance is lower than numerical prediction. Discrepancy between experimental and theoretical results can be associated with losses in the measurement system. The other reasons of the low magnitude of reflectance may be roughness of the amorphous silicon layer, rounding and corrugation of the edges. The Ga ions implantation existing in case of FIB milling is not to be expected to be significant for the reason of trace amounts of the element in material after FIB milling (about 2 %) Greer and Nix (2006). The implanted Ga ions may affect magnitude of reflectance (for example by increasing scattering effect) rather than spectral shape of the reflectance spectra, but in the future this effect may be successfully eliminated by application of chemical cleaning Bayn et al. (2011).

The experimental data were also compared with theoretical results in terms of the spectrum shape. As it was mentioned the measured maximum value of reflectance is lower than data from modelling. Therefore in order to facilitate comparison of the spectra shapes, the experimental results were normalized (divided by the theoretical maximum value) (Fig. 6). We noticed an agreement between the shapes of the numerically predicted and measured spectra. Existing shift between them can be explained by the difference in the actual geometric parameters of the fabricated grating and the ideal one assumed in numerical model. However, the observed discrepancy is low because the HCG reflectivity is not very sensitive to the shape of the strips.

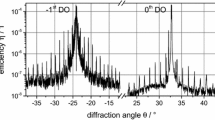

A strong polarization dependence of the measured spectra was also observed in case of optical properties of the cavity, such as its quality factor (Q-factor). This parameter describes how much energy losses are in comparison with the energy stored in the resonator (in this case in the optical cavity). The high value of Q-factor indicates a low rate of the energy loss relative to the stored energy. In optical spectrum of the investigated VECSEL-like structure combined with HCG the high Q-factor is associated with deep cavity in the photonic stopband region (Fig. 7). For TE polarization we observed improvement of the optical cavity Q-factor compared with the result obtained for VECSEL without HCG. This effect does not occur for perpendicular polarization (TM). It can be also noticed that the Q-factor of the cavity changes gradually from the polarization of the incident light (Fig. 7).

\(\mu \hbox {R}\) spectra of HCG combined with a VECSEL-like epitaxial structure in various polarizations of incident light. A strong polarization dependence of the reflectance spectra of the optical cavity can be observed. For TE polarization the presence of HCG results in significant improvement of Q-factor of the optical cavity (labelled as HCG in the plot legend) in comparison with case of the presence of sapphire plate without HCG (labelled as sapphire in the plot legend)

This can be explained by fact that the Q-factor of the optical cavity is associated with the changes of the reflectance values of the HCG structure. This relation can be observed on the theoretical reflectance spectra of the HCG structure for various polarizations (Fig. 8).

5 Summary

In this work HCG mirrors fabricated by FIB etching were characterized by means of micro-reflectance measurements. We confirmed the theoretical predictions about extraordinary optical properties of HCGs. Moreover, the reasonable agreement of the experimental data and results obtained by calculations leads to conclusion that such a large scale HCG structures can be fabricated by FIB process with satisfying quality. The correlation between polarization of incident light and the optical properties of the cavity formed by the HCG combined with VECSEL-like epitaxial structure is very interesting from the point of view of future applications of HCGs as laser mirrors. Our investigations were a first step to the application of such structures fabricated by FIB technique in technology of vertical cavity lasers which can result in a significant facilitation of the heat management without reduction of reflectivity and their optical performance. Obviously, the applied fabrication technology needs optimalization and improvement to obtain higher reflectance of the HCG structures.

References

Bayn, I., Bolker, A., Cytermann, C. , Meyler, B., Richter, V., Salzman, J., Kalish, R.: Diamond processing by focused ion beam—surface damage and recovery. Appl. Phys. Lett. 99, 183109–1–183109–3 (2011)

Calvez, S., Hastie, J.E., Guina, M., Okhotnikov, O.G., Dawson, M.D.: Semiconductor disk lasers for the generation of visible and ultraviolet radiation. Laser Photon. Rev. 3(5), 407–434 (2009)

Chang-Hasnain, C.J., Yang, W.: High-contrast gratings for integrated optoelectronics. Adv. Opt. Photon. 4(3), 379–440 (2012)

Chernikov, A., Herrmann, J., Koch, M., Kunert, B., Stolz, W., Chatterjee, S., Koch, S.W., Wang, T.L., Kaneda, Y., Yarborough, J.M., Hader, J., Moloney, J.V.: Heat management in high-power vertical-external-cavity surface-emitting lasers. IEEE J. Sel. Top. Quantum Electron. 17(6), 1772–1778 (2011)

Czerwinski, A., Pluska, M., Łaszcz, A., Ratajczak, J., Pierściński, K., Pierścińska, D., Gutowski, P., Karbownik, P., Bugajski, M.: Formation of coupled-cavities in quantum cascade lasers using focused ion beam milling. Microelectron. Reliab. 1(55), 2142–2146 (2015)

Gebski, M., Kuzior, O., Wasiak, M., Szerling, A., Wójcik-Jedlińska, A., Pałka, N., Dems, M., Xie, Y.Y., Xu, Z.J., Wang, Q.J., Zhang, D.H., Czyszanowski, T.: High-contrast grating reflectors for 980 nm vertical-cavity surface-emitting lasers. Proc. SPIE 9372, 937206–937206-9 (2015)

Gębski, M., Dems, M., Szerling, A., Motyka, M., Marona, L., Kruszka, R., Urbańczyk, D., Walczakowski, M., Pałka, N., Wójcik-Jedlińska, A., Wang, Q.J., Zhang, D.H., Bugajski, M., Wasiak, M., Czyszanowski, T.: Monolithic high-index contrast grating: a material independent high-reflectance VCSEL mirror. Opt. Express 23(9), 11674–11686 (2015)

Greer, J.R., Nix, W.D.: Nanoscale gold pillars strengthened through dislocation starvation. Phys. Rev. B 73, 45410–1–245410–6 (2006)

Huang, M.C.Y., Zhou, Y., Chang-Hasnain, C.J.: A surface-emitting laser incorporating a high-index-contrast subwavelength grating. Nat. Photon. 1(5), 119–122 (2007)

Kim, C.-S., Ahn, S.-H., Jang, D.-Y.: Review: developments in micro/nanoscale fabrication by focused ion beams. Vacuum 86(8), 1014–1035 (2012)

Łaszcz, A., Nogala, W., Czerwiński, A., Ratajczak, J., Katcki, J.: Fabrication of electrochemical nanoelectrode for sensor application using focused ion beam technology. Pol. J. Chem. Technol. 16(3)(1), 40–44 (2014)

Lee, J., Ahn, S., Chang, H., Kim, J., Park, Y., Jeon, H.: Polarization-dependent GaN surface grating reflector for short wavelength applications. Opt. Exp. 17(25), 22535–22542 (2009)

Mateus, C.R.F., Huang, M.C.Y., Chen, L., Chang-Hasnain, C.J., Suzuki, Y.: Broad-band mirror (1.12–1.62 \(\upmu\)m) using a subwavelength grating. IEEE Photon. Technol. Lett. 16(7), 1676–1678 (2004a)

Mateus, C.F.R., Huang, M.C.Y., Deng, Y., Neureuther, A.R., Chang-Hasnain, C.J.: Ultra-broadband mirror using low index cladded subwavelength grating. IEEE Photon. Technol. Lett. 16(2), 518–520 (2004b)

Wan, R., Karagodsky, V., Chang-Hasnain, C.J. : High reflectivity subwavelength metal grating for vcsel applications. In 2011 Conference on Lasers and Electro-Optics (CLEO), pp. 1–2, May 2011

Acknowledgments

The authors acknowledge support from MPNS COST ACTION MP1204-TERA-MIR Radiation, Materials, Generation, Detection and Applications. M. Gębski acknowledges the support by the Polish National Science Centre within the project PRELUDIUM 2013/11/N/ST7/02826.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of the Topical Collection on TERA-MIR: Materials, Generation, Detection and Applications.

Guest Edited by Mauro F. Pereira, Anna Wojcik-Jedlinska, Renata Butkute, Trevor Benson, Marian Marciniak and Filip Todorov.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Urbańczyk, D., Wójcik-Jedlińska, A., Muszalski, J. et al. Optical examination of high contrast grating fabricated by focused-ion beam etching. Opt Quant Electron 48, 267 (2016). https://doi.org/10.1007/s11082-016-0544-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-016-0544-8