Abstract

Dry friction dampers in turbomachinery not only decrease the vibration level, but also generate frictional heat. This thermal process may cause a significant temperature rise at the contact interface, producing thermal expansion and altering tribological properties subsequently. These effects in turn can change structural dynamics. Besides, the temperature rise may also cause the material melting and ablation, leading to damper failure. Hence, the structural dynamics and the thermal process in dry friction systems are interacting. The thermomechanical coupling should be included in analyses. In this paper, a novel numerical method, namely Dry Friction Thermo-Mechanical Coupling Response Prediction (DFTMCP), is proposed. Based on the multi-harmonic balance method, the DFTMCP can synchronously predict the nonlinear forced response and interface temperature in the steady state. This method is under the framework of steady heat transfer assumption, and a dimensionless number is proposed to determine the rationality of the assumption. To guarantee efficiency and convergence, an ad hoc model reduction technique for the nonlinear thermomechanical coupling problem and the corresponding analytical Jacobian matrix, which are also the highlights of the work, are implemented. The former reduces the dimension of the governing equations by over 98.6% while the latter makes the time cost drop over 37 times. By using the proposed numerical method, two essential coupling factors, the thermoelastic deformation and the friction coefficient variation at the interface, are considered and discussed quantitatively for the influence on the forced response through the finite element model of a blade with a flat underplatform damper in engineering. A convergence analysis has been performed to validate the correctness of the simulation results. Results show that under the specific rotational speed, the average temperature at the contact surface rises by 415 °C, and the maximum local temperature increases to 1229 °C, which is close to the melting point. Ignoring the thermomechanical coupling effect leads to a 19.0% misprediction of the optimal centrifugal force and a 21.4% underestimation of the resonant peak.

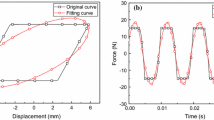

Graphical abstract

Similar content being viewed by others

Data availability

The results presented in this work can be replicated by implementing the equations and the finite element model presented in this paper. All relevant equations have been included to enable readers to replicate the results. The mesh of the finite element model will be made available by request.

Change history

27 June 2023

A Correction to this paper has been published: https://doi.org/10.1007/s11071-023-08668-4

References

Griffin, J.H.: A review of friction damping of turbine blade vibration. Int. J. Turbo Jet Engines 7(3–4), 297–308 (1990)

Ferhatoglu, E., Gastaldi, C., Botto, D., Zucca, S.: An experimental and computational comparison of the dynamic response variability in a turbine blade with under-platform dampers. Mech. Syst. Signal. Pr. 172, 108987 (2022)

Krack, M., Salles, L., Thouverez, F.: Vibration prediction of bladed disks coupled by friction joints. Arch. Comput. Method E 24(3), 589–636 (2017)

Cherikh, M., Bauzin, J., Laraqi, N.: Experimental estimation of transient evolution of three thermal parameters characterizing a dry friction interface. Int. J. Heat Mass Trans. 169, 120986 (2021)

Jabbar, N.A., Hussain, I.Y., Abdullah, O.I.: Thermal and thermoelastic problems in dry friction clutch: a comprehensive review. Heat Transf 50(8), 7855–7878 (2021)

Lavella, M., Botto, D.: Fretting wear of alloy steels at the blade tip of steam turbines. Wear 426–427, 735–740 (2019)

Botto, D., Lavella, M.: High temperature tribological study of cobalt-based coatings reinforced with different percentages of alumina. Wear 318(1–2), 89–97 (2014)

Pauzi, A.A., Ghazali, M.J., Zamri, W.F.H.W., et al.: Wear characteristics of superalloy and hardface coatings in gas turbine applications-a review. Metals 10(9), 1171 (2020)

Pearson, S.R., Shipway, P.H., Abere, J.O., et al.: The effect of temperature on wear and friction of a high strength steel in fretting. Wear 303(1–2), 622–631 (2013)

Guérin, N., Thorin, A., Thouverez, F., et al.: Thermomechanical model reduction for efficient simulations of rotor-stator contact interaction. J. Eng. Gas Turbine Power 141(2), 022501 (2019)

Thorin, A., Guérin, N., Legrand, M., et al.: Nonsmooth thermoelastic simulations of blade-casing contact interactions. J. Eng. Gas Turbine Power 141(2), 022502 (2019)

Lavella, M.: Contact properties and wear behaviour of nickel based superalloy René 80. Metals 6, 159 (2016)

Schwingshackl, C.W., Petrov, E.P., Ewins, D.J.: Measured and estimated friction interface parameters in a nonlinear dynamic analysis. Mech Syst Signal Pr 28, 574–584 (2012)

Gastaldi, C., Berruti, T.M., Gola, M.M.: Best practices for underplatform damper designers, proceedings of the institution of mechanical engineers. Proc. Inst. Mech. Eng., Part C 232(7), 1221–1235 (2018)

Gastaldi, C., Gola, M.M.: Criteria for best performance of pre-optimized solid dampers. J. Eng. Gas Turbines Power 141(4), 75961 (2019)

Bowden, F.P., Ridler, K.E.W.: A note on the surface temperature of sliding metals. Math. Proc. Cambr. 31(3), 431–432 (1935)

Blok, H.: Theoretical study of temperature rise at surfaces of actual contact under oiliness lubricating conditions. Gen. Discussion Lubric. Inst. Mech. Eng. London 2, 222–235 (1937)

Jaeger, J.C.: Moving sources of heat and the temperature at sliding contacts. Proc. R. Soc. New South Wales 76, 203–224 (1942)

Archard, J.F.: The temperature of rubbing surfaces. Wear 2, 438–455 (1959)

Hamraoui, M., Zouaoui, Z.: Modelling of heat transfer between two rollers in dry friction. Int. J. Therm. Sci. 48(6), 1243–1246 (2009)

Nosko, O.: Thermal boundary conditions to simulate friction layers and coatings at sliding contacts. Int. J. Heat Mass Trans. 127, 1128–1137 (2018)

Bauzin, J., Nguyen, M., Laraqi, N., Cherikh, M.: Thermal characterization of frictional interfaces using experiments and inverse heat conduction methods. Int. J. Therm. Sci. 137, 431–437 (2019)

Smith, E.H., Arnell, R.D.: A new approach to the calculation of flash temperatures in dry, sliding contacts. Tribol. Lett. 52(3), 407–414 (2013)

Smith, E.H., Arnell, R.D.: The prediction of frictional temperature increases in dry, sliding contacts between different materials. Tribol. Lett. 55(2), 315–328 (2014)

Wang, L., He, Y., Zhou, J., et al.: Effect of temperature on the frictional behaviour of an aluminium alloy sliding against steel during ball-on-disc tests. Tribol. Int. 43(1–2), 299–306 (2010)

Mann, R., Magnier, V., Brunel, J.F., Dufrenoy, P., Henrion, M., Guillet-Revol, E.: Thermomechanical characterization of high-speed train braking materials to improve models: numerical validation via a comparison with an experimental braking test. Tribol. Int. 156, 106818 (2021)

Li, W., Pang, D., Hao, W.: Effects of the helix angle, the friction coefficient and mechanical errors on unsteady-state temperature field of helical gear and thermal sensitivity analysis. Int. J. Heat Mass Trans. 144, 118669 (2019)

Lavella, M., Botto, D., Gola, M.M.: Design of a high-precision, flat-on-flat fretting test apparatus with high temperature capability. Wear 302(1–2), 1073–1081 (2013)

Lavella, M., Botto, D.: Fretting wear characterization by point contact of nickel superalloy interfaces. Wear 271, 1543–1551 (2011)

Rowe, K.G., Bennett, A.I., Krick, B.A., et al.: In situ thermal measurements of sliding contacts. Tribol. Int. 62, 208–214 (2013)

Belov, V.M., Tkachuk, D.V., Bogdanovich, P.N.: Methods for recording the temperature in the friction and mechanical working of the solid bodies: a review. J. Frict. Wear 27(4), 74–83 (2006)

Oestringer, L.J., Proppe, C.: On the transient thermomechanical contact simulation for two sliding bodies with rough surfaces and dry friction. Tribol. Int. 170, 107425 (2022)

Chen, W.W., Wang, Q.J.: Thermomechanical analysis of elastoplastic bodies in a sliding spherical contact and the effects of sliding speed, heat partition, and thermal softening. J. Tribol. 130, 041402 (2008)

Seitz, A., Wall, W.A., Popp, A.: Nitsches method for finite deformation thermomechanical contact problems. Comput. Mech. 63, 1091–1110 (2019)

Batailly, A., Agrapart, Q., Millecamps, A., et al.: Experimental and numerical simulation of a rotor/stator interaction event localized on a single blade within an industrial high-pressure compressor. J. Sound Vib. 375, 308–331 (2016)

Almeida, P., Gibert, C., Thouverez, F., et al.: Experimental analysis of dynamic interaction between a centrifugal compressor and its casing. J. Eng. Gas Turbines Power 137(3), 031008 (2015)

Pesaresi, L., Salles, L., Jones, A., et al.: Modelling the nonlinear behaviour of an underplatform damper test rig for turbine applications. Mech. Syst. Signal. Pr. 85, 662–679 (2017)

Botto, D., Lavella, M., Gola, M.M.: Measurement of Contact Parameters of Flat on Flat Contact Surfaces at High Temperature, pp. 1325–1332. American Society of Mechanical Engineers (ASME), Copenhagen (2012)

Molinari, A., Estrin, Y., Mercier, S.: Dependence of the coefficient of friction on the sliding conditions in the high velocity range. J. Tribol. 121, 35–41 (1999)

Jiang, J., Ulbrich, H.: Derivation of coefficient of friction at high sliding speeds from energy conservation over the frictional interface. Wear 247(1), 66–75 (2001)

Yuan, J., Fantetti, A., Denimal, E., et al.: Propagation of friction parameter uncertainties in the nonlinear dynamic response of turbine blades with underplatform dampers. Mech Syst Signal Pr 156, 107673 (2021)

Schwingshackl, C.W., Petrov, E.P., Ewins, D.J.: Effects of contact interface parameters on vibration of turbine bladed disks with underplatform dampers. J. Eng. Gas Turbines Power 134(3), 032507 (2012)

Korkmaz, I., Barrau, J.J., Berthillier, M., Creze, S.: Theoretical dynamic analysis of a cantilever beam damped by a dry friction damper. Int. Design Eng. Tech. Conf. Comput. Inf. Eng. Conf. 3A, 0358 (1995)

Toufifine, A., Barrau, J.J., Berthillier, M.: Dynamic study of a simplified mechanical system with presence of dry friction. J. Sound Vib. 225(1), 95–109 (1999)

Ullah, M.W., Rahman, M.S., Uddin, M.A.: A modified harmonic balance method for solving forced vibration problems with strong nonlinearity. J. Low Freq. Noise Vib. Act. Control 40(2), 1096–1104 (2021)

Wu, Y.G., Li, L., Fan, Y., et al.: Design of semi-active dry friction dampers for steady-state vibration: sensitivity analysis and experimental studies. J. Sound Vib. 459, 114850 (2019)

Radecki, R., Leamy, M.J., Packo, P., Klepka, A.: Prediction of higher-order harmonics generation due to contact stiffness hysteresis using Harmonic Balance: theory and experimental validation. Nonlinear Dyn. 103, 541–556 (2021)

Zucca, S., Firrone, C.M.: Nonlinear dynamics of mechanical systems with friction contacts: coupled static and dynamic multi-harmonic balance method and multiple solutions. J. Sound Vib. 333(3), 916–926 (2014)

Ma, H.Y., Li, L., Wu, Y.G., et al.: Design of dry friction dampers for thin-walled structures by an accelerated dynamic Lagrange method. J. Sound Vib. 489, 115550 (2020)

Berthold, C., Gross, J., Frey, C., Krack, M.: Development of a fully-coupled harmonic balance method and a refined energy method for the computation of flutter-induced Limit Cycle Oscillations of bladed disks with nonlinear friction contacts. J. Fluid Struct. 102, 103233 (2021)

Krack, M., Gross, J.: Harmonic Balance for Nonlinear Vibration Problems. Springer, Cham (2019)

Woiwode, L., Gross, J., Krack, M.: Effect of modal interactions on friction-damped self-excited vibrations. J. Vibr. Acoust. Trans. ASME 143(3), 031003 (2021)

Siewert, C., Panning, L., Wallaschek, J., et al.: Multiharmonic forced response analysis of a turbine blading coupled by nonlinear contact forces. J. Eng. Gas Turbines Power 132(8), 082501 (2010)

Afzal, M., Lopez Arteaga, I., Kari, L.: An analytical calculation of the Jacobian matrix for 3D friction contact model applied to turbine blade shroud contact. Comput. Struct. 177, 204–217 (2016)

Wu, Y.G., Li, L., Fan, Y., et al.: Design of wave-like dry friction and piezoelectric hybrid dampers for thin-walled structures. J. Sound Vib. 493, 115821 (2021)

Poudou, O.: Modeling and analysis of the dynamics of dry-friction-damped structural systems, 2007.

Petrov, E.P., Ewins, D.J.: Effects of damping and varying contact area at blade-disk joints in forced response analysis of bladed disk assemblies. J. Eng. Gas Turbines Power 128, 403–410 (2006)

Laxalde, D., Thouverez, F., Lombard, J.P.: Forced response analysis of integrally bladed disks with friction ring dampers. J. Vib. Acoust. 132(1), 011013 (2010)

Petrov, E.P.: A high-accuracy model reduction for analysis of nonlinear vibrations in structures with contact interfaces. J. Eng. Gas Turbines Power 133(10), 102503 (2011)

Quaegebeur, S., Chouvion, B., Thouverez, F.: Model reduction of nonlinear cyclic structures based on their cyclic symmetric properties. Mech. Syst. Signal. Pr. 145, 106970 (2020)

Nyssen, F., Vadcard, T., Piollet, E., et al.: Strongly coupled thermo-mechanical casing/abradable model for rotor/stator interactions. ASME Turbo Expo Turbomach. Tech. Conf. Expos. 7B, 91447 (2019)

Nachtergaele, P., Rixen, D.J., Steenhoek, A.M.: Efficient weakly coupled projection basis for the reduction of thermo-mechanical models. J. Comput. Appl. Math. 234(7), 2272–2278 (2010)

Guerin, N., Thouverez, F., Gibert, C., et al.: Thermomechanical component mode synthesis for blade casing interaction prediction. ASME Turbo. Expo 2017 Turbomach. Tech. Conf. Expos. 7, 64342 (2017)

Liu, Z., Kannatey-Asibu, E., Wang, Y., et al.: Nonlinear dynamic analysis of ultrasonic metal welding using a harmonic balance method. Procedia CIRP 76, 89–93 (2018)

Liu, Z., Li, Y., Wang, Y., et al.: Nonlinear dynamics of friction heating in ultrasonic welding. J. Eng. Ind. 141(6), 061011 (2019)

Agrapart, Q., Nyssen, F., Lavazec, D., Dufrenoy, P., Batailly, A.: Multi-physics numerical simulation of an experimentally predicted rubbing event in aircraft engines. J. Sound Vib. 460, 114869 (2019)

Krack, M.: Extension of the single-nonlinear-mode theory by linear attachments and application to exciter-structure interaction. J. Sound Vib. 505, 116120 (2021)

Nyssen, F., Batailly, A.: Thermo-mechanical modeling of abradable coating wear in aircraft engines. J. Eng. Gas Turbines Power 141(2), 021031 (2019)

Afzal, A., Abdul Mujeebu, M.: Thermo-mechanical and structural performances of automobile disc brakes: a review of numerical and experimental studies. Arch. Comput. Method E 26, 1489–1513 (2019)

Hu, B., Zhang, X., Liu, Y., Yan, J., Liu, X., Wang, X., Sun, R.: 3D quasi-transient thermo-mechanical analysis for vehicle brake disc. J. Mech. Sci. Technol. 36, 969–981 (2022)

Cameron, T.M., Griffin, J.H.: An alternating frequency/time domain method for calculating the steady-state response of nonlinear dynamic systems. J. Appl. Mech. 56(1), 149–154 (1989)

Botto, D., Zucca, S., Gola, M.M.: Reduced-order models for the calculation of thermal transients of heat conduction/convection FE models. J. Therm. Stresses 30(8), 819–839 (2007)

Yuan, J., Sun, Y., Schwingshackl, C., Salles, L.: Computation of damped nonlinear normal modes for large scale nonlinear systems in a self-adaptive modal subspace. Mech. Syst. Signal Process. 162, 108082 (2022)

Reed, R.C.: The Superalloys: Fundamentals and Applications. Cambridge University Press, Cambridge (2006)

Acknowledgements

This work is funded by funded by Major Projects of Aero-Engines and Gas Turbines (J2019-IV-0005-0073 and J2019-IV-0023-0091), Jet Propulsion Creativity Center (Projects HKCX2020-02-013, HKCX2020-02-016 and HKCX2022-01-009).

Author information

Authors and Affiliations

Contributions

QG was involved in investigation, methodology, software, validation, writing—original draft, writing—review and editing. YF helped in supervision, writing—review and editing, resources, funding acquisition, project administration. YGW contributed to conceptualization, methodology, investigation, supervision, writing—review and editing, funding acquisition, project administration. LL helped in supervision, project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

The transient temperature part of the \(i{\text{th}}\) component in the temperature vector \({\tilde{\mathbf{\theta }}}^{k}\) for the \({0}^{\mathrm{th}}\) harmonic:

The transient temperature part of the \(i{\text{th}}\) component in the temperature vector \({\tilde{\mathbf{\theta }}}^{k}\) for other harmonics:

Appendix 2

Supposing M and N are the invertible matrices with \(m \times m\) and \(n \times n\) dimensions. P is the \(m \times n\) matrix. The inverse of the integral matrix can be expressed through the block matrix calculation as:

The condensation process can be expressed as

in which A, B, C and D are the static or dynamic stiffness matrix, x is the response vector. \({\mathbf{F}}_{{{\text{nl}}}}\) and \({\mathbf{F}}_{{{\text{nl}}}}\) are the nonlinear force vector and the excitation force vector, respectively. The subscripts o and s refer to the reduced DOFs and the retained DOFs, respectively. Substituting Eqs. (47) and (48) into (19), one can derive the reduced thermomechanical coupling equations:

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, Q., Fan, Y., Wu, Y. et al. A harmonic balance-based method to predict nonlinear forced response and temperature rise of dry friction systems including frictional heat transfer. Nonlinear Dyn 111, 14263–14291 (2023). https://doi.org/10.1007/s11071-023-08607-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-023-08607-3