Abstract

Carbon nanotube (CNT) resonant sensors are small in size and have high sensitivity. However, the CNT resonators are susceptible to nonlinear effect. The existing methods to avoid the nonlinearity would decrease the quality factor of the resonator. Here, a novel method for reducing nonlinear effect and increasing quality factor for a CNT resonant mass sensor is proposed. Based on the circuit model and mechanics model of the CNT resonant mass sensor with two feedback loops, the nonlinear vibration equation of the CNT resonant mass sensor is deduced which includes the non-local effect and the feedback control effects. Using this equation, the amplitude–frequency characteristics of the CNT and its variation with size parameters and feedback gain are studied. A method of simulating the nonlinear effect and quality factor of the sensor through the VAR module of ADS is proposed, which provides a reference for simulating nonlinear effect of field effect transistor sensors by using computer-aided design tools. Results show that by tuning feedback gain, the nonlinear effect of the CNT resonant mass sensor could be reduced and its quality factor could be increased. Using the feedback control strategy provided in this paper, the CNT sensor can be in a linear vibration state with high quality factor in a low-vacuum environment by only adjusting the feedback modulation gain, avoiding the expensive and complex ultra-low-temperature system.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Tarasov, A.E., Badamshina, E.R., Anokhin, D.V.: The effect of small additions of carbon nanotubes on the mechanical properties of epoxy polymers under static and dynamic loads. Tech. Phys. 63, 32–40 (2018). https://doi.org/10.1134/S1063784218010267

Banna, A.H., Kayang, K.W., Volkov, A.N.: Effects of the nanotube length and network morphology on the deformation mechanisms and mechanical properties of cross-linked carbon nanotube films. J. Appl. Phys. 129, 105101 (2021). https://doi.org/10.1063/5.0033442

Cai, X., Xu, L.: Multifield coupled dynamics model of resonant carbon nanotube mass sensor based on nonlocal elastic and electromagnetic effects. IEEE. Trans. Ind. Electron. 68, 11511–11522 (2021). https://doi.org/10.1109/TIE.2020.3038090

Craighead, H.G.: Nanoelectromechanical systems. Science 290, 1532–1536 (2000). https://doi.org/10.1063/1.1927327

Ekinci, K.L., Roukes, M.L.: Nanoelectromechanical systems. Rev. Sci. Instrum. (2005). https://doi.org/10.1063/1.1927327

Midolo, L., Schliesser, A., Fiore, A.: Nano-opto-electro-mechanical systems. Nat. Nanotechnol. 13, 11–18 (2018). https://doi.org/10.1038/s41565-017-0039-1

Yang, Y.T., Callegari, C., Feng, X.L.: Zeptogram-scale nanomechanical mass sensing. Nano. Lett. 6, 583–586 (2006). https://doi.org/10.1021/nl052134m

Chaste, J., Eichler, A., Moser, J.: A nanomechanical mass sensor with yoctogram resolution. Nat. Nanotechnol. 7, 300–303 (2012). https://doi.org/10.1038/nnano.2012.42

Moser, J., Guettinger, J., Eichler, A.: Ultrasensitive force detection with a nanotube mechanical resonator. Nat. Nanotechnol. 8, 493–496 (2013). https://doi.org/10.1038/nnano.2013.97

Losby, J.E., Sani, F.F., Grandmont, D.T.: Torque-mixing magnetic resonance spectroscopy. Science 350, 798–801 (2015). https://doi.org/10.1126/science.aad2449

O’connell, A.D., Hofheinz, M., Ansmann, M.: Quantum ground state and single-phonon control of a mechanical resonator. Nature 464, 697–703 (2010). https://doi.org/10.1038/nature08967

Rossi, M., Mason, D., Chen, J.: Measurement-based quantum control of mechanical motion. Nature 563, 53–54 (2018). https://doi.org/10.1038/s41586-018-0643-8

Wang, Z.L., Poncharal, P., Heer, W.A.: Measuring physical and mechanical properties of individual carbon nanotubes by in situ TEM. J. Phys. Chem. Solids. 61, 1025–1030 (2000). https://doi.org/10.1016/S0022-3697(99)00350-9

Li, H., Wang, X.A., Wang, H.B.: The nonlocal frequency behavior of nanomechanical mass sensors based on the multi-directional vibrations of a buckled nanoribbon. Appl. Math. Model. 77, 1780–1796 (2020). https://doi.org/10.1016/j.apm.2019.09.023

Schwab, K.: Spring constant and damping constant tuning of nanomechanical resonators using a single-electron transistor. Appl. Phys. Lett. 80, 1276–1278 (2002). https://doi.org/10.1063/1.1449533

Tamayo, J., Humphris, A.D.L., Owen, R.J.: High-Q dynamic force microscopy in liquid and its application to living cells. Biophys. J. 81, 526–537 (2001). https://doi.org/10.1016/S0006-3495(01)75719-0

Wang, X., Ma, S.: A celestial analytic positioning method by stellar horizon atmospheric refraction. Chinese. J. Aeronaut. 22, 293–300 (2009). https://doi.org/10.1016/S1000-9361(08)60102-8

Alex, T.K., Shrivastava, S.K.: On-board correction of systematic error of Earth sensors. IEEE Trans. Aerosp. Electron. Syst. 25, 373–379 (1989). https://doi.org/10.1109/7.30792

Tekawy, J.A., Wang, P., Gray, C.W.: Scanning horizon sensor attitude correction for Earth oblateness. J. Guid. Control. Dynam. 19, 706–708 (1996). https://doi.org/10.2514/3.21679

Li, J.: Simple correction algorithm of scanning horizon sensor measurement for Earth oblateness. J. Guid. Control. Dynam. 22, 187–190 (1996). https://doi.org/10.2514/2.7628

Wang, Q., Liew, K.M.: Application of nonlocal continuum mechanics to static analysis of micro- and nano-structures. Phys Lett A. 363, 236–242 (2007). https://doi.org/10.1016/j.physleta.2006.10.093

Kiani, K.: Non local continuous models for forced vibration analysis of two- and three-dimensional ensembles of single-walled carbon nanotubes. Physica E. 60, 229–245 (2014). https://doi.org/10.1016/j.physe.2014.01.033

Kiani, K.: In- and out-of-plane dynamic flexural behaviors of two-dimensional ensembles of vertically aligned single-walled carbon nanotubes. Physica B. 449, 164–180 (2014). https://doi.org/10.1016/j.physb.2014.04.044

Kiani, K.: Non local discrete and continuous modeling of free vibration of stocky ensembles of vertically aligned single-walled carbon nanotubes. Curr. Appl. Phys. 14, 1116–1139 (2014). https://doi.org/10.1016/j.cap.2014.05.018

Kiani, K.: Free vibration of in-plane-aligned membranes of single-walled carbon nanotubes in the presence of in-plane-unidirectional magnetic fields. J. Vib. Control. 22, 3736–3766 (2016). https://doi.org/10.1177/1077546314565684

Sazonova, V., Yaish, Y., Ustunel, H.: A tunable carbon nanotube electromechanical oscillator. Nature 431, 284–287 (2004). https://doi.org/10.48550/arXiv.cond-mat/0409407

Mei, J., Li, L.J.: Frequency self-tuning of carbon nanotube resonator with application in mass sensors. Sensor Actuat. B-Chem. 188, 661–668 (2013). https://doi.org/10.1016/j.snb.2013.07.030

Sidhardh, S., Patnaik, S., Semperlotti, F.: Fractional-order shell theory: formulation and application to the analysis of nonlocal cylindrical panels. J. Appl. Mech.-T Asme. (2022). https://doi.org/10.1115/1.4054677

Patnaik, S., Sidhardh, S., Semperlotti, F.: Displacement-driven approach to nonlocal elasticity. Eur. J. Mech. A-Solid. (2022). https://doi.org/10.1016/j.euromechsol.2021.104434

Patnaik, S., Sidhardh, S., Semperlotti, F.: Fractional-Order models for the static and dynamic analysis of nonlocal plates. Commun. Nonlinear Sci. (2021). https://doi.org/10.1016/j.cnsns.2020.105601

Patnaik, S., Sidhardh, S., Semperlotti, F.: Towards a unified approach to nonlocal elasticity via fractional-order mechanics. Int. J. Mech. Sci. (2021). https://doi.org/10.1016/j.ijmecsci.2020.105992

Patnaik, S., Semperlotti, F.: Modeling contacts and hysteretic behavior in discrete systems via variable-order fractional operators. J. Comput. Nonlinear Dyn. (2020). https://doi.org/10.1115/1.4046831

Patnaik, S., Semperlotti, F.: Variable-order fracture mechanics and its application to dynamic fracture. npj Comput. Mater. (2021). https://doi.org/10.1038/s41524-021-00492-x

Djebali, R., Mebarek-Oudina, F., Rajashekhar, C.: Similarity solution analysis of dynamic and thermal boundary layers: further formulation along a vertical flat plate. Phys. Scripta. (2021). https://doi.org/10.1088/1402-4896/abfe31

Farhan, M., Omar, Z., Mebarek-Oudina, F.: Implementation of the one-step one-hybrid block method on the nonlinear equation of a circular sector oscillator. Comput. Math. Model. 31, 116–132 (2020). https://doi.org/10.1007/s10598-020-09480-0

Warke, A.S., Ramesh, K., Mebarek-Oudina, F.: Numerical investigation of the stagnation point flow of radiative magnetomicropolar liquid past a heated porous stretching sheet. J. Therm. Anal. Calorim. 147, 6901–6912 (2022). https://doi.org/10.1007/s10973-021-10976-z

Liu, C.C., Ding, Q., Gong, Q.M., Ma, C.C., Yue, S.C.: Axial control for nonlinear resonances of electrostatically actuated nanobeam with graphene sensor. Appl Math Mech-Engl. 38, 527–542 (2017). https://doi.org/10.1007/s10483-017-2184-6

Ke, L.L., Wang, Y.S., Wang, Z.D.: Nonlinear vibration of the piezoelectric nanobeams based on the nonlocal theory. Compos Struct. 94, 2038–2047 (2012). https://doi.org/10.1016/j.compstruct.2012.01.023

Comi, C., Corigliano, A., Zega, V.: Non-linear response and optimization of a new z-axis resonant micro-accelerometer. Mechatronics 40, 235–243 (2016). https://doi.org/10.1016/j.mechatronics.2016.05.013

Cho, H., Lee, H., Oh, E.: Hierarchical structure of carbon nanotube fibers, and the change of structure during densification by wet stretching. Carbon 136, 409–416 (2018). https://doi.org/10.1016/j.carbon.2018.04.071

Sun, Y.G., Yao, X.H., Liang, Y.J., Han, Q.: Nonlocal beam model for axial buckling of carbon nanotubes with surface effect. EPL (2012). https://doi.org/10.1209/0295-5075/99/56007

Wu, J.X., Li, X.F., Tang, G.J.: Bending wave propagation of carbon nanotubes in a bi-parameter elastic matrix. PHYSICA B. 407, 684–688 (2012). https://doi.org/10.1016/j.physb.2011.11.057

Gunay, M.G.: Free transverse vibration of nickel coated carbon nanotubes. Int. J. Struct. Stab. Dyn. (2021). https://doi.org/10.1142/s0219455421500851

Sahmani, S., Ansari, R.: Nonlocal beam models for buckling of nanobeams using state-space method regarding different boundary conditions. J. Mech. Sci. Technol. 25, 2365–2375 (2011). https://doi.org/10.1007/s12206-011-0711-6

Darban, H., Luciano, R., Basista, M.: Calibration of the length scale parameter for the stress-driven nonlocal elasticity model from quasi-static and dynamic experiments. Mech. Adv. Mater. Struct. (2022). https://doi.org/10.1080/15376494.2022.2077488

Ouakad, H.M., Sedighi, H.M.: Rippling effect on the structural response of electrostatically actuated single-walled carbon nanotube based NEMS actuators. Int. J. Nonlinear Mech. 87, 97–108 (2016). https://doi.org/10.1016/j.ijnonlinmec.2016.09.009

Moradweysi, P., Ansari, R., Hosseini, K., Sadeghi, F.: Application of modified Adomian decomposition method to pull-in instability of nano-switches using nonlocal Timoshenko beam theory. Appl. Math. Model. 54, 594–604 (2018). https://doi.org/10.1016/j.apm.2017.10.011

Yang, J., Ke, L.L., Kitipornchai, S.: Nonlinear free vibration of single-walled carbon nanotubes using nonlocal Timoshenko beam theory. Physica E. 42, 1727–1735 (2010). https://doi.org/10.1016/j.physe.2010.01.035

Ke, L.L., Xiang, Y., Yang, J., Kitipornchai, S.: Nonlinear free vibration of embedded double-walled carbon nanotubes based on nonlocal Timoshenko beam theory. Comp. Mater. Sci. 47, 409–417 (2009). https://doi.org/10.1016/j.commatsci.2009.09.002

Wang, X., Yang, H.K.: Bending stability of multiwalled carbon nanotubes. Phys. Rev. B (2006). https://doi.org/10.1103/PhysRevB.73.085409

Wang, C.Y., Ru, C.Q., Mioduchowski, A.: Pressure effect on radial breathing modes of multiwall carbon nanotubes. J. Appl. Phys. (2005). https://doi.org/10.1063/1.1836007

Talebian, S.T., Tahani, M., Abolbashari, M.H.: An analytical solution for thermal shock analysis of multiwall carbon nanotubes. Comp. Mater. Sci. 61, 291–297 (2012). https://doi.org/10.1016/j.commatsci.2012.04.041

Parker, G.W.: Electric field outside a parallel plate capacitor. Am. J. Phys. 70, 751–754 (2002). https://doi.org/10.1119/1.1463738

Witkamp, B., Poot, M., Van, D.: Bending-mode vibration of a suspended nanotube resonator. Nano Lett. 6, 2904–2908 (2006). https://doi.org/10.1021/nl062206p

Ning, Z.Y., Fu, M., Wu, G.: Remarkable influence of slack on the vibration of a single-walled carbon nanotube resonator. Nanoscale 8, 8658–8665 (2016). https://doi.org/10.1039/c6nr00713a

Conley, W.G., Raman, A., Krousgrill, C.M., Mohammadi, S.: Nonlinear and nonplanar dynamics of suspended nanotube and nanowire resonators. Nano Lett. 8, 1590–1595 (2008). https://doi.org/10.1021/nl073406j

Xia, X., Li, X.: Resonance-mode effect on microcantilever mass-sensing performance in air. Rev. Sci. Instrum. (2008). https://doi.org/10.1063/1.2949390

Yao, Z., Zhu, C.C., Min, C.: Mechanical properties of carbon nanotube by molecular dynamics simulation. Comp. Mater. Sci. 22, 180–184 (2001). https://doi.org/10.1016/S0927-0256(01)00187-2

Gil-Santos, E., Baker, C., Nguyen, D.T.: High-frequency nano-optomechanical disk resonators in liquids. Nat. Nanotechnol. 10, 810–812 (2015). https://doi.org/10.1038/nnano.2015.160

Wang, G.S., Wen, B., He, S.: Multiple nonlinear dielectric resonance of ultra-long silver trimolybdate nanowire. J. Solid. State. Chem. 202, 320–323 (2013). https://doi.org/10.1016/j.jssc.2013.01.033

Qian, X., Fan, W., Wang, S.: Nonlinear effect of forced harmonic oscillator subject to sliding friction and simulation by a simple nonlinear circuit. Am. J. Phys. (2018). https://doi.org/10.1119/1.5082534

Photiadis, D.M., Judge, J.A.: Attachment losses of high Q oscillators. Appl. Phys. Lett. 85, 482 (2004). https://doi.org/10.1063/1.1773928

Wilson-Rae, I.: Intrinsic dissipation in nanomechanical resonators due to phonon tunneling. Phys. Rev. B (2008). https://doi.org/10.1103/PhysRevB.77.245418

Cross, M.C., Lifshitz, R.: Elastic wave transmission at an abrupt junction in a thin plate with application to heat transport and vibrations in mesoscopic systems. Phys. Rev. B. 46, 69–71 (2001). https://doi.org/10.1103/PhysRevB.64.085324

Acknowledgements

The authors thank helps from MEMS Research center of Yanshan University.

Funding

This research was funded by the National key R & D Program of China, 2018YFB1304800.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethics approval and consent to participate

The research in this paper does not involve any ethical research.

Consent for publication

All authors agree to publish this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

The static displacement and modal function of the CNT vibration are solved as follows:

The CNT has an initial deformation under the action of bias voltage and molecular force [4], and the forced vibration occurs on this basis. The average displacement of the CNT under static deformation is:

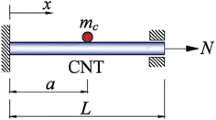

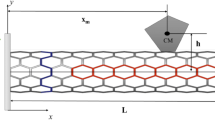

When a concentrated mass (adsorbed particles) is attached to an arbitrary position (x = d) at the CNT, the CNT resonator can be considered to consist of two parts (w1 (0 ≤ x ≤ d) and w2 (d ≤ x ≤ L)). The mode function can be given by:

where the constants C1, C2, C3, C4, C5, C6, C7, and C8 are determined by boundary conditions and continuity conditions [4, 23].

The CNT is fixed at both ends. The boundary conditions are:

When the mass and position of the adsorbed particles are given, the continuity conditions are:

Substituting these conditions into Eq. (28) yields:

where

where \({a}_{1}=\mathrm{sin}{\lambda }_{1}d , {a}_{2}=\mathrm{sin}{\lambda }_{2}d , {a}_{3}=\mathrm{cos}{\lambda }_{1}d , {a}_{4}=\mathrm{ch}{\lambda }_{2}d, {a}_{5}=\mathrm{sh}{\lambda }_{2}d ,{a}_{6}=\mathrm{cos}{\lambda }_{1}L , {a}_{7}=\mathrm{sin}{\lambda }_{1}L , {a}_{8}=\mathrm{sh}{\lambda }_{2}L ,{a}_{9}=\mathrm{ch}{\lambda }_{2}L ,{a}_{10}=m{\left(2\pi f\right)}^{2} /EI\)

Equation (31) has a nonzero solution if and only if the coefficient determinant equals zero, that is:

Using Eq. (34), the natural frequencies of the carbon nanotube resonator can be obtained. Substituting the natural frequencies into Eq. (31), constants C1, C2, C3, C4, C5, C6, C7, and C8 can be determined. Substituting them into Eq. (28), the mode function can be given.

Appendix 2

ADS is a special software for microwave RF circuit and system design developed by Aglient, with powerful circuit simulation function. The nonlinear capacitance Cs in the equivalent circuit changes with the excitation frequency, so the S1P_Eqn to S6P_Eqn module for S-parameter simulation is used to simulate it. For single-port- or multi-port-based components, the S1P_Eqn to S6P_Eqn blocks can be used to simulate frequency-dependent impedance components such as resistors, capacitors, and inductors. It has up to six ports, and the impedance between each port and each port can be defined. The S1P_Eqn single port has ± two interfaces, and the + interface is often used as an input terminal. S1P_Eqn defines the impedance element through the equivalent impedance, which can realize the definition of a single impedance element or a composite element after combining several impedance elements. To define a component with impedance a + b j, simply make S[X,Y] = a + b j or S[X,Y] = (a,b). The capacitive reactance introduced by the nonlinear capacitor Cs in this study is:

Let S[1, 1] = Zs in the S1P_Eqn module, as shown in Fig.

13. The VAR module is used to define Zs and establish the relationship between Zs and signal frequency.

In the forced vibration amplitude–frequency relationship formula (13), the relationship between the amplitude z and f can be expressed as an explicit function:

The functional relationship between Zs and f is transformed into the language in ADS, as shown in Fig. 10 and Fig. 13, thus completing the establishment of the nonlinear capacitance Cs that varies with the signal frequency f. After the S-parameter simulation, the relationship between the S21 parameter of the sensor and the excitation frequency f can be obtained.

Appendix 3

In order to prove that the latter terms can be ignored in the Taylor expansion formula of electrostatic force (Eq. (6)) in this paper, the following proofs are made:

The electrostatic force can be expressed as:

where \(f_{K1} { = }\frac{{ - \varepsilon \varepsilon_{0} \varepsilon_{r} r\left( {{\text{KV}}_{K} /h} \right)^{2} }}{{h^{2} \overline{{w_{0} }} }}\),\(f_{K2} { = }\frac{{ - 3\varepsilon \varepsilon_{0} \varepsilon_{r} r\left( {{\text{KV}}_{K} /h} \right)^{2} }}{{2h^{3} \overline{{w_{0} }} }}\), and \(f_{K3} { = }\frac{{ - 2\varepsilon \varepsilon_{0} \varepsilon_{r} r\left( {{\text{KV}}_{K} /h} \right)^{2} }}{{h^{4} \overline{{w_{0} }} }}\).

In order to calculate fK, the dimensions and control parameters of the CNT need to be acquired. As shown in Table

4, according to the conclusions drawn in Fig. 3, a certain size and control parameters when the vibration can achieve stable hysteresis are selected.

Taking \(\overline{{\Delta w}}\) as the average amplitude in the vibration process of the CNT, then under the parameters shown in Table 4, \(\overline{{\Delta w}} { = 5}\;{\text{nm}}\).

After calculation, \(f_{K1}\Delta w^{3} { = }\) 1.82 × 10–12 N, \(f_{K2}\Delta w^{4} { = }\) 1.92 × 10–13 N, \(f_{K3}\Delta w^{5} { = }\) 1.72 × 10–14 N can be obtained. If only the first term of the expansion is considered when using Eq. (7), the calculation error of fK is about 9.5%, and the resulting analysis error of K is about 3.0%. According to Fig. 4, it can be obtained that when the K fluctuates by 3.0%, the influence on the analysis of the nonlinear state is negligible. Therefore, when using this model to analyze the nonlinear control parameters, it is sufficient to only consider the first term in the expansion of the electrostatic force exerted by the top plate on the CNT.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cai, X., Xu, L. Control of vibration nonlinearity and quality factor for a carbon nanotube mass sensor. Nonlinear Dyn 111, 6179–6197 (2023). https://doi.org/10.1007/s11071-022-08164-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-022-08164-1