Abstract

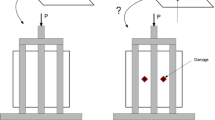

Fiber-reinforced composite laminates (FRCL) is susceptible to the external impacting. Understanding the crack propagation and structural mechanical properties of the damaged FRCL under low-velocity oblique impact is of great value in practical application. A new analytical dynamic model is developed in this work to research the dynamic response and damage property of FRCL under oblique impacting. The displacement field and strain–displacement relations of the FRCL are established by utilizing higher-order shear plate theory. The matrix damage and fiber rupture in FRCL under oblique impacting are captured by an internal variable-based continuum damage constitutive relation. To accurately predict the oblique impacting force, an analytical dynamic impacting model is proposed basing on a developed contact model, where normal and tangential contact is coupled and solved simultaneously. The whole initial boundary value problem is iteratively solved by synthetically using finite differential method and Newmark-\(\beta \) method. The solving convergence and accuracy of the model is demonstrated and validated. Simulations show that the matrix damage is more easily to appear in FRCL under shear force due to oblique contact when under oblique impacting, and the damage profile is different from normal impacting. The dynamic responses of the FRCL plate under oblique impacting differ also greatly from normal impacting. The current research provides a theoretical basis for FRCL design and its engineering application when under low-velocity impacting.

Similar content being viewed by others

References

Zhang, Y.X., Yang, C.H.: Recent developments in finite element analysis for laminated composite plates. Compos. Struct. 88, 147–157 (2009)

Caminero, M.A., Rodríguez, G.P., Muñoz, V.: Effect of stacking sequence on Charpy impact and flexural damage behavior of composite laminates. Compos. Struct. 345–357 (2016)

Caprino, G., Carrino, L., Durante, M., Langella, A., Lopresto, V.: Low impact behaviour of hemp fibre reinforced epoxy composites. Compos. Struct. 133, 892–901 (2015)

Shi, Y., Swait, T., Soutis, C.: Modelling damage evolution in composite laminates subjected to low velocity impact. Compos. Struct. 94, 2902–2913 (2012)

Sabzikar, B.M., Yasser, K.: Low velocity impact analysis of composite laminated beams subjected to multiple impacts in thermal field. ZAMM C J. Appl. Math. Mech. (2015)

Vaziri, R., Quan, X., Olson, M.D.: Impact analysis of laminated composite plates and shells by super finite elements. Int. J. Impact Eng. 18, 765–782 (1996)

Mili, F., Necib, B.: Impact behavior of cross-ply laminated composite plates under low velocities. Compos. Struct. 51, 237–244 (2001)

Arakawa, K., Mada, T., Komatsu, H., Shimizu, T., Satou, M., Takehara, K., Etoh, G.: Dynamic contact behavior of a golf ball during an oblique impact. Exp. Mech. 46, 691–697 (2006)

Eghtesad, A., Shafiei, A.R., Mahzoon, M.: Study of dynamic behavior of ceramic-metal FGM under high velocity impact conditions using CSPM method. Appl. Math. Model. 36, 2724–2738 (2012)

Krishnamurthy, K.S., Mahajan, P., Mittal, R.K.: Impact response and damage in laminated composite cylindrical shells. Compos. Struct. 59, 15–36 (2003)

Lim, C.T., Stronge, W.J.: Oblique elastic-plastic impact between rough cylinders in plane strain. Int. J. Eng. Sci. 37, 97–122 (1999)

Nagel, G.M., Thambiratnam, D.P.: Dynamic simulation and energy absorption of tapered thin-walled tubes under oblique impact loading. Int. J. Impact Eng. 32, 1595–1620 (2006)

Gupta, N.K., Madhu, V.: An experimental study of normal and oblique impact of hard-core projectile on single and layerd plates Int. J. Impact Eng. 19, 395–414 (1997)

Assie, A.E., Eltaher, M.A., Mahmoud, F.F.: Modeling of viscoelastic contact-impact problems. Appl. Math. Model. 34, 2336–2352 (2010)

Khoei, A.R., Keshavarz, S., Khaloo, A.R.: Modeling of large deformation frictional contact in powder compaction processes. Appl. Math. Model. 32, 775–801 (2008)

Mao, Y.Q., Fu, Y.M., Chen, C.P., Li, Y.L.: Nonlinear dynamic response for functionally graded shallow spherical shell under low velocity impact in thermal environment. Appl. Math. Model. 35, 2887–2900 (2011)

Mushayabasa, S., Bhunu, C.P., Webb, C., Dhlamini, M.: A mathematical model for assessing the impact of poverty on yaws eradication. Appl. Math. Model. 36, 1653–1667 (2012)

Zhang, Q.J., Qin, Q.H., Wang, J.Z.: A theoretical model on coupled fluid-structure impact buckling. Appl. Math. Model. 17, 25–33 (2993)

Teng, T.L., Chu, Y.A., Chang, F.A., Chin, H.S.: Numerical analysis of oblique impact on reinforced concrete. Cement. Concrete Comp. 27, 481–492 (2005)

Dai, H.L., Guo, Z.Y., Yang, L.: Nonlinear dynamic response of functionally graded materials circular plates subject to low-velocity impact. J. Compos. Mater. 47, 2797–2807 (2013)

Dai, H.L., Liu, H.B., Zheng, Z.Q.: Investigation on thermomechanical behavior of a HSLA-stiffened rectangular plate under low-velocity impact. J. Therm. Stress. 39, 795–819 (2016)

Zhang, J.H., Pan, S.C.: Dynamic response of functionally graded circular plate under thermal shock. In: International Conference on Mechanics and Civil Engineering (2014)

Khoei, A.R., Biabanaki, S.O.R., Parvaneh, S.M.: 3D dynamic modeling of powder forming processes via a simple and efficient node-to-surface contact algorithm. Appl. Math. Model. 37, 443–462 (2013)

Teodorescu, M., Rahnejat, H., Gohar, R., Dowson, D.: Harmonic decomposition analysis of contact mechanics of bonded layered elastic solids. Appl. Math. Model. 33, 467–485 (2009)

Argatov, I.: Contact problem for a thin elastic layer with variable thickness: application to sensitivity analysis of articular contact mechanics. Appl. Math. Model. (2013). doi:10.1016/j.apm.2013.1003.1042

Krajcinovic, D.: Damage mechanics: accomplishments, trends and needs. Int. J. Solid. Struct. 37, 267–277 (2000)

Ibijola, E.A.: On some fundamental concepts of continuum damage mechanics. Comput. Method Appl. Mech. Eng. 191, 1505–1520 (2002)

Chen, J.F., Morozov, E.V., Shankar, K.: A combined elastoplastic damage model for progressive failure analysis of composite materials and structures. Compos. Struct. 94, 3478–3489 (2012)

Kim, E.H., Rim, M.S., Lee, I., Hwang, T.K.: Composite damage model based on continuum damage mechanics and low velocity impact analysis of composite plates. Compos. Struct. 95, 123–134 (2013)

LeBlanc, J., Shukla, A.: Dynamic response and damage evolution in composite materials subjected to underwater explosive loading: An experimental and computational study. Compos. Struct. 92, 2421–2430 (2010)

Wang, Q., Bian, L., Li, H.: Effective elastic modulus and micro-structure damage of particle-reinforced composites. Compos. Struct. 94, 2218–2226 (2012)

Fu, Y.M., Mao, Y.Q., Tian, Y.P.: Damage analysis and dynamic response of elasto-plastic laminated composite shallow spherical shell under low velocity impact Int. J. Solid. Struct. 47, 126–137 (2010)

Dell’Isola, F., Giorgio, I., Pawlikowski, M., Rizzi, N.L.: Large deformations of planar extensible beams and pantographic lattices: heuristic homogenization, experimental and numerical examples of equilibrium. Proc. R. Soc. A 472 (2016)

Boisse, P., Hamila, N., Guzman-Maldonado, E., Madeo, A., Hivet, G., Dell’Isola, F.: The bias-extension test for the analysis of in-plane shear properties of textile composite reinforcements and prepregs: a review. Int. J. Mater. Form. 1–20 (2016)

Dell’Isola, F., Steigmann, D., Corte, A.D.: Synthesis of fibrous complex structures: designing microstructure to deliver targeted macroscale response. Appl. Mech. Rev. 67 (2015)

Mitchell, J.A., Reddy, J.N.: A refined hybrid plate theory for composite lamiantes with piezoelectric laminate. Int. J. Solid. Struct. 32, 2345–2367 (1996)

Ribeiro, M., Tita, V., Vandepitte, D.: A new damage model for composite laminates. Compos. Struct. 94, 635–642 (2012)

Talreja, R.: Damage mechanics and fatigue life assessment of composite materials. Int. J. Damage Mech. 8, 339–354 (1999)

Talreja, R.: Damage development in composites: mechanisms and modeling. J. Strain Anal. Eng. Des. Prof. Eng. Publishing, 4 (1989)

Talreja, R.: A continuum mechanics characterization of damage in composite materials. In: Proceedings of Royal Society London. A399, 1817, June, 8, London, pp. 195–216 (1985)

Mao, Y., Fu, Y., Tian, Y.: Nonlinear dynamic response and active control of Piezoelastic laminated shallow spherical shells with damage. Int. J. Damage Mech. 783–809 (2012)

Mao, Y.Q., Fu, Y.M.: Nonlinear dynamic response and active vibration control for piezoelectric functionally graded plate. J. Sound Vib. 24, 2015–2028 (2010)

Fu, Y.M., Mao, Y.Q., Tian, Y.P.: Damage analysis and dynamic response of elasto-plastic laminated composite shallow spherical shell under low velocity impact. Int. J. Solid. Struct. 47, 126–137 (2010)

Mindlin, R.D., Deresiewicz, H.: Elastic spheres in contact under varying oblique forces. ASME J. Appl. Mech. 20, 327–344 (1953)

Vu-Quoc, L., Zhang, X., Lesburg, L.: Normal and tangential force-displacement relations for frictional elasto-plastic contact of spheres. Int. J. Solids Strucut. 38, 6455–6489 (2001)

Wang, X.C.: Finite Element Method. Tsinghua University Press, Tsinghua (2002)

Choi, I.H.: Contact force history analysis of composite sandwich plates subjected to low-velocity impact. Compos. Struct. 75, 582–586 (2006)

Acknowledgments

This study is supported by the Natural Science Foundation of China (no. 11302004) and the Natural Science Foundation of China (no. 11272270).

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Detailed forms of coefficients for the damage constitutive relations (Eq. 7 in the text)

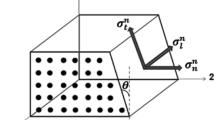

Consider that the damage of the fiber-reinforced composite material with orthotropic property is induced by cracks in the matrix. The local coordinate system \(o-123\) is adopted, in which axis1 is parallel to fibrous direction, axis2 is normal to fibrous direction and axis3 is normal to the mid-surface by adopting the fundamental assumption on the shell \(\varepsilon _{13} =\varepsilon _{23} =0\) and applying Voigt notation to describe strains and damage variables, the Helmholtz free energy can be given as

Consider that the cracks in the matrix under the bending deformation have the same direction, then \(n=1\), and the stress can be given as

where \([C_{pq}^{\;0} ]\) and \([C_{pq} ]\) are symmetric matrices having the forms as follows

in the above expressions, superscript \(m=1\) is omitted.

For the fiber-reinforced composite plate with matrix cracks that is vertical to the fibrous direction, in all damage variables only \(\omega _{\;1}\) is not zero, then coefficient matrix in (46) is simplified as

Because all cracks are parallel to the coordinate plane \(2-3\), its effect on stiffness in this coordinate plane can be neglected. Then the last matrix can be further simplified as

Letting \(\sigma _3 =0\), the constitutive relation of the composite uni-ply shell with damage in the status of plane stress can be obtained as follows

where

Obviously, \([C_{pq}^{\;0} ]\) is the stiffness matrix without damage, and

Appendix 2: Detailed solving of normal and tangential contact force at each iterative step

We have to consider four cases to obtain the convergent contact force when iterative solve Eqs. (28) and (35) by applying Eqs. (23)–(27) and (29)–(34) in the main text.

Case A normal contact loading, tangential contact loading, i.e., \(\Delta q_N>0,\Delta q_T >0\), then Eqs. (28) and (35) in the main text are directly used to calculate the contact force as

here \((K_T )_0 =(K_{T,0} )_{q_N =q_N^J }\), \((K_T )_{12} =(K_{T,0} )_{q_N =q_N^{J+1} } \left( {1-\frac{q_T^J }{\mu q_N^{J+1} }} \right) ^{1/3}\).

Case B normal contact unloading, tangential contact loading, i.e., \(\Delta q_N <0,\Delta q_T >0\), then from the backward Euler method, we have the following contact force by Eqs. (28), (31) and (35) in the main text,

here \((K_T )_{12} =(K_{T,0} )_{q_N =q_N^J } (1-\frac{q_T^J +\mu \Delta q_N }{\mu q_N^{J+1} })^{1/3}\).

Case C normal contact loading, tangential contact unloading, i.e., \(\Delta q_N >0,\Delta q_T <0\), we have the following contact force by Eqs. (28), (33) and (35) in the main text,

here, \((K_T )_{12} =(K_{T,0} )_{q_N =q_N^{J+1} } \left( {1-\frac{q_T^{*} -q_T^J }{2\mu q_N^{J+1} \;}} \right) ^{1/3}\) and \(q_T^{*}\) is the maximum tangential contact force.

Case D normal contact unloading, tangential contact unloading, i.e., \(\Delta q_N<0,\Delta q_T <0\), we have the following contact force by Eqs. (28), (33) and (35) in the main text,

here, \((K_T )_{12} =(K_{T,0} )_{q_N =q_N^J } \left( {1-\frac{q_T^{*} -q_T^J }{2\mu q_N^{J+1} }} \right) ^{1/3}\), \((K_T )_{23} =(K_{T,0} )_{q_N =q_N^{J+1} } \left( {1-\frac{q_T^{*} -q_T^J }{2\mu q_N^{J+1} }} \right) ^{1/3}\).

Rights and permissions

About this article

Cite this article

Mao, Y., Hong, L., Ai, S. et al. Dynamic response and damage analysis of fiber-reinforced composite laminated plates under low-velocity oblique impact. Nonlinear Dyn 87, 1511–1530 (2017). https://doi.org/10.1007/s11071-016-3130-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-016-3130-5