Abstract

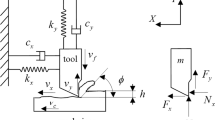

The thermal distortion of the cutting tool is an important factor that can affect machining precision. A new single degree of freedom chatter model of the regenerative orthogonal turning process takes into account the thermal distortion of the cutting tool is proposed in this work. The cutting tool of the turning system is modeled as one-dimensional oscillator with nonlinear stiffness and the thermal distortion both in axial and in radial direction. Numerical method is employed to explore the effect of the largest thermal distortion on the dynamics of the cutting system. The results show that the motion of the cutting tool will transition among periodic, quasi-periodic, and chaotic motions with the time delay and the largest thermal distortion changed, at the same time, the different bifurcation patterns are found that indicate the dynamics of the cutting system is influenced by the largest thermal distortion. In addition, the stability of cutting system will be broken earlier with the increase in the largest thermal distortion.

Similar content being viewed by others

References

Budak, E., Ozlu, E.: Analytical modeling of chatter stability in turning and boring operations: a multi-dimensional approach. CIRP Ann. Manuf. Technol. 56(1), 401–404 (2007)

Insperger, T., Stépán, G., Turi, J.: State-dependent delay in regenerative turning processes. Nonlinear Dyn. 47(1–3), 275–283 (2007)

Siddhpura, M., Paurobally, R.: A review of chatter vibration research in turning. Int. J. Mach. Tools Manuf. 61, 27–47 (2012)

Kim, P., Seok, J.: Bifurcation analyses on the chatter vibrations of a turning process with state-dependent delay. Nonlinear Dyn. 69(3), 891–912 (2012)

Altintas, Y., Budak, E.: Analytical prediction of stability lobes in milling. CIRP Ann. Manuf. Technol. 44(1), 357–362 (1995)

Insperger, T., Stépán, G., Bayly, P.V., Mann, B.P.: Multiple chatter frequencies in milling processes. J. Sound Vib. 262(2), 333–345 (2003)

Long, X.H., Balachandran, B., Mann, B.P.: Dynamics of milling processes with variable time delays. Nonlinear Dyn. 47(1–3), 49–63 (2007)

Arvajeh, T., Ismail, F.: Machining stability in high-speed drilling—part 1: modeling vibration stability in bending. Int. J. Mach. Tools Manuf. 46(12), 1563–1572 (2006)

Arvajeh, T., Ismail, F.: Machining stability in high speed drilling—part 2: time domain simulation of a bending-torsional model and experimental validations. Int. J. Mach. Tools Manuf. 46(12), 1573–1581 (2006)

Campbell, S.A., Stone, E.: Analysis of the chatter instability in a nonlinear model for drilling. J. Comput. Nonlinear Dyn. 1(4), 294–306 (2006)

Edhi, E., Hoshi, T.: Stabilization of high frequency chatter vibration in fine boring by friction damper. Precis. Eng. 25(3), 224–234 (2001)

Atabey, F., Lazoglu, I., Altintas, Y.: Mechanics of boring processes—part II–multi-insert boring heads. Int. J. Mach. Tools Manuf. 43(5), 477–484 (2003)

González-Brambila, O., Rubio, E., Jáuregui, J.C., Herrera-Ruiz, G.: Chattering detection in cylindrical grinding processes using the wavelet transform. Int. J. Mach. Tools Manuf. 46(15), 1934–1938 (2006)

Yan, Y., Xu, J., Wang, W.: Nonlinear chatter with large amplitude in a cylindrical plunge grinding process. Nonlinear Dyn. 69(4), 1781–1793 (2012)

Tobias, S.A.: Machine tool vibration research. Int. J. Mach. Tool Des. Res. 1(1), 1–14 (1961)

Tobias, S.A.: Machine-tool vibration. Blackie and Son Limited, London (1965)

Wiercigroch, M., Budak, E.: Sources of nonlinearities, chatter generation and suppression in metal cutting. Philos. Trans. R. Soc. Lond. A Math. Phys. Eng. Sci. 359(1781), 663–693 (2001)

Taylor, F.W.: The art of cutting metals. Sci. Am. 63, 25942–25944 (1907)

Tobias, S.A., Fishwick, W.: The chatter of lathe tools under orthogonal cutting conditions. Trans. ASME 80(2), 1079–1088 (1958)

Hanna, N.H., Tobias, S.A.: A theory of nonlinear regenerative chatter. J. Manuf. Sci. Eng. 96(1), 247–255 (1974)

Nayfeh, A.H., Chin, C.M., Pratt, J.: Perturbation methods in nonlinear dynamics—applications to machining dynamics. J. Manuf. Sci. Eng. 119(4A), 485–493 (1997)

Nayfeh, A.H., Nayfeh, N.A.: Analysis of the cutting tool on a lathe. Nonlinear Dyn. 63(3), 395–416 (2011)

Deshpande, N., Fofana, M.S.: Nonlinear regenerative chatter in turning. Robot. Comput Integr. Manuf. 17(1), 107–112 (2001)

Nosyreva, E.P., Molinari, A.: Analysis of nonlinear vibrations in metal cutting. Int. J. Mech. Sci. 40(8), 735–748 (1998)

Moradi, H., Bakhtiari-Nejad, F., Movahhedy, M.R., Ahmadian, M.T.: Nonlinear behaviour of the regenerative chatter in turning process with a worn tool: forced oscillation and stability analysis. Mech. Mach. Theory 45(8), 1050–1066 (2010)

Banihasan, M., Bakhtiari-Nejad, F.: Chaotic vibrations in high-speed milling. Nonlinear Dyn. 66(4), 557–574 (2011)

Litak, G., Schubert, S., Radons, G.: Nonlinear dynamics of a regenerative cutting process. Nonlinear Dyn. 69(3), 1255–1262 (2012)

Moradi, H., Vossoughi, G., Movahhedy, M.R.: Bifurcation analysis of nonlinear milling process with tool wear and process damping: sub-harmonic resonance under regenerative chatter. Int. J. Mech. Sci. 85, 1–19 (2014)

Zhou, R., Zhang, W., Zu, J.W.: Analysis on nonlinear dynamics of a thin-plate workpiece in milling process with cutting force nonlinearities. J. Mech. Sci. Technol. 28(7), 2511–2526 (2014)

Rusinek, R., Wiercigroch, M., Wahi, P.: Orthogonal cutting process modelling considering tool-workpiece frictional effect. Proced. CIRP 31, 429–434 (2015)

Cao, H.J., Zhu, L.B., Li, X.G., Chen, P., Chen Y.P.: Thermal error compensation of dry hobbing machine tool considering workpiece thermal deformation. Int. J. Adv. Manuf. Technol. (2016). doi:10.1007/s00170-015-8314-5

Rusinek, R., Mitura, A., Warminski, J.: Time delay Duffing’s systems: chaos and chatter control. Meccanica 49(8), 1869–1877 (2014)

Ma, F.B., Chen, X.J.: Effect of thermal deformation of cutting tools on detail process precision. Coal Mine Mach. 9, 27–29 (2004). (in Chinese)

Acknowledgments

We are grateful for the support of the National Natural Science Foundation of China under Grant Nos. 11372122 and 51465029.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, A., Jin, W., Wang, G. et al. Analysis on dynamics of a cutting tool with the thermal distortion in turning process. Nonlinear Dyn 86, 1183–1191 (2016). https://doi.org/10.1007/s11071-016-2956-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-016-2956-1