Abstract

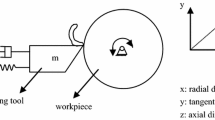

A more comprehensive orthogonal turning model is developed in order to further study the influence of feed velocity on frictional chatter. Nonlinear dynamic behavior of the cutting tool in two directions is presented by using bifurcation diagram, phase portrait, and Poincaré section. It can be found that the cutting tool has a variety of dynamic behaviors at different feed velocity and cutting velocity, such as periodic motion, quasi-periodic motion, and chaotic motion. Furthermore, the vibration displacement of the cutting tool is affected by the feed velocity, especially for relatively high feed velocity which will result in the cutting tool vibration displacement increase in the cutting direction but a decrease in the feed direction. In addition, it is clear that the stick–slip phenomenon only appears in the cutting direction in our work.

Similar content being viewed by others

References

Quintana, G., & Ciurana, J. (2011). Chatter in machining processes: A review. International Journal of Machine Tools and Manufacture, 51(5), 363.

Wiercigroch, M., & Krivtsov, A. M. (2001). Frictional chatter in orthogonal metal cutting. Philosophical Transactions of the Royal Society of London Series A: Mathematical, Physical and Engineering Sciences, 359(1781), 713–738.

Rusinek, R., Wiercigroch, M., & Wahi, P. (2015). Orthogonal cutting process modelling considering tool-workpiece frictional effect. Procedia CIRP, 31, 429–434.

Kecik, K., Rusinek, R., & Warminski, J. (2013). Modeling of high-speed milling process with frictional effect. Proceedings of the Institution of Mechanical Engineers, Part K: Journal of Multi-body Dynamics, 227(1), 3–11.

Faassen, R. P. H., Van de Wouw, N., Oosterling, J. A. J., & Nijmeijer, H. (2003). Prediction of regenerative chatter by modelling and analysis of high-speed milling. International Journal of Machine Tools and Manufacture, 43(14), 1437–1446.

Molnár, T. G., Insperger, T., & Stépán, G. (2016). State-dependent distributed-delay model of orthogonal cutting. Nonlinear Dynamics, 84(3), 1147–1156.

Nayfeh, A. H., & Nayfeh, N. A. (2011). Analysis of the cutting tool on a lathe. Nonlinear Dynamics, 63(3), 395–416.

Kalmár-Nagy, T., Stépán, G., & Moon, F. C. (2015). Subcritical hopf bifurcation in the delay equation model for machine tool vibrations. Nonlinear Dynamics, 26, 121–142.

Tlusty, .J, Polacek, M. The stability of the machine tool against self-excited vibration in machining. Mach Sci Technol.1963.

Wiercigroch, M., & Budak, E. (2001). Sources of nonlinearities, chatter generation and suppression in metal cutting. Philosophical Transactions of the Royal Society of London Series A: Mathematical, Physical and Engineering Sciences, 359(1781), 663–693.

Taylor, F. W. (1906). On the art of cutting metals. American Society of Mechanical Engineers., 63(1619), 25942–25944.

Arnold, R. (1946). Cutting tools research: report of subcommittee on carbide tools: the mechanism of tool vibration in the cutting of steel. Proceedings of the Institution of Mechanical Engineers, 154(1), 261–284.

Grabec, I. (1986). Chaos generated by the cutting process. Physics Letters A, 117, 384–386.

Kotaiah, K. R., & Srinivas, J. (2010). Dynamic analysis of a turning tool with a discrete model of the workpiece. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 224(2), 207–215.

Nosyreva, E. P., & Molinari, A. (1998). Analysis of nonlinear vibrations in metal cutting. International Journal of Mechanical Sciences, 40, 735–748.

Vogler, M. P., Devor, R. E., & Kapoor, S. G. (2002). Nonlinear influence of effective lead angle in turning process stability. Journal of Manufacturing Science and Engineering Transaction of the ASME, 124, 473–475.

Rusinek, R., Wiercigroch, M., & Wahi, P. (2014). Influence of tool flank forces on complex dynamics of cutting process. International Journal of Bifurcation and Chaos, 24(09), 1450115.

Rusinek, R., Wiercigroch, M., & Wahi, P. (2014). Modelling of frictional chatter in metal cutting. International Journal of Mechanical Sciences, 89, 167–176.

Wang, A., Jin, W. Y., Wang, G. P., & Li, X. Y. (2016). Analysis on dynamics of a cutting tool with the thermal distortion in turning process. Nonlinear Dynamics, 2, 1183–1191.

Weremczuk, A., & Rusinek, R. (2017). Influence of frictional mechanism on chatter vibrations in the cutting process–analytical approach. The International Journal of Advanced Manufacturing Technology, 89(9–12), 2837–2844.

Yan, Y., Xu, J., & Wiercigroch, M. (2016). Regenerative chatter in self-interrupted plunge grinding. Meccanica, 51, 3185–3202.

Yan, Y., Xu, J., & Wiercigroch, M. (2017). Influence of workpiece imbalance on regenerative and frictional grinding chatters. Procedia IUTAM, 22, 146–153.

Yi, S., Nelson, P. W., & Ulsoy, A. G. (2007). Delay differential equations via the matrix lambert w function and bifurcation analysis: application to machine tool chatter. Mathematical Biosciences and Engineering, 4(2), 355–368.

Wang, A., Jin, W. Y., Chen, W. C., Feng, R. C., & Xu, C. W. (2018). Bifurcation and chaotic vibration of frictional chatter in turning process. Advances in Mechanical Engineering, 10(4), 168781401877126.

Grossi, N., Montevecchi, F., Sallese, L., Scippa, A., & Campatelli, G. (2018). Correction to: Chatter stability prediction for high-speedmilling through a novel experimental-analytical approach. The International Journal of Advanced Manufacturing Technology, 96(9), 4541–4544.

Acknowledgements

The research is supported by the National Natural Science Foundation of China (No. 11372122) and Science and Technology Program of Gansu Province of China (No. 1610RJYA020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Substituting Eqs. 2,3,4 and 5 into Eq. (1), we obtain the vibration response of the cutting tool motion in both directions

In order to reduce the number of parameters, Eq. (6) is simplified as the following dimensionless equation.

Rights and permissions

About this article

Cite this article

Wang, A., Jin, W. Influence of Feed Velocity on Nonlinear Dynamics of Turning Process. Int. J. Precis. Eng. Manuf. 22, 1069–1079 (2021). https://doi.org/10.1007/s12541-021-00516-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-021-00516-y