Abstract

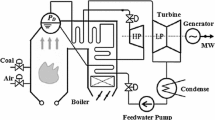

In the presence of harmonic disturbances, boiler–turbine units may demonstrate quasi-periodic behaviour due to the occurrence of various types of bifurcation. In this article, a nonlinear model of boiler–turbine unit is considered in which drum pressure, electric output and drum water level are controlled via manipulation of valve positions for fuel, steam and feed-water flow rates. For bifurcation control in tracking problem, two controllers are designed based on gain scheduling and feedback linearization (FBL). To investigate the efficiency of control strategies, three cases are considered for desired tracking objectives (a sequence of steps, ramps/steps, and a combination of them). According to the results, FBL controller works successfully in suppression of harmonic perturbations and consequently bifurcation control. As it is implemented, quasi-periodic solutions (caused by Hopf bifurcation) are vanished; leading to the appearance of periodic solutions with low amplitudes. Consequently, appropriate tracking performance with less oscillatory behaviour is observed for the drum pressure, electric output, and drum water level (desirable for the power grid). In addition, when FBL controller is used, less control efforts are predicted for the bifurcation control.

Similar content being viewed by others

References

Moradi, H., Bakhtiari-Nejad, F., Saffar-Avval, M.: Robust control of an industrial boiler system; a comparison between two approaches: sliding mode control & \(H_{\infty }\) technique. Energy Convers. Manage. 50, 1401–1410 (2009)

Astrom, K.J., Eklund, K.: A simplified nonlinear model of a drum boiler turbine unit. Int. J. Control. 16(1), 145–169 (1972)

Lo, K.L., Zeng, P.L., Marchand, E., Pinkerton, A.: Modelling and state estimation of power plant steam turbines. IEEE Proc. 137(2), 80–94 (1990)

Murty, V.V., Sreedhar, R., Fernandez, B., Masada, G.Y., Hill, A.S.: Boiler system identification using sparse neural networks. Proceedings of advances in robust and nonlinear control systems. ASME Winter Meeting, New Orleans, Louisiana, USA. Article no. 53, 103–112 (1993)

Donate, P.D., Moiola, J.L.: Model of a once-through boiler for dynamic studies. Lat. Am. Appl. Res. 24, 159–166 (1994)

Bracco, S., Troilo, M., Trucco, A.: A simple dynamic model and stability analysis of a steam boiler drum. Proc. Inst. Mech. Eng. A: J. Power Energy 223(7), 809–820 (2009)

Aranda, E., Frye, M., Chunjiang, Q.: Model development, state estimation, and controller design of a nonlinear utility boiler system, Proceedings of the IEEE International Conference on Industrial Technology (ICIT’08). Sichuan University, Chengdu, China, Article No. 4608412, 1–6 (2008)

Kouprianov, V.I., Kaewboonsong, W.: Modeling the effects of operating conditions on fuel and environmental costs for a 310 MW boiler firing fuel oil. Energy Convers. Manage. 45(1), 1–14 (2004)

Kouadri, A., Namoun, A., Zelmat, M.: Modelling the nonlinear dynamic behaviour of a boiler–turbine system using a radial basis function neural network. Int. J. Robust Nonlinear Control. (2013). doi:10.1002/rnc.2969

Astrom, K.J., Bell, R.D.: Drum-boiler dynamics. Automatica 36, 363–378 (2000)

Li, C., Zhou, J., Li, Q., An, X., Xiang, X.: A new T–S fuzzy-modeling approach to identify a boiler–turbine system. Expert Syst. Appl. 37(3), 2214–2221 (2010)

Liu, X.J., Kong, X.B., Hou, G.L., Wang, J.H.: Modeling of a 1000 MW power plant ultra super-critical boiler system using fuzzy-neural network methods. Energy Convers. Manage. 65, 518–527 (2013)

Collazo, J., Porteiro, J., Míguez, J.L., Granada, E., Gómez, M.A.: Numerical simulation of a small-scale biomass boiler. Energy Convers. Manage. 64, 87–96 (2012)

Yang, S., Qian, C.: Real-time optimal control of a boiler–turbine system using pseudospectral methods. 19th Annual Joint ISA POWID/EPRI Controls and Instrumentation Conference and 52nd ISA POWID Symposium, Rosemont, IL, USA, Article No. 477, 166–177 (2009)

Liu, H., Li, S., Chai, T.: Intelligent decoupling control of power plant main steam pressure and power output. Int. J. Electr. Power Energy Syst. 25(10), 809–819 (2003)

Liu, X., Kong, X.: Nonlinear fuzzy model predictive iterative learning control for drum-type boiler–turbine system. J. Process Control. 23(8), 1023–1040 (2013)

Li, Y., Shen, J., Lee, K.Y., Liu, X.: Offset-free fuzzy model predictive control of a boiler–turbine system based on genetic algorithm. Simul. Model. Practice Theory 26, 77–95 (2012)

Li, X. F., Zhang, W.: Coordinated control of fossil-fuel power plant based on the fuzzy PID control. Proceedings of the IEEE Conference on Decision and Control, Maui, Hawaii, USA, Article No. 6427049, 3080–3085 (2012)

Thangavelusamy, D., Ponnusamy, L.: Elimination of chattering using fuzzy sliding mode controller for drum boiler–turbine system. Control Eng. Appl. Inform. 15(2), 78–85 (2013)

Chen, P.C., Shamma, J.S.: Gain-scheduled \(l^{1}\)-optimal control for boiler–turbine dynamics with actuator saturation. Process Control. 14, 263–277 (2004)

Yu, T., Chan, K.W., Tong, J.P., Zhou, B., Li, D.H.: Coordinated robust nonlinear boiler–turbine–generator control systems via approximate dynamic feedback linearization. Process Control. 20, 365–374 (2010)

Moradi, H., Alasty, A., Bakhtiari-Nejad, F.: Control of a Nonlinear Boiler- Turbine Unit Using Two Methods: Gain Scheduling & Feedback Linearization, 2007 ASME International Mechanical Engineering Congress & Exposition, Seattle, WA, USA, Proceedings of 9/ Part A, Article No. 42945, 491–499 (2008)

Pérez, R.R., Geddes, A., Clegg, A.: Adaptive predictive expert control of superheated steam temperature in a coal-fired power plant. Int. J. Adapt. Control and Signal Process. 26(10), 932–944 (2012)

Fang, F., Wei, L.: Backstepping-based nonlinear adaptive control for coal-fired utility boiler–turbine units. Appl. Energy 88, 814–824 (2011)

Moon, U.C., Lee, K.Y.: An adaptive dynamic matrix control with fuzzy-interpolated step-response model for a DRUM-type boiler–turbine system. IEEE Trans. Energy Convers. 26(2), 393–401 (2011)

Tan, W., Marquez, H.J., Chen, T.: Multivariable robust controller design for a boiler system. IEEE Trans. Control Syst. Technol. 10(5), 735–742 (2002)

Moradi, H., Saffar-Avval, M., Bakhtiari-Nejad, F.: Sliding mode control of drum water level in an industrial boiler unit with time varying parameters: a comparison with H-infinity robust control approach. Process Control 22, 1844–1855 (2012)

Moradi, H., Bakhtiari-Nejad, F.: Improving boiler unit performance using an optimum robust minimum-order observer. Energy Convers. Manage. 52(3), 1728–1740 (2011)

Moradi, H., Alasty, A., Vossoughi, G.R.: Nonlinear dynamics and control of bifurcation to regulate the performance of a boiler–turbine unit. Energy Convers. Manage. 68, 105–113 (2013)

Nayfeh, A.H., Balachandran, B.: Applied Nonlinear Dynamics: Analytical, Computational, and Experimental Methods. Wiley, New York (1995)

Slotine, J.J., Li, W.: Applied Nonlinear Control. Prentice Hall Inc., Englewood cliffs, NJ (1991)

D’Azzo, J., Houpis, H.: Linear Control System Analysis and Design: Conventional and Modern, 4th edn. McGraw-Hill, New York (1995)

Acknowledgments

The authors acknowledge the “National Elite Foundation” of Iran for supporting this research.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Design of controller based on feedback linearization

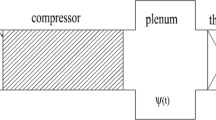

In feedback linearization (FBL) approach, the nonlinear terms of the dynamic system are eliminated by means of state variables feedback. Then a suitable controller is designed to stabilize the desired trajectories of the system [31]. In this section, a brief overview on the design of FBL controller is presented. More details of this approach were discussed in [29]. Consider a square MIMO system in the neighbourhood of the operating point \(\bar{{x}}^{0}\) as [31]

where \(\bar{{x}}\) is \(n \times 1\) the state vector, \(\bar{{u}}\) is \(r \times 1\) control input vector,\(\bar{{y}}\) is \(m \times 1\) outputs vector; \(\Phi \) and H are smooth vector fields and \(\Psi \) is a \(n \times r\) smooth matrix (in this paper, \(m = r =3\)). Assume that \(\delta _{i}\) is the smallest integer that at least one of the inputs appears in \(y_i ^{(\delta _i )}\), then (in this paper, \(y_{i}^{(j)}\) represents the \(j\) order differentiation of \(y_{i}\)):

with repeated Lie derivatives \(L_{\Psi _j } L_{\Phi ^{\delta _i -1}} \mathrm{H}_i (x)\ne 0\) for at least one \(j\) in the vicinity of \(\bar{{x}}^{0}\); while Lie derivative of H with respect to \(\Phi \) is a scalar function defined as:

Similarly, if \(\Psi \) is another vector field, then the scalar function \(L_{\Psi }L_{\Phi }\)H\((x)\) is

Applying the same procedure for each output \(y_{i}\), yields

If \(\mathrm{N} (\bar{{x}})\) is invertible over the region \(\Omega \), the input transformation

yields a simpler form of \(m\)equations as

In this research, it is assumed that the third state variable \((x_{3})\) is measured either directly or by estimation through a robust state observer (with a general design as presented in the previous research [28]). To avoid tedious computations caused by differentiation of \(y_{3}\) as given in Eq. (2), third state variable is chosen as the third output (instead of water level of drum, the fluid density is considered as the third output,\(y_{3} = x_{3}\)). Through simulations, it can be shown that this definition of \(y_{3}\) will not affect the control of real output (i.e., drum water level) represented by Eq. (2). The validity of this assumption was discussed in [29]. Following the same procedure given above (while \(\delta _{i}=1\)), FBL control laws are determined for the dynamic system of Eq. (1) as [29]:

after decoupling the outputs dynamics (Eq. 16), a PI controller is designed as:

where \(r_{i}\) is the command input signal that is desired to be tracked (Fig. 4). Differentiating from Eq. (16), using Eq. (18), and transforming the result into the Laplace domain, yields

To have a characteristic equation similar to the standard second-order system as:

Control signal gains must be adjusted as

Appendix 2: Structure of the feedback control law in MIMO system

Dynamic model of boiler–turbine unit is of rank \(n=3\). Since the controllability matrix

is of rank 3, dynamic system is completely state controllable. Using the similarity transformation \(\mathfrak {R}\) as \(\bar{{x}}= \mathfrak {R}\bar{{z}}\), Eq. (5) is represented as:

where \(\bar{{z}}_\delta \) is the new introduced state vector. Also, using the following transformations:

Equation (22) is described as:

where \(\bar{{v}}_\delta \) is the new control input vector and \(A_{G}, B_{G}\) has the general canonical form with elements of \([A_i ]_{\gamma _i \times \gamma _i }\, , \,[B_i ]_{\gamma _i \times 1} ,\,i =1,2,..,r\) and \(\sum _{i=1}^{r} \gamma _{i} = n\) as [32]:

where \(r\) is the number of input variables (in this case, \(r=3\)). Introducing the modified controllability matrix as:

where \(b_{i}\) are the columns of matrix \(B\) given by Eq. (6); regular basis of \(\bar{{\mathbb {C}}}\) is developed as

where each column, \(A^{j}b_{i}, i = 1,...,r, j = 0,..., r\), is independent from its previous columns. Inverse of \(\hat{{\mathbb {C}}}\) given by Eq. (26) is displayed as ([]\(^{\prime }\) stands for transpose of the [] quantity):

Similarity transformation \(\mathfrak {R}\) is defined as [32]:

Considering again Eq. (24) and constructing the feedback control law as \(v_{\delta }=-\Gamma z_{\delta }\), yields:

where \(A_{d}\) is the desired state matrix including coefficients representing desired closed loop poles \(({\vert }{ sI}-A_{d}{\vert }=(s-\mu _{1})(s-\mu _{2})\ldots (s-\mu _{n}))\); having the general form of \(A_{G}\) as given by Eq. (25). Considering Eqs. (7), (B-2) and similarity transformation \(\bar{{x}}_\delta = \mathfrak {R}\bar{{z}}_\delta \), yields the feedback control law of the system as:

where \(F, P\), and \(\Gamma \) are obtained using Eqs. (23), (24), and (28) as follows:

Rights and permissions

About this article

Cite this article

Moradi, H., Vossoughi, G. & Alasty, A. Suppression of harmonic perturbations and bifurcation control in tracking objectives of a boiler–turbine unit in power grid. Nonlinear Dyn 76, 1693–1709 (2014). https://doi.org/10.1007/s11071-014-1239-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-014-1239-y