Abstract

The publication describes research investigating the effects of microwaves on seeds extracted from Norway spruce (Picea abies) and European larch (Larix decidua) cones. The objective of the conducted experiments was to determine how electromagnetic radiation influences the quality of those seeds. The study material was heated in a microwave-emitting device for 7 or 10 s at four power settings (800, 620, 440, or 130 W). The evaluated parameters included changes in the moisture content and weight of the studied cones following the applied time and power variants of exposure to microwaves, as well as the quality of the obtained seeds expressed in terms of germination energy (GE) and capacity (GC). Increasing the power of microwaves resulted in a greater decrease in the moisture content of cones, but it was not possible to find such a relationship for larch cones, especially for large cones. In most cases, the irradiation of larch cones with electromagnetic waves resulted in class I seeds, in contrast to spruce seeds, which could not be assigned to any class. Our findings show that for optimum results larch cones may be exposed to microwaves at a power not greater than 620 W and for a time not longer than 10 s. Spruce cones were found to be very sensitive to radiation; in their case no microwave treatment should be applied as it adversely affects seed viability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Over the past decades, forests have been affected by numerous adverse changes. The negative effects of both biotic and abiotic factors have not only led to lower stand volume increments, but have caused major disturbances in reproductive processes. In Europe, a variety of physiological abnormalities in the flowering, seed production, and seed quality of forest tree species have been observed. In specific cases, these disturbances may cause changes in the genetic material of individual plants and eliminate some genotypes from the population of forest trees (Korczyk 2000; Paul et al. 2019; Stevens et al. 2020). Negative physiological changes have led to an increasing seed deficit and the reduced silvicultural quality of seedlings (Korczyk 2000). In addition, irregular seed production causes a shortage of good quality seeds for the needs of nurseries (Tylek et al. 2015; Kaliniewicz et al. 2018).

Consequently, efforts are under way to develop seed extraction methods that would increase process efficiency while maintaining the highest quality of the obtained material. To date, numerous studies have been conducted with a view to modernizing the extraction process. Antosiewicz (1979) suggested a higher drying temperature, while Bogdanow (1966) explored lower pressures in the seed extraction chamber. Subsequent studies by Aniszewska (2012, 2013) involved a mechanical reduction of cone size (by cutting off the cone base), size-based sorting, and dipping cones in water during a multi-step seed extraction process. However, the applied treatments failed to generate a significant reduction in extraction time. Seeds were found to be highly sensitive to external factors, and so extraction parameters should be selected carefully to prevent seed damage (Aniszewska 2016).

The most widespread method in seed extraction practice is forced convection drying (Rząca and Witrowa-Rajchert 2007; Chielle et al. 2016; Avhad and Marchetti 2016), but the long process time and high temperature have a detrimental effect on the quality of the resulting biological material (Vadivambal and Jayas 2007; Nowacka et al. 2012; Gürdil et al. 2020). The major shortcomings of this method include its relatively low drying efficiency combined with high energy consumption (Lin et al. 1998).

As compared to traditional methods, microwave drying makes it possible to shorten the process time and improve efficiency (Bartholme et al. 2009; Hemis et al. 2012; Vongpradubchai et al. 2022). Microwaves may be applied as the sole source of energy or in conjunction with hot air. This method greatly facilitates the removal of moisture from the surface of the material, with the temperature being more homogeneous across the material. As the material is heated from the inside (Zielonka et al. 1997; Figiel et al. 2006; Studhalter et al. 2009; Vongpradubchai et al. 2022), a rapid increase in its temperature is achieved, depending on the pressure in the chamber (Drouzas and Schubert 1996). However, exposure to microwaves may also lead to mechanical changes in the structure of the material, potentially damaging or destroying it (Vadivambal and Jayas 2007; Usall et al. 2016).

The existing literature does not provide conclusive evidence suggesting positive or negative effects of short-time exposure to microwave radiation on living organisms, including seeds (Aniszewska 2016). A major obstacle in the drying of biological material is the limited time of exposure to microwave irradiation (Vadivambal and Jayas 2007), as excessive exposure may lead to its charring or burning. This may be caused by an uncontrolled temperature increase in areas with elevated moisture content or where the maximum electric field strength occurs—in so-called hot spots (Araszkiewicz and Kozioł 2010). It is difficult to measure the actual temperature of the material during the drying process; instead, that temperature may be determined by means of theoretical calculations (Jałoszyński et al. 2011) or using special sensors (thermocouples). Despite this difficulty, the application of microwaves in the drying of biological material presents an interesting research problem due to the possibility to significantly shorten and improve the process (Araszkiewicz and Kozioł 2010; Darvishi et al. 2013). Another advantage of microwave drying is the intensity of heat and mass exchange as well as higher drying rates without surface overheating. Energy is supplied directly to the inside and the quality of the resulting material is high. Nevertheless, it is necessary to optimize microwave drying to make sure that the process parameters guarantee the highest product quality (Nowacka et al. 2012; Vongpradubchai et al. 2022).

The present study seeks to identify a faster method of seed extraction (Aniszewska 2007) with decreased energy inputs, which would translate into profits or at least reduced financial losses. The proposed solution involves electromagnetic waves. Their effects on biological material vary depending on many factors, such as wavelength and frequency, the moisture content and structure of the material, as well as exposure time (Yarahmadi et al. 2020; Verma et al. 2020; Nirmaan et al. 2020; Ganeev et al. 2020; Kaseke et al. 2020).

The aim of the study was to evaluate the effects of microwave irradiation at different power settings on the quality of seeds extracted from Norway spruce (Picea abies L. Karst.) and European larch (Larix decidua Mill.) cones. Further objectives were to improve the process of seed extraction and optimize irradiation time and power for commercial seed extraction facilities and laboratories evaluating seed quality.

The present study will help elucidate whether the application of microwave radiation in seed extraction has a positive or negative effect on the resulting seeds.

Material and methods

Material

The material used in the study was obtained from two sources. Norway spruce cones were collected in December 2019 in the Suwałki Forest District (GPS: 54°01′N, 22°57′E), while European larch cones were collected in October 2019 in the Grabowiec Nursery, Bielsk Podlaski Forest District (GPS: 52°41′N, 23°00′E). Both localities belong to the Białystok State Forests Regional Directorate in northeastern Poland. The mean initial moisture content of the cones was 37.7% for spruce and 36.9% for larch.

Research methods

In the first step, 130 spruce cones and 150 larch cones were taken at random from the two cone batches. Their length and maximum width were measured using an electronic caliper model 677,256 (Silverline Tools, Yeovil, United Kingdom) with an accuracy of 0.1 mm and their weight was determined using a WPS210S laboratory moisture analyzer (Radwag, Radom, Poland) with an accuracy of 0.001 g.

Throughout the study, the temperature and relative air humidity in the room were monitored using a FHT 100 m (Geo-FENNEL, Kassel, Germany) at a resolution of 0.01 °C and 0.1% with a maximum permissible error of ± 2 °C (± 1%) Ambient temperature amounted to approx. 20 °C and humidity approx. 24%.

After measurements, cones from both tree species were divided into different size groups (mixed—A, small—B, large—C). During successive experiments, three cones from each size group were placed in an R-200 microwave generator (SHARP, Vestel, Poland) powered by 230 V AC at 50 Hz (Fig. 1).

The criterion for dividing the cones into individual size groups was their length. The average lengths of small cones for spruce and larch were 85.6 ± 8.3 and 25.6 ± 2.8 mm, respectively and for large cones 104.7 ± 7.9 and 32.4 ± 2.6 mm, respectively.

For each size group of cones, measurements were conducted at four power settings (P) of the microwave generator (800, 620, 440, and 130 W) and at two irradiation times (7 and 10 s). The power resulted from the regulatory capabilities of the device, while the time was determined on the basis of previous studies (Aniszewska et al. 2020), in which 5 and 15 s were used, where it was found that 15 s was too long. Experiments were conducted in a single replicate for size group A, and in duplicate for groups B and C, in all experimental variants, which are shown in Table 1.

After completing microwave treatments, the study material was weighed and the cones were left in the room in the open box under constant temperature (21 ± 1 °C) and humidity (24 ± 2%) conditions for two weeks to enable spontaneous scale opening. That procedure was sufficient to extract Norway spruce seeds, but in the case of the European larch it was necessary to apply an additional process of shaking in a 10 L extraction drum (Tulska and Aniszewska 2021) at 30 rpm. Individual cones were placed in screen bags and shaken for 10 min, during which time they hit the walls of the drum and each other, releasing seeds.

The extracted spruce and larch seeds were manually dewinged and divided into 100-seed batches to examine their quality. A single germination sample consisted of three seed batches. In each experimental variant, the seeds were placed in a Jacobsen germinator (Laborset, Łódź, Poland), and evaluated after 7 and 14 days. The seeds were placed on filter paper discs in three replicates (3 × 100) and covered with plastic domes. Throughout the trial, a constant substrate temperature of 24 ± 1 °C was maintained in the germinator and the seeds were artificially lit for 8 h a day. The evaluation criterion for individual seeds was a shoot length of at least half the seed length (PKN 1998).

The collected data were used to calculate germination energy (GE) and capacity (GC) according to the standard PN-R-65700 (Załęski 1995; PKN 1998) as the percentage of seeds that were able to germinate within 7 and 14 days pursuant to the aforementioned standard or within 21 days according to the requirements of the International Seed Testing Association (ISTA 1993, 1999, 2021a, b). Table 2 presents the quality classes specified for the studied tree species.

Empty cones were placed in a Heraeus UT 6120 circulating air oven (Kendro Laboratory Products GmbH, Hanau, Germany) for 24 h at 105 ± 2 °C to determine their dry weight, which was needed for calculating the moisture content of cones before and after exposure to microwave radiation of different powers.

The procedures for determining changes in cone weight and seed viability were based on the methodology used by Aniszewska et al. (2019) in a study on the effects of microwave radiation on Scots pine cones.

Unit radiant flux (\({\gamma }_{k})\), defined as the ratio of microwave power (P) to the weight of the material (mk) after irradiation, was calculated from Eq. (1) (Aniszewska et al. 2021):

In turn, unit radiant energy (\({\varepsilon }_{u})\) per loss of moisture (mu) during processing was determined according to Eq. (2) (Aniszewska et al. 2021):

where t is time in seconds and mp is the weight of the material before irradiation in grams.

Statistical analysis

Statistical evaluations of the results, including analysis of variance (ANOVA) and post-hoc least significant difference (LSD) tests of the size, weight, and moisture content changes of the studied material, were conducted using Statistica 13.3 software (TIBCO 2017), at a confidence interval of α = 0.05.

Results

Cone size and weight parameters

Table 3 shows statistical metrics for the measured size parameters. The largest spruce cone was 141 mm long, and the smallest only 66 mm long, with a mean of 96.4 ± 15.3 mm. The mean width of spruce cones was 23.7 ± 2.4 mm and their initial weight was 23.460 ± 7.0 g, with a coefficient of variation of 30%.

The length of European larch cones was 28.4 ± 4.1 mm, ranging from 19 to 39 mm; their width was 13.6 ± 1.8 mm and their mean initial weight was 2.772 ± 0.912 g, with a coefficient of variation of 33%.

The mean initial absolute moistures of the cones from the whole batch, regardless of the size group, for spruce and larch were 39.1 ± 4.3% and 36.9 ± 5.5, respectively.

Table 4 presents the basic size parameters for the cones used in each experimental variant (differing in terms of microwave power and treatment time).

ANOVA did not reveal significant differences (p > 0.05) in mean spruce cone length and width between the studied batches treated at the four microwave power settings and two process times. In the case of larch cones, neither ANOVA nor the post-hoc LSD test showed significant differences in cone width and length for the applied experimental setups. However, a significant difference (p < 0.05) was found in larch cone length between the 7 and 10 s treatments, giving rise to two homogeneous groups.

Changes in moisture content

Table 5 gives data on changes in absolute moisture content (ΔMC) for three cone size groups (A, B, C) of the two studied tree species, broken down by microwave power setting and treatment time.

A 130 W microwave treatment applied for 7 s caused spruce cones in all size groups (A, B, C) to lose more than 0.10% of their initial moisture content. The greatest mean moisture loss was found for batch S1C containing large cones (0.11 ± 0.05%). In the case of spruce cones exposed to a 440 W treatment, the largest decrease in moisture content was recorded for the S2A batch with mixed size cones (0.16 ± 0.04%), while the smallest decrease (0.09 ± 0.03%) was found for the S2C batch with large cones. As can be seen from Table 5, after a 7 s exposure to 620 W microwave power, all three size groups considered together lost approx. 0.35% of their initial moisture. The largest loss of moisture (0.12 ± 0.04%) for an individual cone was identified for the largest cone size group (S3C batch). An increase in microwave power to 800 W caused the highest moisture loss per individual cone (0.18 ± 0.03%) in the S4A batch containing mixed size cones. In the case of the other cone batches, i.e., S4B (small) and S4C (large), moisture loss amounted to 0.14 ± 0.10 and 0.12 ± 0.02%, respectively.

Table 5 presents data on changes in the moisture content of spruce cones after 10 s exposure to different microwave powers. The mean moisture loss at 130 W microwave radiation was 0.10% for the mixed size batch (S5A) and 0.12% for the small cone batch (S5B). At the 440 W setting, the mean moisture loss was very similar for all size groups, with the greatest moisture reduction recorded for the batch containing the largest cones (S6C)—0.15 ± 0.03%. In the case of 620 W microwave power, the mean moisture loss per cone was 0.24 ± 0.07% for the batch with the largest cones. The results for the other two batches at this power setting were similar: 0.12 ± 0.04% for S7A and 0.14 ± 0.03% for S7B. At 800 W microwave power, the greatest mean moisture reduction was found for the batch containing the smallest cones (S8B—0.22 ± 0.10%); the other two batches also exhibited high moisture loss, with the lowest one being as much as 0.14 ± 0.04%.

In the case of larch cones, the largest mean difference in moisture content amounted to 0.96% (L1B—Table 5) for individual cones in the batch containing small cones exposed to 130 W microwave radiation for 7 s. However, none of the batches exceeded a moisture content difference of 1%. It should be noted that at 440 W radiation, only one batch containing small cones exhibited a mean moisture loss of less than 1%. The highest moisture reduction (1.16 ± 0.33%) was found for batch L2C, containing the largest cones. Following a 7 s exposure to 620 W microwave radiation, the mean moisture content was the highest for batch L3B with small cones (1.50 ± 0.70%). Finally, at the 800 W setting, the highest mean moisture loss was found for the batch containing small cones (1.88 ± 1.02%), while the lowest moisture reduction 1.05 ± 0.23% was recorded for the largest cones (batch L4C).

At the longer exposure setting (10 s), the greatest mean loss of moisture at 130 W was found for the mixed size cone batch at 2.62%, while the lowest mean value—for the batch with large cones (1.04%). At 440 W microwave power, the greatest mean moisture reduction was recorded for the mixed size batch (L6A) at 2.03%. It should be noted that another mixed sized batch (L7A) exhibited the highest moisture loss after 660 (2.63%); in the other two cases (small and large cones), moisture reduction did not exceed 2%. After increasing microwave output to 800 W, the highest mean moisture loss was recorded for the batch containing small cones (L8B—3.40%), which was significantly greater as compared to the large cone batch (L8C—1.25%).

In the case of spruce cones, the LSD test showed significant differences in moisture loss for batches of large cones exposed to 620 and 800 W microwave power for 10 s. In turn, the same test for larch cones revealed significant differences for small and mixed sized batches exposed to 620 and 800 W microwave power for 10 s.

As can be seen from Table 6, greater moisture reduction was obtained for cones treated at higher microwave settings. A significant linear relationship between moisture loss and microwave power was found in three out of four cases; with the one exception being larch cones exposed to microwave radiation for 10 s (L10sec). The critical value of the R coefficient for simple correlations was 0.811. The linear regression equations are given below:

Table 7 gives the values calculated according to Eqs. (1) and (2) from the Research methods section.

Unit radiant flux increased with microwave power (Fig. 2): in the case of larch cones exposed to electromagnetic radiation for 7 and 10 s, an increment in power output by 100 W increased unit radiant flux by approx. 50 W g−1, as compared to approx. 4 W g−1 for spruce cones under the same conditions. Also unit radiant energy increased with microwave power, on average by 25–45 kJ g−1, for cones of both species—L7 and S7, respectively.

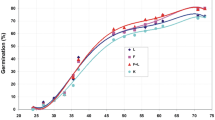

Evaluation of the quality of spruce and larch seeds following exposure to microwaves

The results of germination tests involving seeds extracted from spruce and larch cones exposed to microwave radiation for 7 s and 10 s are given in Table 8. As can be seen, no spruce batch reached a minimum of 71 germinated seeds over 14 days, which mean that none could be assigned to any quality class. Spruce seeds were probably damaged by the electromagnetic radiation acting on the cones. In turn, the control sample of spruce seeds not exposed to microwaves exhibited a germination energy of 90% and a germination capacity of 94%, thus qualifying for quality class I.

Germination results showed that most larch seeds obtained from irradiated cones met the requirements of quality class I. The exceptions were larch seeds from cones exposed to 800 W microwave power for 7 and 10 s, which were assigned to quality classes II and III, respectively. This means that the highest microwave power had an adverse effect on the germination quality of the tested seeds. A control trial involving seeds obtained from cones unexposed to microwave radiation resulted in 51% for germination energy and 53% for germination capacity, meeting the criteria for class I. Class I viability thresholds specified in the standards amount to 40–60 germinated seeds for larch and 91–100 germinated seeds for spruce.

The substantial differences in viability classifications between the two tree species may be attributable to the anatomical structure or their seeds. The seed coat of spruce is much thinner as compared to that of larch (Suszka 2000; Aniszewska 2014), and so the microwave effect on the seed proper may have been much greater in the former case, impairing germination capacity.

Discussion

Efforts are currently underway to improve the seed extraction process. Guidelines are being developed for the design of devices applying microwaves in the first step of one- and two-step processes. Microwaves are supposed to lower the initial moisture content of cones for the purpose of shortening the time of scale deflection away from the rachis. In the first step, the cones are exposed to radiation for a short time which leads to a rapid reduction in moisture content in cones that are still closed. This decreases cone weight and initiates scale opening. Due to the application of microwaves the scales deflect more rapidly and to a greater degree, which makes the seeds more exposed. This is of importance in the next processing step taking place in the extraction chamber or cabinet (Aniszewska 2016). Microwave radiation is a physical factor that has been rarely used for pre-sowing seed stimulation. However, in the literature there is some research concerning the effects of microwaves on seed quality (Pietruszewski and Kania 2011; Hemis et al. 2012) as well as the combined use of microwave and convective drying (Darvishi et al. 2013; Hemis et al. 2015).

In the 1990s, the Department of Physics, Agricultural Academy in Lublin, initiated intensive research on the effects of microwave radiation and electromagnetic fields on the quality of plants. According to some reports, seeds store the received energy and convert it into chemical energy for their growth processes. The energy supplied in this way has also been said to increase the energetic potential of seeds (Pietrzyk 2006). Chen et al. (2005) suggested that a preliminary microwave treatment of seeds may improve the inner energy of seeds, enhance cotyledon enzymes, and accelerate cell metabolism, resulting in significantly higher emissions of biophotons.

Olchowik and Gawda (2020) used microwaves to improve the germination capacity of flax seeds. They found that capacity to be significantly increased by 42.15 and 53.57 GHz frequencies applied for less than 1 min. For a long time now researchers have been striving to utilize the effects of electromagnetic fields on living organisms and in numerous studies those effects have been demonstrated to be positive. According to Adair (2003), electromagnetic waves can increase seed viability by killing the pathogens present on the surface of the seed coat. In turn, Nelson (Nelson 1985) noted that electromagnetic waves can soften the seed coat, enabling earlier germination. Other advantages of electromagnetic waves include the elimination of parasitic fungi and pests in wood (Krajewski 1990, 2001). Microwaves have been used instead of herbicides to disinfect soil (Thuery 1992) and to inhibit the germination of undesirable seeds on arable land (Velázquez-Martí et al. 2006). Forest nurseries and greenhouses use special devices for the microwave treatment of the soil (Słowiński 2013). A study conducted by Kuzugudenli (2018) on stone pine (Pinus pinea L.) seeds irradiated with microwaves and the resulting seedlings demonstrated the beneficial effects of a 45 MHz magnetic field. In another study describing relationships between some applications of magnetic fields and stone pine development, a 9.42 mT magnetic field was shown to have a beneficial effect on seedling growth (Kirdar et al. 2016). Similar results were obtained for chickpea (Cicer arietinum L.) by Vashisth and Nagarajan (2008), for tomato (Lycopersicon esculentum Mill.) by Souza Torres et al. (1999) and Martínez et al. (2009), for wheat (Triticum aestivum L. cv. Bezostaya) and bean (Phaseolus vulgaris L. cv. Gina) by Cakmak et al. (2010), for corn (Zea mays L.) by Răcuciu (2012), for potato by Cramariuc et al. (2005), and for sunflower by Vashisth and Nagarajan (2010).

Magnetic fields may accelerate the development of seedlings, especially due to their influence on the metabolism of auxin, cytokinin and gibberellin. Cytokinin is primarily responsible for cell division, while auxin and gibberellin—for increased cell elongation (Arteca 1996). This is consistent with the study by Kuzugudenli (2018), who reported that the application of 280 W microwaves at 160 μT for 60 s enhanced plant development and growth.

However, other authors claim that microwaves have an adverse effect on seeds. In a study by Ballard et al. (1976), it was found that seeds dried using microwaves had a lower germination capacity under laboratory conditions as compared to seeds subjected to convective drying. In turn, according to Aniszewska (2016), the degree of germination reduction depends on the moisture content of seeds (they will be damaged by microwaves if that content is too high). A decrease in seed quality following exposure to microwave irradiation was also reported by Aniszewska et al. (2019) in a study involving the irradiation of Scots pine cones with 800 W microwaves (seed viability was substantially compromised by exposures longer than 5 s).

In the present study, the viability of seeds extracted from spruce cones exposed to microwaves was detrimentally affected by electromagnetic radiation. Increasing the microwave power, while the process temperature was not controlled, increased the temperature inside the seeds and caused the formation of hot spots. This could be due to inhomogeneity in heating caused by the sine wave of microwaves. An adverse effect of microwaves on wheat seeds was also found by Hemis et al. (2012), who reported that the higher the microwave power, the lower the seed viability and its germination percentage. Łupińska et al. (2009) found that less damaged seeds and greater germination capacity can be obtained with microwave drying with power up to 400 W. This was confirmed in the presented research results, where the germination capacity (GC) of larch seeds for the power of 800 W depends on since radiation, has dropped to 29 and 24%. In turn, Kazancı (2014) reported from a study of post-fire germination that high temperature (100–140 °C) had a negative effect on seed germination in 37 of the studied 71 taxa. In this context, it should be noted that according to the literature (Tyszkiewicz 1951; Antosiewicz and Załęski 1987; Załęski and Aniśko 2003; Aniszewska et al. 2019), the process temperature in facilities extracting seeds from conifer cones does not exceed 50 °C.

Seeds from spruce of cones not exposed to microwaves reached germination quality of more than 90%. In turn, larch seeds were characterized by high viability irrespective of exposure to microwave radiation. Thus, the seeds contained in larch cones can be subjected to microwaves, although the present study showed that microwave power should not be greater than 620 W and exposure time should not exceed 10 s (at those process parameters the cones lost on average 1.67% of their moisture content, which corresponds to an approx. 0.04 g reduction in their weight).

The next step in the research will involve evaluation of the quality and morphological traits of the seedlings obtained from cones exposed to microwave radiation. However, it should be remembered that microwaves are not yet widely applied for commercial purposes (Vadivambal and Jayas 2007; Usall et al. 2016) due to technical and economic factors.

Conclusions

The present work discussed changes in the moisture content of cones exposed to microwave radiation of different power levels and durations for two tree species, the Norway spruce and European larch, as well as the quality of seeds obtained from such cones.

The average loss of mass and moisture of small and large spruce cones, regardless of the amount of applied power, was greater in the case of longer irradiation time. The higher the microwave power was, the more the disproportion in the amount of moisture lost between the two time groups increased. Increasing the microwave power resulted in a greater decrease in the moisture of the cones. In the case of larch cones characterized by a lower mass than spruce cones, it was not possible to clearly determine such a relationship, especially for large cones.

In terms of seed quality, spruce seeds were found to be sensitive to microwaves, which adversely affected their viability. In their case, no experimental batch could be assigned to any quality class.

In turn, European larch seeds were resilient to microwave irradiation, and reached a high quality class. In their case, exposure to electromagnetic radiation may be argued to have facilitated the seed extraction process without detrimental effects on seed quality. The irradiation parameters recommended for the improved extraction of larch cones while preserving seed quality are microwave power levels of up to 620 W applied for 10 s.

The heat treatment of seeds with microwaves appears to have a substantial potential, but there still remain many factors that require further research. These include the anatomical structure of the cones, the initial moisture content of the material, the thickness of the layer, the structure of the microwave emission device and many more.

References

Adair RK (2003) Biophysical limits on athermal effects of RF and microwave radiation. Bioelectromagnetics 24:39–48. https://doi.org/10.1002/bem.10061

Aniszewska M (2007) Effectiveness of commercial Scots pine seed extraction at industrial scale. Sylwan 151:22–28

Aniszewska M (2012) Dynamics of the process of seed extraction from pine cones Pinus sylvestris L. performed in one two-steps. Rozprawy naukowe i monografie, Wydawnictwo SGGW

Aniszewska M (2013) Changes in humidity and temperature inside the pine cones (Pinus sylvestris L.) in two stages seed extraction. For Res Pap 74:205–214. https://doi.org/10.2478/frp-2013-0020

Aniszewska M (2014) The analysis of the conformacion of the wings of Larix decidua Mill. in terms of dewinging. Stud Mater Cent Edukac Przyr-Lesn 16:13–19

Aniszewska M (2016) The change in weight and surface temperature of a pine cone (Pinus sylvestris L.) as a result of microwave irradiation. For Res Pap 77:56–67. https://doi.org/10.1515/frp-2016-0007

Aniszewska M, Gendek A, Tulska E et al (2019) Influence of the duration of microwave irradiation of Scots Pine (Pinus sylvestris L.) cones on the quality of harvested seeds. Forests 10:1108. https://doi.org/10.3390/f10121108

Aniszewska M, Zychowicz W, Gendek A (2020) The effectiveness of short-term microwave irradiation on the process of seed extraction from Scots pine cones (Pinus sylvestris L.). IForest - Biogeosciences For 13:73. https://doi.org/10.3832/ifor3089-012

Aniszewska M, Słowiński K, Tulska E, Zychowicz W (2021) Effects of microwave irradiation on the moisture content of various wood chip fractions obtained from different tree species. J Wood Sci 67:28. https://doi.org/10.1186/s10086-021-01958-8

Antosiewicz Z (1979) Wpływ temperatury i wilgotności powietrza na jakość nasion sosny i świerka w czasie łuszczenia szyszek. Las Pol 6:11–12

Antosiewicz Z, Załęski A (1987) Technika i technologia wyłuszczania nasion sosny, świerka i modrzewia w Polsce. Las Pol 7–11

Araszkiewicz M, Kozioł A (2010) Determination of temperature distribution during microwave heating of biological material. Inż Apar Chem 4:12–13

Arteca RN (1996) Plant growth substances: principles and applications, 1st edn. Springer, New York

Avhad MR, Marchetti JM (2016) Mathematical modelling of the drying kinetics of Hass avocado seeds. Ind Crops Prod 91:76–87. https://doi.org/10.1016/j.indcrop.2016.06.035

Ballard LAT, Nelson SO, Buchwald T, Stetson LE (1976) Effects of radiofrequency electric fields on permeability to water of some legume seeds, with special reference to strophiolar conduction. Seed Sci Technol 4:257–274

Bartholme M, Avramidis G, Viöl W, Kharazipour A (2009) Microwave drying of wet processed wood fibre insulating boards. Eur J Wood Wood Prod 67:357–360. https://doi.org/10.1007/s00107-008-0306-9

Bogdanow B (1966) O suszkie szyszek w wakuomie. Lesn Chozjajstwo 3:57–60

Cakmak T, Dumlupinar R, Erdal S (2010) Acceleration of germination and early growth of wheat and bean seedlings grown under various magnetic field and osmotic conditions. Bioelectromagnetics 31:120–129. https://doi.org/10.1002/bem.20537

Chen Y-P, Liu Y-J, Wang X-L et al (2005) Effect of microwave and He-Ne laser on enzyme activity and biophoton emission of Isatis indigotica Fort. J Integr Plant Biol 47:849–855. https://doi.org/10.1111/j.1744-7909.2005.00107.x

Chielle DP, Bertuol DA, Meili L et al (2016) Convective drying of papaya seeds (Carica papaya L.) and optimization of oil extraction. Ind Crops Prod 85:221–228. https://doi.org/10.1016/j.indcrop.2016.03.010

Cramariuc R, Donescu V, Popa M, Cramariuc B (2005) The biological effect of the electrical field treatment on the potato seed: agronomic evaluation. J Electrost 63:837–846. https://doi.org/10.1016/j.elstat.2005.03.082

Darvishi H, Khoshtaghaza MH, Najafi G, Zarein M (2013) Characteristics of sunflower seed drying and microwave energy consumption. Int Agrophysics 27:127–132. https://doi.org/10.2478/v10247-012-0077-8

Drouzas AE, Schubert H (1996) Microwave application in vacuum drying of fruits. J Food Eng 28:203–209. https://doi.org/10.1016/0260-8774(95)00040-2

Figiel A, Szarycz M, Świerk B (2006) Vacuum–microwave drying of apples in the low preassure conditions. Inż Rol 2:293–298

Ganeev I, Karimov K, Fayzrakhmanov S et al (2020) Intensification of the drying process of small seed oilseeds using microwave electromagnetic radiation. Acta Agric Slov 115:261–271. https://doi.org/10.14720/aas.2020.115.2.1359

Gürdil GAK, Kabutey A, Selvi KÇ et al (2020) Investigation of heating and freezing pretreatments on mechanical, chemical and spectral properties of bulk sunflower seeds and oil. Processes 8:411. https://doi.org/10.3390/pr8040411

Hemis M, Choudhary R, Watson DG (2012) A coupled mathematical model for simultaneous microwave and convective drying of wheat seeds. Biosyst Eng 112:202–209. https://doi.org/10.1016/j.biosystemseng.2012.04.002

Hemis M, Choudhary R, Gariépy Y, Raghavan VGS (2015) Experiments and modelling of the microwave assisted convective drying of canola seeds. Biosyst Eng 139:121–127. https://doi.org/10.1016/j.biosystemseng.2015.08.010

ISTA (1993) International rules for seed testing. Seed Sci Technol 21

ISTA (1999) International rules for seed testing. Rules 1999. Seed Sci Technol Suppl 333 + vii pp

ISTA (2021a) International rules for seed testing. Full issue. Int Rules Seed Test 2021:i–19-8(8). https://doi.org/10.15258/istarules.2021.F

ISTA (2021b) Chapter 7: Seed health testing. Int Rules Seed Test 2021:i–7-6(14). https://doi.org/10.15258/istarules.2021.07

Jałoszyński K, Szarycz M, Surma M, Pasławska M (2011) Analysis of microwave–vaccum drying of cauliflower. Inż Rol 9:65–72

Kaliniewicz Z, Mańkowski S, Tylek P et al (2018) Correlations between the physical properties of silver fir seeds. Acta Agrophysica 25:197–212. https://doi.org/10.31545/aagr/92616

Kaseke T, Opara UL, Fawole OA (2020) Effect of microwave pretreatment of seeds on the quality and antioxidant capacity of pomegranate seed oil. Foods 9:1287. https://doi.org/10.3390/foods9091287

Kazancı DD (2014) Akdeniz Bitkilerinin Yangın Sonrası Çimlenme Özelliklerinin Belirlenmesi [Determination of post fire germination properties of mediterranean plants]. Yüksek Lisans Tezi, Hacettepe Üniversitesi Fen Bilimleri Enstitüsü

Kirdar E, Yucedag C, Balaban B (2016) The effects of magnetic field on germination of seeds and growth of seedlings of stone pine. J for 3:1–6. https://doi.org/10.18488/journal.101/2016.3.1/101.1.1.6

Korczyk AF (2000) Kwitnienie, obradzanie i jakość nasion sosny zwyczajnej [Pinus sylvestris L.] świerka pospolitego [Picea abies [L.]Karst.] w Puszczy Białowieskiej. Pr Inst Badaw Lesn Ser A 1:45–73

Krajewski A (1990) Zwalczanie owadów - szkodników technicznych drewna za pomocą mikrofal. Ochr Zabyt 43(1):27–34

Krajewski A (2001) Fizyczne metody dezynsekcji drewna dóbr kultury [Physical methods of wood desinsectisation in monuments culture]. Wydawnictwo SGGW, Warszawa

Kuzugudenli E (2018) Effect of microwave radiation on growth and germination of stone pine (Pinus Pinea L.) seedlings. Appl Ecol Environ Res 16:2837–2844. https://doi.org/10.15666/aeer/1603_28372844

Lin TM, Durance TD, Scaman CH (1998) Characterization of vacuum microwave, air and freeze dried carrot slices. Food Res Int 31:111–117. https://doi.org/10.1016/S0963-9969(98)00070-2

Łupińska A, Kozioł A, Araszkiewicz M, Łupiński M (2009) The changes of quality in rapeseeds during microwave drying. Dry Technol 27:857–862. https://doi.org/10.1080/07373930903021717

Martínez E, Carbonell MV, Flórez M et al (2009) Germination of tomato seeds (Lycopersicon esculentum L.) under magnetic field. Int Agrophysics 23:44–50

Nelson SO (1985) RF and microwave energy for potential agricultural applications. J Microw Power 20:65–70. https://doi.org/10.1080/16070658.1985.11720292

Nirmaan AMC, Rohitha Prasantha BD, Peiris BL (2020) Comparison of microwave drying and oven-drying techniques for moisture determination of three paddy (Oryza sativa L.) varieties. Chem Biol Technol Agric 7:1. https://doi.org/10.1186/s40538-019-0164-1

Nowacka M, Śledź M, Wiktor A, Witrowa-Rajchert D (2012) Physical and chemical properties of microwave dried food products. Żywność Nauka Technol Jakość 19:5–20

Olchowik G, Gawda H (2020) Influence of microwave radiation on germination capacity of flax seeds. Acta Agrophys 62:63–68

Paul C, Brandl S, Friedrich S et al (2019) Climate change and mixed forests: how do altered survival probabilities impact economically desirable species proportions of Norway spruce and European beech? Ann for Sci 76:1–15. https://doi.org/10.1007/s13595-018-0793-8

Pietruszewski S, Kania K (2011) Microwave effect on the germination kinetics of seeds of white lupine and consumptive pea. Acta Agrophys 18:121–129

Pietrzyk W (2006) Standardisation of research on the influence of electromagnetic field on materials of biological origin. Acta Agrophys 8:915–921

PKN (1998) PN-R-65700 - Materiał siewny. Nasiona drzew i krzewów leśnych i zadrzewieniowych [Planting seeds - Seeds of forest trees, shrubs and bushes]. Polish Committee for Standardization, Warsaw, Poland

Răcuciu M (2012) Influence of extremely low frequency magnetic field on assimilatory pigments and nucleic acids in Zea mays and Curcubita pepo seedlings. Romanian Biotechnol Lett 17:7662–7672

Rząca M, Witrowa-Rajchert D (2007) Influence of convective-microwave drying parameters on radicalscavenging activity of dried apples. Żywność Nauka Technol Jakość 14:222–230

Słowiński K (2013) The influence of microwave radiation emitted to non-disinfected nursery soil on the survivability and chosen biometric characteristics of Scots pine (Pinus sylvestris L.). Zesz Nauk Uniw Rol Im H Kołłątaja W Krakowie 517:122

Souza Torres AD, Porras Leon E, Casate Fernandez R (1999) Effect of magnetic treatment of tomato seeds (Lycopersicon esculentum Mill) on germination and seedling growth. Investig Agrar Prod Prot Veg Espana 437–444

Stevens CJ, Bell JNB, Brimblecombe P et al (2020) The impact of air pollution on terrestrial managed and natural vegetation. Philos Trans R Soc Math Phys Eng Sci 378:20190317. https://doi.org/10.1098/rsta.2019.0317

Studhalter B, Ozarska B, Siemon G (2009) Temperature and moisture content behaviour in microwave heated wood prior to bending – Mountain Ash (Eucalyptus regnans). Eur J Wood Wood Prod 67:237–239. https://doi.org/10.1007/s00107-008-0300-2

Suszka B (2000) Nowe technologie i techniki w nasiennictwie leśnym [New technologies and techniques in forest seed]. Bogucki Wydawnictwo Naukowe S.C., Warszawa

Thuery J (1992) Microwaves: industrial, scientific, and medical applications. Artech House Inc., Boston

TIBCO (2017) Statistica, an advanced analytics software package, version 13.3

Tulska E, Aniszewska M (2021) Urządzenie do wytrząsania nasion z szyszek oraz zastosowanie urządzenia do wytrząsania nasion, zwłaszcza z rodzaju Larix albo Pinus

Tylek P, Kaliniewicz Z, Kielbasa P, Zagrobelny T (2015) Mass and density as separation criteria of pedunculate oak (Quercus robur L.) seeds. Electron J Pol Agric Univ Ser for 18:1–10

Tyszkiewicz S (1951) Wyłuszczanie nasion leśnych [Forest seed extraction]. Państwowe Wydawnictwo Rolnicze i Leśne, Warszawa

Usall J, Ippolito A, Sisquella M, Neri F (2016) Physical treatments to control postharvest diseases of fresh fruits and vegetables. Postharvest Biol Technol 122:30–40. https://doi.org/10.1016/j.postharvbio.2016.05.002

Vadivambal R, Jayas DS (2007) Changes in quality of microwave-treated agricultural products—a review. Biosyst Eng 98:1–16. https://doi.org/10.1016/j.biosystemseng.2007.06.006

Vashisth A, Nagarajan S (2008) Exposure of seeds to static magnetic field enhances germination and early growth characteristics in chickpea (Cicer arietinum L.). Bioelectromagnetics 29:571–578. https://doi.org/10.1002/bem.20426

Vashisth A, Nagarajan S (2010) Effect on germination and early growth characteristics in sunflower (Helianthus annuus) seeds exposed to static magnetic field. J Plant Physiol 167:149–156. https://doi.org/10.1016/j.jplph.2009.08.011

Velázquez-Martí B, Gracia-López C, Marzal-Domenech A (2006) Germination inhibition of undesirable seed in the soil using microwave radiation. Biosyst Eng 93:365–373. https://doi.org/10.1016/j.biosystemseng.2006.01.005

Verma S, Sharma V, Kumari N (2020) Microwave pretreatment of tomato seeds and fruit to enhance plant photosynthesis, nutritive quality and shelf life of fruit. Postharvest Biol Technol 159:111015. https://doi.org/10.1016/j.postharvbio.2019.111015

Vongpradubchai S, Makul N, Rattanadecho P (2022) Influence of the microwave-accelerated process on the drying kinetics, mechanical properties and surface appearance of rubberwood (Heavea brasiliensis). Eur J Wood Wood Prod 80:395–407. https://doi.org/10.1007/s00107-021-01766-3

Yarahmadi N, Hojjatoleslamy M, Sedaghat Boroujeni L (2020) Different drying methods of Pistacia Atlantica seeds: impact on drying kinetics and selected quality properties. Food Sci Nutr 8:3225–3233. https://doi.org/10.1002/fsn3.1582

Załęski A (1995) Nasiennictwo leśnych drzew i krzewów iglastych [Seeds of forest trees and coniferous shrubs]. Oficyna Edytorska Wydawnictwo Świat, Warszawa

Załęski A, Aniśko E (2003) Suszenie nasion wybranych gatunków drzew [Drying the seeds of selected tree species]. Not Nauk Inst Badaw Lesn 1:1–2

Zielonka P, Gierlik E, Matejak M, Dolowy K (1997) The comparison of experimental and theoretical temperature distribution during microwave wood heating. Holz Als Roh- Werkst 55:395–398. https://doi.org/10.1007/s001070050253

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Conceived and designed the study M.A., A.G. and E.T.; methodology M.A. and A.G.; implemented the study M.A., A.G., A.Z-K., E.T., J.M. (Jan Malat’ák), B.T., J.K. and Jt.M. (Jitka Malat’áková); analysed the data M.A., A.G., B.T., J.M. and J.K.; writing—original draft preparation M.A., and A.G.; writing—review and editing M.A., A.G., J.M., B.T., J.K. and Jt.M.; supervision M.A. and A.G. All authors reviewed the manuscript. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Aniszewska, M., Gendek, A., Tulska, E. et al. Effects of electromagnetic waves on the moisture content of cones and the quality of extracted seeds in the Norway spruce and European larch. New Forests 55, 305–322 (2024). https://doi.org/10.1007/s11056-023-09979-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11056-023-09979-5