Abstract

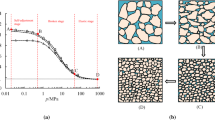

The caving zone in goaf can be regarded as a porous medium consisting of broken coal and a rock mass. During the compaction process of broken coal and a rock mass in a caving zone, the re-breakage of the rock and coal affects the compaction stress and pore characteristics of the caving zone. In this study, a discrete element numerical simulation of a broken coal sample based on the bonded particle model (BPM) was carried out to study the evolution characteristics of stress, strain, and breakage during its compaction. The grading equation of the minimum particle size during the simulation process is given based on a laboratory test. This equation can reduce the effect of the sub-particles, which cannot be further broken through the BPM. The stress–strain curve of the BPM during compaction can be divided into two stages using maximum vertical strain, εm, and the stress calculation model of these two stages is given. In first stage, there was no effect of the particle strength on εm. Here, εm of the BPM was equal to the porosity of the BPM minus the initial porosity of the broken particles. The average slope of a straight-line section after εm was proportional to the elastic modulus of the coal samples with a ratio of 1.0892. In addition, the particle breakage rate, Bs, and its calculation model were proposed to describe the breakage of the BPM during the compaction process. The evolution characteristics of particle breakage and its correlation with the stress, strain, and particle location are illustrated. The breakage rate of the model increased with increase in strain in an S-shape function. When strain was greater than εm, the particles had difficulty breaking again, and the breakage rates of soft coal, medium coal, and hard coal were 96.05%, 87.21%, and 87.78%, respectively. Under the same stress conditions, the breakage rate of soft coal was clearly higher than that of hard coal. The breakage rate increased the fastest when stress was equal to the tensile strength of the coal sample during the compaction process of the BPM.

Similar content being viewed by others

References

Alonso, E. E., Tapias, M., & Gili, J. (2012). Scale effects in rockfill behaviour. Géotechnique Letters,2(3), 155–160.

Aman, S., Tomas, J., & Kalman, H. (2010). Breakage probability of irregularly shaped particles. Chemical Engineering Science,65(5), 1503–1512.

Bai, Q. S., Tu, S. H., & Zhang, C. (2016). DEM investigation of the fracture mechanism of rock disc containing hole (s) and its influence on tensile strength. Theoretical and Applied Fracture Mechanics,86, 197–216.

Bai, Q., & Young, R. P. (2019). Numerical investigation of the mechanical and damage behaviors of veined gneiss during true-triaxial stress path loading by simulation of in situ conditions. Rock Mechanics and Rock Engineering. https://doi.org/10.1007/s00603-019-01898-2.

Bolton, M. D., Nakata, Y., & Cheng, Y. P. (2008). Micro-and macro-mechanical behaviour of DEM crushable materials. Géotechnique,58(6), 471–480.

Brosh, T., Kalman, H., & Levy, A. (2011). Fragments spawning and interaction models for DEM breakage simulation. Granular Matter,13(6), 765–776.

Cheng, G., Ma, T., Tang, C., Liu, H., & Wang, S. (2017). A zoning model for coal mining—induced strata movement based on microseismic monitoring. International Journal of Rock Mechanics and Mining Sciences,94, 123–138.

Cheng, Y. P., Nakata, Y., & Bolton, M. D. (2003). Discrete element simulation of crushable soil. Geotechnique,53(7), 633–641.

Cho, N., Martin, C. D., & Sego, D. C. (2007). A clumped particle model for rock. International Journal of Rock Mechanics and Mining Sciences,44(7), 997–1010.

Cil, M. B., & Buscarnera, G. (2016). DEM assessment of scaling laws capturing the grain size dependence of yielding in granular soils. Granular Matter,18(3), 36–50.

Einav, I. (2007). Breakage mechanics—part I: Theory. Journal of the Mechanics and Physics of Solids,55(6), 1274–1297.

Feng, G., Li, Z., Hu, S., Zhang, Y., Zhang, A., Gao, Q., et al. (2018). Distribution of gob empty space for methane drainage during the longwall mining: A case study. Journal of Natural Gas Science and Engineering,60, 112–124.

Gao, F. Q., & Stead, D. (2014). The application of a modified voronoi logic to brittle fracture modelling at the laboratory and field scale. International Journal of Rock Mechanics and Mining Sciences,68(68), 1–14.

Gao, F., Stead, D., & Coggan, J. (2014). Evaluation of coal longwall caving characteristics using an innovative UDEC Trigon approach. Computers and Geotechnics,55, 448–460.

Hardin, B. O. (1985). Crushing of soil particles. Journal of Geotechnical Engineering,111(10), 1177–1192.

Hardin, B. O., & Blandford, G. E. (1989). Elasticity of particulate materials. Journal of Geotechnical Engineering,115(6), 788–805.

Hu, S., Han, D., Feng, G., Zhang, A., Hao, G., Hu, L., & Li, B. (2019). Influence of stress on void ratios of compacted crushed rock masses in coal mine gobs. Natural Resources Research. https://doi.org/10.1007/s11053-019-09495-4.

Hu, S., Zhang, A., Feng, G., Guo, X., Miu, X., Li, C., & Kang, L. (2018). Methane extraction from abandoned mines by surface vertical wells: A case study in China. Geofluids. https://doi.org/10.1155/2018/8043157.

Itasca Consulting Group Inc. PFC2D/3D (Particle Flow Code in 2/3 Dimensions), Version 3.1. Minneapolis, MN: ICG; 2004.

Jiang, H., & Xu, M. (2014). Study of stress-path-dependent behavior of rockfills using discrete element method. Engineering Mechanics,31(10), 151–157.

Karacan, C. Ö. (2010). Prediction of porosity and permeability of caved zone in longwall gobs. Transport in Porous Media,82(2), 413–439.

Kazerani, T., & Zhao, J. (2010). Micromechanical parameters in bonded particle method for modelling of brittle material failure. International Journal for Numerical and Analytical Methods in Geomechanics,34(18), 1877–1895.

Liu, W., Li, Y., Yang, C., Daemen, J. J., Yang, Y., & Zhang, G. (2015). Permeability characteristics of mudstone cap rock and interlayers in bedded salt formations and tightness assessment for underground gas storage caverns. Engineering Geology,193, 212–223.

Lobo-Guerrero, S., & Vallejo, L. E. (2006). Discrete element method analysis of railtrack ballast degradation during cyclic loading. Granular Matter,8(3–4), 195–204.

Ma, G., Zhou, W., & Chang, X. L. (2014). Modeling the particle breakage of rockfill materials with the cohesive crack model. Computers and Geotechnics,61, 132–143.

Manso, J., Marcelino, J., & Caldeira, L. (2018). Crushing and oedometer compression of rockfill using DEM. Computers and Geotechnics,101, 11–22.

Marsal, R. J. (1967). Large-scale testing of rockfill materials. Journal of the Soil Mechanics and Foundations Division,93(2), 27–43.

Pappas, D. M., & Mark, C. (1993). Behavior of simulated longwall gob material. US Department of the Interior, Bureau of Mines: Report of Investigations, RI-9458

Potyondy, D. O. (2004). A bonded-particle model for rock. International Journal of Rock Mechanics and Mining Sciences,41(8), 1329–1364.

Ryder, J. A., & Wagner, H. (1978). 2D analysis of backfill as a means of reducing energy release rates at depth. Unpublished research report. Johannesburg: Chamber of Mines of South Africa.

Tsoungui, O., Vallet, D., & Charmet, J. C. (1999). Numerical model of crushing of grains inside two-dimensional granular materials. Powder Technology,105(1–3), 190–198.

Wang, Y., Li, C. H., & Hu, Y. Z. (2019). 3D image visualization of meso-structural changes in a bimsoil under uniaxial compression using X-ray computed tomography (CT). Engineering Geology,248, 61–69.

Xia, T., Wang, X., Zhou, F., Kang, J., Liu, J., & Gao, F. (2015). Evolution of coal self-heating processes in longwall gob areas. International Journal of Heat and Mass Transfer,86, 861–868.

Xu, K., Zhou, W., Ma, G., Chang, X., & Yang, L. (2018). Review of particle breakage simulation based on DEM. Chinese Journal of Geotechnical Engineering,40(5), 880–889.

Yang, G., Xu, J., & Liu, K. (2015). Numerical simulation of particle breakage of coarse aggregates. Rock and Soil Mechanics,36(11), 3301–3306.

Ye, J., Zhang, J., & Zou, W. (2018). Influences of grain shape on pore characteristics of filled breakstone aggregate. Rock and Soil Mechanics,39(12), 169–179.

Yuan, Y., Chen, Z., Yuan, C., Zhu, C., Wei, H., & Zhang, X. (2019). Numerical simulation analysis of the permeability enhancement and pressure relief of auger mining. Natural Resources Research. https://doi.org/10.1007/s11053-019-09501-9.

Zhang, C., Tu, S., & Zhang, L. (2017). Analysis of broken coal permeability evolution under cyclic loading and unloading conditions by the model based on the hertz contact deformation principle. Transport in Porous Media,119(3), 739–754.

Zhang, C., Tu, S., & Zhang, L. (2019b). Field measurements of compaction seepage characteristics in longwall mining goaf. Natural Resources Research. https://doi.org/10.1007/s11053-019-09479-4.

Zhang, C., Tu, S., Zhang, L., Bai, Q., Yuan, Y., & Wang, F. (2016). A methodology for determining the evolution law of gob permeability and its distributions in longwall coal mines. Journal of Geophysics and Engineering,13(2), 181–193.

Zhang, C., Tu, S., & Zhao, Y. (2019a). Compaction characteristics of the caving zone in a longwall goaf: a review. Environmental Earth Sciences,78(1), 27–46.

Zhang, C., & Zhang, L. (2019). Permeability characteristics of broken coal and rock under cyclic loading and unloading. Natural Resources Research,28(3), 1055–1069.

Zhang, C., Zhang, L., Tu, S., Hao, D., & Teng, T. (2018). Experimental and numerical study of the influence of gas pressure on gas permeability in pressure relief gas drainage. Transport in Porous Media,124(3), 995–1015.

Zhao, J., Yin, L., & Guo, W. (2018). Stress–seepage coupling of cataclastic rock masses based on digital image technologies. Rock Mechanics and Rock Engineering,51(8), 2355–2372.

Zhou, W., Yang, L., Ma, G., Chang, X., Lai, Z., & Xu, K. (2016). DEM analysis of the size effects on the behavior of crushable granular materials. Granular Matter,18(3), 64–74.

Zhu, D., Tu, S., Ma, H., Wei, H., Li, H., & Wang, C. (2019). Modeling and calculating for the compaction characteristics of waste rock masses. International Journal for Numerical and Analytical Methods in Geomechanics,43(1), 257–271.

Zou, Q., Liu, H., Cheng, Z., Zhang, T., & Lin, B. (2019). Effect of slot inclination angle and borehole-slot ratio on mechanical property of pre-cracked coal: Implications for ECBM recovery using hydraulic slotting. Natural Resources Research. https://doi.org/10.1007/s11053-019-09544-y.

Zou, Q., Liu, H., Zhang, Y., Li, Q., Fu, J., & Hu, Q. (2020). Rationality evaluation of production deployment of outburst-prone coal mines: A case study of Nantong coal mine in Chongqing, China. Safety Science,122, 104515.

Acknowledgments

Financial support for this work was provided by the National Natural Science Foundation of China (NO. U1910206, 51874312, 51874281), the Open Fund of State Key Laboratory of Coal Resources and Safe Mining (No. SKLCRSM19KFA17), the State Key Laboratory Cultivation Base for Gas Geology and Gas Control (Henan Polytechnic University) (WS2019A05) and the Yue Qi Distinguished Scholar Project, China University of Mining & Technology, Beijing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

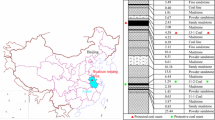

Zhang, C., Liu, J., Zhao, Y. et al. Numerical Simulation of Broken Coal Strength Influence on Compaction Characteristics in Goaf. Nat Resour Res 29, 2495–2511 (2020). https://doi.org/10.1007/s11053-019-09613-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-019-09613-2