Abstract

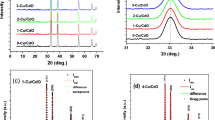

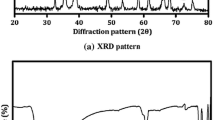

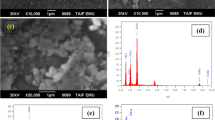

Copper-doped cadmium sulfide (CdS:Cu) nanocrystalline thin films were coated on glass substrates with different Cu concentrations (0 wt.%, 3 wt.%, and 6 wt.%) using the sol–gel spin coating technique. X-ray diffraction (XRD) spectrometry, scanning electron microscope (SEM), and energy-dispersive X-ray (EDX) analysis were used to analyze the average crystallite size, surface morphology, and chemical analysis of prepared thin films in 3 and 6 wt.% of Cu concentrations. According to the XRD results and SEM micrographs, nanocrystalline grains of doped thin films have an almost regular geometric shape, which become slightly larger by increasing Cu concentration from 3 to 6 wt.%. The optical and electrical characteristics of all three films were examined by spectroscopy ellipsometry (SE) technique in the wavelength range between 300 and 900 nm. Based on the SE results, the thin film prepared with 0 wt.% Cu concentration showed a higher refractive index, extinction coefficient, and absorbance compared to the other Cu-doped thin films. The CdS:Cu thin films with 3 and 6 wt.% Cu concentrations demonstrated significantly higher transparency than pure ones (0 wt.% Cu doped), making them particularly suitable for different optoelectronic applications. Moreover, the optical band gap energy (Eg) values were evaluated. It can be concluded that the pure film has the largest band gap energy, and Cu doping reduces the Eg values. The spin-coated 6 wt.% CdS:Cu thin film showed high transparency (67.83%), good homogeneity, and a substantial Eg value (2.6 eV), making it ideal for photocatalytic and photovoltaic applications.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated and analyzed during the current study will be used in the continuation of the university project, so data sharing is not applicable.

References

Das NS, Ghosh PK, Mitra MK, Chattopadhyay KK (2010) Effect of film thickness on the energy band gap of nanocrystalline CdS thin films analyzed by spectroscopic ellipsometry. Physica E 42:2097–2102

Munirah, Shahid Khan M, Aziz A, Abdul Rahman S, Raza Khan Z (2013) Spectroscopic studies of sol–gel grown CdS nanocrystalline thin films for optoelectronic devices. Mater Sci Semicond Process 16:1894–1898

Kumar S, Reddy KR, Reddy ChV, Shetti NP, Sadhu V, Shankar MV, Reddy VG, Raghu AV, Aminabhavi TM (2021) Metal nitrides and graphitic carbon nitrides as novel photocatalysts for hydrogen production and environmental remediation, Springer. Cham. https://doi.org/10.1007/978-3-030-72076-6_19

Tsao C, Fang M, Hsu Y (2021) Modulation of interfacial charge dynamics of semiconductor heterostructures for advanced photocatalytic applications. Coord Chem Rev 438:213876

Kabra K, Chaudhary R, Sawhney RL (2004) Treatment of hazardous organic and inorganic compounds through aqueous-phase photocatalysis: a review. Ind Eng Chem Res 43(24):7683–7696

Reddy KR, Jyothi MS, Raghu AV, Sadhu V, Naveen S, Aminabhavi TM (2019) Nanocarbons-supported and polymers-supported titanium dioxide nanostructures as efficient photocatalysts for remediation of contaminated wastewater and hydrogen production. Springer. https://doi.org/10.1007/978-3-030-12619-3_6

Bora LV, Mewada RK (2017) Visible/solar light active photocatalysts for organic effluent treatment: fundamentals, mechanisms, and parametric review. Renew Suitable Energy Rev 76:1393–1421

Jyothi MS, Nayak V, Reddy KR, Naveen S, Raghu AV (2019) Chapter 3, Non-metal (Oxygen, Sulphur, Nitrogen, Boron and Phosphorus)-Doped metal oxide hybrid nanostructures as highly efficient photocatalysts for water treatment and hydrogen generation. American Jewish Year Book 2018. Springer, Cham, pp 83–105. https://doi.org/10.1007/978-3-030-10609-6_3

Cheng L, Xiang Q, Liao Y, Zhang H (2018) CdS-based photocatalysts. Energy Environ Sci 11(6):1362–1391

Zhou R, Yang Z, Xu J, Cao G (2018) Synergistic combination of semiconductor quantum dots and organic-inorganic halide perovskites for hybrid solar cells. Coord Chem Rev 374:279–313

Hyun BR, Zhong YW, Bartnik AC, Sun L, Abruna HD, Wise FW, Goodreau JD, Matthews JR, Leslie TM, Borrelli NF (2008) Electron injection from colloidal PbS quantum dots into titanium dioxide nanoparticles. ACS Nano 2(11):2206–2212

Ali N, Hussain A, Ahmed R, Wang MK, Zhao C, Haq BU, Fu YQ (2016) Advances in nanostructured thin film materials for solar cell applications. Renew Energy Rev 59:726–737

Chtouki T, El Kouari Y, Kulyk B, Louardi A, Rmili A, Erguig H, Elidrissi B, Soumahoro L, Sahraoui B (2017) Spin-coated nickel doped cadmium sulfide thin films for third harmonic generation applications. J Alloy Compd 696:1292–1297

Oliva AI, Corona JE, Patiño R, Oliva-Avilés AI (2014) Chemical bath deposition of CdS thin films doped with Zn and Cu. Bull. Mater Sci 37:247–255

SonawaneShivaji M (2018) Characterization of CdS thin film grown by chemical bath deposition, Int. Res J Sci Eng A 2:221–224

Heiba ZK, Mohamed MB, Imam NG (2015) Biphasic quantum dots of cubic and hexagonal Mn doped CdS, necessity of Rietveld analysis. J Alloys Compd 618:280–286

Kumar N, Pathak TK, Purohit LP, Swart HC, Goswami YC (2018) Self-assembled Cu doped CdS nanostructures on flexible cellulose acetate substrates using low-cost sol-gel route. Nano-structures & Nano-objects 16:1–8

Bairy R, Jayarama A, Shivakumar GK, Kulkarni SD, Maidur SR, Patil PS (2018) Effect of aluminum doping on photoluminescence and third-order nonlinear optical properties of nanostructured CdS thin films for photonic device applications. Phys B: Phys Condens Matter. https://doi.org/10.1016/j.physb.2018.11.054

AbdolahzadehZiabari A, Ghodsi FE (2012) Growth, characterization and studying of sol-gel–derived CdS nanoscrystalline thin films incorporated in polyethyleneglycol: effects of post-heat treatment. Sol Energy Mater Solar Cells 105:249–262

AbdolahzadehZiabari A, Ghodsi FE (2013) Influence of Cu doping and post heat treatment on the microstructure, optical properties and photoluminescence features of sol-gel–derived nanostructured CdS thin films. J Lumin 141:121–129

ShahidKhan MM, Aziz A, Rahman SA, RazaKhan Z (2013) Spectroscopic studies of sol-gel–grown CdS nanocrystalline thin films for optoelectronic devices. Mater Sci Semicond Process 16:1894–1898

Al-Jawad SMH (2017) Comparative study between CBD and SILAR methods for deposited TiO2, CdS, and TiO2/CdS core-shell structure. Mater Sci Semicond Process 67:75–83

Guo Y, Jiang J, Zuo S, Shi F, Tao J, Hu Z, Hu X, Hu G, Yang P, Chu J (2018) RF-sputtered CdS films as independent or buffered electron transport layer for efficient planar perovskite solar cell. Sol Energy Mater Sol Cells 178:186–192

Nobari N, Behboudnia M, Maleki R (2017) Systematics in morphological, structural and optoelectrical properties of nanocrystalline CdS thin films grown by electrodeposition method. Mater Sci Eng, B 224:181–189

Barreca D, Gasparotto A, Maragno C, Tondello E (2004) J Electrochem Soc 151:428–435

Liu B, Luo R, Li B, Zhang J, Li W, Wu L, Feng L, Wu J (2016) J Alloys Compd 654:333–339

Shaban M, Mustafa M, El Sayed AM (2016) Structural, optical, and photocatalytic properties of the spray-deposited nanoporous CdS thin films, influence of copper doping, annealing, and deposition parameters. Mater Sci Semicond Process 56:329–343

Sandoval-Paz MG, Ramírez-Bon R (2009) Analysis of the early growth mechanisms during the chemical deposition of CdS thin films by spectroscopic ellipsometry. Thin Solid Films 517:6747–6752

Rmili A, Ouachtari F, Bouaoud A, Louardi A, Chtouki T, Elidrissi B, Erguig H (2013) Structural, optical and electrical properties of Ni-doped CdS thin films prepared by spray pyrolysis. J Alloy Compd 557:53–59

Fricke L, Bontgen T, Lorbeer J, Bundesmann C, Grund RS, Grundmann M (2014) An extended Drude model for the in-situ spectroscopic ellipsometry analysis of ZnO thin layers and surface modifications. Thin Solid Films 571:437–441

Galvan AM, Cruz CT, Lee J, Bhattacharyya D, Metson J, Evans PJ, Pal U (2006) Effect of metal-ion doping on the optical properties of nanocrystalline ZnO thin films. J Appl Phys 99:014306

Motallebi Aghgonbad M, Sedghi H (2018) Spectroscopic ellipsometry studies on zinc oxide thin films deposited by sol-gel method with various precursor concentrations. Surf Rev Lett 26(1850158):9. https://doi.org/10.1142/S0218625X18501585

Fujiwara H (2007) Spectroscopic ellipsometry principles and applications. John Wiley & Sons, Ltd

Leng J, Opsal J, Chu H, Senko M, Aspnes DE (1998) Analytic representations of the dielectric functions of materials for device and structural modeling. Thin Solid Films 313–314:132–136

Peters S (2009) Spectra ray and application tutorial, spectroscopic ellipsometry-theory and application.

NazariSetayesh A, Sedghi H (2021) Sol-gel growth of Ni-doped CdS on glass substrates: effect of spin coating speed and dopant concentration. Nanosci Nanotechnol-Asia 11(2):230–236

Aboud AA, Mukherjee A, Revaprasadu N, Nagaty Mohamed A (2019) The effect of Cu-doping on CdS thin films deposited by the spray pyrolysis technique. J Mater Res Technol 8:2021–2030

Dakhel AA (2009) Influence of dysprosium doping on the electrical and optical properties of CdO thin films. Sol Energy 83:934–939

Mustapha S, Ndamitso MM, Abdulkareem AS, Tijani JO, Shuaib D, Mohammed AK, Sumaila A (2019) Comparative study of crystallite size using Williamson-Hall and Debye-Scherrer plots for ZnO nanoparticles. Adv Nat Sci Nanosci Nanotechnol 10(8pp):045013

Nath D, Singh F, Das R (2020) X-ray diffraction analysis by Williamson-Hall, Halder-Wagner, and size-strain plot methods of CdSe nanoparticles—a comparative study. Mater Chem Phys 239:122021

Sen SK, Barman UC, Manir MS, Mondal P, Dutta S, Paul M, Chowdhury MAM, Hakim MA (2020) X-ray peak profile analysis of pure and Dy-doped α-MoO3 nanobelts using Debye–Scherre, Williamson–Hall and Halder–Wagner methods. Adv Nat Sci: Nanosci Nanotechnol 11(025004):10. https://doi.org/10.1088/2043-6254/ab8732

Jonnalagadda M, Prasada VB, Raghu AV (2021) Synthesis of composite nanopowder through Mn doped ZnS-CdS systems and its structural, optical properties. J Mol Struct 1230:129875

Muthusamy M, Muthukumaran S (2015) Effect of Cu-doping on structural, optical and photoluminescence properties of CdS thin films. Optik-Int J Light Electron Opt 126:5200–5206

Xie R, Su J, Li M, Guo L (2013) Structural and photoelectrochemical properties of Cu-doped CdS thin films prepared by ultrasonic spray pyrolysis. Int J Photoenergy 620134:7

Bensouici F, Bououdina M, Dakhel AA, Tala-lghil R, Tounane M, Iratni A, Souier T, Liu S, Cai W (2017) Optical, structural and photocatalysis properties of Cu-doped TiO2 thin films. Appl Surf Sci 395:110–116. https://doi.org/10.1016/j.apsusc.2016.07.034

Singh J (1995) Semiconductor optoelectronics: physics and technology. Mc Graw-Hill, New York

Mott NF, Davis EA (1979) Electronic process in non-crystalline materials. Calendron press, Oxford

Liu F, Lai Y, Liu J, Wang B, Kuang S, Zhang Zh, Li J, Liu Y (2010) Characterization of chemical bath–deposited CdS thin films at different deposition temperature. J Alloy Compd 493:305–308

Kariper A, Guneri E, Göde F, Gümüs C, Özpozan T (2011) The structural, electrical and optical properties of CdS thin films as a function of pH. Mater Chem Phys 129:183–188

Diaz-Grijalva OI, Berman-Mendoza D, Flores-Pacheco A, López-Delgado R, Ramos-Carrazco A, Alvarez-Ramos ME (2020) Cu-doped CdS thin films by chemical bath deposition and ion exchange. J Mater Sci: Mater Electron 31:1722–1730

Yılmaz S (2015) The investigation of spray pyrolysis grown CdS thin films doped with fluorine atoms. Appl Surf Sci 357:873–879

Thirumoorthi M, Thomas Joseph Prakash J (2016) A study of Tin doping effects on physical properties of CdO thin films prepared by sol–gel spin coating method. J Asian Ceram Soc 4:39–45

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Also, material preparation, data collection, and analysis of data were carried out by all the authors named Atefeh Nazari Setayesh and Sahar Moradi and Hasan Sedghi. The first draft of the manuscript was written by Atefeh Nazari Setayesh, and all the authors commented on the previous version of the manuscript. All the authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nazari Setayesh, A., Moradi, S. & Sedghi, H. Fabrication, structural, morphological, and optical studies of CdS:Cu nanostructured thin films: effect of Cu concentration. J Nanopart Res 25, 4 (2023). https://doi.org/10.1007/s11051-022-05653-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-022-05653-7