Abstract

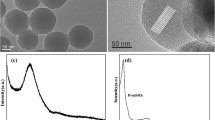

The aim of the present study is to investigate the structure optimization of ceria-based composite particle abrasives for improved chemical mechanical polishing (CMP) performance. The core/shell-structured composite particles, comprising dendritic-like mesoporous silica (D-mSiO2) internal cores and grafted Ce1 − xSmxO2 (x = 0, 0.2) solid solutions, were prepared via a facile aqueous solution-based co-precipitation approach. The morphologies, chemical compositions, and crystalline structures of the as-formed samples were characterized by powder X-ray diffraction, high-resolution transmission electron microscopy, field-emission scanning electron microscopy, X-ray photoelectron spectroscopy, scanning transmission electron microscopy, and energy-dispersive X-ray spectroscopy. The silicon oxide wafers before and after CMP were examined in terms of atomic force microscopy and 3D noncontact interferometric microscopy for the information on surface quality and roughness, sectional profile, and material removal rate. The developed ceria-based abrasives presented significantly improved polishing performance toward silica by comparison with commercial ceria abrasives. The D-mSiO2 cores were expected to reduce surface roughness and eliminate surface scratch, and the samarium doping into the coated ceria nanoparticles contributed to the improvement of removal efficiency. The present results provide a facile strategy toward the design and synthesis of novel ceria-based abrasives with potential applications in achieving high-efficiency and damage-free finishing.

Similar content being viewed by others

References

Anjaneya KC, Nayaka GP, Manjanna J, Govindaraj G, Ganesha KN (2013) Studies on structural, morphological and electrical properties of Ce0.8Ln0.2O2-δ (Ln = Y3+, Gd3+, Sm3+, Nd3+ and La3+) solid solutions prepared by citrate complexation method. J Alloys Compd 585:594–601

Artini C, Pani M, Carnasciali MM, Buscaglia MT, Plaisier JR, Costa GA (2015) Structural features of Sm- and Gd-doped ceria studied by synchrotron X-ray diffraction and μ-Raman spectroscopy. Inorg Chem 54:4126–4137

Artini C, Pani M, Carnasciali MM, Plaisier JR, Costa GA (2016) Lu-, Sm-, and Gd-doped ceria: a comparative approach to their structural properties. Inorg Chem 55:10567–10579

Bararia B, Omranib E, Moghadamb AD, Menezesc PL, Pillaia KM, Rohatgiba PK (2016) Mechanical, physical and tribological characterization of nano-cellulose fibers reinforced bio-epoxy composites: an attempt to fabricate and scale the ‘Green’ composite. Carbohyd Polym 147:282–293

Bhatta UM, Reid D, Sakthivel T, Sayle TXT, Sayle D, Molinari M, Parker SC, Ross IM, Seal S, Möbus G (2013) Morphology and surface analysis of pure and doped cuboidal ceria nanoparticles. J Phys Chem C 117:24561–24569

Biswas RK, Khan P, Mukherjee S, Mukhopadhyay AK, Ghosh J, Muraleedharan K (2018) Study of short range structure of amorphous silica from PDF using Ag radiation in laboratory XRD system, RAMAN and NEXAFS. J Non-Cryst Solids 488:1–9

Burroughs P, Hamnett A, Orchard AF, Thornton G (1976) Satellite structure in the X-ray photoelectron spectra of some binary and mixed oxides of lanthanum and cerium. J Chem Soc Dalton Trans 1686-1698

Chen Y, Lu J (2012) Facile fabrication of porous hollow CeO2 microspheres using polystyrene spheres as templates. J Porous Mat 19:289–294

Chen Y, Qin JW, Wang YY, Li ZF (2015) Core/shell composites with polystyrene cores and meso-silica shells as abrasives for improved chemical mechanical polishing behavior. J Nanopart Res 17:363

Chen A, Long J, Li Z, Chen Y (2018a) Dependency of structural change and polishing efficiency of mesosilica/ceria core/shell composite abrasives on calcination temperatures. J Mater Sci: Mater EL 29:11466–11477

Chen Y, Zuo C, Li Z, Chen A (2018b) Design of ceria grafted mesoporous silica composite particles for high-efficiency and damage-free oxide chemical mechanical polishing. J Alloys Compd 736:276–288

Chong WWF, Ng JH (2016) An atomic-scale approach for biodiesel boundary lubricity characterization. Int Biodeter Biodegr 113:34–43

Cook LM (1990) Chemical processes in glass polishing. J Non-Cryst Solids 120:152–171

Gilliss SR, Bentley J, Carter CB (2004) Nanochemistry of ceria abrasive particles. Mater Res Soc 818:9–14

Guo M, Lu J, Wu Y, Wang Y, Luo M (2011) UV and visible Raman studies of oxygen vacancies in rare-earth-doped ceria. Langmuir 27:3872–3877

Janoš P, Ederer J, Pilařová V, Henych J, Tolasz J, Milde D, Opletal T (2016) Chemical mechanical glass polishing with cerium oxide: effect of selected physico-chemical characteristics on polishing efficiency. Wear 362-363:114–120

Kim T, Chung P, Lin VS (2010) Facile synthesis of monodisperse spherical MCM-48 mesoporous silica nanoparticles with controlled particle size. Chem Mater 22:5093–5104

Korsvik C, Patil S, Seal S, Self WT (2007) Superoxide dismutase mimetic properties exhibited by vacancy engineered ceria nanoparticles. Chem Commun 10:1056–1058

Lin Y, Wu Z, Wen J, Poeppelmeier KR, Marks LD (2014) Imaging the atomic surface structures of CeO2 nanoparticles. Nano Lett 14:191–196

Liu B, Liu J, Li T, Zhao Z, Gong X, Chen Y, Duan A, Jiang G, Wei Y (2015) Interfacial effects of CeO2-supported Pd nanorod in catalytic CO oxidation: a theoretical study. J Phys Chem C 119:12923–12934

Mai H, Sun L, Zhang Y, Si R, Feng W, Zhang H, Liu H, Yan C (2005) Shape-selective synthesis and oxygen storage behavior of ceria nanopolyhedra, nanorods, and nanocubes. J Phys Chem B 109:24380–24385

Naowanon W, Chueachot R, Klinsrisuk S, Amnuaypanich S (2018) Biphasic synthesis of amine-functionalized mesoporous silica nanospheres (MSN-NH2) and its application for removal of ferrous (Fe2+) and copper (Cu2+) ions. Powder Technol 323:548–557

Niwa Y, Aika K (1996) The effect of lanthanide oxides as a support for ruthenium catalysts in ammonia synthesis. J Catal 162:138–142

Nobuki O, Muneyuki I, Miho N, Kubo M (2012) Polishing process simulation of SiO2 by CeO2 abrasive grain under wet environment. Hyomen Kagaku 33:351–356

Oh M, Nho J, Cho S, Lee J, Singh RK (2011) Polishing behaviors of ceria abrasives on silicon dioxide and silicon nitride CMP. Powder Technol 206:239–245

Polychronopoulos K, Zedan AF, Katsiotis MS, Baker MA, AlKhoori AA, AlQaradawi SY, Hinder SJ, AlHassan S (2017) Rapid microwave assisted sol-gel synthesis of CeO2 and CexSm1−xO2 nanoparticle catalysts for CO oxidation. J Mol Catal A-Chem 428:41–55

Portier J, Poizot P, Campet G, Subramanian MA, Tarascon JM (2003) Acid-base behavior of oxides and their electronic structure. Solid State Sci 5:695–699

Praveen BVS, Cho B, Park J, Ramanathan S (2015) Effect of lanthanum doping in ceria abrasives on chemical mechanical polishing selectivity for shallow trench isolation. Mat Sci Semicon Proc 33:161–168

Riegraf M, Hoerlein MP, Costa R, Schiller G, Friedrich KA (2017) Sulfur poisoning of electrochemical reformate conversion on nickel/gadolinium-doped ceria electrodes. ACS Catal 7:7760–7771

Sebastian A, Zhang F, Dodda A, May-Rawding D, Liu H, Zhang T, Terrones M, Das S (2019) Electrochemical polishing of two-dimensional materials. ACS Nano 13:78–86

Singhania A (2017) High surface area M (M = La, Pr, Nd, and Pm)-doped ceria nanoparticles: synthesis, characterization, and activity comparison for CO oxidation. Ind Eng Chem Res 56:13594–13601

Sreeremya TS, Prabhakaran M, Ghosh S (2015) Tailoring the surface properties of cerium oxide nanoabrasives through morphology control for glass CMP. RSC Adv 5:84056–84065

Sutradhar N, Sinhamahapatra A, Pahari S, Jayachandran M, Subramanian B, Bajaj HC, Panda AB (2011) Facile low-temperature synthesis of ceria and samarium-doped ceria nanoparticles and catalytic allylic oxidation of cyclohexene. J Phys Chem C 115:7628–7637

Thorat AV, Ghoshal T, Carolan P, Holmes JD, Morris MA (2014) Defect chemistry and vacancy concentration of luminescent europium doped ceria nanoparticles by the solvothermal method. J Phys Chem C 118:10700–10710

Trovarelli A, Llorca J (2017) Ceria catalysts at nanoscale: how do crystal shapes shape catalysis? ACS Catal 7:4716–4735

Wu L, Dholabhai PP, Uberuaga BP, Castro RHR (2017) Temperature dependence discontinuity in the stability of manganese-doped ceria nanocrystals. Cryst Growth Des 17:446–453

Zhang L, Meng J, Yao F, Zhang W, Liu X, Meng J, Zhang H (2018) Insight into the mechanism of the ionic conductivity for Ln-doped ceria (Ln = La, Pr, Nd, Pm, Sm, Gd, Tb, Dy, Ho, Er, and Tm) through first-principles calculation. Inorg Chem 57:12690–12696

Zhao Y, Teng B, Wen X, Zhao Y, Chen Q, Zhao L, Luo M (2012) Superoxide and peroxide species on CeO2(111), and their oxidation roles. J Phys Chem C 116:15986–15991

Zhao D, Shen D, Yang J, Li X, Zhou L, Zhang R, Li W, Chen L, Wang R, Zhang F (2014) Biphase stratification approach to three-dimensional dendritic biodegradable mesoporous silica nanospheres. Nano Lett 14:923–932

Zheng X, Xu S, Wang Y, Sun X, Gao Y, Gao B (2018) Enhanced degradation of ciprofloxacin by graphitized mesoporous carbon (GMC)-TiO2 nanocomposite: strong synergy of adsorption-photocatalysis and antibiotics degradation mechanism. J Colloid Interf Sci 527:202–213

Funding

The project is supported by the National Natural Science Foundation of China (Grant Nos. 51405038, 51575058, 51875052) and the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Y., Cai, W., Wang, W. et al. Preparation, characterization, and application of dendritic silica-supported samarium-doped ceria nanoparticles in ultra-precision polishing for silica films. J Nanopart Res 21, 226 (2019). https://doi.org/10.1007/s11051-019-4684-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-019-4684-1