Abstract

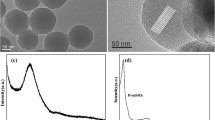

Owing to the development of electronic semiconductors and optical systems, semiconductor wafers, ceramics, and optical glass increasingly need to have higher surface quality and processing accuracy, which is placing higher demands on chemical mechanical polishing (CMP). In this paper, nano-sized ceria particles coated on the silica surface with different doping ratios of Nd3+ were designed as an abrasive and synthesized by the precipitation method. The structures and properties of binary particles were characterized using X-ray diffraction (XRD), field-emission scanning microscopy (FE-SEM), energy dispersive spectroscopy (EDS), transmission electron microscopy (TEM), UV–vis spectroscopy, and Raman spectra. CMP using the abrasives on silicon wafers was investigated and the results demonstrated an increase in polishing efficiency due to doping. The material removal rate (MRR) improved by 105% from 67.34 ± 11.66 to 138.05 ± 5.83 nm/min at a doping ratio of Nd3+ up to 9.1% compared with undoped abrasives.

Similar content being viewed by others

Data availability

The datasets used or analysed during the current study are available from the corresponding author on reasonable request.

References

Lee H, Kim H, Jeong H (2021) Approaches to sustainability in chemical mechanical polishing (CMP): a review. Int J Precis Eng Manuf-Gt 9:349–367. https://doi.org/10.1007/s40684-021-00406-8

Shi XL, Xu L, Zhou Y, Zou CL, Wang RR, Pan GS (2018) An in situ study of chemical-mechanical polishing behaviours on sapphire (0001) via simulating the chemical product-removal process by AFM-tapping mode in both liquid and air environments. Nanoscale 10:19692–19700. https://doi.org/10.1039/c8nr04645j

Krishnan M, Nalaskowski JW, Cook LM (2010) Chemical mechanical planarization: slurry chemistry, materials, and mechanisms. Chem Rev 110:178–204. https://doi.org/10.1021/cr900170z

Gong H, Pan GS, Zhou Y, Shi XL, Zou CL, Zhang SA (2015) Investigation on the surface characterization of Ga-faced GaN after chemical-mechanical polishing. Appl Surf Sci 338:85–91. https://doi.org/10.1016/j.apsusc.2015.02.107

Dandu PRV, Penta NK, Babu SV (2010) Novel alpha-amine-functionalized silica-based dispersions for selectively polishing polysilicon and Si(100) over silicon dioxide, silicon nitride or copper during chemical mechanical polishing. Colloids Surf A 371:131–136. https://doi.org/10.1016/j.colsurfa.2010.09.019

Lagudu URK, Isono S, Krishnan S, Babu SV (2014) Role of ionic strength in chemical mechanical polishing of silicon carbide using silica slurries. Colloids Surf A 445:119–127. https://doi.org/10.1016/j.colsurfa.2014.01.038

Kozlowski MR, Carr J, Hutcheon I, Torres R, Sheehan L, Camp D, Yan M (1998) Depth profiling of polishing-induced contamination on fused silica surfaces. Laser-Induced Damage in Optical Materials: 1997, Proceedings 3244:365–375. https://doi.org/10.1117/12.307031

Li Y, Zhang J, Ni X, Wang L, Yang C (2018) Facile fabrication of raspberry-like polystyrene/ceria composite particles and their catalytic application. Colloids Surf A 538:818–824. https://doi.org/10.1016/j.colsurfa.2017.11.077

Wang M, Shen M, Jin XX, Tian JJ, Li ML, Zhou YJ, Zhang LX, Li YS et al (2019) Oxygen vacancy generation and stabilization in CeO2-x by Cu introduction with improved CO2 photocatalytic reduction activity. ACS Catal 9:4573–4581. https://doi.org/10.1021/acscatal.8b03975

Chen A, Duan Y, Mu Z, Cai W, Chen Y (2021) Meso-silica/Erbium-doped ceria binary particles as functionalized abrasives for photochemical mechanical polishing (PCMP). Appl Surf Sci 550:149353–149365. https://doi.org/10.1016/j.apsusc.2021.149353

Chen Y, Long R (2011) Polishing behavior of PS/CeO2 hybrid microspheres with controlled shell thickness on silicon dioxide CMP. Appl Surf Sci 257:8679–8685. https://doi.org/10.1016/j.apsusc.2011.05.047

Zhang Z, Liu W, Zhu J, Song Z (2010) Synthesis, characterization of ceria-coated silica particles and their chemical mechanical polishing performance on glass substrate. Appl Surf Sci 257:1750–1755. https://doi.org/10.1016/j.apsusc.2010.09.009

Aida H, Takeda H, Doi T (2021) Analysis of mechanically induced subsurface damage and its removal by chemical mechanical polishing for gallium nitride substrate. Precis Eng 67:350–358. https://doi.org/10.1016/j.precisioneng.2020.10.007

Ni Z, Chen G, Xu L, Zhang P, Dai M, Qian S, Bian D, Zhang H (2021) Preparation of ceria-coated silica nanoparticles and their chemical mechanical planarization performance on Si-Face 6H-SiC substrates. ECS J Solid State Sci Technol 10:123011–123016. https://doi.org/10.1149/2162-8777/ac40d5

Zhang ZY, Liao LX, Wang XZ, Xie WX, Guo DM (2020) Development of a novel chemical mechanical polishing slurry and its polishing mechanisms on a nickel alloy. Appl Surf Sci 506:144670. https://doi.org/10.1016/j.apsusc.2019.144670

Zhang ZY, Shi ZF, Du YF, Yu ZJ, Guo LC, Guo DM (2018) A novel approach of chemical mechanical polishing for a titanium alloy using an environment-friendly slurry. Appl Surf Sci 427:409–415. https://doi.org/10.1016/j.apsusc.2017.08.064

Oh MH, Lee JS, Gupta S, Chang FC, Singh RK (2010) Preparation of monodispersed silica particles coated with ceria and control of coating thickness using sol-type precursor. Colloids Surf A 355:1–6. https://doi.org/10.1016/j.colsurfa.2009.09.038

Nolan M, Parker SC, Watson GW (2005) The electronic structure of oxygen vacancy defects at the low index surfaces of ceria. Surf Sci 595:223–232. https://doi.org/10.1016/j.susc.2005.08.015

Cook LM (1990) Chemical processes in glass polishing. J Non-Cryst Solids 120:152–171. https://doi.org/10.1016/0022-3093(90)90200-6

Hoshino T, Kurata Y, Terasaki Y, Susa K (2001) Mechanism of polishing of SiO2 films by CeO2 particles. J Non-Cryst Solids 283:129–136. https://doi.org/10.1016/S0022-3093(01)00364-7

Chen Y, Mu Z, Wang W, Chen A (2020) Development of mesoporous SiO2/CeO2 core/shell nanoparticles with tunable structures for non-damage and efficient polishing. Ceram Int 46:4670–4678. https://doi.org/10.1016/j.ceramint.2019.10.198

Chen Y, Wang MH, Cai WJ, Wang TY, Chen AL (2022) Structural regulation and polishing performance of dendritic mesoporous silica (D-mSiO2) supported with samarium-doped cerium oxide composites. Adv Powder Technol 33:103595–103607. https://doi.org/10.1016/j.apt.2022.103595

Song X, Jiang N, Li Y, Xu D, Qiu G (2008) Synthesis of CeO2-coated SiO2 nanoparticle and dispersion stability of its suspension. Mater Chem Phys 110:128–135. https://doi.org/10.1016/j.matchemphys.2008.01.042

Cheng J, Huang S, Li Y, Wang T, Xie L, Lu X (2020) RE (La, Nd and Yb) doped CeO2 abrasive particles for chemical mechanical polishing of dielectric materials: experimental and computational analysis. Appl Surf Sci 506:144668–144675. https://doi.org/10.1016/j.apsusc.2019.144668

Kim E, Lee J, Bae C, Seok H, Kim H-U, Kim T (2022) Effects of trivalent lanthanide (La and Nd) doped ceria abrasives on chemical mechanical polishing. Powder Technol 397:117025–117032. https://doi.org/10.1016/j.powtec.2021.11.069

Gao B, Zhai WJ, Zhai Q, Wang C (2021) Novel photoelectrochemically combined mechanical polishing technology for scratch-free 4H-SiC surface by using CeO2–TiO2 composite photocatalysts and PS/CeO2 core/shell abrasives. Appl Surf Sci 570:151141–151149. https://doi.org/10.1016/j.apsusc.2021.151141

Huang YC, Wu SH, Hsiao CH, Lee AT, Huang MH (2020) Mild synthesis of size-tunable CeO2 octahedra for band gap variation. Chem Mater 32:2631–2638. https://doi.org/10.1021/acs.chemmater.0c00318

Chen Y, Zuo C, Li Z, Chen A (2018) Design of ceria grafted mesoporous silica composite particles for high-efficiency and damage-free oxide chemical mechanical polishing. J Alloys Compd 736:276–288. https://doi.org/10.1016/j.jallcom.2017.11.112

R.C. Evans (1965) An Introduction to Crystal Chemistry 2nd ed. Cambridge University Press, London

Channei D, Inceesungvorn B, Wetchakun N, Phanichphant S, Nakaruk A, Koshy P, Sorrell CC (2013) Photocatalytic activity under visible light of Fe-doped CeO2 nanoparticles synthesized by flame spray pyrolysis. Ceram Int 39:3129–3134. https://doi.org/10.1016/j.ceramint.2012.09.093

Taniguchi T, Watanabe T, Sugiyama N, Subramani AK, Wagata H, Matsushita N, Yoshimura M (2009) Identifying defects in ceria-based nanocrystals by UV resonance Raman spectroscopy. J Phys Chem C 113:19789–19793. https://doi.org/10.1021/jp9049457

Ke J, Xiao JW, Zhu W, Liu HC, Si R, Zhang YW, Yan CH (2013) Dopant-induced modification of active site structure and surface bonding mode for high-performance nanocatalysts: CO oxidation on capping-free (110)-oriented CeO2: Ln (Ln = La-Lu) nanowires. J Am Chem Soc 135:15191–15200. https://doi.org/10.1021/ja407616p

Carey JJ, Nolan M (2016) Dissociative adsorption of methane on the Cu and Zn doped (111) surface of CeO2. Appl Catal B 197:324–336. https://doi.org/10.1016/j.apcatb.2016.04.004

Wang T, Chen Y, Chen A, Chen Y (2022) Development of carbon sphere/ceria (CS/CeO2) heterostructured particles and their applications to functional abrasives toward photochemical mechanical polishing. Appl Surf Sci 593:153449–153463. https://doi.org/10.1016/j.apsusc.2022.153449

Schwarz K (2006) Materials design of solid electrolytes. Proc Natl Acad Sci USA 103:3497–3497. https://doi.org/10.1073/pnas.0600327103

Lin Y, Wu Z, Wen J, Poeppelmeier KR, Marks LD (2014) Imaging the atomic surface structures of CeO2 nanoparticles. Nano Lett 14:191–196. https://doi.org/10.1021/nl403713b

Alety SR, Sagi KV, Babu SV (2017) Role of Ce3+ ions in achieving high silicon nitride polish rates. Ecs J Solid State Sc 6:P898–P903. https://doi.org/10.1149/2.0351712jss

Praveen BVS, Cho BJ, Park JG, Ramanathan S (2015) Effect of lanthanum doping in ceria abrasives on chemical mechanical polishing selectivity for shallow trench isolation. Mater Sci Semicond Process 33:161–168. https://doi.org/10.1016/j.mssp.2015.01.049

Paier J, Penschke C, Sauer J (2013) Oxygen defects and surface chemistry of ceria: quantum chemical studies compared to experiment. Chem Rev 113:3949–3985. https://doi.org/10.1021/cr3004949

Shi YN, Wang LY, Wang ZY, Vinai G, Braglia L, Torelli P, Aruta C, Traversa E et al (2021) Defect engineering for tuning the photoresponse of ceria-based solid oxide photoelectrochemical cells. ACS Appl Mater Interfaces 13:541–551. https://doi.org/10.1021/acsami.0c17921

Kim E, Hong J, Hong S, Kanade C, Seok H, Kim HU, Kim T (2021) Improvement of oxide removal rate in chemical mechanical polishing by forming oxygen vacancy in ceria abrasives via ultraviolet irradiation. Mater Chem Phys 273:124967–1249743. https://doi.org/10.1016/j.matchemphys.2021.124967

Koettgen J, Grieshammer S, Duck G, Ulbrich G, Lerch M, Martin M (2020) Ab initio and experimental oxygen ion conductivities in Sm–Zr and Gd–Zr co-doped ceria. Solid State Ionics 355:115422–115427. https://doi.org/10.1016/j.ssi.2020.115422

Liu YL, Zhang RL (2020) Study of doped mesoporous ceria with tailored oxygen vacancies for enhances activity for ethylbenzene oxidation application. Colloids Surf A 603:125163–125169. https://doi.org/10.1016/j.colsurfa.2020.125163

Hu PF, Chen Y, Sun R, Chen Y, Yin YR, Wang ZC (2017) Synthesis, characterization and frictional wear behavior of ceria hybrid architectures with 111 exposure planes. Appl Surf Sci 401:100–105. https://doi.org/10.1016/j.apsusc.2017.01.005

Acknowledgements

This work was financially supported Jilin Province Science and Technology Development Program (Grants YDZJ202201ZYTS518) and Special science and technology project of Northern rare earth (BFXT-2022-D-0021 and BFXT-2023-D-0014).

Funding

This work was financially supported Jilin Province Science and Technology Development Program (Grants YDZJ202201ZYTS518) and Special science and technology project of Northern rare earth (BFXT-2022-D-0021 and BFXT-2023-D-0014).

Author information

Authors and Affiliations

Contributions

JJ contributed to the conception of the study, performed the experiment, and wrote the manuscript. YF helped analyze study data. LZ contributed to the review and revision of original draft and supervision of research activities. JT helped manage and coordinate the entire experimental process and provided financial support for the experiment.

Corresponding authors

Ethics declarations

Conflict of interest

All co-authors have contributed to the work, seen and agreed with the contents of the manuscript. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not applicable.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiao, J., Fan, Y., Chen, C. et al. Preparation, characterization, and application of Nd-doped ceria-coated silica nanoparticles for chemical mechanical polishing. J Mater Sci 58, 18014–18028 (2023). https://doi.org/10.1007/s10853-023-09103-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09103-0