Abstract

Scheelite-type Ca1−xMnxMoO4 (x = 0.0, 0.01, 0.05, 0.10 and 0.15) nanomaterials were successfully synthesized via a combustion route. Dielectric studies showed a weak n-type electrical conductivity characteristic for insulators and low relative permittivity (εr < 15) decreasing with increasing Mn2+ content. CaMoO4 and Mn2+-doped nanomaterials are chemically compatible with Al and Ag electrodes and promising for low-temperature co-fired ceramic applications. Magnetic studies showed, at room-temperature diamagnetism for pure CaMoO4, the balance between diamagnetism and paramagnetism for Ca1−xMnxMoO4 (x = 0.01) and paramagnetic behaviour when 0.05 ≤ x ≤ 0.15 as well as the short-range antiferromagnetic interactions growing in strength as Mn2+ content increases. The Landé factor fitting procedure showed a spin-only contribution to the magnetic moment. CaMoO4 matrix unexpectedly revealed the residual paramagnetism at low temperatures derived probably from the molybdenum ions having unpaired 4d electrons as well as a paramagnetic-diamagnetic transition at 70 K.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Metal molybdates form a wide and important class of inorganic materials that have a high application potential in various fields such as scintillator detectors, phosphors and electro-optic applications (Zhang et al. 2015; Bavykina et al. 2009; Zhou et al. 2011; Danevich et al. 2014; Belogurov et al. 2005; Mikhailik et al. 2007; Korzhik et al. 2008; Lei and Yan 2008; Shivakumara et al. 2015). Divalent metal molybdates with relatively large cations such as Ca2+, Sr2+, Ba2+ and Pb2+ (ionic radius above 99 pm) exist in scheelite-type structure (tetragonal symmetry, space group I41/a; Z = 4) where molybdenum ions adopt tetrahedral coordination, while divalent metal ions represent an eight-coordinated position (Sczancoski et al. 2008; Sczancoski et al. 2009; Ghosh et al. 2015). Generally, metal molybdates are obtained by conventional solid-state reaction method (Pawlikowska et al. 2017; Piątkowska and Tomaszewicz 2016; Tomaszewicz et al. 2016). However, powders obtained in this way are characterized by large and irregular grains. Furthermore, molybdenum oxide has a tendency to vaporize at high temperatures and inhomogeneous compounds might be easily formed. These problems can be avoided by applying combustion synthesis, wet chemical route, Pechini and other methods (Pawlikowska et al. 2017; Thongtem et al. 2010; Marques et al. 2010; Gong et al. 2006; Chen et al. 2006; Piątkowska et al. 2017).

Rapid growth of wireless communication within last years has caused increasing expectations for new microwave dielectric materials. Such new dielectric ceramics can be applied as band gap filters, antenna switches and dielectric resonators in mobile and satellite communications, intelligent transport systems, voltage-controlled oscillators and duplexers. These systems operating at high frequencies require new materials with relatively low dielectric permittivity (εr), high-quality factor (Qxf) and stable and near-to-zero-temperature coefficient of resonant frequency (τf), as well as co-fired with internal metal electrodes, i.e. Al, Ag or Cu (Kim et al. 2006; Vidya et al. 2013; Xi et al. 2014; Choi et al. 2007). In particular, a low value of εr is important because a signal propagation velocity is a function of dielectric permittivity. Low-temperature co-fired ceramic (LTCC) technology allows to combine thin layers of dielectric ceramics and conducting electrodes to produce multilayer modules. Pure scheelites such as CaWO4, BaWO4, PbMoO4 and AMoO4 (A = Ca, Sr and Ba) were investigated and reported with good microwave dielectric properties (Kim et al. 2006; Vidya et al. 2013; Xi et al. 2014; Choi et al. 2007). The microwave dielectric properties for microcrystalline calcium molybdate (CaMoO4) sintered at 1373 K were found to be the dielectric permittivity as 10.79, the high-quality factor as 89,700 GHz and the temperature coefficient of resonant frequency as − 57 ppm/°C (Choi et al. 2007). Its chemical compatibility with some internal electrode such as Al, Ag or Cu has not been investigated so far.

In the present work, CaMoO4 and Ca1−xMnxMoO4 (x = 0.01, 0.05, 0.10 and 0.15) nanomaterials were successfully synthesized via citrate-nitrate combustion route. Low-sintering temperature behaviour, phase composition, microstructure, some dielectric properties and chemical compatibility with metallic aluminium and silver of these nanomaterials were investigated to meet the requirement of microwave devices. Furthermore, magnetic properties of pure matrix and Mn2+-doped nanomaterials were investigated. The Landé factor estimated from the Curie constant was used to interpret the magnetic contributions to the magnetic interactions.

Experimental

Materials

The following precursors were used in a synthesis: manganese oxide (MnO; Fluka), calcium carbonate (CaCO3; Alfa Aesar) and ammonium molybdate ((NH4)6Mo7O24·1.3586H2O; Alfa Aesar). Citric acid monohydrate (C6H8O7·H2O; Alfa Aesar) was used as a fuel. All the solid reagents used were of analytical purity and without further purification. In addition, nitric acid (~ 30%) and ammonia (~ 25%) were used as the aid reactants during a combustion synthesis. For analysis of a chemical compatibility, Al and Ag powders (both metals with purity of 99.9%, 4–7 μm; Alfa Aesar) were applied.

Combustion synthesis of Mn2+-doped nanomaterials

Nanocrystalline samples of pure CaMoO4 and a solid solution described by the formula of Ca1−xMnxMoO4 (x = 0.01, 0.05, 0.10 and 0.15) were successfully obtained via citrate-nitrate combustion route. In the first step, an adequate amount of MnO (0.0353 g; 0.498 mmol when x = 0.05) and CaCO3 (0.9471 g; 9.463 mmol when x = 0.05) was dissolved in hot aqueous solution of nitric acid. Then, citric acid (5.2337 g; 24.906 mmol when x = 0.05) and deionized water were added to the solution containing Mn2+ and Ca2+ ions. The pH of as-obtained solution (solution A) was adjusted to the value of ~ 5 with an ammonia solution. Precursor of Mo (1.6911 g; 1.423 mmol when x = 0.05) was dissolved in hot and deionized water (solution B). Next, the both solutions were mixed together and gently heated to completely evaporate water. In the next step, obtained pink gel was heated carefully at 473 K. During the combustion process, the gel has burned out with a rapid evolution of a large quantity of fume, yielding voluminous powder. In the last step, the as-prepared nanomaterials were heated at 723 K for 2 h in air to obtain the final white or light grey product (~ 2 g; ~ 9.962 mmol when x = 0.05). To investigate a chemical compatibility of CaMoO4 and Mn2+-doped nanomaterials with aluminum and silver powders, 30 mass% Al as well as 30 mass% Ag were mixed with CaMoO4 and Ca1−xMnxMoO4 (x = 0.05) nanomaterials and co-fired at 873 K for 4 h.

Analysis and material characterization

Powder X-ray diffraction patterns of CaMoO4 and manganese-doped nanomaterials were collected within the 10–100° 2θ range with the scanning step of 0.013° on an Empyrean II diffractometer (PANalytical) using CuKα1,2 radiation (λ = 0.15418 nm). XRD patterns were analysed by HighScore Plus 4.0 software. Lattice constants were calculated using the least-squares refinement procedure and Powder software (Taupin 1968; Taupin 1973).. The morphology and grain size of Mn2+-doped nanomaterials were observed by scanning electron microscopy (SEM) using a Hitachi S-3400N equipped with an energy-dispersive X-ray spectroscopy (EDS) detector. Thermo Scientific UltraDry was used. The powders were coated with a thin gold alloy layer to facilitate conductivity. Transmission electron microscopy (TEM) measurements were carried out for nanopowdered samples on a HRTEM (FEI Titan3™ G2 60-300; FEI, Hillsboro, USA). The electrical conductivity (σ(T)) of the nanoceramics under study was measured within the temperature range of 76–400 K by the DC method using a Keithley 6517B Electrometer/High Resistance Meter. The thermoelectric power (S(T)) was measured within the temperature range of 300–600 K with the help of a Seebeck Effect Measurement System (MMR Technologies, Inc., USA). Broadband dielectric spectroscopy measurements were carried out using pellets, polished and sputtered with (~ 80 nm) Ag electrodes within the frequency range of 5·102–1·106 Hz using a Hioki 3532-50 LCR HiTester (TEquipment.NET, LLC Company, USA) and within the temperature range of 76–400 K. For the electrical measurements, the powder samples were compacted in a disc form (10 mm in diameter and 1–2 mm in thickness) using a pressure of 1.5 GPa and then they were heated for 2 h at 723 K. The electrical and thermal contacts were made by a silver lacquer mixture (Degussa Leitsilber 200). Static (dc) magnetic susceptibility was measured in two different cooling modes. In the zero-field-cooled (ZFC) mode, the sample was first cooled down in the absence of an external magnetic field and then investigated while heating in a given magnetic field of Hdc = 1 kOe. Field-cooled (FC) mode usually followed ZFC run when the same magnetic field was set on at high temperatures and measurements were performed with decreasing temperature. Dynamic (ac) magnetic susceptibility was measured at an internal oscillating magnetic field of Hac = 3.9 Oe with an internal frequency of f = 1 kHz. Both ac and dc susceptibilities were measured within the temperature range of 2–300 K. Magnetization isotherms were measured at 2 K, 10 K, 20 K, 40 K, 60 K and 300 K in applied external fields up to 70 kOe. Magnetic measurements were made using a Quantum Design MPMS-XL-7AC SQUID magnetometer. The effective magnetic moment was determined using the following equation: \( {\mu}_{\mathrm{eff}}=\sqrt{\frac{3{k}_{\mathrm{B}}C}{N_{\mathrm{A}}{\mu}_{\mathrm{B}}^2}}\cong 2.828\sqrt{C} \) (Groń et al. 1995; Krok-Kowalski et al. 1997), where kB is the Boltzmann constant, NA is the Avogadro number, μB is the Bohr magneton and C is the molar Curie constant.

Results and discussion

XRD, SEM and TEM analysis of Mn2+-doped nanomaterials

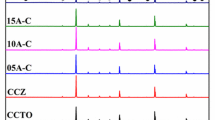

Figure 1 shows the powder XRD patterns of nanocrystalline CaMoO4 and Ca1−xMnxMoO4 when x = 0.01, 0.05, 0.10 and 0.15 heated at 723 K for 4 h. All powder XRD patterns were indexed based on the JCPDS file number 04-013-6763 for pure CaMoO4 with tetragonal scheelite-type structure. No second phases over the entire compositional range were detected indicating the formation of scheelite-type Ca1−xMnxMoO4 solid solution. The diffraction patterns of samples when x is > 0.15 (not shown here) revealed simultaneously the peaks attributed to Ca0.85Mn0.15MoO4 (the saturated solid solution) as well as the diffraction lines characteristic of manganese molybdate. It means that the maximum solubility of manganese ions in the scheelite-type matrix of CaMoO4 is not higher than 15.00 mol% (x ≤ 0.15). It was also observed that all diffraction lines of Ca1−xMnxMoO4 solid solution shift significantly to a higher 2θ angle with increasing manganese ions content due to the substitution of Ca2+ (1.12 Å, CN = 8) ions by much smaller Mn2+ (0.96 Å, CN = 8) ones (Shannon 1976).

The SEM and TEM measurements were performed on as-prepared samples to characterize their morphology, microstructure, particle size and chemical composition. The SEM images are displayed in Fig. 2a–d. The sample of pure matrix (Fig. 2a) is composed of irregular shape of grains differing in their size significantly. Smaller grains are partially agglomerated and form larger aggregates. In contrast, manganese-doped sample (x = 0.05, Fig. 2b) contains spherical and much smaller grains only partially agglomerated in bigger clusters. EDS analysis was used to confirm the chemical composition and purity of CaMoO4 and manganese-doped nanopowders. EDS analysis (not shown here) of the Mn2+-doped sample (x = 0.05) heated at 473 K indicated the presence of five elements, i.e. Ca, Mn, Mo, O and C. It means that this temperature is too low for combustion synthesis and the sample was contaminated by amorphous carbon. The presence of carbon has not been confirmed in XRD studies. The powder XRD pattern of the above-mentioned sample consisted of broad diffraction lines which could be associated only to scheelite-type lattice (Fig. 4a). EDS analysis of the Mn-doped sample heated at higher temperature, i.e. 723 K (not presented here also) reveals that the only elements existed were Ca, Mn, Mo and O. No peaks of any impurities were detected, suggesting the high purity of nanocrystalline Mn2+-doped calcium molybdate. It was also found that all detected chemical elements are evenly distributed throughout the whole area, revealing a uniform proposed chemical composition of this sample. Figure 3a–h show TEM and HRTEM images of CaMoO4 and Mn2+-doped nanomaterials. As can be seen from the TEM images, all samples are composed of uniform and oval grains. The grain size of pure matrix and doped nanomaterials varies between ~ 20 and ~ 50 nm, and a significant change in the grain size with increasing Mn2+ content in the samples was not observed (Fig. 3a, c, e–h). The HRTEM images presented in Fig. 3b, d give more details on the morphology and suggest that the nanoparticles with grain sizes of about 10–20 nm are highly crystallized. The high-magnification TEM image of the part in the plane of figure shows the measured interlayer spacing of 0.479 nm and 0.310 nm that corresponds to the (101) and (112) crystallographic planes of scheelite-type structure (JCPDS no. 04-013-6763), respectively (Fig. 3b, d).

To assess the chemical compatibility of new nanomaterials with Al and Ag internal electrodes, 30 mass% of these powder metals was mixed with CaMoO4 and Ca1−xMnxMoO4 when x = 0.05 and co-fired at 873 K for 2 h. Backscattered electron (BSE) images and XRD patterns of the co-fired samples are shown in Figs. 2c, d and 4b–d, respectively. Only diffraction lines of scheelite-type lattice and Al (JCPDS no. 04-016-2981) or Ag (JCPDS no. 04-016-1389) were observed in powder XRD patterns of co-fired samples, implying that both CaMoO4 and Ca1−xMnxMoO4 (x = 0.05) nanomaterials did not react with metallic Al and Ag (Fig. 4b–d). Manganese-doped samples and co-fired with Al as well as Ag exhibited two distinct phase grains (Fig. 2c, d). The corresponding EDS analysis shows that the black-coloured grains are metallic Al (Fig. 2c) and the white ones are Ag (Fig. 2d), which is in well agreement with XRD results (Fig. 4c, d).

Electrical studies

Results of the electrical measurements of CaMoO4 and Ca1−xMnxMoO4 (x = 0.01, 0.05, 0.10 and 0.15) nanomaterials showed insulating behaviour with small values of the n-type electrical conductivity of σ ~ 10−9 S/m, independent of the manganese ions content (Figs. 5 and 6). This behaviour well correlates with the band gap values (Eg) determined by us earlier (Pawlikowska et al. 2017), and they are displayed in Fig. 5. The above-mentioned values are slightly smaller than 4 eV, and in principle, they do not depend on the content of manganese ions in a sample. No thermal activation of the current carriers was observed. Similar behaviour was found in other materials , i.e. R2WO6 tungstates (R = Nd, Sm, Eu, Gd, Dy and Ho) (Urbanowicz et al. 2009), CdRE2W2O10 (RE = Y, Pr, Nd, Sm and Gd–Er) (Kukuła et al. 2012; Kukuła et al. 2013) and Cd1−3xGd2x□xMoO4 molybdates (where 0 < x ≤ 0.2222, and □ denotes cationic vacancies) (Sawicki et al. 2015). The residual electrical conduction of n-type in the nanocrystalline molybdates under study seems to be connected with anionic vacancies. Other explanation may be related to the fact that in a state of thermal equilibrium, structural defects (n) are always present in the lattice even in the crystal which is ideal in other respects. A necessary condition for free energy minimalization gives n ≅ Nexp(− EV/kT) for n ≪ N, where N is the number of atoms in the crystal and EV is the energy required to transfer the atom from the bulk of the crystal on its surface (Kittel 1971). Therefore, we expect deep trap levels localized in the energy gap of 4.2 eV (Pawlikowska et al. 2017) hindering the electron transport.

Dielectric properties

Studies of broadband dielectric spectroscopy of pure CaMoO4 and Ca1−xMnxMoO4 (x = 0.05, 0.10 and 0.15) nanomaterials displayed in Fig. 7a, b showed low relative dielectric permittivity (εr < 15) decreasing with increasing Mn2+ content, its weaker dependence on temperature and frequency except for the broad maximum between 150 and 350 K (Fig. 7a), and the loss tangent (tanδ) with the highest value up to 0.6 for x = 0.05 (Fig. 7b). For all samples, the dielectric constant and the loss tangent decrease with increasing frequency. The temperature coefficient of dielectric constant (τε) between 400 and 100 K at 1 MHz was calculated using the equation shown below (Vidya et al. 2013)

The calculated τε values for Ca1−xMnxMoO4 are 198 ppm/K (x = 0.0), 292 ppm/K (x = 0.05), 0 ppm/K (x = 0.10) and 114 ppm/K (x = 0.15). Generally, Ca1−xMnxMoO4 nanomaterials (except x = 0.10) have a positive temperature coefficient of dielectric constant whose value changes non-linearly as a Mn2+ content was increasing in samples under study. For comparison, microcrystalline MPr2W2O10 (M = Co, Mn) (Kukuła et al. 2012) and M2FeV3O11 (M = Mg, Zn, Pb, Co, and Ni) (Groń et al. 2017) compounds containing 3d elements with the unpaired electrons showed both much higher relative permittivity values and loss tangent than the nanomaterials under study. This may mean that small grain size hampers an accumulation of electric charge in each sample. Usually, a majority charge carriers in insulators can be partially recombined in the deep trapping centers (Li et al. 2001) lying under the bottom of the conduction band. Natural source of these traps can be grain boundaries with depletion layers of adjacent grains, as it has been observed for ZnO varistors (Li et al. 2001) and Nb2VSbO10 ceramics (Groń et al. 2013) as well as some novel copper/cobalt and rare-earth metal tungstates (Groń et al. 2014). However, for the nanomaterials under study, this does not lead to an accumulation of induced charge or to a blocking of a current cross section by boundary phases under the influence of the applied electric external field.

Magnetic properties

Results of magnetic susceptibility measurements of Ca1−xMnxMoO4 (x = 0.0, 0.01, 0.05, 0.10 and 0.15) nanomaterials are depicted in Table 1 and in Figs. 8, 9, 10, 11, 12, 13 and 14. All studied molybdates are paramagnetic at low temperatures and have short-range antiferromagnetic interactions visible in the negative values of Curie-Weiss temperature. Oscillating around zero the imaginary component of ac susceptibility (Figs. 8, 9, 10, 11 and 12) as well as no splitting between the ZFC and FC magnetic susceptibilities (Fig. 13) for any phase suggest no long-range interactions and spin frustration within the temperature range of 2–300 K. The effective magnetic moment (μeff) is comparable (except for x = 0.01) with the effective number of Bohr magnetons (peff) for the Mn2+ ion with the effective spin of S = 5/2, given by the 2[S(S + 1)]1/2 expression (Morrish 1965). This fact can mean that the magnetic moment originates only from a spin. This is also confirmed by the value of Landé factor (g) estimated from the Curie constant (Table 1) and obtained by fitting the spectra to a spin Hamiltonian in EPR studies (Dai et al. 2012). Nanocrystalline CaMoO4 (Figs. 8 and 13) requires a special attention because it does not have paramagnetic ions, and exhibits residual paramagnetism at low temperatures both on the curve of susceptibility and on the magnetic isotherms. Moreover, when the temperature was increasing, we observed the transition from paramagnetic to diamagnetic, which took place at T1 = 70 K. Probably, the reason for this behaviour may be an appearance of a small amount of molybdenum ions with unpaired electrons on the 4d orbitals. These ions could also have an effect on the magnetic properties of the sample containing the minimum amount of manganese ions (x = 0.01) for which a deviation from the spin magnetism (g = 2.5 in Table 1) was observed. Results of magnetic moment measurements of molybdates under study are shown in Table 1 and in Fig. 14. Magnetic isotherms do not have hysteresis, coercive field, remanence and saturation. Paradoxically, only pure CaMoO4 without paramagnetic ions has saturation at 70 kOe. When manganese content was increasing, the remaining samples were increasingly difficult to magnetize. The reason for this may be magnetocrystalline anisotropy. At room temperature, magnetic isotherms in Fig. 14 show diamagnetism for x = 0.0, the balance between diamagnetism and paramagnetism for x = 0.01 and paramagnetic behaviour for 0.05 ≤ x ≤ 0.15.

Conclusions

Nanocrystalline CaMoO4 and Mn2+-doped calcium molybdates with the formula of Ca1−xMnxMoO4 (x = 0.01, 0.05, 0.10 and 0.15) were successfully prepared by combustion method. The structural investigations showed the formation of tetragonal, scheelite-type structure (space group I41/a) at 723 K without evidence of any other phases. The electrical measurements revealed that obtained nanomaterials are n-type paramagnetic insulators with low relative dielectric permittivity, loss tangent and, in the most Mn2+ concentrations, a positive temperature coefficient of dielectric constant at 1 MHz. The chemical compatibilities of Ca1−xMnxMoO4 with Al and Ag powders at 873 K make nanomaterials under study suitable for LTCC applications. The magnetic studies showed short-range antiferromagnetic interactions and magnetic contribution coming only from the spin. Pure CaMoO4 unexpectedly revealed the residual paramagnetism at low temperatures derived probably from the molybdenum ions having unpaired 4d electrons whose effect is a paramagnetic-diamagnetic transition at 70 K. The most interesting conclusion is that reducing grains to nanosizes makes it difficult to accumulate electric charge.

References

Bavykina I, Angloher G, Hauff D, Kiefer M, Petricca F, Pröbst F (2009) Development of cryogenic phonon detectors based on CaMoO4 and ZnWO4 scintillating crystals for direct dark matter search experiments. Opt Mater 31:1382–1387

Belogurov S, Kornoukhov V, Annenkov A, Borisevich A, Fedorov A, Korzhik M, Ligoun V, Missevitch O, Kim SK, Kim SC, Kim SY, Kwak JW, Lee HS, Lee J, Myung SS, Lee MJ, Kim YD, Lee JY, Lee JI, Kim HJ, Kwon YJ, Hwang MJ, Zhu JJ (2005) CaMoO4 scintillation crystal for the search of 100Mo double beta decay. IEEE Trans Nucl Sci 52:1131–1135

Chen D, Tang K, Li F, Zheng H (2006) A simple aqueous mineralization process to synthesize tetragonal molybdate microcrystallites. Cryst Growth Des 6:247–252

Choi GK, Kim JR, Yoon SH, Hong KS (2007) Microwave dielectric properties of scheelite (A = Ca, Sr, Ba) and wolframite (A = Mg, Zn, Mn) AMoO4 compounds. J Eur Ceram Soc 27:3063–3067

Dai Q, Zhang G, Liu P, Wang J, Tang J (2012) pH- and dopant-dependent CdMoO4:Mn nanocrystals:luminescence and magnetic properties. Inorg Chem 51:9232–9239

Danevich FA, Kobychev VV, Kobychev RV, Kraus H, Mikhailik VB, Mokina VM, Solsky IM (2014) Impact of geometry on light collection efficiency of scintillation detectors for cryogenic rare event searches. Nucl Instrum Methods Phys Res B 336:26–30

Ghosh SK, Rout SK, Tiwari A, Yadav P, Sczancoski JC, Filho MGR, Cavalcante LS (2015) Structural refinement, Raman spectroscopy, optical and electrical properties of (Ba1−xSrx)MoO4 ceramics. J Mater Sci 26:8319–8335

Gong Q, Qian X, Ma X, Zhu Z (2006) Large-scale fabrication of novel hierarchical 3D CaMoO4 and SrMoO4 mesocrystals via a microemulsion-mediated route. Cryst Growth Des 6:1821–1825

Groń T, Krok-Kowalski J, Duda H, Mydlarz T, Gilewski A, Walczak J, Filipek E, Bärner K (1995) Metamagnetism in Cr2V4-xMoxO13+0.5x. Phys Rev B 51:16021–16024

Groń T, Filipek E, Piz M, Duda H, Mydlarz T (2013) I–V characteristics in Nb2VSbO10–ceramics. Mater Res Bull 48:2712–2714

Groń T, Tomaszewicz E, Kukuła Z, Pawlus S, Sawicki B (2014) Dielectric permittivity of some novel copper/cobalt and rare-earth metal tungstates. Mater Sci Eng B 184:14–17

Groń T, Blonska-Tabero A, Filipek E, Urbanowicz P, Sawicki B, Duda H, Stokłosa Z (2017) Electrical transport properties of M2FeV3O11 (M=Mg, Zn, Pb, Co, Ni) ceramics. Ceram Int 43:6758–6764

Kim ES, Kim SH, Lee BI (2006) Low-temperature sintering and microwave dielectric properties of CaWO4 ceramics for LTCC applications. J Eur Ceram Soc 26:2101–2104

Kittel C (1971) Introduction to solid state physics. John Wiley & Sons Inc, New York

Korzhik MV, Kornoukhov VN, Missevitch OV, Fedorov AA, Annenkov AN, Buzanov OA, Borisevicth AE, Dormenev VI, Kholmetskii AL, Kim SK, Kim Y, Kim H, Bratyakina AV (2008) Large volume CaMoO4 scintillation crystals. IEEE Trans Nucl Sci 55:1473–1475

Krok-Kowalski J, Groń T, Warczewski J, Mydlarz T, Okońska-Kozłowska I (1997) Ferrimagnetism and metamagnetism in Cd1-xCuxCr2S4. J Magn Magn Mater 168:129–138

Kukuła Z, Tomaszewicz E, Mazur S, Groń T, Duda H, Pawlus S, Kaczmarek SM, Fuks H, Mydlarz T (2012) Dielectric and magnetic permittivities of three new ceramic tungstates MPr2W2O10 (M = Cd, Co, Mn). Philos Mag 92:4167–4181

Kukuła Z, Tomaszewicz E, Mazur S, Groń T, Pawlus S, Duda H, Mydlarz T (2013) Electrical and magnetic properties of CdRE2W2O10 tungstates (RE= Y, Nd, Sm, Gd-Er). J Phys Chem Sol 74:86–93

Lei F, Yan B (2008) Hydrothermal synthesis and luminescence of CaMoO4:RE3+ (M = W, Mo; RE = Eu, Tb) submicro-phosphors. J Solid State Chem 181:855–862

Li C, Wang J, Su W, Chen H, Wang W, Zhuang D (2001) Investigation of electrical properties of SnO2·Co2O3·Sb2O3 varistor system. Physica B 307:1–8

Marques VS, Cavalcante LS, Sczancoski JC, Alcantara AFP, Orlandi MO, Moraes E, Longo E, Varela JA, Siu Li M, Santos MRMC (2010) Effect of different solvent ratios of (water/ethylene glycol) on the growth process of CaMoO4 and their optical properties. Cryst Growth Des 10:4752–4768

Mikhailik VB, Henry S, Kraus H, Solskii I (2007) Temperature dependence of CaMoO4 scintillation properties. Nucl Instrum Methods Phys Res A 583:350–355

Morrish AH (1965) Physical principles of magnetism. John Wiley & Sons Inc, New York

Pawlikowska M, Fuks H, Tomaszewicz E (2017) Solid state and combustion synthesis of Mn2+-doped scheelites—their optical and magnetic properties. Ceram Int 43:14135–14145

Piątkowska M, Tomaszewicz E (2016) Synthesis, structure and thermal stability of new scheelite type Pb1-3x□xPr2x(MoO4)1-3x(WO4)3x ceramic materials. J Therm Anal Cal 126:111–119

Piątkowska M, Fuks H, Tomaszewicz E, Kochmańska AE (2017) New vacancied and Gd3+-doped lead molybdato-tungstates and tungstates prepared via solid state and citrate-nitrate combustion method. Ceram Int 43:7839–7850

Sawicki B, Groń T, Tomaszewicz E, Duda H, Górny K (2015) Some optical and transport properties of a new subclass of ceramic tungstates and molybdates. Ceram Int 41:13080–13089

Sczancoski JC, Cavalcante LS, Joya MR, Varela JA, Pizani PS, Longo E (2008) SrMoO4 powders processed in microwave-hydrothermal: synthesis, characterization and optical properties. Chem Eng J 140:632–637

Sczancoski JC, Bomio MDR, Cavalcante LS, Joya MR, Pizani PS, Varela JA, Longo E, Siu Li M, Andrés JA (2009) Morphology and blue photoluminescence emission of PbMoO4 processed in conventional hydrothermal. J Phys Chem C 113:5812–5822

Shannon RD (1976) Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr A 32:751–767

Shivakumara C, Saraf R, Behera S, Dhananjaya N, Nagabhushana H (2015) Synthesis of Eu3+-activated BaMoO4 phosphors and their Judd–Ofelt analysis: applications in lasers and white LEDs. Spectrochim Acta A 151:141–148

Taupin D (1968) Une methode generale pour l'indexation des diagrammes de poudre. J Appl Crystallogr 1:87

Taupin D (1973) A powder - diagram automatic - indexing routine. J Appl Crystallogr 6:380-385

Thongtem T, Kungwankunakorn S, Kuntalue B, Phuruangrat A, Thongtem S (2010) Luminescence and absorbance of highly crystalline CaMoO4, SrMoO4, CaWO4 and SrWO4 nanoparticles synthesized by co-precipitation method at room temperature. J Alloys Compd 506:475–481

Tomaszewicz E, Piątkowska M, Pawlikowska M, Groń T, Oboz M, Sawicki B, Urbanowicz P (2016) New vacancied and Dy3+-doped molybdates—their structure, thermal stability, electrical and magnetic properties. Ceram Int 42:18357–18367

Urbanowicz P, Tomaszewicz E, Groń T, Duda H, Pacyna AW, Mydlarz T (2009) Magnetic properties of R2WO6 (where R= Nd, Sm, Eu, Gd, Dy and Ho). Physica B 404:2213–2217

Vidya S, Solomon S, Thomas JK (2013) Synthesis, characterization, and low temperature sintering of nanostructured BaWO4 for optical and LTCC applications. Adv Cond Mat Phys hhtp://dx.doi.org/10.1155/2013/409620

Xi HH, Zhou D, He B, Xie HD (2014) Microwave dielectric properties of scheelite structured PbMoO4 ceramic with ultralow sintering temperature. J Am Ceram Soc 97:1375–1378

Zhang X, Lin J, Mikhalik VB, Kraus H (2015) Studies of scintillation properties of CaMoO4 at milikelvin temperatures. Appl Phys Lett 106:241904

Zhou WW, Wei B, Zhao W, Wang GF, Bao X, Chen YH, Wang FW, Du JM, Yu HJ (2011) Intense yellow emission in Dy3+-doped LiGd(MoO4)2 crystal for visible lasers. Opt Mater 34:56–60

Acknowledgements

The authors are grateful to the team of the workshop at the Institute of Physics (University of Silesia) and the Department of Inorganic and Analytical Chemistry (West Pomeranian University of Technology, Szczecin) for providing the practical and technical assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Groń, T., Karolewicz, M., Tomaszewicz, E. et al. Dielectric and magnetic characteristics of Ca1−xMnxMoO4 (0 ≤ x ≤ 0.15) nanomaterials. J Nanopart Res 21, 8 (2019). https://doi.org/10.1007/s11051-018-4450-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-018-4450-9