Abstract

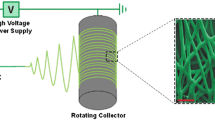

In this research, a novel nanofibrous composite of KCC-1/nylon 6 was prepared using electrospinning techniques. First, fibrous silica nanospheres (KCC-1) were synthesized via conventional polycondensation method with a new solvent system. The scanning electron microscopy (SEM) images showed a spongy spherical morphology with a uniform distribution of particle sizes and an average diameter of around 305 nm. Synthesized KCC-1 nanospheres are considered as mesoporous materials due to their high BET specific surface area of 576 m2 g−1 and BJH average pore diameter of 3.28 nm. The KCC-1/nylon 6 composite was fabricated by preparing a dispersion of nanosilica (10–50 % w/w) in a solution of nylon 6 (15 % w/v) in formic acid. Upon applying a high voltage, the nonwoven electrospun KCC-1/nylon 6 composite nanofibers were obtained. The KCC-1 nanospheres were arranged in line along the nylon 6 fibers like rosary beads wrapped in the polymer. Based on the SEM images, we obtained a well-distributed nanocomposite even at higher silica content. The prepared KCC-1/nylon 6 composite showed 29–55 % higher BET specific surface area compared with pure nylon 6 nanofibers which makes it a good candidate to be used as a sorbent material for environmental or drug delivery applications.

Graphical Abstract

Similar content being viewed by others

References

Abdal-hay A, Mousa HM, Khan A, Vanegas P, Lim JH (2014) TiO2 nanorods coated onto nylon 6 nanofibers using hydrothermal treatment with improved mechanical properties. Colloids Surf A 457:275–281. doi:10.1016/j.colsurfa.2014.05.058

Agarwal S, Greiner A, Wendorff JH (2013) Functional materials by electrospinning of polymers. Prog Polym Sci 38:963–991. doi:10.1016/j.progpolymsci.2013.02.001

Ahn BW, Kang TJ (2012) Preparation and characterization of magnetic nanofibers with iron oxide nanoparticles and poly(ethylene terephthalate). J Appl Polym Sci 125:1567–1575. doi:10.1002/app.34953

Bagheri H, Aghakhani A (2011) Novel nanofiber coatings prepared by electrospinning technique for headspace solid-phase microextraction of chlorobenzenes from environmental samples. Anal Methods-UK 3:1284–1289. doi:10.1039/C0ay00766h

Bagheri H, Aghakhani A (2012) Polyaniline-nylon-6 electrospun nanofibers for headspace adsorptive microextraction. Anal Chim Acta 713:63–69. doi:10.1016/j.aca.2011.11.027

Bagheri H, Aghakhani A, Akbari M, Ayazi Z (2011) Electrospun composite of polypyrrole-polyamide as a micro-solid phase extraction sorbent. Anal Bioanal Chem 400:3607–3613. doi:10.1007/s00216-011-4993-4

Bagheri H, Aghakhani A, Baghernejad M, Akbarinejad A (2012a) Novel polyamide-based nanofibers prepared by electrospinning technique for headspace solid-phase microextraction of phenol and chlorophenols from environmental samples. Anal Chim Acta 716:34–39. doi:10.1016/j.aca.2011.03.016

Bagheri H, Ayazi Z, Aghakhani A, Alipour N (2012b) Polypyrrole/polyamide electrospun-based sorbent for microextraction in packed syringe of organophosphorous pesticides from aquatic samples. J Sep Sci 35:114–120. doi:10.1002/jssc.201100509

Bagheri H, Akbarinejad A, Aghakhani A (2014) A highly thermal-resistant electrospun-based polyetherimide nanofibers coating for solid-phase microextraction. Anal Bioanal Chem 406:2141–2149

Barnes CP, Sell SA, Boland ED, Simpson DG, Bowlin GL (2007) Nanofiber technology: Designing the next generation of tissue engineering scaffolds. Adv Drug Deliver Rev 59:1413–1433. doi:10.1016/j.addr.2007.04.022

Deniz AE, Vural HA, Ortaç B, Uyar T (2011) Gold nanoparticle/polymer nanofibrous composites by laser ablation and electrospinning. Mater Lett 65:2941–2943. doi:10.1016/j.matlet.2011.06.045

Ellison AH, Zisman WA (1954) Wettability studies on nylon, polyethylene terephthalate and polystyrene. J Phys Chem 58:503–506. doi:10.1021/j150516a013

Fihri A, Bouhrara M, Patil U, Cha D, Saih Y, Polshettiwar V (2012) Fibrous nano-silica supported ruthenium (KCC-1/Ru): A sustainable catalyst for the hydrogenolysis of alkanes with good catalytic activity and lifetime. Acs Catal 2:1425–1431. doi:10.1021/cs300179q

Giraldo LF, López BL, Pérez L, Urrego S, Sierra L, Mesa M (2007) Mesoporous silica applications. Macromol Symp 258:129–141. doi:10.1002/masy.200751215

Hao Y, Chong Y, Li S, Yang H (2012) Controlled synthesis of Au nanoparticles in the nanocages of SBA-16: Improved activity and enhanced recyclability for the oxidative esterification of alcohols. J Phys Chem C 116:6512–6519. doi:10.1021/jp2093252

Hu H, Jiang W, Lan F, Zeng X, Ma S, Wu Y, Gu Z (2013) Synergic effect of magnetic nanoparticles on the electrospun aligned superparamagnetic nanofibers as a potential tissue engineering scaffold. Rsc Adv 3:879–886. doi:10.1039/C2RA22726F

Huang W-C, Chang L-L, Sakamoto Y, Lin C-Y, Lai N-C, Yang C-M (2011) Kinetically controlled formation of helical mesoporous silica nanostructures correlated to a ribbon intermediate phase. Rsc Adv 1:229–237. doi:10.1039/C1RA00013F

Huang X et al (2014) Dendritic silica nanomaterials (KCC-1) with fibrous pore structure possess high DNA adsorption capacity and effectively deliver genes in vitro. Langmuir 30:10886–10898. doi:10.1021/la501435a

Innocenzi P, Falcaro P, Grosso D, Babonneau F (2003) Order—disorder transitions and evolution of silica structure in self-assembled mesostructured silica films studied through FTIR spectroscopy. J Phys Chem B 107:4711–4717. doi:10.1021/jp026609z

Ji L, Saquing C, Khan SA, Zhang X (2008) Preparation and characterization of silica nanoparticulate–polyacrylonitrile composite and porous nanofibers. Nanotechnology 19:085605. doi:10.1088/0957-4484/19/8/085605

Jin Y, Yang D, Kang D, Jiang X (2009) Fabrication of necklace-like structures via electrospinning. Langmuir 26:1186–1190. doi:10.1021/la902313t

Kanehata M, Ding B, Shiratori S (2007) Nanoporous ultra-high specific surface inorganic fibres. Nanotechnology 18:315602

Kim Y-J, Ahn CH, Lee MB, Choi M-S (2011) Characteristics of electrospun PVDF/SiO2 composite nanofiber membranes as polymer electrolyte. Mater Chem Phys 127:137–142. doi:10.1016/j.matchemphys.2011.01.046

Li W, Chen B, Walz JY (2015) Positioning growth of scalable silica nanorods on the interior and exterior surfaces of porous composites. J Mater Chem A 3:2019–2024. doi:10.1039/C4TA04844J

Lilly Thankamony AS et al (2014) Insights into the catalytic activity of nitridated fibrous silica (KCC-1) nanocatalysts from 15N and 29Si NMR spectroscopy enhanced by dynamic nuclear polarization. Angew Chem Int Ed 54:2190–2193. doi:10.1002/ange.201406463

Lim J-M, Moon JH, Yi G-R, Heo C-J, Yang S-M (2006) Fabrication of one-dimensional colloidal assemblies from electrospun nanofibers. Langmuir 22:3445–3449. doi:10.1021/la053057d

Lim J-M, Yi G-R, Moon JH, Heo C-J, Yang S-M (2007) Superhydrophobic films of electrospun fibers with multiple-scale surface morphology. Langmuir 23:7981–7989. doi:10.1021/la700392w

Mahmoudifard M, Shoushtari A, Mohsenifar A (2012) Fabrication and characterization study of electrospun quantum dot—poly vinyl alcohol composite nanofiber for novel engineering applications. Fiber Polym 13:1031–1036. doi:10.1007/s12221-012-1031-x

Min S-Y et al (2014) Electrospun polymer/quantum dot composite fibers as down conversion phosphor layers for white light-emitting diodes. Rsc Adv 4:11585–11589. doi:10.1039/C3RA46809G

Newsome TE, Olesik SV (2014) Electrospinning silica/polyvinylpyrrolidone composite nanofibers. J Appl Polym Sci. doi:10.1002/app.40966

Park C-H et al (2012) Preparation and characterization of (polyurethane/nylon-6) nanofiber/(silicone) film composites via electrospinning and dip-coating. Fibers Polym 13:339–345. doi:10.1007/s12221-012-0339-x

Patil U, Fihri A, Emwas A-H, Polshettiwar V (2012) Silicon oxynitrides of KCC-1, SBA-15 and MCM-41 for CO2 capture with excellent stability and regenerability. Chem Sci 3:2224–2229. doi:10.1039/C2SC20356A

Polshettiwar V, Cha D, Zhang X, Basset JM (2010) High-surface-area silica nanospheres (KCC-1) with a fibrous morphology. Angew Chem Int Ed 49:9652–9656. doi:10.1002/anie.201003451

Raghu AV, Gadaginamath GS, Priya M, Seema P, Jeong HM, Aminabhavi TM (2008a) Synthesis and characterization of novel polyurethanes based on N1,N4-bis[(4-hydroxyphenyl)methylene]succinohydrazide hard segment. J Appl Polym Sci 110:2315–2320. doi:10.1002/app.27366

Raghu AV, Jeong H, Kim J, Lee Y, Cho Y, Sirsalmath K (2008b) Synthesis and characterization of novel polyurethanes based on 4-{(4-hydroxyphenyl)iminomethyl}phenol. Macromol Res 16:194–199. doi:10.1007/BF03218852

Ramakrishna S, Fujihara K, Teo W, Lim T, Ma Z (2005) An introduction to electrospinning and nanofibers. World Scientific, Singapore

Reddy K, Raghu A, Jeong H (2008) Synthesis and characterization of novel polyurethanes based on 4,4′-{1,4-phenylenebis[methylylidenenitrilo]}diphenol. Polym Bull 60:609–616. doi:10.1007/s00289-008-0896-8

Reddy KR, Nakata K, Ochiai T, Murakami T, Tryk DA, Fujishima A (2010) Nanofibrous TiO2-Core/conjugated polymer-sheath composites: synthesis, structural properties and photocatalytic activity. J Nanosci Nanotechnol 10:7951–7957. doi:10.1166/jnn.2010.3143

Reddy KR, Nakata K, Ochiai T, Murakami T, Tryk DA, Fujishima A (2011) Facile fabrication and photocatalytic application of Ag nanoparticles-TiO2 nanofiber composites. J Nanosci Nanotechno 11:3692–3695. doi:10.1166/jnn.2011.3805

Reddy KR, Hassan M, Gomes VG (2015) Hybrid nanostructures based on titanium dioxide for enhanced photocatalysis. Appl Catal A 489:1–16. doi:10.1016/j.apcata.2014.10.001

Rutledge GC, Fridrikh SV (2007) Formation of fibers by electrospinning. Adv Drug Deliver Rev 59:1384–1391. doi:10.1016/j.addr.2007.04.020

Saha J, De G (2013) Highly ordered cubic mesoporous electrospun SiO2 nanofibers. Chem Commun 49:6322–6324. doi:10.1039/C3CC42338G

Shao C, Kim H, Gong J, Lee D (2002) A novel method for making silica nanofibres by using electrospun fibres of polyvinylalcohol/silica composite as precursor. Nanotechnology 13:635–637. doi:10.1088/0957-4484/13/5/319

Sharma N, McKeown SJ, Ma X, Pochan DJ, Cloutier SG (2010) Structure—property correlations in hybrid polymer—nanoparticle electrospun fibers and plasmonic control over their dichroic behavior. ACS Nano 4:5551–5558. doi:10.1021/nn100582f

Sheehan D (2013) Physical biochemistry: principles and applications, 2nd edn. Wiley-Blackwell, Singapore

Shi Q, Vitchuli N, Ji L, Nowak J, McCord M, Bourham M, Zhang X (2011) A facile approach to fabricate porous nylon 6 nanofibers using silica nanotemplate. J Appl Polym Sci 120:425–433. doi:10.1002/app.33161

Showkat AM, Zhang Y-P, Kim M-S, Gopalan AI, Reddy KR, Lee K-P (2007) Analysis of heavy metal toxic ions by adsorption onto amino-functionalized ordered mesoporous silica B Korean. Chem Soc 28:1985–1992

Siddiqui Z, Khan K, Ahmed N (2014) Nano fibrous silica sulphuric acid as an efficient catalyst for the synthesis of β-enaminone. Catal Lett 144:623–632. doi:10.1007/s10562-013-1190-4

Sill TJ, Recum HAV (2008) Electrospinning: applications in drug delivery and tissue engineering. Biomaterials 29:1989–2006. doi:10.1016/j.biomaterials.2008.01.011

Somwangthanaroj A, Tantiviwattanawongsa M, Tanthapanichakoon W (2012) Mechanical and gas barrier properties of nylon 6/clay nanocomposite blown films. Eng J 16:93–105. doi:10.4186/ej.2012.16.2.93

Tatavarty R, Hwang ET, Park J-W, Kwak J-H, Lee J-O, Gu MB (2011) Conductive quantum dot-encapsulated electrospun nanofibers from polystyrene and polystyrene-co-maleic anhydride copolymer blend as gas sensors. React Funct Polym 71:104–108. doi:10.1016/j.reactfunctpolym.2010.11.029

TIFR (2010) Fibrous nano-Silica (KCC-1): Synthesis and applications. Tata Institute of Fundamental Research. http://www.nanocat.co.in/fibrous-nano-silica-kcc-1-synthesis–applications.html. 3 April 2015

Tonan K, S-i Ikawa (1996) Intramolecular hydrogen bonding and conformation of small peptides: variable-temperature FTIR study on N-acetyl-l-Pro-l-Leu-Gly-NH2 and related compounds. J Am Chem Soc 118:6960–6965. doi:10.1021/ja953380a

TTI (2014) Fibrous silica nanospheres (KCC-1). Technology Transfer and Innovation. https://innovation.kaust.edu.sa/technologies/fibrous-silica-nanospheres-kcc-1. Accessed 3 Jan 2015

van Zyl WE, García M, Schrauwen BAG, Kooi BJ, De Hosson JTM, Verweij H (2002) Hybrid polyamide/silica nanocomposites: synthesis and mechanical testing. Macromol Mater Eng 287:106–110. doi:10.1002/1439-2054(20020201)287:2<106:AID-MAME106>3.0.CO;2-2

Wang H-S, Fu G-D, Li X-S (2009) Functional polymeric nanofibers from electrospinning. Recent Pat Nanotech 3:21–31

Yang H, Li S, Zhang X, Wang X, Ma J (2014) Imidazolium ionic liquid-modified fibrous silica microspheres loaded with gold nanoparticles and their enhanced catalytic activity and reusability for the reduction of 4-nitrophenol. J Mater Chem A 2:12060–12067. doi:10.1039/C4TA01513D

Chen Y-Z, Zhang Z-P, Yu J, Guo Z-X (2009) Poly(methyl methacrylate)/silica nanocomposite fibers by electrospinning. J Polym Sci Part B 47:1211–1218. doi:10.1002/polb.21727

Zhang Y-P, Lee S-H, Reddy KR, Gopalan AI, Lee K-P (2007) Synthesis and characterization of core-shell SiO2 nanoparticles/poly(3-aminophenylboronic acid) composites. J Appl Polym Sci 104:2743–2750. doi:10.1002/app.25938

Zheng J, Siegel RW, Toney CG (2003) Polymer crystalline structure and morphology changes in nylon-6/ZnO nanocomposites. J Polym Sci B Polym Phys 41:1033–1050. doi:10.1002/polb.10452

Acknowledgments

The research council and the graduate office of the Material and Energy Research Center are thanked for supporting and funding this project (No. 571392052).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aghakhani, A., Kazemi, E. & Kazemzad, M. Preparation of a novel KCC-1/nylon 6 nanocomposite via electrospinning technique. J Nanopart Res 17, 386 (2015). https://doi.org/10.1007/s11051-015-3190-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-015-3190-3