Abstract

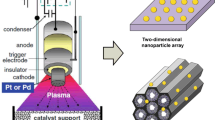

Carbon nanotubes (CNTs) are a promising material for many applications, due to their extraordinary properties. Some of these properties vary in relation to the diameter of the nanotubes; thus, precise control of CNT diameter can be critical. Porous anodic alumina (PAA) membranes have been successfully used to template electrodeposited catalyst. However, the catalysts used in CNT synthesis are frequently deposited with more precise techniques, such as electron beam deposition. We test the efficacy of PAA as a template for electron beam-deposited catalyst by studying the diameter distribution of CNTs grown catalyst of various thicknesses supported by PAA. These are then compared by ANOVA to the diameter distributions of CNTs grown on metal catalyst supported by a conventional alumina film. These results also allow a unified description of two templating effects, the more common particles-in-pores model, and the recently described particles-between-pores.

Similar content being viewed by others

Notes

Here, the term porous anodic alumina is used, and abbreviated PAA, as this seems the most common convention in the literature. Other terminology has been used, including porous aluminum oxide (PAOX) (Schneider et al. 2008), anodic alumina nanoholes (AAN) (Iwasaki et al. 1999), anodic alumina template (AAT) (Sui et al. 2001b), anodic aluminum oxide (Hu et al. 2001), or simply nanoporous alumina (PA) (Lan et al. 2001).

The ET3000 furnace is a thermal CVD system with horizontal flow through a quartz tube. The quartz tube has an inner diameter of approximately 7.5 cm, and a length of approximately 61 cm. The heated length is marginally shorter, due to the tube insulation.

References

Acosta RI (2010) Ostwald ripening of iron (Fe) catalyst nanoparticles on aluminum oxide surfaces (Al2O3) for the growth of carbon nanotubes. Dissertation, Wright State University

Altalhi T, Ginic-Markovic M, Han N, Clarke S, Losic D (2011) Synthesis of carbon nanotube (CNT) composite membranes. Membranes 1:37–47

Alvarez NT, Li F, Pint CL, Mayo JT, Fisher EZ, Tour JM, Colvin VL, Hauge RH (2011) Uniform large diameter carbon nanotubes in vertical arrays from premade near-monodisperse nanoparticles. Chem Mater 23:3466–3475

Alvine KJ, Shpyrko OG, Pershan PS, Shin K, Russell TP (2006) Capillary filling of anodized alumina nanopore arrays. Phys Rev Lett 97:1–4 175503

Amama PB, Pint CL, Kim SM, McJilton L, Eyink KG, Stach EA, Hauge RH, Maruyama B (2001) Influence of alumina type on the evolution and activity of alumina-supported Fe catalysts in single-walled carbon nanotube carpet growth. ACS Nano 4:895–904

Bentley AK, Farhoud M, Ellis AB, Nickel AML, Lisensky GC, Crone WC (2005) Template Synthesis and Magnetic Manipulation of Nickel Nanowires. J Chem Educ 82:765–768

Butt HJ, Kappl M (2009) Normal capillary forces. Adv Colloid Interface Sci 146:48–60

Caupin F (2007) Comment on ‘‘capillary filling of anodized alumina”. Phys Rev Lett 98:259601

Celestini F (1997) Capillary condensation within nanopores of various geometries. Phys Lett A 228:84–90

Celestini F, Ten Bosch A (1995) Effect of shape on phase transition temperature of clusters. Phys Lett A 207:307–314

Che G, Lakshmi BB, Martin CR, Fisher E, Ruoff RS (1998) Carbon nanotubule membranes for electrochemical energy storage and production. Chem Mater 10:260–267

Chen Y (2010) CVD synthesis of single-walled carbon nanotubes from selected catalysts. Masters Thesis, University of Cincinnati, Ohia, USA

Cui X, Wei W, Harrower C, Chen W (2009) Effect of catalyst particle interspacing on the growth of millimeter-scale carbon nanotube arrays by catalytic chemical vapor deposition. Carbon 47:3441–3451

Dimitrov DI, Milchev A, Binder K (2007) Capillary rise in nanopores: molecular dynamics. Phys Rev Lett 99:054501

Fedlheim DL, Foss CA (2001) Metal nanoparticles: Synthesis, Characterization, and Applications. CRC Press, Boca Raton

Fisher R (1925) Statistical methods for research workers. Oliver and Boyd, Edinburgh

Gao H, Mu C, Wang F, Xu D, Wu K, Xie Y, Liu S, Wang E, Xu J, Yu D (2003) Field emission of large-area and graphitized carbon nanotube array on anodic aluminum oxide template. J Appl Phys 93:5602–5605

Hashishin T, Tono Y, TamakI J (2006) Guide growth of carbon nanotube arrays using anodic porous alumina with Ni catalyst. Jpn J Appl Phys 45:333–337

Henry CR (1998) Surface studies of supported model catalysts. Surf Sci Rep 31:231–325

Hu W, Gong D, Chen Z, Yuan L, Saito K, Grimes GA, Kichambare P (2001) Growth of well-aligned carbon nanotube arrays on silicon substrates using porous alumina film as a nanotemplate. Appl Phys Lett 79:3083–3085

Huber P, Knorr K, Kityk AV (2005) Capillary rise of liquids in nanopores. Materials Research Society Symposium Proceedings, Boston

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58

Iwasaki T, Motoi T, Den T (1999) Multiwalled carbon nanotubes growth in anodic alumina nanoholes. Appl Phys Lett 1999(75):2044–2046

Jeong SH, Hwang HY, Hwang SK, Lee KH (2004) Carbon nanotubes based on anodic aluminum oxide nano-template. Carbon 42:2073–2080

Jessensky O, Muller F, Gosele U (1998) Self-organized formation of hexagonal pore arrays in anodic alumina. App Phys Lett 72:1173–1175

Keller F, Hunter M, Robinson D (1953) Structural features of oxide coatings on aluminum. J Electrochem Soc 100:411–419

Kumar M, Ando Y (2010) Chemical vapor deposition of carbon nanotubes: a review on the growth mechanism and mass productions. J Nanosci Nanotechnol 10:3739–3758

Kyotani T, Tsai LF, Tomita A (1996) Preparation of ultrafine carbon tubes in nanochannels of an anodic aluminum oxide film. Chem Mater 8:2109–2113

Lan Y, Wang Y, Ren Z (2001) Physics and applications of aligned carbon nanotubes. Adv Phys 60:553–678

Lee OJ, Hwang SK, Jeong SH, Lee PS, Lee KH (2005) Synthesis of carbon nanotubes with identical dimensions using an anodic aluminum oxide template on a silicon wafer. Synth Met 148:263–266

Li J, Papadopoulos C, Xu JM, Moskovits M (1999) Highly-ordered carbon nanotube arrays for electronic applications. Appl Phys Lett 75:367–369

Meshot ER, Zhao Z, Lua W, Hart AJ (2014) Self-ordering of small-diameter metal nanoparticles by dewetting on hexagonal mesh templates. Nanoscale 6:10106

Nanda KK, Sahu SN, Behera SN (2002) Liquid-drop model for the size-dependent melting of low-dimensional systems. Phys Rev A 66:013208

O’Sullivan J, Wood G (1970) The morphology and mechanism of formation of porous anodic films on aluminium. Proc R Soc Lond Ser A 317:511–543

Rabin O, Herz PR, Lin Y-M, Akinwande AI, Cronin SB, Dresselhaus MS (2013) Formation of thick porous anodic alumina films and nanowire arrays on silicon wafers and glass. Adv Funct Mater 13:631–638

Rabinovich YI, Adler JJ, Esayanur MS, Ata A, Singh RK, Moudgil BM (2002) Capillary forces between surfaces with nanoscale roughness. Adv Colloid Interface Sci 96:213–230

Rashidi A, Omidi M, Choolaei M, Nazarazadeh M, Yadegari A, Haghierosadat F, Oroojalian F, Azhdari M (2013) Electromechanical properties of vertically aligned carbon nanotube. Adv Mater Res 705:332–336

Rummeli M, Kramberger C, Schaffel F, Borowiak-Palen E, Gemming T, Rellinghaus B, Jost O, Loffler M, Ayala P, Pichler T, Kalenczuk AR (2007) Catalyst size dependencies for carbon nanotubes synthesis. Phys Status Solidi (b) 244:3911–3915

Saito R, Dresselhaus G, Dresselhaus M (1998) Electronic structure of single-wall nanotubes. Physical properties of carbon nanotubes. Imperial College Press, London, pp 59–72

Schneider JJ, Maksimova NI, Engstler J, Joshi R, Schierholz R, Feile R (2008) Catalyst free growth of a carbon nanotube-alumina composite structure. Inorg Chim Acta 361:1770–1778

Schneider C, Rasband W, Eliceiri K (2012) NIH image to imageJ: 25 years of image analysis. Nat Methods 9:671–675

Shingubara S (2003) Fabrication of nanomaterials using porous alumina templates. J Nanopart Res 5:17–30

Sohn JI, Kim YS, Nam C, Cho B, Seong TY, Lee S (2005) Fabrication of high-density arrays of individually isolated nanocapacitors using anodic aluminum oxide templates and carbon nanotubes. Appl Phys Lett 87:123115

Sui Y, Gonzalez-Leon J, Bermudez A, Saniger J (2001a) Synthesis of multi branched carbon nanotubes in porous anodic aluminum oxide template. Carbon 39:1709–1715

Sui Y, Cui B, Guardian R, Acosta D, Martinez L, Perez R (2001b) Synthesis and frictional properties of array film of amorphous carbon nanofibers on anodic aluminum oxide. Carbon 40:1011–1016

Takagi M (1954) Electron-Diffraction Study of Liquid-Solid Transition of Thin Metal Films. J Phys Soc Jpn 9:359–363

Vogel EE, Vargas P, Altbir D, Escrig J (2010) Magnetic nanotubes. Handbook of nanophysics: nanotubes and nanowires. CRC Press, Boca Raton, pp 14–16

Wang YM, Kuo HH, Verbrugge MW, Lian J, Wang L, Zhou W (2005) Template synthesis of ordered Pt nanorods in porous anodic alumina. Microsc Microanal 11:1408–1409

Yu WJ, Cho YS, Choi GS, Kim D (2005) Patterned carbon nanotube field emitter using the regular array of an anodic alumium oxide tempate. Nanotechnology 16:S291–S295

Zhi L, Wu J, Li J, Kolb U, Müllen K (2005) Carbonization of disclike molecules in porous alumina membranes: toward carbon nanotubes with controlled graphene-layer orientation. Angew Chem Int Ed 44:2120–2123

Acknowledgments

Financial support for this work was provided by the National Science Foundation (NSF), through the following Grants: Engineering Research Center (ERC), number 0812348; Grant Opportunities for Academic Liaison with Industry (GOALI), number 1120382. Additional support was provided by the Office of Naval Research, through Defense University Research Instrumentation Program (DURIP). Melodie Fickenscher and the Cincinnati branch of the National Institute for Occupational Safety and Health (NIOSH) provided assistance in collecting the Hi-resolution Transmission Electron Microscopy images central to this work. Svitlana Fialkova, of the Center for Advanced Materials and Smart Structures (CAMMS) lab at North Carolina Agricultural and Technical State University (NCAT), provided assistance in collecting and measuring the Hi-resolution Scanning Electron Microscopy images of PAA and CNTs on PAA.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

11051_2015_3159_MOESM1_ESM.docx

Electronic Supplementary Information (ESI) available: Supplementary information includescomplete histograms of the diameter, examples of the TEM images used to collect the diameterdata, and the recipe used to synthesize the carbon nanotubes. Supplementary material 1 (DOCX 12288 kb)

Rights and permissions

About this article

Cite this article

Haase, M.R., Alvarez, N.T., Malik, R. et al. Unifying the templating effects of porous anodic alumina on metallic nanoparticles for carbon nanotube synthesis. J Nanopart Res 17, 359 (2015). https://doi.org/10.1007/s11051-015-3159-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-015-3159-2