Abstract

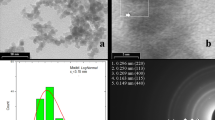

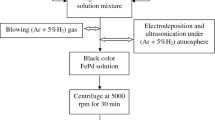

We report on the phase stability and phase formation of Nd–Fe–B nanoparticles from the gas phase in the size range from 10 to 25 nm. Particular attention is paid to the question, if the intermetallic \(\hbox {Nd}_{2}\hbox {Fe}_{14}\hbox {B}\) phase also forms in free particles with a few nanometers in size that grow without contact to any solid or liquid matrix in a low pressure Ar atmosphere. The paper also addresses the possible influence of segregation phenomena that go along with the phase formation and the effect of (rapid) thermal annealing on the structure and phase stability of the particles. Aberration-corrected transmission electron microscopy in combination with spectroscopic methods was used to determine the local atomic structure and the chemical composition of the particles. Unheated particles are found to be mainly amorphous, while the rapidly optically annealed particles are crystalline. In both cases, we observe an enrichment of Nd in the shell of the particles and a Fe enrichment in the core. This segregation of Nd toward the particles' surface is more pronounced in heated particles, which form a clear core-shell structure with a Fe core surrounded by a \(\hbox {Nd}_{2}\hbox {O}_{3}\) shell. This finding is attributed to the comparably small surface energy and the higher affinity of Nd to oxygen as compared to Fe. A simple model is introduced and used in order to estimate these surface energies. These estimations support the experimentally observed segregation phenomena. It is further found that B prefers the vicinity of Fe over that of Nd atoms, which as a consequence leads to a B enrichment in the Fe-rich parts of the particles. Magnetic measurements show a soft magnetic behavior for both, unheated and heated Nd–Fe–B nanoparticles.

Similar content being viewed by others

References

Akdogan NG, Hadjipanayis GC, Sellmyer DJ (2010) Novel \({\text{Nd}_{2}\text{Fe}_{14}\text{B}}\) nanoflakes and nanoparticles for the development of high energy nanocomposite magnets. Nanotechnology 21(29):295705

Baletto F, Ferrando R (2005) Structural properties of nanoclusters: energetic, thermodynamic, and kinetic effects. Rev Mod Phys 77(1):371–423

Bieniek B, Pohl D, Schultz L, Rellinghaus B (2011) The effect of oxidation on the surface-near lattice relaxation in FeNi nanoparticles. J Nanopart Res 13(11):5935–5946

Bosman M, Keast VJ (2008) Optimizing EELS acquisition. Ultramicroscopy 108(9):837–846

Chen S-Y, Gloter A, Zobelli A, Wang L, Chen C-H, Colliex C (2009) Electron energy loss spectroscopy and ab initio investigation of iron oxide nanomaterials grown by a hydrothermal process. Phys Rev B 79(10):104103

Coey JMD (2001) Magnetic materials. J Alloys Compd 326(1–2):2–6

Coey JMD (2010) Magnetism and magnetic materials. Cambridge University Press, Cambridge ISBN 9780521816144

Colliex C, Manoubi T, Ortizu C (1991) Electron-energy-loss-spectroscopy near-edge fine-structures in the iron–oxygen system. Phys Rev B 44(20):11402–11411

Dempsey NM, Woodcock TG, Sepehri-Amin H, Zhang Y, Kennedy H, Givord D, Gutfleisch O (2013) High-coercivity Nd–Fe–B thick films without heavy rare earth additions. Acta Mater 61(13):4920–4927

Fu X, Han X, Du Z, Feng H, Li Y (2013) Microstructural investigation of Nd-rich phase in sintered Nd–Fe–B magnets through electron microscopy. J Rare Earths 31(8):765–771

Fu B-Q, Liu W, Li Z-L (2009) Calculation of the surface energy of hcp-metals with the empirical electron theory. Appl Surf Sci 255(23):9348–9357

Gubin SP, Koksharov YA, Khomutov GB, Yurkov GY (2005) Magnetic nanoparticles: preparation methods, structure and properties. Russ Chem Rev 74(6):489–520

Gutfleisch O (2000) Controlling the properties of high energy density permanent magnetic materials by different processing routes. J Phys D 33(17):R157–R172

Ibusuki T, Kojima S, Kitakami O, Shimada Y (2001) Magnetic anisotropy and behaviors of Fe nanoparticles. IEEE Trans Magn 37(4):2223–2225

Kang S, Shi S, Jia Z, Thomson GB, Nikles DE, Harrell JW, Li D, Poudyal N, Nandwana V, Liu JP (2007) Microstructures and magnetic alignment of \(\text{L}1_{0}\) FePt nanoparticles. J Appl Phys 101(9):09J113

Krishnan G, Verheijen Ma, ten Brink GH, Palasantzas G, Kooi BJ (2013) Tuning structural motifs and alloying of bulk immiscible Mo–Cu bimetallic nanoparticles by gas-phase synthesis. Nanoscale 5(12):5375–5383

Lange N (1999) Handbook of chemistry, soil science, 15th edn. McGraw-Hill Professional, New York

Lentzen M, Jahnen B, Jia CL, Thust A, Tillmann K, Urban K (2002) High-resolution imaging with an aberration-corrected transmission electron microscope. Ultramicroscopy 92(3–4):233–242

Liu WF, Suzuki S, Machida K (2007) Magnetic properties of Nd–Fe–B film magnets prepared by RF sputtering. J Magn Magn Mater 308(1):126–130

Mohn E (2012) Optische Kurzzeit-Wärmebehandlung von FePt-nanopartikeln im flug: Einfluss auf Struktur und Magnetismus. TU Dresden, IFW Dresden, PhD Thesis

Mosendz O, Pisana S, Reiner JW, Stipe B, Weller D (2012) Ultra-high coercivity small-grain FePt media for thermally assisted recording. J Appl Phys 111(7):07B729

Perro A, Reculusa S, Ravaine S, Bourgeat-Lami E, Duguet E (2005) Design and synthesis of Janus micro- and nanoparticles. J Mater Chem 15(35–36):3745–3760

Pohl D, Surrey A, Schultz L, Rellinghaus B (2012) The impact of oxygen on the morphology of gas-phase prepared Au nanoparticles. Appl Phys Lett 101(26):263105

Pohl D, Wiesenhütter U, Mohn E, Schultz L, Rellinghaus B (2014) Near-surface strain in icosahedra of binary metallic alloys: segregational versus intrinsic effects. Nano Lett 14(4):1776–1784

Rellinghaus B, Stappert S, Wassermann EF, Sauer H, Spliethoff B (2001) The effect of oxidation on the structure of nickel nanoparticles. Phys J D 252:249–252

Rellinghaus B, Mohn E, Schultz L, Gemming T, Acet M, Kowalik A, Kock BFF (2006) On the L10 ordering kinetics in Fe–Pt nanoparticles. IEEE Trans Magn 42(10):3048–3050

Roh K, Martin DC, Lahann J (2005) Biphasic Janus particles with nanoscale anisotropy. Nat Mater 4(10):759–763

Rong C, Li D, Nandwana V, Poudyal N, Ding Y, Wang ZL, Liu JP (2006) Size-dependent chemical and magnetic ordering in L10-FePt nanoparticles. Adv Mater 18(22):2984–2988

Schmidt F (2013) Optimierung des Lichtofens für das optische Heizen von Nanopartikeln im Flug und seine Anwendung bei der Herstellung von Nd–Fe–B-Partikeln. TU Dresden, IFW Dresden, Diploma Thesis

Sepehri-Amin H, Ohkubo T, Shima T, Hono K (2012) Grain boundary and interface chemistry of an Nd–Fe–B-based sintered magnet. Acta Mater 60(3):819–830

Swaminathan V, Deheri PK, Bhame SD, Ramanujan RV (2013) Novel microwave assisted chemical synthesis of \(\text{Nd}_{2}\text{Fe}_{14}\text{B}\) hard magnetic nanoparticles. Nanoscale 5(7):2718–2725

Weller D, Moser A, Folks L, Best ME, Toney MF, Schwickert M, Doerner MF (2000) High \(\text{K}_{{\rm u}}\) materials approach to \(100\,\text{Gbits/in}^2\). IEEE Trans Magn 36(1):10–15

Woodcock TG, Khlopkov K, Walther a, Dempsey NM, Givord D, Schultz L, Gutfleisch O (2009) Interaction domains in high-performance NdFeB thick films. Scripta Mater 60(9):826–829

Woodcock TG, Zhang Y, Hrkac G, Ciuta G, Dempsey NM, Schrefl T, Givord D (2012) Understanding the microstructure and coercivity of high performance NdFeB-based magnets. Scripta Mater 67(6):536–541

Yu M, Liu Y, Liou SH, Sellmyer DJ (1998) Nanostructured NdFeB films processed by rapid thermal annealing. J Appl Phys 83(11):6611–6613

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The surface energy is estimated by determining the change in energy per area upon breaking all bonds between the atoms within a given facet and those in the “disconnected” hemisphere. For this at first, the individual binding energy, \(W_{{\rm at}-{\rm at}}\), is calculated from the (molar) heat of atomization, \(\Delta _{{\rm at}}H\), per bond of a dedicated surface atom

Here, \({\Delta _\mathrm{at}H},\,{N_A}\), and \({\beta }\) are heat of atomization of the involved elements, which represents the binding energy per mole, the Avogadro number, and the coordination number, respectively. Based on this, the surface energy is calculated as the total change in energy, W, per area, A, i.e., \({\gamma =\frac{W}{A}}\), and it follows:

The (molar) heats of atomization are available in the literature, while the number of atoms, \(N_\mathrm{at}\), within an area, \(A\), of a given facet and the number of broken bonds, \(N_\mathrm{bb}\), have to be determined from the crystal structure. An illustration of the lattice planes of interest and the broken bonds of the involved atoms is shown in Fig. 13.

The results of these estimations for the surface energy are summarized in Table 1. Although the absolute values differ from the results of empirical electron theory, the general trend and thus the relative preference of the various facets are in perfect agreement with the results of Fu et al. (2009).

Rights and permissions

About this article

Cite this article

Schmidt, F., Pohl, D., Schultz, L. et al. Segregation phenomena in Nd–Fe–B nanoparticles. J Nanopart Res 17, 170 (2015). https://doi.org/10.1007/s11051-015-2977-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-015-2977-6