Abstract

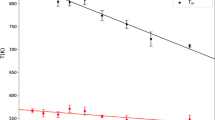

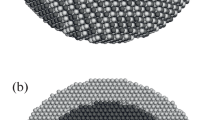

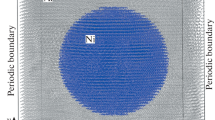

Molecular dynamics simulations are performed to investigate the thermochemical behavior of aluminum-coated nickel particles in the size range of 4–13 nm, beyond which asymptotic behavior is observed. The atomic interactions are captured using an embedded atom model. Emphasis is placed on the particle melting behavior, diffusion characteristics, and inter-metallic reactions. Results are compared with the corresponding properties of nickel-coated nano-aluminum particles. Melting of the shell, which is a heterogeneous process beginning at the outer surface of the particle, is followed by diffusion of aluminum and nickel atoms and inter-metallic reactions. The ensuing chemical energy heats up the particle under adiabatic conditions. The alloying reactions progressively transform the core–shell structured particle into a homogeneous alloy. The melting temperature of the shell is weakly dependent on the core size, but increases significantly with increasing shell thickness, from 750 K at 1 nm to 1,000 K at 3 nm. The core melts at a temperature comparable to the melting point of a nascent particle, contrary to the phenomenon of superheating observed for nickel-coated aluminum particles. The melting temperature of the core decreases from 1,730 to 1,500 K, when its diameter decreases from 10 to 7 nm. For smaller cores, the majority of nickel atoms participate in reactions before melting. The diffusion coefficient of nickel atoms in aluminum shell exhibits a temperature dependence of the form D = D 0 exp(−E A/RT), with an activation energy of 43.65 kJ/mol and a pre-exponential factor of 1.77 × 10−7 m2/s. The adiabatic reaction temperature, also a size-dependent quantity, increases with increasing core diameter, attains a maximum value of 2,050 K at 5 nm, and decreases with further increase in the core diameter. The calculated values agree reasonably with those obtained via chemical equilibrium analysis. The burning time exhibits strong dependence of particle core size and shell thickness of the form τ b = a d nc δ ms , where the exponents n and m are 1.70 and 1.38, respectively. The finding further corroborates the fact that the reaction rate is controlled by diffusion process.

Similar content being viewed by others

Abbreviations

- A :

-

Area

- Al:

-

Aluminum

- C p :

-

Specific heat

- D :

-

Diffusion coefficient

- d :

-

Diameter

- E A :

-

Activation energy

- F :

-

Force

- H :

-

Enthalpy

- k B :

-

Boltzmann constant

- M :

-

Mass

- m :

-

Thickness exponent, mass

- N :

-

Number of atoms

- n :

-

Diameter exponent

- Ni:

-

Nickel

- P :

-

Pressure

- q :

-

Generalized coordinate

- Q :

-

Inertia factor

- R :

-

Gas constant

- r :

-

Position vector, radius

- s :

-

Thermostat degree of freedom

- T :

-

Temperature

- t :

-

Thickness

- U :

-

Potential energy

- V :

-

Volume, pair potential function

- ρ :

-

Electron density function

- δ s :

-

Shell thickness

- δ t :

-

Thermal displacement

- τ b :

-

Burning time

- ad:

-

Adiabatic

- c:

-

Core

- cm:

-

Center of mass

- f:

-

Formation

- i :

-

Initial, interface, atom index variable

- j :

-

Atom index variable

- m:

-

Melting

- p:

-

Particle

- prod:

-

Products

- reac:

-

Reactants

References

Andersen HC (1980) Molecular dynamics simulations at constant pressure and/or temperature. J Chem Phys 72:2384–2393

Andrzejak TA, Shafirovich E, Varma A (2007) Ignition mechanism of nickel-coated aluminum particles. Combust Flame 150:60–70

Aruna ST, Mukasyan AS (2008) Combustion synthesis and nanomaterials. Curr Opin Solid State Mater Sci 12:44–50

Baras F, Politano O (2011) Molecular dynamics simulations of nanometric metallic multilayers: reactivity of the Ni-Al system. Phys Rev B 84:024113

Du Y, Chang YA, Huang B, Gong W, Jin Z, Xu H, Yuan Z, Liu Y, He Y, Xie FY (2003) Diffusion coefficients of some solutes in FCC and liquid Al: critical evaluation and correlation. Mater Sci Eng 363:140–151

Eckert J, Holzer JC, Ahn CC, Fu Z, Johnson WL (1993) Melting behavior of nanocrystalline aluminum powders. Nanostruct Mater 2:407–413

Ejima T, Yamamura T, Uchida N, Matsuzaki Y, Nikaido M (1980) Impurity diffusion of fourth period solutes (Fe Co, Ni, Cu and Ga) and homovalent solutes (In and Tl) into molten aluminium. J Jpn Inst Met 44:316–323

Farber L, Klinger L, Gotman I (1998) Modeling of reactive synthesis in consolidated blends of fine Ni and Al powders. Mater Sci Eng A 254:155–165

Fischer SH, Grubelich MC (1996) A survey of combustion of metals, thermites, and intermetallics for pyrotechnic applications. AIAA Paper No. 96-3018

Fischer SH, Grubelich MC (1998) Theoretical energy release of thermites, intermetallics, and combustible metals. In: Proceedings of the international pyrotechnics seminar

Foley TJ, Johnson CE, Higa KT (2005) Inhibition of oxide formation on aluminum nanoparticles by transition metal coating. Chem Mater 17:4086–4091

Henz BJ, Hawa T, Zachariah M (2009) Molecular dynamics simulation of the energetic reaction between Ni and Al nanoparticles. J Appl Phys 105:124310

Huang Y, Risha GA, Yang V, Yetter RA (2009) Effect of particle size on combustion of aluminum particle dust in air. Combust Flame 156:5–13

Hunt EN, Plantier KB, Pantoya ML (2004) Nano-scale reactants in the self-propagating high-temperature synthesis of nickel aluminide. Acta Mater 52:3183–3191

Lai SL, Carlsoon JRA, Allen LH (1998) Melting point depression of Al clusters generated during the early stages of film growth: nanocalorimetry measurements. Appl Phys Lett 72:1098–1100

Levchenko EV, Evteev AV, Riley DP, Belova IV, Murch GE (2010) Molecular dynamics simulation of the alloying reaction in Al-coated Ni nanoparticle. Comput Mater Sci 47:712–720

Levitas VI, Samani K (2011) Size and mechanics effects in surface-induced melting of nanoparticles. Nat Commun 2:284

Li HP (2003) An investigation of the ignition manner effects on combustion synthesis. Mater Chem Phys 80:758–767

Lu SN, Ahrens TJ (2003) Superheating systematics of crystalline solids. Appl Phys Lett 82:1836–1838

Massalski TB (1992) Binary phase diagrams. ASM International, Materials Park

Mei QS, Lu K (2007) Melting and superheating of crystalline solids: from bulk to nanocrystals. Prog Mater Sci 52:1175–1262

Meschel SV, Kleppa OJ (2001) Thermochemistry of alloys of transition metals and lanthanide metals with some IIIB and IVB elements in the periodic table. J Alloys Compd 321:183–200

Morsi K (2001) Reaction synthesis processing of Ni–Al intermetallic materials. Mater Sci Eng A 299:1–15

Nose S (1984) A unified formulation of the constant temperature molecular dynamics methods. J Chem Phys 81:511–519

Papanicolaou NI, Chamati H, Evangelakis GA, Papaconstantopoulos DA (2003) Second-moment interatomic potential for Al, Ni and Ni–Al alloys, and molecular dynamics application. Comput Mater Sci 27:191–198

Politano O, Baras F, Mukasyan AS, Vadchenko SG, Rogachev AS (2013) Microstructure development during NiAl intermetallic synthesis in reactive Ni–Al nanolayers: numerical investigations vs TEM observations. Surf Coat Technol 215:485–492

Praizey JP, Garandet JP, Frohberg G, Griesche A, Kraatz KH (2000) Diffusion experiments in liquid metals. In: Proceedings of the first international symposium on microgravity research & applications in physical sciences and biotechnology, pp 481–490

Puri P, Yang V (2007) Effect of particle size on melting of aluminum at nano-scales. J Phys Chem C 111:11776–11783

Qi Y, Cagin T, Johnson WL, Goddard WA (2001) Melting and crystallization in Ni nanoclusters: the mesoscale regime. J Chem Phys 115:385–394

Reeves RV, Mukasyan AS, Son SF (2010) Thermal and impact reaction initiation in Ni/Al heterogeneous reactive systems. J Phys Chem C 114:14772–14780

Sundaram DS, Puri P, Yang V (2013) Thermochemical behavior of nickel-coated nanoaluminum particles. J Phys Chem C 117:7858–7869

Thiers L, Mukasyan AS, Varma A (2002) Thermal explosion in Ni–Al system: influence of reaction medium microstructure. Combust Flame 131:198–2009

Yih P (2000) U.S. Patent 6,010,610

Zhao S, Germann TC, Strachan A (2006) Atomistic simulations of shock-induced alloying reactions in Ni/Al nanolaminates. J Chem Phys 125:164707

Acknowledgments

The authors would like to thank the Air Force Office of Scientific Research (AFOSR) for their sponsorship of this program under Contract No. FA9550-11-1-0002. The support and encouragement provided by Dr. Mitat Birkan is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sundaram, D.S., Puri, P. & Yang, V. Thermochemical behavior of nano-sized aluminum-coated nickel particles. J Nanopart Res 16, 2392 (2014). https://doi.org/10.1007/s11051-014-2392-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-014-2392-4