Abstract

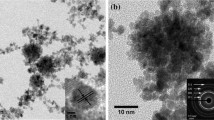

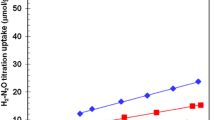

Monodispersed platinum (Pt) nanoparticles were synthesized from reducing hydrated hydrogen hexachloroplatinic acid (H2PtCl6·nH2O) with ethanol in the presence of polyvinylpyrrolidone (PVP) as a steric stabilizer. Concentration of both PVP and ethanol influenced the aggregate structure and crystallite size of the nanoparticles. When the molar ratio of monomeric unit of PVP to Pt, i.e., [PVP]/[Pt], was one, the synthesized Pt particles coagulated pronouncedly into an inter-connected particulate network or self-organized into spherical superstructures with an apparent diameter ranging from 60 to 80 nm, depending on the ethanol concentration. The geometry and structure of these complex aggregates were characterized by fractal analysis. Fractal dimensions of 2.13–2.23 in three dimensions were determined from the Richardson’s plot, which suggests that a reaction-limited cluster–cluster aggregation model (RCLA) was operative. The Pt colloids became apparently more stable when the [PVP]/[Pt] ratio was increased greater than 20. Crystallite size of the Pt nanoparticles was found to increase linearly with the ethanol concentration as the [PVP]/[Pt] was held at one. This suggests that the reduction rate of PtCl6 2− ions in solution is critically important to the synthesized crystallite size.

Similar content being viewed by others

References

Ahmadi TS, Wang ZL, Green TC, Henglein A, El-Sayed MA (1996) Shape-controlled synthesis of colloidal platinum nanoparticles. Science 272:1924–1925. doi:10.1126/science.272.5270.1924

Burda C, Chen X, Narayanan R, El-Sayed MA (2005) Chemistry and properties of nanocrystals of different shapes. Chem Rev 105:1025–1102. doi:10.1021/cr030063a

Chen CW, Akashi M (1997) Synthesis, characterization, and catalytic properties of colloidal platinum nanoparticles protected by poly (N-isopropylacrylamide). Langmuir 13:6465–6472. doi:10.1021/la970634s

Duff DG, Edwards PP, Johnson BFG (1995) Formation of a polymer-protected platinum sol: a new understanding of the parameters controlling morphology. J Phys Chem 99:15934–15944. doi:10.1021/j100043a036

Feder J (1988) Fractals. Plenum Press, New York

Feldheim DL (2007) The new face of catalysis. Science 316:699–700. doi:10.1126/science.1143093

Hirai H (1979) Formation and catalytic functionality of synthetic polymer noble metal colloid. J Macromol Sci-Chem A13:633–649. doi:10.1080/00222337908056678

Hirai H, Nakao Y, Toshima N (1978) Preparation of colloidal rhodium in polyvinyl-alcohol by reduction with methanol. J Macromol Sci-Chem A12:1117–1141. doi:10.1080/00222337808063179

Hirai H, Nakao Y, Toshima N (1979) Preparation of colloidal transition-metals in polymers by reduction with alcohols or ethers. J Macromol Sci-Chem A13:727–750. doi:10.1080/00222337908056685

Holmberg K, Jönsson B, Kronberg B, Lindman B (2003) Surfactants and polymers in aqueous solution. Wiley, UK

Kim T, Takahashi M, Nagai M, Kobayashi K (2004) Preparation and characterization of carbon supported Pt and PtRu alloy catalysts reduced by alcohol for polymer electrolyte fuel cell. Electrochim Acta 50:817–821. doi:10.1016/j.electacta.2004.01.124

Kozan M, Thangala J, Bogale R, Mengüc MP, Sunkara MK (2008) In-situ characterization of dispersion stability of WO3 nanoparticles and nanowires. J Nanopart Res 10:599–612. doi:10.1007/s11051-007-9290-y

Liu Z, Lee JY, Chen W, Han M, Gan LM (2004) Physical and electrochemical characterizations of microwave-assisted polyol preparation of carbon-supported PtRu nanoparticles. Langmuir 20:181–187. doi:10.1021/la035204i

Narayanan R, El-Sayed MA (2004) Shape-dependent catalytic activity of platinum nanoparticles in colloidal solution. Nano Lett 4:1343–1348. doi:10.1021/nl0495256

Paulus UA, Endruschat U, Feldmeyer GJ, Schmidt TJ, Bönnemann H, Behm RJ (2000) New PtRu alloy colloids as precursors for fuel cell catalysts. J Catal 195:383–393. doi:10.1006/jcat.2000.2998

Pugh RJ, Bergström L (1994) Surface and colloid chemistry in advanced ceramics processing. Marcel Dekker, Inc., New York

Sánchez-López JC, Fernández A (2000) TEM study of fractal scaling in nanoparticle agglomerates obtained by gas-phase condensation. Acta Mater 48:3761–3771. doi:10.1016/S1359-6454(00)00174-9

Shiraishi Y, Nakayama M, Takagi E, Tominaga T, Toshima N (2000) Effect of quantity of polymer on catalysis and superstructure size of polymer-protected Pt nanoclusters. Inorg Chem 300–302:964–969

Teranishi T, Hosoe M, Tanaka T, Miyake M (1999) Size control of monodispersed Pt nanoparticles and their 2d organization by electrophoretic deposition. J Phys Chem B 103:3818–3827. doi:10.1021/jp983478m

Tian N, Zhou ZY, Sun SG, Ding Y, Wang ZL (2007) Synthesis of tetrahexahedral platinum nanocrystals with high-index facets and high electro-oxidation activity. Science 316:732–735. doi:10.1126/science.1140484

Acknowledgment

This work was financially supported by the National Science Council through contract no. 95-2218-E-005-005.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, SR., Tseng, W.J. Aggregate structure and crystallite size of platinum nanoparticles synthesized by ethanol reduction. J Nanopart Res 11, 947–953 (2009). https://doi.org/10.1007/s11051-008-9482-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11051-008-9482-0