Abstract

Computational robustness is a fundamental requirement for wheel–rail dynamic interaction simulations. To improve the computational robustness of a wheel–rail non-Hertzian contact model (NHM) for cases with sudden changes in the wheel–rail initial contact point and lateral extreme of the contact area, in this paper, we develop a robust wheel–rail non-Hertzian contact model (RNHM) by improving the original MKP+FASTSIM model. Four improved strategies are applied in the RNHM: improving the wheel–rail contact angle, the wheel–rail rigid slip, the virtual penetration region reduction factor, and the ellipse-equivalent method for the nonelliptical contact area. The computational accuracy and robustness of the RNHM are validated by taking the robust Kalker variational method (RKVM) and other NHMs without model improvements as references, and the contact behavior between a worn wheel and a standard rail is used to verify the model. The simulation results indicate that the RNHM exhibits good computational accuracy and robustness in both the wheel–rail static contact analysis and the wheel–rail dynamic contact analysis and that all four improvement strategies are effective and necessary for increasing the computational robustness of the NHM. The improvement of the wheel–rail contact angle and the wheel–rail rigid slip significantly improve the calculation robustness of wheel–rail lateral force and wheel–rail longitudinal force, respectively; the improvement of the virtual penetration region reduction factor and the ellipse-equivalent method improves the calculation robustness of both the wheel–rail lateral force and the wheel–rail longitudinal force.

Similar content being viewed by others

References

Polach, O., Berg, M., Iwnicki, S.: Simulation of railway vehicle dynamics. In: Iwnicki, S., Spiryagin, M., Cole, C., McSweeney, T. (eds.) Handbook of Railway Vehicle Dynamics, pp. 651–722. CRC Press, Boca Raton (2020)

Ye, Y., Zhu, B., Huang, P., Peng, B.: OORNet: a deep learning model for on-board condition monitoring and fault diagnosis of out-of-round wheels of high-speed trains. Measurement 199, 111268 (2022)

Enblom, R.: Deterioration mechanisms in the wheel–rail interface with focus on wear prediction: a literature review. Veh. Syst. Dyn. 47(6), 661–700 (2009)

Shabana, A., Zaazaa, K., Escalona, J., et al.: Development of elastic force model for wheel/rail contact problems. J. Sound Vib. 269(1–2), 295–325 (2004)

Zhai, W.: Vehicle–Track Coupled Dynamics Theory and Applications. Springer, Singapore (2019)

Marques, F., Magalhães, H., Pombo, J., Ambrósio, J., Flores, P.: A three-dimensional approach for contact detection between realistic wheel and rail surfaces for improved railway dynamic analysis. Mech. Mach. Theory 149, 103825 (2020)

Aceituno, J.F., Urda, P., Briales, E., Escalona, J.L.: Analysis of the two-point wheel-rail contact scenario using the knife-edge-equivalent contact constraint method. Mech. Mach. Theory 148, 103803 (2020)

Meymand, S., Keylin, A., Ahmadian, M.: A survey of wheel–rail contact models for rail vehicles. Veh. Syst. Dyn. 54(3), 386–428 (2016)

Sun, Y., Ling, L.: An optimal tangential contact model for wheel-rail non-Hertzian contact analysis and its application in railway vehicle dynamics simulation. Veh. Syst. Dyn. 60(9), 3240–3268 (2022)

Ayasse, J., Chollet, H., Sebès, M.: Wheel-rail contact mechanics. In: Iwnicki, S., Spiryagin, M., Cole, C., McSweeney, T. (eds.) Handbook of Railway Vehicle Dynamics, pp. 242–278. CRC Press, Boca Raton (2020)

Kalker, J.: Three-Dimensional Elastic Bodies in Rolling Contact. Kluwer Academic, Dordrecht (1990)

Johnson, K.: Contact Mechanics. Cambridge University Press, Cambridge (1985)

Kalker, J.: A fast algorithm for the simplified theory of rolling contact. Veh. Syst. Dyn. 11(1), 1–13 (1982)

Sichani, M., Enblom, R., Berg, M.: An alternative to FASTSIM for tangential solution of the wheel–rail contact. Veh. Syst. Dyn. 54(6), 748–764 (2016)

Zhai, W., Wang, K., Cai, C.: Fundamentals of vehicle–track coupled dynamics. Veh. Syst. Dyn. 47(11), 1349–1376 (2009)

Liu, B., Bruni, S.: Comparison of wheel–rail contact models in the context of multibody system simulation: Hertzian versus non-Hertzian. Veh. Syst. Dyn. 60(3), 1076–1096 (2022)

Knothe, K., Hung, L.T.: Determination of the tangential stresses and the wear for the wheel-rail rolling contact problem. Veh. Syst. Dyn. 15(sup1), 264–277 (1986)

Piotrowski, J., Liu, B., Bruni, S.: The Kalker book of tables for non-Hertzian contact of wheel and rail. Veh. Syst. Dyn. 55(6), 875–901 (2017)

Sun, Y., Zhai, W., Guo, Y.: A robust non-Hertzian contact method for wheel-rail normal contact analysis. Veh. Syst. Dyn. 56(12), 1899–1921 (2018)

Zhao, X., Li, Z.: The solution of frictional wheel–rail rolling contact with a 3D transient finite element model: validation and error analysis. Wear 271(1), 444–452 (2011)

Vollebregt, E.: User guide for CONTACT, Rolling and sliding contact with friction. Technical report TR 20-01, version 20.2, Vtech CMCC, Delft (2020)

Li, Z.: Wheel–rail rolling contact and its application to wear simulation. Ph.D. thesis, Delft University of Technology, Delft (2002)

Vollebregt, E., Segal, G.: Solving conformal wheel–rail rolling contact problems. Veh. Syst. Dyn. 52(sup1), 455–468 (2014)

Kaiser, I.: Refining the modelling of vehicle–track interaction. Veh. Syst. Dyn. 50(sup1), 229–243 (2012)

Kaiser, I., Poll, G., Vinolas, J.: Modelling the impact of structural flexibility of wheelsets and rails on the wheel-rail contact and the wear. Wear 504–505, 203445 (2020)

Linder, C.: Verschleiß von Eisenbahnrädern mit Unrundheiten. Ph.D. thesis, ETH, Zurich (1997)

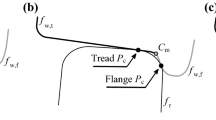

Piotrowski, J., Kik, W.: A simplified model of wheel/rail contact mechanics for non-Hertzian problems and its application in rail vehicle dynamic simulations. Veh. Syst. Dyn. 46(1–2), 27–48 (2008)

Liu, B., Bruni, S., Vollebregt, E.: A non-Hertzian method for solving wheel–rail normal contact problem taking into account the effect of yaw. Veh. Syst. Dyn. 54(9), 1226–1246 (2016)

Ayasse, J., Chollet, H.: Determination of the wheel rail contact patch in semi-Hertzian conditions. Veh. Syst. Dyn. 43(3), 161–172 (2005)

Sichani, M., Enblom, R., Berg, M.: A novel method to model wheel–rail normal contact in vehicle dynamics simulation. Veh. Syst. Dyn. 52(12), 1752–1764 (2014)

Qazi, A., Yin, H., Sebès, M., Chollet, H., Pozzolini, C.: A semi-analytical numerical method for modelling the normal wheel–rail contact. Veh. Syst. Dyn. 60(4), 1322–1340 (2020)

An, B., Wang, P.: A wheel-rail normal contact model using the combination of virtual penetration method and strip-like Boussinesq’s integral. Veh. Syst. Dyn., 1–19 (2022). https://doi.org/10.1080/00423114.2022.2085587, published online

Ye, Y., Sun, Y., Shi, D., Peng, B., Hecht, M.: A wheel wear prediction model of non-Hertzian wheel-rail contact considering wheelset yaw: comparison between simulated and field test results. Wear 474, 203715 (2021)

Tao, G., Wen, Z., Zhao, X., Jin, X.: Effects of wheel–rail contact modelling on wheel wear simulation. Wear 366, 146–156 (2016)

An, B., Ma, D., Wang, P., Zhou, J., Chen, R., Xu, J., Cui, D.: Assessing the fast non-Hertzian methods based on the simulation of wheel–rail rolling contact and wear distribution. Proc. Inst. Mech. Eng., Part F, J. Rail Rapid Transit 234(5), 524–537 (2020)

Burgelman, N., Sichani, M., Enblom, R., Berg, M., Li, Z., Dollevoet, R.: Influence of wheel–rail contact modelling on vehicle dynamic simulation. Veh. Syst. Dyn. 53(8), 1190–1203 (2015)

Magalhaes, H., Marques, F., Liu, B., Antunes, P., Pombo, J., Flores, P., Ambrósio, J., Piotrowski, J., Bruni, S.: Implementation of a non-Hertzian contact model for railway dynamic application. Multibody Syst. Dyn. 48(1), 41–78 (2020)

Magalhaes, H., Marques, F., Antunes, P., Flores, P., Pombo, J., Ambrósio, J., Qazi, A., Sebes, M., Yin, H., Bezin, Y.: Wheel-rail contact models in the presence of switches and crossings. Veh. Syst. Dyn. 61(3), 838–870 (2023)

Bezin, Y., Pålsson, B.A., Kik, W., Schreiber, P., Clarke, J., Beuter, V., Sebes, M., Persson, I., Magalhaes, H., Wang, P., Klauser, P.: Multibody simulation benchmark for dynamic vehicle–track interaction in switches and crossings: results and method statements. Veh. Syst. Dyn. 61(3), 660–697 (2023)

Vollebregt, E.: Comments on ‘the Kalker book of tables for non-Hertzian contact of wheel and rail’. Veh. Syst. Dyn. 56(9), 1451–1459 (2018)

Piotrowski, J., Bruni, S., Liu, B.: Reply to comments on ‘the Kalker book of tables for non-Hertzian contact of wheel and rail’ by EAH Vollebregt. Veh. Syst. Dyn. 56(9), 1460–1469 (2018)

Arnold, M., Netter, H.: Approximation of contact geometry in the dynamical simulation of wheel-rail systems. Math. Comput. Model. Dyn. Syst. 4(2), 162–184 (1998)

Sun, Y., Zhai, W., Ye, Y., Zhu, L., Guo, Y.: A simplified model for solving wheel-rail non-Hertzian normal contact problem under the influence of yaw angle. Int. J. Mech. Sci. 174, 105554 (2020)

Vollebregt, E.: Detailed wheel/rail geometry processing with the conformal contact approach. Multibody Syst. Dyn. 52(2), 135–167 (2021)

Vollebregt, E.: Detailed wheel/rail geometry processing using the planar contact approach. Veh. Syst. Dyn. 60(4), 1253–1291 (2022)

Knothe, K., Stichel, S.: Rail Vehicle Dynamics. Springer, New York (2017)

Zhai, W., Liu, P., Lin, J., Wang, K.: Experimental investigation on vibration behaviour of a CRH train at speed of 350 km/h. Int. J. Rail Transp. 3(1), 1–16 (2015)

Acknowledgements

This work was supported by the National Natural Science Foundation of China [Grant No. 52202473], Natural Science Foundation of Jiangsu Province of China [Grant No. BK20200705], Basic Research Foundation of TaihuLight of China [Grant No. K20221050], and the Open Research Fund of Key Laboratory of Mechanical Behavior Evolution and Control of Traffic Engineering Structures in Hebei [Grant No. SZ2022-02]. We are grateful to the High Performance Computing Center of Nanjing Tech University for supporting the computational resources. Our sincere thanks to the anonymous reviewers for their very detailed and valuable comments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

No potential conflict of interest was reported by the authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Coordinate transformation

Without loss of generality, assuming that the position vector of any point \(p\) in the coordinate system \(o_{m}\) - \(x_{m} y_{m} z_{m}\) is \(\mathbf{r}_{p}^{\left ( m \right )}\), the position vector of point \(p\) in the coordinate system \(o_{n}\) - \(x_{n} y_{n} z_{n}\) can be expressed as

where \(\mathbf{r}_{o_{m}}^{\left ( n \right )}\) denotes the coordinate of the origin \(o_{m}\) in the coordinate system \(o_{n}\) – \(x_{n} y_{n} z_{n}\), and \(\mathbf{A}\)(nm) represents the direction transformation matrix between the coordinate system \(o_{m}\) – \(x_{m} y_{m} z_{m}\) and the coordinate system \(o_{n}\) – \(x_{n} y_{n} z_{n}\). In addition, any point \(p\) in the absolute coordinate system \(O\)–XYZ is expressed as \(\mathbf{r}_{p}^{\left ( m \right )}\), and the direction transformation matrix between the coordinate system \(o_{m}\) – \(x_{m} y_{m} z_{m}\) and the absolute coordinate system \(O\)–XYZ is expressed as \(\mathbf{A}\)(m).

The transformation between the different wheel/rail coordinates introduced in Sect. 2.1.1 can be expressed as follows.

(1) Transformation between the absolute coordinate system and the wheelset coordinate system:

with

and

where \(y\)w0, \(z\)w0 is the \(Y\)- and \(Z\)-coordinates of the mass center of the wheelset without dynamic motions.

(2) Transformation between the wheelset dynamic coordinate system and the right wheel–rail contact coordinate system:

with

and

where (\(x\)cR, \(y\)cR, \(z\)cR) are the coordinates of the wheel–rail initial contact point, and \(\theta \)wR is the right wheel–rail contact angle.

(3) Transformation between the absolute coordinate system and the right wheel–rail contact coordinate system:

with

and

(4) Transformation between the absolute coordinate system and the right rail coordinate system:

with

and

where \(Y\)Rr0 and \(Z\)rR0 represent the \(Y\)- and \(Z\)-coordinates of the mass center of the right rail without dynamic motions, \(\phi \)rR0 is the rail cant, \(Y\)rR, \(Z\)rR, and \(\phi\)rR represent the lateral displacement, vertical displacement, and roll angle of the right rail, respectively, and \(Y\)tR and \(Z\)tR represent the lateral and vertical irregularities of the right rail.

Appendix B: Approximation of contact geometry in the dynamical simulation of wheel–rail systems

In the wheel–rail interaction simulation, the wheel–rail initial contact point and wheel–rail normal separation can be obtained based on the wheel–rail contact geometry. Although wheel–rail contact is a 3D contact problem, a 2D method developed by Wang could be applied in the contact geometry simulation with high efficiency. In Wang’s method [5, 43] the contact trace curve, which is the potential contact line on the wheel, is expressed analytically. In addition, the wheel–rail initial contact point and wheel—rail normal distance can be expressed as the distance between the contact trace curve and the dynamic rail location.

The contact trace curve in the absolute coordinate system can be written as

where \(l_{x}\), \(l_{y}\), and \(l_{z}\) are the direction vectors of the wheel coordinates relative to the absolute coordinate system, which can be expressed as

The location of the rail profile in the absolute coordinate system can be written as

where \(z_{\mathrm{r}}\left ( y_{\mathrm{r}} \right )\) is the location of the rail profile in the rail coordinate system.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, Y., Shi, F., Zhang, S. et al. Improving the robustness of non-Hertzian wheel–rail contact model for railway vehicle dynamics simulation. Multibody Syst Dyn 59, 193–237 (2023). https://doi.org/10.1007/s11044-023-09903-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11044-023-09903-x