Abstract

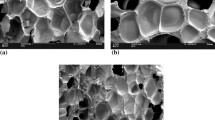

Polyurethane foams with densities of 35, 93, and 200 kg/m3 were tested in compression at three levels of temperatures as: −60 °C, 23 °C, and 80 °C. The influence of speed of testing from 2 mm/min up to 6 m/s (0.0014 to 545 s−1) on the response of the foams is analyzed. Testing is done separately on the rise direction and on the in-plane direction of the foams, and differences in their behavior are commented. With interpolation functions which approximate the plateau and densification region, the specific strain energy is calculated together with the energy efficiency and onset strain of densification. A Nagy-type phenomenological strain-rate-dependent model is proposed to generate engineering stress-strain curves and is validated through comparison with experimental stress-strain curves obtained at different speeds of testing. Starting from a reference experimental curve, two material parameters which are density and temperature dependent are established. Foam recovery for each density of the polyurethane foams is analyzed as a function of direction of testing, temperature, and speed of testing.

Similar content being viewed by others

References

Akay, M., Hanna, R.: A comparison of honeycomb-core and foam-core carbon-fibre/epoxy sandwich panels. Compos. 21, 325–331 (1990)

Apostol, D.A., Miron, M.C., Constantinescu, D.M.: Experimental evaluation of the mechanical properties of foams used in sandwich composites. In: Proceedings 24th DANUBIA-ADRIA Symposium on Developments in Experimental Mechanics, Cluj-Napoca, pp. 35–36 (2007)

Apostol, D.A.: Investigations concerning the behaviour and damage of composites made with rigid and semirigid foams. PhD thesis, University POLITEHNICA of Bucharest, Romania (2011)

Avalle, M., Belingardi, G., Ibba, A.: Mechanical models of cellular solids: Parameters identification from experimental tests. Int. J. Imp. Eng. 34, 3–27 (2007)

Chen, W., Lu, F., Winfree, N.A.: Dynamic compressive response of polyurethane foams of various densities. Exp. Mech. 42, 65–73 (2002)

Christensen, R.M., Lo, K.H.: Solutions for effective shear properties in three phase sphere and cylinder models. J. Mech. Phys. Solids 27, 315–330 (1979)

Christensen, R.M., Lo, K.H.: Erratum. J. Mech. Phys. Solids 34, 639 (1986)

Gibson, L.G., Ashby, M.F.: Cellular Solids, 2nd edn. Cambridge University Press, Cambridge (1997)

Gong, L., Kyriakides, S.: Compressive response of open-cell foams. Part II: initiation and evolution of crushing. Int. J. Solids Struct. 42, 1381–1399 (2005)

Gong, L., Kyriakides, S., Jang, W.Y.: Compressive response of open-cell foams. Part I: morphology and elastic properties. Int. J. Solids Struct. 42, 1355–1379 (2005)

Jin, H., Lu, W.-Y., Scheffel, S., Hinnerichs, T.D., Neilsen, M.K.: Full-field characterization of mechanical behavior of polyurethane foams. Int. J. Solids Struct. 44, 6930–6944 (2007)

Li, Q.M., Magkiriadis, I., Harrigan, J.J.: Compressive strain at the onset of densification of cellular solids. J. Cell. Plast. 42, 371–392 (2006)

Li, Q.M., Mines, R.A.W., Birch, R.S.: Combined strain rate and temperature effects on compression strength of Rohacell 51WF structural foam. In: Lok, T.S., Lim, C.H. (eds.) 3rd Asia Pacific Conference on Shock and Impact Loads on Structures, pp. 221–226 (1999)

Li, Q.M., Mines, R.A.W., Birch, R.S.: The crush behaviour of Rohacell-51WF structural foam. Int. J. Solids Struct. 37, 6321–6341 (2000)

Li, Q.M., Mines, R.A.W.: Strain measures for rigid crushable foam in uniaxial compression. Strain 38, 132–140 (2002)

Marsavina, L., Sadowski, T., Constantinescu, D.M., Negru, R.: Polyurethane foams behaviour. Experiments versus modelling. Key Eng. Mat. 399, 123–130 (2009)

Mills, N.J.: Polymer Foams Handbook. Butterworth/Heinemann, Stoneham (2007)

Mines, R.A.W., Jones, N.: Approximate elastic–plastic analysis of the static and impact behaviour of polymer composite sandwich beams. Compos. 26, 803–814 (1995)

Mines, R.A.W., Worral, C.M., Gibson, A.G.: The static and impact behaviour of polymer composite sandwich beams. Compos. 25, 95–110 (1994)

Mines, R.A.W.: Strain rate effects in crushable structural foams. Appl. Mech. Mat. 7–8, 231–236 (2007)

Nagy, A., Ko, W.L., Lindholm, U.S.: Mechanical behaviour of foamed materials under dynamic compression. J. Cell. Plast. 10, 127–134 (1974). doi:10.1177/0021955X7401000306

Ouellet, S., Cronin, D., Worswick, M.: Compressive response of polymeric foams under quasi-static, medium and high strain rate conditions. Polym. Test. 25, 731–743 (2006)

Rusch, K.: Load-compression behavior of flexible foams. J. Appl. Polym. Sci. 13, 2297–2311 (1969)

Rusch, K.: Energy-absorbing characteristics of foamed polymers. J. Appl. Polym. Sci. 14, 1133–1147 (1970a)

Rusch, K.: Load-compression behavior of brittle foams. J. Appl. Polym. Sci. 14, 1263–1273 (1970b)

Saint-Michel, F., Chazeau, L., Cavaille, J.-Y., Chabert, E.: Mechanical properties of high density polyurethane foams: I. Effect of the density. Compos. Sci. Tech. 66, 2700–2708 (2006)

Song, B., Chen, W., Yanagita, T., Frew, D.J.: Temperature effects on the dynamic compressive and failure behaviors of an epoxy syntactic foam. Compos. Struct. 67, 289–298 (2005)

Viot, P., Beani, F., Lataillade, J.-L.: Polymeric foam behavior under dynamic compressive loading. J. Mat. Sci. 40, 5829–5837 (2005)

Warren, W.E., Kraynik, A.M.: Linear elastic behavior of a low-density kelvin foam with open cells. Trans. ASME J. Appl. Mech. 64, 787–795 (1997)

Zhang, J., Lin, Z., Wrong, A., Kikuchi, N., Li, V.C., Yee, A.F., Nusholtz, G.S.: Constitutive modeling and material characterization of polymeric foams. J. Eng. Mat. Tech. 119, 284–291 (1997)

Acknowledgements

The research done by the PhD student eng. Dragoş Alexandru Apostol has been funded by the Sectoral Operational Programme Human Resources Development 2007–2013 of the Romanian Ministry of Labour, Family and Social Protection through the Financial Agreement POSDRU/6/1.5/S/16.

Both authors are grateful to Professor Gerald Pinter for the help and guidance given to the first author while using the equipment and testing facilities from the Polymer Competence Centre Leoben (PCCL) at the University of Leoben, Austria.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Apostol, D.A., Constantinescu, D.M. Temperature and speed of testing influence on the densification and recovery of polyurethane foams. Mech Time-Depend Mater 17, 111–136 (2013). https://doi.org/10.1007/s11043-012-9179-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-012-9179-8