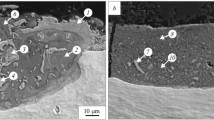

Special features of structural and phase transformations occurring in annealing of an explosion-welded Al – Zr bimetal are considered. It is shown that heat treatment causes formation and growth of an intermetallic layer on the interface, which has a hardness of 9 GPa. The methods of microscopic x-ray spectrum analysis and of phase analysis with the use of synchrotron radiation are used to show that the intermetallic layer is represented by a ZrAl3 phase with a D023-type structure. The lattice constants of this phase vary gradually from the metal-intermetallic interfaces to the center of the layer. Quantum-chemical modeling by the method of density functional is used to show that the zirconium trialuminide is in the steadiest state at a certain distance from the interface due to the process of secondary recrystallization and the accompanying annihilation of crystal structure defects.

Similar content being viewed by others

References

Yu. Yu. Emurlaeva, I. V. Ivanov, D. V. Lazurenko, et al., “On the texture and superstructure formation in Ti – TiAl3 – Al MIL composites,” Intermetallics, 135, 107231 (2021). https://doi.org/10.1016/j.intermet.2021.107231

D. V. Lazurenko, I. A. Bataev, V. I. Mali, et al., “Synthesis of metal-intermetallic laminate (MIL) composites with modified Al3Ti structure and in situ synchrotron x-ray diffraction analysis of sintering process,” Mater. Des., 151, 8 – 16 (2018). https://doi.org/10.1016/j.matdes.2018.04.038

D. V. Lazurenko, I. Y. Petrov, V. I. Mali, et al., “Ti – Al3Ti metal – intermetallic laminate (MIL) composite with a cubic titanium trialuminide stabilized with silver: Selection of fabrication regimes, structure and properties,” J. Alloys Compd., 916, 165480 (2022). https://doi.org/10.1016/j.jallcom.2022.165480

D. V. Lazurenko, V. V. Lozanov, A. Stark, et al., “In situ synchrotron x-ray diffraction study of reaction routes in Ti – Al3Ti-based composites: The effect of transition metals on L12 structure stabilization,” J. Alloys Compd., 875, 160004 (2021). https://doi.org/10.1016/j.jallcom.2021.160004

T. Shimozaki, T. Okino, M. Yamane, et al., “Effect of diffusion barrier and impurities in titanium on the growth rate of TiAl3 layer,” Defect and Diffusion Forum, 143 – 147, 591 – 596 (1997). https://doi.org/10.4028/www.scientific.net/ddf.143-147.591

F. Foadian, M. Soltanieh, M. Adeli, and M. Etminanbakhsh, “The kinetics of TiAl3 formation in explosively welded Ti – Al multilayers during heat treatment,” Metall. Mater. Trans. B, 47, 2931 – 2937 (2016). https://doi.org/10.1007/s11663-016-0710-1

N. Thiyaneshwaran, K. Sivaprasad, and B. Ravisankar, “Nucleation and growth of TiAl3 intermetallic phase in diffusion bonded Ti/Al Metal Intermetallic Laminate,” Sci. Rep., 8, 16797 (2018). https://doi.org/10.1038/s41598-018-35247-0

Y. Zhao, J. Li, R. Qui, and H. Shi, “Growth characterization of intermetallic compound at the Ti/Al solid state interface,” Materials, 12(3), 1 – 11 (2019). https://doi.org/10.3390/ma12030472

D. J. Harach and K. S. Vecchio, “Microstructure evolution in metal-intermetallic laminate (MIL) composites synthesized by reactive foil sintering in air,” Metall. Mater. Trans. A, 32, 1493 – 1505 (2001). https://doi.org/10.1007/s11661-001-0237-0

T. S. Ogneva, I. A. Bataev, and V. I. Mali, “Effect of sintering pressure and temperature on structure and properties of Ni Al metal-intermetallic composites produced by SPS,” Mater. Charact., 180, 111415 (2021). https://doi.org/10.1016/j.matchar.2021.111415

Y. Wang and K. S. Vecchio, “Microstructure evolution in Fe-based-aluminide metallic-intermetallic laminate (MIL) composites,” Mater. Sci. Eng. A, 649, 325 – 337 (2016). https://doi.org/10.1016/j.msea.2015.10.019

Y. Wang, S. Zhou, and K. S. Vecchio, “Annealing effects on the microstructure and properties of an Fe-based metallic-intermetallic laminate (MIL) composite,” Mater. Sci. Eng. A, 665, 47 – 58 (2016). https://doi.org/10.1016/j.msea.2016.04.03

H. Wang, R. Kou, H. Yi, et al., “Mesoscale hetero-deformation induced (HDI) stress in FeAl-based metallic-intermetallic laminate (MIL) composites,” Acta Mater., 213, 116949 (2021). https://doi.org/10.1016/j.actamat.2021.116949

Y.Wang and K. S. Vecchio, “Microstructure evolution in a martensitic 430 stainless steel-Al metallic-intermetallic laminate (MIL) composite,” Mater. Sci. Eng. A, 643, 72 – 85 (2015). https://doi.org/10.1016/j.msea.2015.07.014

A. Macwan, X. Q. Jiang, C. Li, and D. L. Chen, “Effect of annealing on interface microstructures and tensile properties of rolled Al/Mg/Al tri-layer clad steels,” Mater. Sci. Eng. A, 587, 344 – 351 (2013). https://doi.org/10.1016/j.msea.2013.09.002

Z. Chen, D. Wang, X. Cao, et al., “Influence of multi-pass rolling and subsequent annealing on the interface microstructure and mechanical properties of the explosive welding Mg/Al composite plates,” Mater. Sci. Eng. A, 723, 97 – 108 (2018). https://doi.org/10.1016/j.msea.2018.03.042

Z. F. Li, J. Dong, X. Q. Zeng, et al., “Influence of strong static magnetic field on intermediate phase growth in Mg – Al diffusion couple,” J. Alloys Compd., 440, 132 – 136 (2007). https://doi.org/10.1016/j.jallcom.2006.09.032

N. L. Glinka, The General Chemistry [in Russian], Khimiya, Leningrad (1980), 718 p.

V. S. Srivastava, T. Singh, S. Ghosh Chowdhury, and V. Jindal, “Microstructural characteristics of accumulative roll-bonded Ni – Al-based metal-intermetallic laminate composite,” J. Mater. Eng. Perform., 21, 1912 – 1918 (2012). https://doi.org/10.1007/s11665-011-0114-y

F. Takeda and T. Nakajima, “Preparation of Ti – Al gradient composite films by sputtering,” Thin Solid Films, 316, 68 – 72 (1998). https://doi.org/10.1016/S0040-6090(98)00391-5

I. A. Bataev, A. A. Bataev, V. I. Mali, and D. V. Pavlikova, “Structure and mechanical properties of metallic-intermetallic laminate composites produced by explosive welding and annealing,” Mater. Des., 35, 225 – 234 (2012). https://doi.org/10.1016/j.matdes.2011.09.030

D. M. Fronczek, J. Wojewoda-Budka, R. Chulist, et al., “Structural properties of Ti/Al clads manufactured by explosive welding and annealing,” Mater. Des., 91, 80 – 89 (2016). https://doi.org/10.1016/j.matdes.2015.11.087

H.-S. Ding, J.-M. Lee, B.-R. Lee, et al., “Processing and microstructure of TiNi SMA strips prepared by cold roll-bonding and annealing of multilayer,” Mater. Sci. Eng. A, 408, 182 – 189 (2005). https://doi.org/10.1016/j.msea.2005.07.055

V. I. Lysak and S. V. Kuz’min, Explosive Welding [in Russian], Mashinostroenie, Moscow (2005), 543 p.

M. Konieczny, R. Mola, P. Tomas, and M. Kopcial, “Processing, microstructure and properties of laminated Ni-intermetallic composites synthesised using Ni Sheets and Al foils,” Arch. Metall. Mater., 56, 693 – 702 (2011). https://doi.org/10.2478/v10172-011-0076-y

L. M. Gurevich, V. G. Shmorgun, O. V. Slautin, and A. I. Bogdanov, Laminated Intermetallic Composites and Coatings [in Russian], Metallurgizdat, Moscow (2016), 346 p.

A. A. Deribas, The Physics of Hardening and ExplosiveWelding [in Russian], Nauka, Novosibirsk (1980), 207 p.

A. Mehta, J. Dickson, R. Newell, et al., “Interdiffusion and reaction between Al and Zr in the temperature range of 425 to 475°C,” J. Phase Equil. Diff., 40, 482 – 494 (2019). https://doi.org/10.1007/s11669-019-00729-9

J. Dickson, L. Zhou, A. Pazy Puente, et al., “Interdiffusion and reaction between Zr and Al alloys from 425 to 625°C,” Intermetallics, 49, 154 – 162 (2014). https://doi.org/10.1016/j.intermet.2013.12.012

G. V. Kidson and G. D. Miller, “A study of the interdiffusion of aluminum and zirconium,” J. Nucl. Mater., 12, 61 – 69 (1964). https://doi.org/10.1016/0022-3115(64)90108-4

A. Laik, K. Bhanumurthy, and G. Kale, “Intermetallics in the Zr – Al diffusion zone,” Intermetallics, 12, 69 – 74 (2004). https://doi.org/10.1016/j.intermet.2003.09.002

J. Maas, G. Bastin, F. van Lao, and R. Metselaar, “The texture in diffusion-grown layers of trialuminides MeAl3 (Me = Ti, V, Ta, Nb, Zr, Hf) and VNi3,” Int. J. Mater. Res., 74, 294 – 299 (1983). https://doi.org/10.1515/ijmr-1983-740506

J. P. Perdew, K. Burke, and M. Ernzerhof, “Generalized gradient approximation made simple,” Phys. Rev. Lett., 77, 3865 – 3868 (1996). https://doi.org/10.1103/PhysRevLett.77.3865

P. E. Blöchl, “Projector augmented-wave method,” Phys. Rev. B, 50, 17953 – 17979 (1994). https://doi.org/10.1103/PhysRevB.50.17953

J. Enkovaara, C. Rostgaard, J. J. Mortensen, et al., “Electronic structure calculations with GPAW: a real-space implementation of the projector augmented-wave method,” J. Phys., Cond. Matter, 22, 253202 (2010). https://doi.org/10.1088/0953-8984/22/25/253202

A. Hjorth Larsen, J. J. Mortensen, J. Blomqvist, et al., “The atomic simulation environment – a Python library for working with atoms,” J. Phys., Cond. Matter, 29, 273002 (2017). https://doi.org/10.1088/1361-648X/aa680e

W. C. Oliver and G. M. Pharr, “An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments,” J. Mater. Res., 7, 1564 – 1583 (1992). https://doi.org/10.1557/JMR.1992.1564

S. V. Kuz’min, V. I. Lysak, V. V. Rybin, and A. P. Peev, “Special features of plastic deformation of the metal of near-weld zone in explosive welding of dissimilar materials,” Izv. VolgGTU, 5, 4 – 11 (2010).

B. A. Grinberg and M. A. Ivanov, “Interface inhomogeneities in explosive welding,” Fiz. Met. Metalloved., 113, 187 – 200 (2012).

V. I. Lysak, S. V. Kuz’min, A. V. Krokhalev, and B. A. Grinberg, “Structure of boundaries in composite materials obtained using explosive loading,” Fiz. Met. Metalloved., 114, 1026 – 1031 (2013).

B. A. Grinberg, M. A. Ivanov, S. V. Kuz’min, and V. I. Lysak, Explosive Welding: Processes and Structures [in Russian], Innovatsionnoe Mashinostroenie, Moscow (2017), 236 p.

I. A. Bataev, D. V. Lazurenko, S. Tanaka, et al., “High cooling rates and metastable phases at the interfaces of explosively welded materials,” Acta Mater., 135, 277 – 289 (2017). https://doi.org/10.1016/j.actamat.2017.06.038

R. Addaschain, L. Addaschian, and R. E. Reed-Hill, Physical Metallurgy Principles, Cengage Learning (2009), 750 p.

V. I. Anur’ev, A Handbook for Designer and Machine Builder [in Russian], Mashinostrienie, Moscow (2001), Vol. 1, 920 p.

I. K. Kikoin, Tables of Physical Quantities, A Reference Book [in Russian], Atomizdat, Moscow (1976), 1008 p.

A. Priyadarshi, M. Khvari, T. Subrotoet al., “On the governing fragmentation mechanism of primary intermetallics by induced cavitation,” Ultrason. Sonochemistry, 70, 105260 (2021). https://doi.org/10.1016/j.ultsonch.2020.105260

J. Wang, S.-L. Shang, Y. Wang, et al., “First-principles calculations of binary Al compounds: Enthalpies of formation and elastic properties,” Calphad, 35, 562 – 573 (2011). https://doi.org/10.1016/j.calphad.2011.09.009

M. Nakamura and K. Kimura, “Elastic constants of TiAl3 and ZrAl3 single crystals,” J. Mater. Sci., 26, 2208 – 2214 (1991). https://doi.org/10.1007/BF00549190

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 49 – 58, July, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Emurlaeva, Y.Y., Khomyakov, M.N., Aleksandrova, N.S. et al. Structure and Phase Composition of Heat Treated Al – Zr Bimetal. Met Sci Heat Treat 65, 441–449 (2023). https://doi.org/10.1007/s11041-023-00952-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00952-9