The wear resistance of Ni-Hard alloyed cast iron under slurry erosion is studied. An attempt to predict the erosion wear of materials with the help of an artificial neural network (ANN) is made based on the experimental data on the wear of a slurry pot tester under different operating conditions. The ANN model for predicting the erosion wear of materials is proposed, which has been shown to be highly accurate. The model will allow choosing materials that satisfy the specific performance characteristics without conducting long-term tests under various operating conditions.

Similar content being viewed by others

References

K. C. Wilson, G. R. Addie, A. Sellgren, and R. Clift, “Centrifugal Pumps,” in: Slurry Transport Using Centrifugal Pumps, Springer, Boston, MA(2006), pp. 190 – 226.

M. A. Al-Bukhaiti, S. M. Ahmed, F. M. F. Badran, and K. M. Emara, “Effect of impingement angle on slurry erosion behaviour and mechanisms of 1017 steel and high-chromium white cast iron,” Wear, 262(9 – 10), 1187 – 1198 (2007).

L. Haviez, T. Rosario, Mohamad El Youssef, et al., “Semi-physical neural network model for fretting wear estimation,” JIFS, 28(4), 1745 – 1753 (2015).

D. Li, R. Lv, G. Si, and Y. You, “Hybrid neural network-based prediction model for tribological properties of polyamide6-based friction materials,” Polym. Compos., 38(8), 1705 – 1711 (2017).

K. Velten, R. Reinicke, and K. Friedrich, “Wear volume prediction with artificial neural networks,” Tribol. Int., 33(10), 731 – 736 (2000).

S. P. Jones, R. Jansen, and R. L. Fusaro, “Preliminary investigation of neural network techniques to predict tribological properties,” Tribol. Trans., 40(2), 312 – 320 (1997).

L. Frangu and R. Minodora, “Artificial neural networks applications in Tribology—a survey,” in: 2001 NATO Advanced Study Institute on Neural Networks for Instrumentation, Measurement, and Related Industrial Applications: Study Cases (2001), pp. 35 – 42.

T. Kolodziejczyk, R. Toscano, S. Fouvry, and G. Morales-Espejel, “Artificial intelligence as efficient technique for ball bearing fretting wear damage prediction,” Wear, 268(1 – 2), 309 – 315 (2010).

S. Anand Kumar, R. Ganesh Sundara Raman, T. S. N. Sankara Narayanan, and R. Gnanamoorthy, “”Prediction of fretting wear behavior of surface mechanical attrition treated Ti – 6Al – 4V using artificial neural network,” Mater. Des., 49, 992 – 999 (2013).

R. Quiza, L. Figueira, and J. Paulo Davim, “Comparing statistical models and artificial neural networks on predicting the tool wear in hard machining D2 AISI steel,” Int. J. Adv. Manuf. Technol., 37(7), 641 – 648 (2008).

J. Zhu, Y. Shi, X. Feng, et al., “Prediction on tribological properties of carbon fiber and TiO2 synergistic reinforced polytetrafluoroethylene composites with artificial neural networks,” Mater. Des., 30(4), 1042 – 1049 (2009).

L. A. Gyurova and K. Friedrich, “Artificial neural networks for predicting sliding friction and wear properties of polyphenylene sulfide composites,” Tribol. Int., 44(5), 603 – 609 (2011).

S. D. Saravanan and M. Senthilkumar, “Prediction of tribological behavior of rice husk ash reinforced aluminum alloy matrix composites using artificial neural network,” Russ. J. Non-Ferr. Met., 56(1), 97 – 106 (2015).

I. A. El-Sonbaty, U. A. Khashaba, A. I. Selmy, and A. I. Ali, “Prediction of surface roughness profiles for milled surfaces using an artificial neural network and fractal geometry approach,” J. Mater. Process. Technol., 200(1 – 3), 271 – 278 (2008).

B. Dhanasekar and B. Ramamoorthy, “Restoration of blurred images for surface roughness evaluation using machine vision,” Tribol. Int., 43(1 – 2), 268 – 276 (2010).

D. Aleksendriæ and D. C. Barton, “Neural network prediction of disc brake performance,” Tribol. Int., 42(7), 1074 – 1080 (2009).

A. Senatore, V. D’Agostino, R. Di Giuda, and V. Petrone, “Experimental investigation and neural network prediction of brakes and clutch material frictional behavior considering the sliding acceleration influence,” Tribol. Int., 44(10), 1199 – 1207 (2011).

J. Wang, Y. Ma, L. Zhang, et al., “Deep learning for smart manufacturing: Methods and applications,” J. Manuf. Syst., 48, 144 – 156 (2018).

K. T. Butler,W. Davies, H. Cartwright, et al., “Machine learning for molecular and materials science,” Nature, 559(7715), 547 – 555 (2018).

H. Bhadeshia, “Neural networks in materials science,” ISIJ Int., 39(10), 966 – 979 (1999).

W. Sha and K. L. Edwards, “The use of artificial neural networks in materials science based research,” Mater. Des., 28(6), 1747 – 1752 (2007).

J. Raeder, D. Larson, W. Li, et al., “Open GGCM simulations for the THEMIS mission,” Space Sci. Rev., 141(1), 535 – 555 (2008).

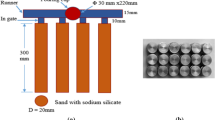

G. R. Desale, B. K. Gandhi, and S. C. Jain, “Improvement in the design of a pot tester to simulate erosion wear due to solid-liquid mixture,” Wear, 259(1 – 6), 196 – 202 (2005).

G. R. Desale, B. K. Gandhi, and S. C. Jain, ”Slurry erosion of ductile materials under normal impact condition,” Wear, 264(3 – 4), 322 – 330 (2008).

G. R. Desale, B. K. Gandhi, and S. C. Jain, “Particle size effects on the slurry erosion of aluminum alloy (AA6063),” Wear, 266(11 – 12), 1066 – 1071 (2009).

G. R. Desale, B. K. Gandhi, and S. C. Jain, “Development of correlations for predicting the slurry erosion of ductile materials,” J. Tribol., 133(3), 031603 (2011).

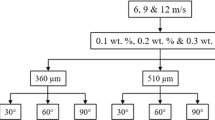

P. P. Shitole, S. H. Gawande, G. R. Desale, and B. D. Nandre, “Effect of impacting particle kinetic energy on slurry erosion wear,” J. Bio TriboCorros., 1(4), 29 (2015).

S. R. More, D. V. Bhatt, and J. V. Menghani, “Study of the parametric performance of solid particle erosion wear under the slurry pot test rig,” Tribol. Ind., 39(4), 471 (2017).

R. Tarodiya and B. K. Gandhi, “Experimental investigation of centrifugal slurry pump casing wear handling solid-liquid mixtures,” Wear, 434, 202972 (2019).

I. Finnie, “Some observations on the erosion of ductile metals,” Wear, 19(1), 81 – 90 (1972).

A. V. Levy and G. Hickey, “Liquid-solid particle slurry erosion of steels,” Wear, 117(2), 129 – 146 (1987).

D. W. Wheeler and R. J. K. Wood, “Erosion of hard surface coatings for use in offshore gate valves,” Wear, 258(1 – 4), 526 – 536 (2005).

S. R. More, D. V. Bhatt, and J. V. Menghani, “Failure analysis of coal bottom ash slurry pipeline in thermal power plant,” Eng. Fail. Anal., 90, 489 – 496 (2018).

A. Rawat, S. N. Singh, and V. Seshadri, “Erosion wear studies on high concentration fly ash slurries,” Wear, 378, 114 – 125 (2017).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Makwana, M.D., Sutaria, B.M. Experimental Study of Slurry Erosion of Ni-Hard Cast Iron and Prediction of Wear of Materials with the Use of Artificial Neural Network (ANN). Met Sci Heat Treat 65, 356–362 (2023). https://doi.org/10.1007/s11041-023-00938-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00938-7