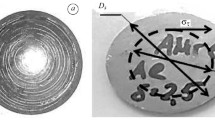

The effect of pulse current ratio on deformation behavior, microstructure and nature of fracture of aluminum bronze BrAZhNMts 9-4-4-1 under tension is studied. Tensile tests are performed and the structure of the bronze is determined. It is shown that pulse current ratio noticeably influences the behavior of the stress-strain curves and bronze mechanical properties. With a minimum pulse ratio within bronze microcrack formation is possible causing accelerated failure.

Similar content being viewed by others

References

O. A. Troitskii, “Electromechanical effect in metals,” JETP Lett., No. 1, 18 – 22(1969).

H. Conrad, “Electroplasticity in metals and ceramics,” Mater. Sci. Eng. A, 287(2), 276 – 287 (2000).

O. A Troitskii, “Electroplastic effect in metals,” Chernaya Metall., No. 9, 65 – 76 (2000).

Yu. V. Baranov, O. ATroitskii, Yu. S. Avramov, and A. D. Shlyapin, Physical Bases of Electro-Impulse and Electroplastic Treatment and New Materials [in Russian], MGIU, Moscow (2001).

K. Moon-Jo, Y. Sangmoon, P. Siwook, et al., “Elucidating the origin of electroplasticity in metallic materials,” Appl. Mater. Today, 1, 100874 (2020).

M. Breda, I. Calliari, S. Bruschi, et al., “Influence of stacking fault energy in electrically assisted uniaxial tension of FCC metals,” Mater. Sci. Technol., 33(3), 317 – 325(2016).

T. A. Perkins, T. J. Kronenberger, and J. T. Roth, “Metallic forging using electrical flow as an alternative to warm/hot working,” J. Manuf. Sci. Eng., 129(1), 84 – 94 (2007).

A. Jordan and D. D. Kinsey, “Investigation of thermal and mechanical effects during electrically-assisted microbending,” J. Mater. Process. Technol., 221, 1 – 12 (2015).

M. S. Smakovskii, M. A. Katsyuba, Yu. D. Morendel’, et al., “Use of applied coatings strengthened with borides for a bronze ship fitting,” Tyazheloe Mashin., No. 3, 11 – 14 (2022).

É. V. Kornilov, P. V. Boiko, and É. I. Golofastov, Handbook for Subsidiary Mechanisms and Ship Systems [in Russian], Ékspress-Reklama, Odessa (2009).

M. A. Pakhomov and V. V. Stolyarov, “Specific features of electroplastic effect in mono- and polycrystalline aluminium,” Met. Sci. Heat Treat., 63(5 – 6), 236 – 242 (2021).

J. He, Zh. Zeng, H. Li, and Sh. Wang, “The microstructure and mechanical properties of copper in electrically assisted tension,” Mater. Des., 196, 109171 (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 31 – 35, May, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pakhomov, M.A., Savenkov, G.G., Smakovsky, M.A. et al. Effect of Pulsed Current Duty Factor on Deformation Behavior of Aluminum Bronze. Met Sci Heat Treat 65, 292–297 (2023). https://doi.org/10.1007/s11041-023-00928-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00928-9